S 2% COLORCER INORGANIC PIGMENTS FOR 1% · PDF fileStainsfor cera micsglazeSta am ic sg laz eS...

Transcript of S 2% COLORCER INORGANIC PIGMENTS FOR 1% · PDF fileStainsfor cera micsglazeSta am ic sg laz eS...

S t a i n s f o r c e r a m i c s g l a z e S t a

a m i c s g l a z e S t a i s f o r s a n i t a

t a i n s f o r s a n i t a r w a r e B o d y s t

i n s f o r s a n i t a r y w a r e B o d y s t a i

r y w a r e B o d y s t a i n E n a m e l c o l o

a i n s E n a m e l c o l o r S t a i n s f o r c

t a r y w B o d y s t n s E n a m e l c o

n s E n a m e l c o l o r s S t a i n s f o r c e r

r s S t a i n s f o r c e r a i c s g l a z e S

e r a m l a z e S t i n s f o r s a n i

l o r s S t a i n s f o r c e r a m i c s g l a z e

COLORITALIA BONET S.r.l.Via Monte Bianco n.81

41042 Fiorano Modenese (MO) - ItalyTel: +39 0536/845220 - 921841Fax: +39 0536/845412 - 921839

www.coloritalia.it - [email protected]

The pigments in the COLORCER® S series are created through the synthesis of metal oxides, and are defi ned by their high resistance, purity and stability in coloration. The products are tested in accordance with strict quality standards. These tests are performed according to methods that have been carefully developed and researched with reference to the fi nal applications of the product: glazes with different (transparent and matt) characteristics, methods of application, and fi ring cycles. Results are checked by comparison with standard products and by measuring the colorimetric values using the CIELAB* L,a,b system, with a total determination of ∆E max 1.0.The uniformity of the stain particles’ granulometry, an intrinsic characteristic of the stability and quality of the color tone of the pigment itself, is measured by a CILAS laser granulometer. The range of stains in the COLORCER® S series enables the creation of specifi c glazes for all types of production. Detailed information on each product can be found in the technical specifi cations and on the safety data sheets. The COLORITALIA® customer service staff is available to answer any questions and to suggest how to achieve the best results using our products.

COLORCER® S INORGANIC PIGMENTS FOR GLAZE, BODY, SANITARYWARE, ENAMEL

COLORCER® CP ONGLAZE COLORS LEADCONTAINING

COLORCER® CA ONGLAZE LEAD FREE COLORS

COLORCER® CI INGLAZE LEAD FREE COLORS

COLORCER® G 70 OPAQUE GLASS COLORS

COLORCER® G 72 OPAQUE RESISTANT GLASS COLORS

COLORCER® G 73 METALLIC GLASS COLORS

COLORCER® E CERAMIC THIRD FIRING AND MAJOLICA COLORS

COLORGLAZE® THIRD FIRING SPECIAL EFFECT

COLORCER® M PRECIOUS METALS AND LUSTERS

COLORCER®

StainsS Kg. 25

Weight box

max 1,0

∆E

Colorimetricvalues

<20 µm

Particle sizedistribution

Big bag500/1000 Kg

Body Stains2%

1%

Colours shown are as close to the real as the limitation of the printing process will allow.

COLORS INDEX

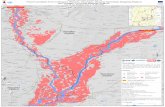

CODE DESCRIPTION STRUCTURE TEMP. °CS 42146 YELLOW ZIRCON 1300°S 42665 ORANGE RUTILE 1300°S 43162 CORAL RED ZIRCON 1300°S 43370 PINK CORUNDUM 1300°S 43590 BRICK RED Fe/Al 1300°S 44301 GREEN SPINEL 1300°S 45203 BLUE SPINEL 1300°S 47800 BROWN RUTILE 1300°S 49190 BLACK HEMATITE 1300°

S 42665 Ti/Sb/Cr S 43162 Si/Fe

S 44301 Co/Cr/Al

S 45203 Co/Al

S 42146 Zr/Si/Pr

S 43590 Fe/Al

S 49190 Fe/Cr

S 43370 Mn/Al

S 47800 Ti/Cr/W

The body stains range is characterized by its colorimetric yield, homogeneous consistency and compatibility with all types of body without altering the shrink ratio of the body itself.The production criteria adopted for the stains in this range have been chosen so that the pigments have a negligible % of salts and have been refi ned so as to attain a high quality-price ratio. COLORCER® S stains can generally be mixed with each other in all percentages, except for the pinks and those containing Manganese.COLORCER® S stains are stable in oxidizing fi ring cycles at lower temperatures than the maximum temperatures indicated below. These are recommended temperatures which must be tested in accordance with each individual industrial procedure.

COLORS INDEX

CODE DESCRIPTION STRUCTURE SUITABILITYS 32308 YELLOW WURTZITE TransparentS 32622 YELLOW RUTILE Titanium WhiteS 32623 ORANGE WURTZITE TransparentS 33631 RED WURTZITE TransparentS 33636 DARK RED WURTZITE TransparentS 34307 BLUE GREEN SPINEL Transparent, Zr, SbS 34601 GREEN OXIDE Transparent, Zr, SbS 35222 DARK BLUE SPINEL Transparent, Zr, SbS 35800 BLUE SPINEL Transparent, Zr, SbS 37301 BROWN SPINEL Transparent, Zr, SbS 38119 GREY RUTILE Transparent, Zr, Sb, TiS 39201 BLACK SPINEL Transparent, Zr, Sb

Enamel Stains

The stains in this range must fulfi ll specifi c requirements relating to the vitreous frit used. It is of utmost importance to choose the correct frit in accordance with the pigment’s crystalline structure; particularly for the structures of Cd/Se stains, transparent frits are required for the color to develop and intensify. As it is impossible to adequately describe all the frits, we advise the user to trial test the stains in their own environment, paying special attention to the type of opacifi er used and initially comparing the different frits utilized.

COLORCER® S stains are generally suitable to be mixed together in all percentages, except for the pinks and those containing Manganese.

The stability and fi ring cycle of COLORCER® S stains in the vitreous glazes is highly dependent on the composition of the frit. Generally a temperature between 800-840°C and duration of 2 to 5 minutes is suitable.

The stains for sanitary ceramics must fulfi ll specifi c technical requirements: the granulometric uniformity of the stain particles is fundamental to ensure the stability and quality of the color; specifi c monitoring during the production phases assure our products are highly dispersible in the products to which they are added. Fire tests with particularly long cycles and at very high temperatures are carried out in order to guarantee the stability of the stain. Re-fi ring is then carried out to verify the stability of the tested dye. We can therefore guarantee high performance from all our stains. COLORCER® S stains are generally suitable to be mixed together in all percentages, except for the different shades of pink.

4% TransparentSanitaryware Stains

S 14713 S 15144Zr/Cd/Se/Cr Zr/Si/V S 15304 Co/Si

S 12711 Zr/Cd/Se S 13150 Zr/Si/Fe S 13280 Zr/Cd/SeS 12114 Zr/Si/Pr

S 14315 Cr/Co/Al

Colours shown are as close to the real as the limitation of the printing process will allow.

S 34307 Cr/Co/Al S 34601 Cr S 35222 Co/Al

S 32622 Ti/Sb/Cr S 32623 Cd/S/Se S 33631 Cd/S/SeS 32308 Cd/S

S 33636 Cd/S/Se

S 37301 Zn/Cr/Fe S 38119 Sn/Sb S 39201 Fe/Cr/Co/NiS 35800 Co/Cr/Al

opacoopaque

trasparentetransparenttrasparentetransparenttrasparente5% The colorings indicated in the table refer to the

coloring of transparent and opaque glaze at 5%

COLORCER® S

Colours shown are as close to the real as the limitation of the printing process will allow.

S 26107 Sn/Ca/Cr

S 27130 Zn/Cr/Fe

S 29240 Fe/Cr/Ni/Co

S 27105 Zn/Cr/Fe

S 26250 Sn/Cr

S 27226 Zn/Cr/Fe/Al

S 29545 Fe/Cr/Ni/Mn

S 28119 Sn/Sb

S 26110 Sn/Ca/Cr

S 27155 Zn/Cr/Fe

S 29304 Fe/Cr/Co/Ni/Mn

S 27582 Fe/Cr/Mn

COLORS INDEX

CODE DESCRIPTION STRUCTURE SUITABILITY TINTOMETER INFORMATIONS 22114 YELLOW ZIRCON ZrSiO4 + T Usable in all types of glazes.S 22701 YELLOW ZIRCON ZrSiO4 +

Inclusion stains intense, brilliant, stable for all types of glazes.

S 22709 ORANGE ZIRCON ZrSiO4 +S 23223 LIGHT RED ZIRCON ZrSiO4 +S 23245 DARK RED ZIRCON ZrSiO4 + TS 23287 DARK RED ZIRCON ZrSiO4 +S 23115 CORAL PINK ZIRCON ZrSiO4 +

Usable in all glazes.Zircon-combinations

are stabilizers.

S 23150 CORAL PINK ZIRCON ZrSiO4 + TS 23155 CORAL RED ZIRCON ZrSiO4 + TS 25144 TURQUOISE ZIRCON ZrSiO4 + T S 24307 BLUE GREEN SPINEL AI2O3 +

Zinc-free glazes are recommended.S 24410 BLUE GREEN SPINEL AI2O3 + T

S 24210 GREEN SPINEL AI2O3 +, ZnO – TS 25222 BLUE SPINEL Al2O3 +, ZnO+ T

High % of AI2O3 get matt.S 25301 BLUE OLIVINE T

COLORS INDEX

CODE DESCRIPTION STRUCTURE SUITABILITY TINTOMETER INFORMATIONS 26107 PINK SPHENE CaO +, ZnO – Not mixable with other stains,

CaO and SnO2 have a benefi cial effect

S 26110 PINK SPHENE CaO +, ZnO –S 26250 VIOLET SPHENE CaO +, ZnO –S 27226 YELLOW BROWN SPINEL ZnO + T

Usable in all glazes.For high brilliance color shades glazes

should contain Zinc.

S 27130 BROWN SPINEL ZnO + TS 27105 GOLDEN BROWN SPINEL ZnO +S 27155 RED BROWN SPINEL ZnO + TS 27582 COFFEE BROWN SPINEL ZnO + TS 28119 GREY CASSERITE T Usable in all glazes.S 29240 BLACK SPINEL ZnO – T Usable in all glazes.

High rate of ZnO in glazes shift the shade to brown

S 29545 BLACK SPINEL ZnO –S 29304 BLACK SPINEL ZnO –

The stains’ stability mainly depends on the composition of the glazes. COLORCER® S stains can generally be mixed with each other in all percentages, except for the pinks and those containing Manganese. COLORCER® S stains are stable in oxidizing fi ring cycles at lower temperatures. In the list below we also suggest 15 suitable pigments for the Tintometric System, marked with a T . The stains are selected due to their colorimetric yeld, degree saturation and higly uniform particle size.

Glaze Stains

S 23115 Zr/Si/Fe

S 24210 Cr/Al

S 23150 Zr/Si/Fe

S 24307 Cr/Co/Al

S 23245 Zr/Cd/SeS 23223 Zr/Cd/Se

S 22114 Zr/Si/Pr S 22701 Zr/Si/Cd S 22709 Zr/Cd/Se

S 23155 Zr/Si/Fe

S 24410 Cr/Co

S 23287 Zr/Si/Cd/S/Se

S 25144 Zr/Si/V S 25222 Co/Al S 25301 Co/Si

Colours shown are as close to the real as the limitation of the printing process will allow.

COLORS INDEX

CODE DESCRIPTION STRUCTURE TEMP. °CS 12114 YELLOW ZIRCON 1300°S 12711 ORANGE ZIRCON 1250°S 13150 CORAL ZIRCON 1250°S 13280 RED ZIRCON 1250°S 14315 BLUE GREEN SPINEL 1250°S 14713 ACID GREEN ZIRCON 1250°S 15144 TURQUOISE ZIRCON 1280°S 15304 BLUE SPINEL 1400°S 16107 PINK SPHENE 1250°S 16110 DARK PINK SPHENE 1250°S 17200 RED BROWN SPINEL 1300°S 19304 BLACK SPINEL 1300°

S 16110 Sn/Ca/CrS 16107 Sn/Ca/Cr S 17200 Zn/Cr/Fe S 19304 Co/Ni/Cr/Fe