s 1793966606000072

Transcript of s 1793966606000072

-

7/27/2019 s 1793966606000072

1/6

-

7/27/2019 s 1793966606000072

2/6

4

Systems Research Forum

system level becomes an important task in the developmentof a reliable and cost effective system. Potential benefits andrisks from the integration of system design accountabilitywith qualified equipment suppliers need to be considered,e.g., in the perspective of critical mass.

Tunnel Installation CategoriesThe number of installed systems in a vehicular tunnel will

vary, depending on the size and type of tunnel, but cantypically be found within the following groups:

Tunnel ventilation Traffic controls Lighting Plant controls Power distribution Communication Technical room ventilation

Drainage Fire-fighting Systems Control And Data Acquisition (SCADA)

For stakeholders like owners and users, the specificperformances of the individual components, subsystems,or even systems would be of minor interest. The primaryobjective would rather be at the following level:

The tunnel installations shall in coordination provide aneffective traffic system and a safe tunnel environment for

passengers and staff under normal modes of operation,

maintenance conditions, and emergency conditions.

The word effective could in this context be translated intocosteffective due to the increased focus on life-cycle cost,reflecting on specifications and the selection of system

solutions and individual groups of equipment.

Tunnel Ventilation: The conceptual and detailed tunnelventilation system designs would traditionally in mostcases be performed by consulting engineers on behalf ofthe end-user or civil contractor(s). From a number ofconceptually developed options one solution would beselected for further development at a detailed design level,

typically by the same design team. This also would involvethe development of equipment specifications for fans,dampers, silencers, controls, drives, power supply, etc.

The tunnel ventilation system would in this structurebe procured with vendors at product/equipment level withpractically no system design accountability going beyondthe consultant.

Ventilation Equipment Supply: Conventional or onlyslightly modified industrial fans were originally used for

tunnel ventilation purposes. The more demanding tunnelventilation applications, however, over time gradually

imposed more specific demands on tunnel fans andrelated equipment. The application know-how became amore pronounced prerequisite for an effective and adaptedproduct development.

Some fundamentally important technologies in fanengineering lend themselves to expansion into tunnel

ventilation system design. Fan manufacturers whoidentified tunnel ventilation as a separate business segment

developed substantial competences in tunnel applicationsand the related ventilation system design, mainly for thefollowing reasons:

1. To better understand the specific requirements anddesign criteria related to tunnel fans

2. To further improve the communication with specifiersand clients, and to also offer system design capabilities(as a competitive advantage

3. To expand the business volume in order to build

critical mass in R&D and engineering

This development caused some overlapping with thetraditional tunnel ventilation consultant areas.

The system orientation accordingly appeared to createa good base for product development, and also potentiallya system design capability advantage. This became valuableto clients at the earlier stages of tunnel projects, when

conceptual solutions are under evaluation and the client,and the clients consultant, often needs the combined inputof system parameters and product features.

The combined product/system know-how in theend should add to the overall quality and performance of

the system. There would, for the fan supplier, appear tobe good reasons, both from a system performance and amarket point of view, to expand the scope of supply fromequipment to system level, essentially based on expanded

existing technologies.The overall tunnel ventilation system performance in

terms of air quality under normal and congested modes ofoperation, as well as under emergency operation, dependson system-wide, as well as local-system-related parameters,and also on the performance of the installed equipment.A widened scope of supply would give sufficient volumeto develop the expertise in areas where both products and

systems would benefit.Contractually, however, the scope of supply for the

fan maker would in most cases be restricted to fans andrelated equipment only. Accordingly, there would be no

premium beyond product value because procurement and

specification are defined at product base level with no systemdesign accountability.

The added value by the system-oriented equipmentsupplier would need to be materialized in a system-basedspecification and related procurement. It is, however, also

clear that certain areas of expertise in tunnel ventilationsystems should remain with specialized consultants.

-

7/27/2019 s 1793966606000072

3/6

Systems Research Forum

5

A system-based procurement of the more advancedtunnel ventilation systems would therefore demandproject-based alliances between equipment suppliers andconsultants. This is due to issues on critical mass in specifictechnology areas and to cover the interfaces with otherinstallation packages.

Tunnel Ventilation Technology

Certain segments within the fan technology platforms (likeacoustics, aerodynamics, thermodynamics, and structuralmechanics) lend themselves to be expanded and appliedto tunnel ventilation system design. These expandedbranches of fan technology do, however, not necessarilyhave to cover all aspects of tunnel ventilation (joint ventureor subcontractor).

The expanded and adapted technology platformconstitutes the tool to offer system design capabilities with

an integrated product/system know-how. It also gives the

opportunity to provide input to projects at the earlierstages of tunnel projects, long before equipment-basedissues become of interest. It also forms a strong base forproduct development adapted to the specific demands oftunnel systems.

A prerequisite for expanding fan technology intosystems is that there is an existing strong fan technology basein the company. The scope of supply would expand from

products to functions, which raises the question of corecompetences, the sourcing of technologies internally andexternally, the issue of networking, and risk management.The definition of responsibilities in terms of inside/outsidescope of supply becomes crucial. The question of defining

key capabilities and technologies within the companywhen building new alliances with, e.g., technical institutes,companies, and consultants, becomes high in priority.

It is, however, important to realize that even if the

system/function orientation raises the issue of movingsegments of the existing tunnel ventilation market fromthe traditional equipment supply into a function/systemscope of supply by the fan maker, it must be rememberedthat an important share of all tunnel projects is likely tostill remain product based in the project specifications.Technical excellence at product level still would be the base

for the business.

Tunnel Ventilation Specifications and Orders

The contract to build the tunnel would be placed bythe owner with a civil contractor(s). The installations(including tunnel ventilation) would be specified by theend-users consultant for procurement and would be partof the civil contract(s), or be separately purchased bythe end-user.

The specification of the tunnel ventilation systemwould either be: a functional specification with system

design responsibility, or a detailed equipment/productspecification with no system design responsibility.

1. Installation Contract Under Civil Contractor: The civilcontractor would typically split his contract in two:1. Civil works2. Installation works, including tunnel ventilation

Item 2 would be purchased from an installation

contractor (electro mechanical contractor) with the focusto do one of two things:

1. Purchase equipment from different suppliers at thelow cost end, with no system design responsibilityfrom the equipment supplier, or

2. Purchase function and detailed system designresponsibility from the equipment supplierItem 1 has traditionally been dominating. In this

scenario the tunnel ventilation supplier would bid anumber of different installation contractors with non-identical specifications.

2. Tunnel Ventilation Contract Under End-User: Asper above, the specification would either be a functionalspecification with system design responsibility, ordetailed equipment specification with no systemdesign responsibility.

In this case there is only one bid to be made: to the end-user. Although this scenario deals directly with the end-user, in reality it becomes difficult to apply a fully functional

specification for the tunnel ventilation procurement. Somesystem-related principles need to be defined previously atconceptual design stage because they have an impact onthe civil tunnel structures. Therefore, typically, the startingpoint would be a conceptual solution defined by the

owners consultant.There still are, regardless of the contractor or end-user,

a number of system-related issues within the conceptualinstallation that benefit from being linked to the equipment

supplier, thereby eliminating borderlines between systemand equipment accountability (e.g., air flow/pressure dropsto develop the required environmental and emergencyconditions, installation effects on equipment performance,acoustic properties, and LCC).

The equipment supplier would integrate underone responsibility, within a network of internal andexternal resources with defined technical and financial

responsibilities, the system-wide functions with thefunctions of the local systems and the related equipment.

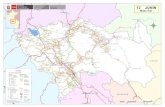

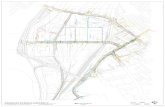

Case Study: High-Speed Rail Tunnel

Tunnel Data

The Ltschberg Basislinie high-speed rail tunnel systemin Switzerland is a current example where a functional

specification was used for the procurement, defining afull system function and equipment accountability for

-

7/27/2019 s 1793966606000072

4/6

6

Systems Research Forum

the supplier (contractor), based on the conceptual designprovided by the client in the specification. All systemfunctions should accordingly be met within the constraintsdefined by the geometries and ventilation concepts given inthe specification.

The main tunnel parameters are as follows:

Tunnel Length: 36 km (twin tunnel 14 km, singletunnel 22 km, with a later option for an extension into

a full 36 km twin tunnel). Trains: Spanning the range from high-speed trains

(250 km/h) to freight trains (80 km/h), imposinga large span of train movement induced pressuretransients in the tunnel, and with a potential fora large impact on the aerodynamic and structuralperformance of the tunnel ventilation system.

Tunnel Operational Modes: Normal train operationmode, tunnel maintenance mode, emergency mode

(e.g., congestion, fire, evacuation of passengers).

The clients conceptual design provides for threeventilation stations equipped with main axial fans,controllable dampers, controllable/ manual doors andventilation orifices. Jet fans will be offered as an optionat one of the tunnel portals. The decision on jet fans willbe taken after a detailed study within the design program(Computational Fluid Dynamics [CFD]).

A number of the main axial fans are specified tobe high-temperature fans (400C for two hours ofsmoke extraction under emergency), with controllableperformance based on optional blade pitch control orvariable fan speed. The final decision would be based on

further detailed analysis and testing.

Tunnel Ventilation: Main Objectives

1. Normal Train Operation Mode

The main objectives are to accomplish the following: Prevent pollutants from exceeding predetermined

levels Safely dilute and remove any methane ingress Keep temperature within predefined limits Keep humidity within predefined limits.

2. Tunnel Maintenance Mode

The main objective is to maintain specified values fortemperature, humidity, methane, diesel fumes, and dust inall sections of the running tunnels.

3. Emergency Mode

The main objective is to provide smoke-free egress route(s)for evacuees.

Methodology

It is, for functional specifications in general, fundamentally

important that all assumptions and boundary conditionsare identified, defined and well understood. This evidently

applies to the potential contractor regarding, for instance,contractual obligations, limitations, and risks but equallyas much to the obligations and risks for the client anduser implied by the selected conceptual design once thesite acceptance tests have been successfully performed. Anopen-minded pre-contractual communication on these

matters between the two parties would form the basis ofan overall risk evaluation and appeared, in this case, to be a

prerequisite for preparing and presenting a bid. In a longerperspective it is also a prerequisite for a successful project.

When preparing the bid for this complex tunnelventilation system, the first step was to criticallyreview the clients proposed design concept in terms ofpotential traffic scenarios, means of tunnel maintenance,emergency scenarios, applied/assumed basic boundaryconditions (geological conditions, train data, maintenanceprocedures), interfering contracts etc. This was in order to

define clear borderlines for the tunnel ventilation contract,

based on which the functional accountability could bedefined and agreed to. This was deemed to be necessaryfrom a contractor standpoint to avoid risk exposure relatedto unlimited consequential damage.

The prerequisite for the bid was that it be based ontechnical data and scenarios as defined in the clientsconceptual specification. It would accordingly be necessaryto base the proposal on the assumption that the clients

reference ventilation would perform satisfactorily for allmodes of operation and meteorological conditions. Thiswas to be validated in a detailed tunnel ventilation systemreview by the supplier, however, only after the signing ofthe full contract.

An extensive technical document therefore wasprepared where all system features were described andquantified based on the clients conceptual design.Comments and questions on this design concept were

given and limitations identified, so as to clarify a numberof issues of type boundary conditions, etc., and to definethe contractual borders in terms of accountabilities forcontractor and client/user. Fundamental deficiencies inthe conceptual design would be requested to form thebasis for additional investigations falling outside the scopeof the proposal (extension/limitation of contract/scopeof work).

The potential contractor might, when first presentingthis approach, appear to the client as taking a highlyprotective and defensive approach. However, after athorough review, this approach turned out to be a valuabletool in the clients understanding of the system functionsand overall risk exposure while at the same time givinga good basis to his evaluation of different competingcontractors approaches to the functional specification.

A number of parameters and data were identifiedwhere an intermediate freeze at the commencement of the

preliminary detailed design would be required. Therefore,immediately after receiving an instruction to proceed with

-

7/27/2019 s 1793966606000072

5/6

Systems Research Forum

7

the design work, a data requirements document wouldbe produced.

This would include, but not be limited to thefollowing: Tunnel geometry Tunnel lining temperatures

Distribution and nature of equipment within thetunnel together with likely heat generation

Water ingress and wetted surface areas Tunnel surface roughness (including type of track-

work, linings, walkways, etc.) Methane ingress Train details (including geometry, performance, etc.) Heat transfer to the train structure Diesel vehicle details (including emissions, usage,

etc.) Train operations (including speed profiles, frequency,

headways, etc.)

Maintenance operations (including duration andlocation of activities, pollutant generating proceduresused, etc.)

Emergency procedures (including egress and accessarrangements, evacuation times, etc.)

Miscellaneous details (including door leakage param-eters, air lock operation and leakage parameters, etc.)

Each identified item of information would beaccompanied by details of the source, responsible authorityand any pertinent comments regarding the confidencewith which it might be used. This document would becontinually updated until the commencement of the final

detailed design.The specification also advised that a test tunnel would

be available at the time of contract. Immediately aftercontract three main tests would be performed, serving as a

basis for the design work: Aerodynamic Climatic/heat transfer Smoke spread

At the preliminary design stage a computer model ofthe system was to be developed to investigate the ventilationof the underground system during normal, maintenance

and emergency operations.At the final detail design stage the computer model

would be revisited to incorporate the latest interfaceinformation and further develop the analysis incritical areas.

Responsibilities

The proposal was structured to include the full detailedtunnel ventilation design and supply based on theconceptual design made by the client.

The system-wide analysis and the local ventilationsystem analysis were planned within the fan manufacturers

scope of supply based on a consortium or sub-supplierarrangement with a qualified institute or consultantagency. Through close cooperation, already at biddingstage the system design responsibilities were analyzedand defined. The risk review and design accountabilitywere reviewed with the client at bidding stage. This

defined the limitations of the system and relatedinstalled equipment and identified potential tradeoffs

to be made (for instance, related to train operations andservice/maintenance).

Implications

The development of tunnel ventilation systems follows themain steps applied in SE:

1. Requirements analysis based on objectives and

stakeholders2. Functional definition based on requirements3. Physical definition/optional system architectures

based on functions with potential tradeoffs4. Definition of system model5. Design validation

The system functions are to be translated into

requirements for subsystems, components, subcomponents,and parts. There is an important area where competencesby system design specialists and component designspecialists overlap.

By imposing a functions-based specification and

a conceptual design as a frameworkand by invit-ing contractors with component/equipment designspecialists to interpret, comment, and propose op-tions and tradeoffsthe overall system design will ben-

efit, accountabilities will become clear, and the overallrisk and risk accountabilities will be better understoodand reduced.

The integrated product/system accountability typeof contract gives more room for a creative functionalanalysis and a qualified risk evaluation related to systemfunctions combined with equipment performancethan the traditional type of strictly separated product/

system contracts.

References

Karlsson, Anders. 2005. Coping with legacy, complexityand change of paradigmA case study. ProceedingsCSER 2005, March 23-25, Hoboken, New Jersey.

Kossiakoff, Alexander, and William N. Sweet. 2003. Systemsengineering, principles and practice. Hoboken, NewJersey: John Wiley & Sons, Inc.

-

7/27/2019 s 1793966606000072

6/6

8

Systems Research Forum

Sheard A.G. 2005. Emergency ventilation for vehicular,rail and metro tunnels. Paper presented for Congresson Safety Innovation Criteria Inside Tunnels, inGijon Spain.

Biography

Hkan Bard, born in 1946 in Sweden, holds a M.Sc. inmechanical engineering (1971) and a Ph.D. in turbomachines (1980) from Chalmers University of Technology,Sweden. From 1971 to 2003 Bard held different positionsat the Flkt/ABB Flkt/ FlktWoods companies, such asTechnical Director of industrial fans and Vice Presidentof tunnel ventilation. In 2003 he joined Vxj University,School of Technology and Design. At present, within

a cooperation agreement between Stevens Institute of

Technology and Vxj University, he introduces systemsengineering at the Masters level in the mechanicalengineering program while also developing the cooperationon a research basis between the university and the heavyvehicles industry within the southeast region of Sweden.