Rupture Disc

-

Upload

smab2162094 -

Category

Documents

-

view

29 -

download

0

description

Transcript of Rupture Disc

-

11

Bursting discsBreather valvesSignalling units

-

About us

REMBE-headquarters in Brilon / Germany

The REMBE headquarters are located in Brilon/Germany.Since 1973 REMBE GmbH SAFETY + CONTROl has manufac-tured world class safety- and measurements products.

Our unique team at REMBE is a highly motivated crew of70 people comprising both, skilled craftsmen and degreedengineers. Combining their dedication with an unequal-led track record in the safety and control business is a per-fect starting point for worldwide success. Every REMBE

employee is an important component of this system, inte-grated into the whole by living it and consequently ta-king the tasks to heart. Quality became a way of life forus and is a decisive feature in the superb performance ofall REMBE products.

In the Safety Division we provide bursting discs for gene-ral applications and pressure / vacuum relief valves as wellas explosion protection systems engineered for variousapplications.

By means of the latest production technologies, as thereare laser- and welding equipments combined with preci-sion tools we are manufacturing the products of theSafety Division as standardised or engineered units.

Our extensive material stock is the basis for flexible pro-duction which offer you even exotic materials (Inconel,Hastelloy, Titanium, Tantalum, Aluminium, Monel, Gold,FEP, etc.) at any time. It enables us to realize even extra-ordinary customer requests at short term.

All REMBE products are manufactured acc. to nationaland international guidelines / normatives including ASME,ATEX, DIN-EN ISO 4126-2,-4126-6, AD2000-Merkblatt A1,PED, Promatomnadzor, GOST, SQL, API, BS2915, KTA,NFPA...

Numerous applications in chemical-, plastics-, pharmaceu-tical- and food industries testify the reliability of the REM-BE products as well as the long-lasting, custom-designedexperience of our degreed engineers.

-

Smart solutions for the safety of your facilities

ELEVENT Pressure and vacuum protecti-on of non-pressure tanks andvessels from 2 mbar

the outstanding tightness of theELEVENT guarantees reduced costs fornitrogen inert systems. 4

IKB With imperfection technologyto the perfect bursting disc

the IKB is the ideal alternative comparedwith the fragile graphite bursting disc.

5

BT / ODV / STAR / VSI ... Pressure protection withtriple-section and multi-layer bursting discs

with the different layers of the ODVeven low response pressures at full vacuumresistance can be realised. 6

IG Holder units forbursting discs

the IG holder units provide safeseat between flanges.

7

KUB@

KUB-V-SeriesKUB-G-SeriesTC(R)-KUB

ZW

Reverse buckling-pin bursting disc

Tri-clamp bursting discTwo-way bursting disc

using the KUB-V-Series bursting discin front of safety valves you benefit fromreduced operational costs.

891011

UKB-LS

Special-/Extruderbursting discs

Compact bursting discs

engineeredfor special applications

REMBE always offers even for extra-ordinary applications an attractive solution. 12

13

FOSSK / BIRD / SB-S

Signalling bursting discsfor all applications

as the fibre optical signalling burstingdisc FOS runs without electricity, even criticaloperational sites can safely be monitored. 13

14

Please see your competent contact on page 15!

-

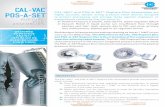

4ELEVENT

Pressure / vacuum breather valves forrelief settings from 2 mbar

The unique ELEVENT valve design withdeep-drawn full stainless steel resp. me-tal housing, modular assembly as well asinterchangeable components offers anoptimised protection for applicationwith low bursting pressures.

The relieving pressures range from 2 mbarto 200 mbar. The ELEVENT provides ad-vanced seal technology and extreme sta-bility despite low weight. The uncompli-cated assembly of the valve and the veryeasy disassembly by means of clamp bo-dy connections are additional path-fin-ding features of the ELEVENT.

Installation and storage costs are redu-ced to a minimum. Costs for maintenan-ce and inspection have not been lowerever before!

The optimised air cushion sealing prin-ciple provides a smooth valve stroke andre-seating during operation and pre-vents from valve flutter and abrasion.

Further options

HALAR-coating, variousspecial materials

steam jacketed or steam traced

pressure and vacuum relief settings

individual sizes, burstingpressures and connectionflanges on request

Your benefits:

extreme stability

low weight

the outstanding tightnessguarantees reduced costs fornitrogen inert system

advice

ELEVENT Fresh Air Supply at a reactor

ELEVENT

Pressure/vacuum reliefvalve E (dimensions pleasesee below)

ELEVENT quality control

ELEVENT

with swivel flanges

ELEVENT pressure relief valvemade from ss 316 L

tank connection

vent side

connection for vacuum relief

ELEVENT concept

Dimensions valid for design with DIN EN 1092/PN16 flanges

TYPE DN NPSDimensions [mm]

A B C D E

ELV E-1/1 25 1" 100 100 195 105 150

ELV E-2/2 50 2" 125 130 263 155 200

ELV E-3/3 80 3" 155 155 375 208 263

ELV E-4/4 100 4" 175 175 395 208 263

ELV E-6/6 150 6" 255 255 510 325 385

-

5IKB

* reduced relief areabursting tolerance range : < 0.5 bar (15 psi) 0,1 bar and 0,5 bar (15 psi) 10%bursting tolerance range : > 0.5 bar (15 psi) 2% on request

DN NPSmin. burst pressure max. burst pressure relief area height

pmin*[barg] pmin*[psig] pmax [barg] pmax [psig] [cm2] [in2] [mm] [in]25 1" 0.60 8.70 4.5 58.0 4.5 0.698 22 0.8740 1.5" 0.50 7.25 4.5 58.0 11.0 1.705 25 0.98

50 2" 0.35 5.08 3.0 43.5 22.0 3.410 26 1.04

65 2.5" 0.35 5.08 3.0 43.5 35.0 5.425 30 1.18

80 3" 0.30 4.35 2.0 29.0 50.0 7.750 35 1.38

100 4" 0.30 4.35 2.0 29.0 80.0 12.400 37 1.46

With imperfection technologyto the perfect bursting disc

Pat. pend. 10 2006 022 478.7

Your benefits:

fully metallic, robust design

easy installation

no influence on torque pressure

longer maintenance intervals

advice

Bursting discs have successfully proventhemselves not only as passive high pres-sure, but as vacuum pressure protectionelements. In case of low pressure 15 psi( 0.5 bar acc. to PED), the metal andgraphite bursting discs meet their limits,also due to sensitivity. The graphite bur-sting disc has a further burden when itbursts as there is particle fragmentation.

The utilization of the directives ASMESEC. VIII, Div. 1 provide the possibility to

avoid expensive and returning inspecti-ons when either a pressure protection 15 psi (ASME) or 0.5 bar (PED) is instal-led.

The team-play consisting of 35 years ofbursting disc experience, cooperationwith leading universities and the use ofmainframe computers led to a complete-ly new design of the bursting disc. Forthe first time imperfection technologywas successfully implemented for the

opening of a bursting disc. Even withthis low bursting pressure, the largestventing areas can be achieved withoutfragmentation.

Further advantages are its aseptic de-sign, vacuum resistance, pressure cycleresistance and a working area of up to96%. For the most common areas ofapplication, there are materials suchas 316 (L) and Hastelloy C276 availableon stock.

The newest generation of bursting discIKB is supplied in a sandwich constructi-on. It is installed between all commonflange and pipe connections. The torquepressure on the flange bolts does not in-fluence the function of the bursting disc.

Low pressure bursting disc IKB

-

6BT / ODV / STAR / VSI ...

The STAR bursting disk has especiallybeen designed for higher response pres-sures.

For all bursting disc types there aremany accessories available:

signalling devices

controllers

weatherproof insulation IK or IADpreventing from reduced dewpoint or noise

integrated heat insulations(up to 1,400 C / 2,552 F and more)

sealings in all kind of qualities

flanges, rings and frames

Process bursting discs BT (bursting discwith tag plate) and BT-VSI (with integra-ted vacuum support) are used for medi-um to high burst pressures. Safe installa-tion in pipeline systems is ensured by me-ans of holder units. Working pressurecan go up to 70 % of the burst pressure(MAWP).

Triple-section bursting discs ODV, etc.are utilised for low and medium pressu-res. They work up to 80 % of the burstpressure. Both types are suitable for ga-ses and liquids and resist vacuum in V-version. Triple-section bursting discs aremost commonly used for low burst pres-sures up to 1 bar. The extremely stable

construction offers easy handling. TheF-version is installed between regularflanges, the FL-version between angularframes and rings. REMBE triple-sectionbursting discs guarantee unlimited life-time even under pulsation or changingpressure conditions.

BT-IKSKODV-FL cut-away sample with signalling unit and insulation IK

BT-STAR with star-shaped opening

BT-SK/ODV-HL bursting disc with holder

Pressure protection with triple-section-and multi-layer bursting discs

Minimum possible burst pressure at a temperature of 22 C (71.6 F) in dependence of nominal pipe size and theused material of the sealing part. Higher temperatures cause a lower burst pressure, lower temperatures anincrease in burst pressure. Other sizes on request!

Sealing material FEP/PTFE Aluminium Nickel Monel Inconel Stainless Steel

Max. temperature 205 / 230 C 401 / 446 F 120 C 248 F 120 C 248 F 120 C 248 F 120 C 248 F 120 C 248 F

DN NPS bar g psig bar g psig bar g psig bar g psig bar g psig bar g psig

20 3/4" 1.7 24.70 6.0 87.00 14.0 203.0 18.0 261.0 35.0 508.0 39.0 566.0

25 1" 1.6 23.20 3.5 50.80 12.0 174.0 17.0 247.0 28.0 406.0 33.0 479.0

40 1,5" 1.0 14.50 2.5 36.30 10.0 145.0 12.0 174.0 20.0 290.0 25.0 363.0

50 2" 1.0 14.50 1.5 21.80 6.0 87.0 7.0 102.0 12.0 174.0 13.0 189.0

65 2,5" 1.0 14.50 1.3 18.90 4.0 58.0 5.0 72.5 10.0 145.0 11.0 160.0

80 3" 0.7 10.20 1.0 14.50 3.0 43.5 6.0 87.0 9.0 131.0 9.0 131.0

100 4" 0.4 5.80 0.8 11.60 3.0 43.5 4.0 58.0 7.0 102.0 7.0 102.0

150 6" 0.2 2.90 0.5 7.25 2.5 36.3 3.0 43.5 5.0 72.5 6.0 87.0

200 8" 0.1 1.45 0.3 4.35 2.0 29.0 2.5 36.3 3.0 43.5 4.5 65.3

250 10" 0.1 1.45 0.3 4.35 1.5 21.8 2.0 29.0 2.5 36.3 3.5 50.8

300 12" 0.1 1.45 0.2 2.90 1.5 21.8 2.0 29.0 2.0 29.0 3.5 50.8

350 14" 0.1 1.45 0.2 2.90 1.5 21.8 2.0 29.0 1.5 21.8 3.5 50.8

400 16" 0.1 1.45 0.1 1.45 1.5 21.8 2.0 29.0 1.5 21.8 3.0 43.5

450 18" 0.1 1.45 0.1 1.45 1.5 21.8 2.0 29.0 1.5 21.8 3.0 43.5

500 20" 0.05 0.725 0.1 1.45 1.5 21.8 1.5 21.8 1.5 21.8 2.0 29.0

600 24" 0.05 0.725 0.1 1.45 3.0 43.5 4.0 58.0 3.5 50.8 2.0 29.0

Insulation cassette IK

Upper part O

Sealing part D

Lower part U/Vacuum support V

Signalling cable SK

-

dire

ctio

nof

flow

7

Bursting discholder unit

IG

The bursting disc holder unit IG has beendesigned for bursting discs with angularsealing surfaces, e. g. BT, BT-ODV, etc.The holder unit consists of an inlet andoutlet part. It can directly be installedbetween flanges.

The bursting disc unit is installed bet-ween flanges. At the same time it dispo-ses of a sufficient leak-proof, even in ca-se of high pressures.

The installation of the bursting disc inthe pipe system on site is considerablysimplified by pre-assembling it into theholder unit. In case of bursting the bur-sting disc is replaced. The holder unitcan be used again.

The holder unit IG can be produced fromCarbon-Steel, Stainless Steel, Titanium,Nickel, Hastelloy, Inconel and other spe-cial materials. The selection of the mate-rials depending on the specification, thetemperature resp. corrosion resistance isindividually agreed with the customer.

The installation is made (s. above) bet-ween flanges. This model range is avail-able for all kind of flanges (DIN / ANSI /JIS s. table). Seal faces and dimensionsof the holder units can be suited to allcurrent standards.

Bursting disc pre-assembled in disc holder IG andsandwiched between flanges.

A

DN NPSANSIRating

Amm

Bmm

15 1/2150300 / 600900

445060

424242

20 3/4150300 / 600900 / 1500

536366

424242

25 1150300 / 600900 / 1500

636976

424242

32 1,25150300 / 600900 / 1500

737985

424242

40 1,5150300 / 600900 / 1500

829295

424242

50 2150300 / 600900 / 1500

101107139

424242

65 2,5150300 / 600900 / 1500

120127162

424242

80 3

150300 / 6009001500

133146165171

42424242

100 4

150300600900 / 1500

171177190203

45454545

125 5

150300600900

193209238244

55555555

150 6

150300600900

219247263285

55555588

200 8150300600

276304317

555588

250 10150300

336358

6262

300 12150300

406419

6363

350 14150300

447482

7575

400 16150300

511536

7878

450 18150300

546593

7878

500 20150300

603647

8787

600 24150300

714771

9696

650 26150300

771831

150150

700 28150300

828895

150150

750 30150300

879949

150150

800 32150300

9361003

150150

DN NPS PN Amm

Bmm

15 1/210-4064-160

5161

4242

20 3/4 10-40 61 42

25 110-4064-160

7182

4242

32 1,25 10-40 82 42

40 1,510-4064-160

92103

4242

50 210-4064

105113

4242

65 2,5

10-254064100

125127138144

42424242

80 310-4064100

142148154

425454

100 410/1625/4064

162167174

454554

125 510/1625/4064

192194210

555555

150 610/1625/4064

217223247

555588

200 810/162540

272283290

555588

250 1010/162540

325340352

626262

300 12101625

375383400

636363

350 14101625

435443457

757575

400 16101625

485496514

787878

500 20101625

594617624

878787

600 24

6101625

679695734731

96969696

700 28

6101625

784810804833

150150150150

800 32

6101625

890917911942

150150150150

Further pressures and nominalpipe sizes on request!B

ritish

Stan

dar

d32

93B

-

8KUB Pat. pend.

Your benefits:

torque independent

no fragmentation

separation of functioning

suitable for all gases,vapour and liquids

advice

Reverse buckling pin bursting disc

In 1774 Leonard Euler developed theformula for buckling of pins. His aid washis knowledge of mathematics. In 1991REMBE introduced the patented reversebuckling pin bursting disc KUB. This ti-me, the aid was the most modern pro-duction technology which made it possi-ble to integrate the buckling pins direct-ly into the dome of the bursting disc.Computer controlled KUB productionenables 2 % bursting tolerance withthe most accurate response pressures.

The process side consists of an integra-ted convex, smooth reverse sealing-membrane. Thus, the first essentials ofsterile, sanitary service are met. More-over, the sealing membrane protects thebuckling pin element from corrosion.Constant burst pressure and unlimitedservice lifetime are guaranteed.

KUB bursting discs are fully torque in-dependent. Torque of the flange bolts isonly defined by the sealing and pressurerating requirements. The KUB can be in-stalled using the KUB holder unit or, atlow to medium pressures, directly bet-ween standard DIN or ANSI flanges wit-hout specially trained personell.Testingacc. to PED 97/23/EG-Modul B or ASMEguideline is part of everysupply.

KUBwith cut away holder unit

KUB afterresponding with100 % opening

KUB with holderunit under nor-mal operation

The buckling pin layer element definesthe bursting pressure without beingeffected by the process media.

1 of 6 KUB buckling-pins KUB after responding

-

9KUB-V-Series

Eliminating downtimeStretching maintenance intervals

The KUB-V-Series is the result of con-tinued research and development. Thebenefit the KUB-V-Series offers is assimple as ingenious: by putting the spa-ce between disc and safety valve slowlyunder pressure the valve can be checkedfor leakage or smooth performance. Thisunique durability against backpressureof the KUB-V-Series is achieved by mo-difying the proven double layer KUB

design. It will never be obtained bysingle-layer or pre-weakened scoredbursting discs.

Due to special reinforcements of the se-cond protecting layer the V-Series with-stands twice the pressure in reverse di-rection as it does in venting direction.Even after multiple valve-testing perfor-mance and durability of the burstingdisc remain unchanged. Single-layer orpre-weakened bursting discs will nevermeet these requirements.

KUB-V-Series keeps safety valvesperforming like new

Your benefits:

easy and safe installation

reduced maintenance

extended valve durability

advice

Step 2: Test operation, chamber inbetween pressurized with test pressure

Step 1: Normal operation,vessel under working pressure

Step 3: Test operation, safety valveresponds, function/leakage testing finalized

Safety valvedischargestest pressure

Putting the spacebetween burstingdisc and safetyvalve slowly underpressure by meansof the volution-unit

-

10

Yet another highlight of the KUB-familyis the G-Series.

It is the worlds first ever made burstingdisc tailored to the challenging demandsof geothermal power plant applications.For these applications the endurance ofa bursting disc is defined by extremetemperatures and ongoing corrosion.

Special finishing technologies of theKUB-G-Series withstand these aggressi-ve effects and double the life time ofthe bursting disc.

KUB-G-Seriesbefore and after responding

KUB-G-Series

Safety even under harshest conditions

Your benefits:

quick installation,double lifetime

no special tools required

specifically designedfor geothermal applications

advice

The KUB, KUB-V-Series and KUB-G-Series bursting discs are available in following sizes:

KUBPat. pend.

DN [mm] 25 40 50 65 80 100 150 200 250 300 350 400 450 500 600 700 800

NPS [in] 1 1,5 2 2,5 3 4 6 8 10 12 14 16 18 20 24 28 32

Eff. Venting Area [cm2] 4.5 11 22 35 50 80 180 280 440 650 860 1100 1485 1855 2710 3680 4850

Eff. Venting Area [in2] 0.7 1.70 3.29 4.72 7.33 12.4 27.9 43.4 68.2 100.7 133 171 230 288 420 570 752

-

TC(R)-KUB in a test laboratory

11

The bi-directional acting bursting dischas the function of two bursting discs,but only requires one installation point.It protects in one direction against in-admissible pressure and in the opposite

direction against inadmissible vacuum.Due to its construction the two-in-onebursting disc offers benefits like stabilityand robustness. It is maintenance-free,even at low response pressures.

The ZW opens in both directions and isfragmentation-free. The bursting disc issuitable for liquid and gaseous media.

Your benefits:

smooth application in pharma-ceutical-, biotechnical- and foodindustries

safeguarding sterility

direct mounting betweenclamp fittings

advice

Your benefits:

easy and safe mounting

no special tools required

reduced operational costs

advice

All-purpose sanitary use

The TC(R)-KUB is the result of a conti-nuous development of the KUB reversebuckling pin bursting disc. As the KUB

is now directly integrated into a clampsealing ring a direct installation of thisbursting disc into standard clamp pipeconnections is now possible. Resultingfrom this the KUB provides multipleoptions.

TCR-KUB

with clamp pipe connections

ZW special design at a vesselin the chemical industry

Two-Way bursting discwith proximity switch

TC(R)-KUB

Two-in-one bursting disc ZW

DN NPS Eff. Venting Area 1)

mm in cm2 in2

25* 1 3 0.4740* 1,5 8 1.2450* 2 14 2.1765 2,5 25 3.8880 3 40 6.20

100 4 62 9.61

* Available in TC(R)-KUB-version,further sizes on request

1) Clamp standard ISO2852 and pipe standardDIN11850 correspond to DIN32676.TC(R)-KUB bursting discs are also availablefor other systems.

ZWDN [mm] DN 50 DN 65 DN 80 DN 100 DN 150 DN 200 DN 250 DN 300 DN 350 DN 400 DN 500 DN 600 DN 700 DN 800

NPS [in] 2" 2.5" 3" 4" 6" 8" 10" 12" 14" 16" 20" 24" 28" 32"

pmin. pressure [barg] 1.0 1.0 0.7 0.35 0.2 0.1 0.1 0.1 0.1 0.1 0.05 0.05 0.045 0.035

pmin. pressure [psig] 14.5 14.5 10.2 5.08 2.9 1.45 1.45 1.45 1.45 1.45 0.73 0.73 0.65 0.65

pmin. vacuum [barg] -0.400 -0.300 -0.150 -0.025 -0.020 -0.020 -0.020 -0.015 -0.015 -0.015 -0.015 -0.010 -0.010 -0.010

pmin. vacuum [psig] -5.8 -4.35 -2.18 -0.36 -0.29 -0.29 -0.29 -2.18 -2.18 -2.18 -2.18 -0.145 -0.145 -0.145

The TC(R)-KUB bursting disc has asmooth convex surface on the pressureside which definitely guarantees sterility.

The TC(R)-KUB was specifically develo-ped for pressure protection that de-mands aseptic and sterile conditions, e.g.in the pharmaceutical-, biotechnical- andfood industries. The especially stable androbust construction enables a safe andeasy installation. The TCR-KUB is fittedwith an integrated PTFE-gasket (FDA/USPSclass VI) conformity) that can be renewedon demand.

-

12

Bursting disc with high gas tightness,e.g. for cryogenic systems

Bursting disc for cryogenic applicationReverse acting bursting disc UKB-LSwith guaranteed helium tightness

Compact bursting discs

Special applications require special bur-sting discs. The UKB-LS meets critical fea-tures such as highly leakproofness (Heli-um), cleanroom demand, fully metal de-sign even at lowest burst pressures.Furthermore this vacuum resistant com-pact bursting disc distinguishes itself byhigh working pressure and back pressureresistance as well as by lowest toleran-ces. In addition to many standard sizesthe UKB-LS is manufactured to specificcustomers requirements.

UKB-LS bursting discs are suited to appli-cations in the aerospace-, hydraulic, cryo-genic-, pharmaceutical- and medicaltechnology and there where compactpressure protection is requested combi-ned with the lowest possible weight andeasy handling.

The compact bursting discs are absolutetightly welded via laser- or micro wel-ding with the respective swivel. Thegentle welding method provides anexcellent leakproofness even on thin-nest burst membranes. Installation is ef-fected torque independent and timesa-ving.

For example, when ESA required a light-weight, easy to handle bursting disc pro-tecting a deep cold gas vessel they chosethe UKB-LS.

Your benefits:

maintenance-free

easy installation

unlimited lifetime

bursting pressures from100 mbar (1.45 psi)to 500 bar (7250 psi)

sizes from DN 15 (1/2)to DN 600 (24)

advice

Bursting discs individually manufactured acc. to customers requirements

UKB-LS

-

13

Bursting disc for hydraulic systems

Extruder bursting discs

Extruder bursting discwith signalling unit

Bursting discs for special applicationsSignalling bursting disc

Bursting plugs / Extruder bursting discs

REMBE offers so-called extruder bur-sting disc units for safeguarding both,extruders and moulding machines in theplastics processing industry against pres-sure.

Bursting plugs are used in hydraulic sy-stems and in compressed air systems. Thegas-tight bursting membrane welded

Fibre optic signalling bursting disc FOS

Bursting discsfor compressed air systems

In case of a bursting disc response thenew fibre optic signalling bursting discgenerates an optical signal and takes itto the process monitoring unit via EMI(Electro Magnetic Interference) and highvoltage insensitive fibre optic cables forevaluation.

In case of the signalling bursting discbeing set in motion, the luminous flux is

interrupted due to the tear of the opti-cal fibre. The following FOA (fibre opticevaluation unit) immediately provides anelectrical signal for optical or acousticalert that can also be used for furtherdata processing. If necessary, several si-gnalling bursting discs can be intercon-nected, forming an optical chain, so thatonly one FOA is required for evaluation.

Your benefits:

suitable for use in hazardousareas (Ex) since no electricityat site

disturbance-free signaltransmission

advice

or soldered is directly located next tothe process. Therefore a high fitting ac-curacy as well as wall-flush sealing in themelting channel with 100 % tightness isensured.

The bursting pressures are in accordanceto the individual application. Pressuresup to some thousand bar (psi) and tem-peratures of 600 C (1,112 F) are possi-ble.

The extruder bursting disc units areoptionally available with integral signal-ling unit.

Your benefits:

easy installation

tag number hard stamped

pressures from 30 bar (435 psi)to 7000 bar (100000 psi)

sizes DN 4 (1/8) to DN 200 (8),standard tolerance 10 %

advice

Fibre optical signalling bursting disc FOS for use in hazardous areas (Ex)

-

14

BIRD with protection shield

BIRD (Burst Indicator REMBE design) retrofitable

A responded disc has to be detected eit-her it has opened fully or only lifted torelease little pressure or vacuum. Severalsystems with different methods of sig-nalling are available integrated andrefittable signalling units as well as se-parate ones.

The basic principle is an intrinsically safelow voltage power circuit that is inter-rupted when the disc responds. The in-terruption is caused by tearing a smartwire or thin foil apart or breaking a spe-cial detection pin. This signal can be im-plemented into the local control panel,monitoring system or just trigger analert or alarm device. In connection withpurpose designed monitoring units andseparation amplifiers the use of such si-gnalling devices and membranes is suit-able for hazardous areas (Ex).

REMBE signalling bursting discs can alsobe used to detect leakages, especially incombination with safety valves either infront of the valve or behind.

Your benefits:

monitoring of upstreambursting discs

immediate system deactivationafter response of the signallingunit

advice

SK / BIRD / SB-S

Signalling Units

Proximity switchfor response monitoring

of ZW bursting discs

Signalling bursting disc SBfor leakage monitoring and signalling

of bursting discs

BIRD for responsemonitoring of triple-section

bursting discs

Hot BIRD with silicon coated cable forresponse monitoring of triple-sectionbursting discs at high temperatures

Signal cablefor response monitoring

of explosion panels

Signal bursting disc SB-Sfor response monitoring

of bursting discs

-

15

Thomas MnstermannManager Process Safety Department /Product Manager KUB

[email protected]: +49 (0) 29 61 / 74 05 - 14

Georg VonnahmeSenior Sales Engineer /Manager Replacement [email protected]: +49 (0) 29 61 / 74 05 - 31

Heinz RustemeierSenior Sales Engineer /Product Manager [email protected]: +49 (0) 29 61 / 74 05 - 32

Orhan KaragzInternational Sales Manager /Product Manager ELEVENT

[email protected]: +49 (0) 29 61 / 74 05 - 34

Safety Division

Since 1990with REMBE

Since 1998with REMBE

Since 1977with REMBE

Since 1981with REMBE

Gerd MayerPresident REMBE, Inc.Charlotte, NC / [email protected]: +1 (704) 443 7022Since 2006

with REMBE

In affiliation with REMBE, Inc.

S M A R T S A F E T Y C O N C E P T S F R O M

S P E C I A L I S T S I N T H E R E M B E - N E T W O R K

Roland BunseManager Explosion Protection Department /Product ManagerQ-Rohr-3, Q-BOX, EXKOPII, Q-Bic, [email protected]: +49 (0) 29 61 / 74 05 - 40

Since 1994with REMBE

In 35 years REMBE has built-up a highly quali-fied team of experts. This unique experience inapplications combined with our technical know-how gives you the confidence required whenplanning and carrying out your explosion pro-tection concept.

Your benefits from REMBE:

1. Active cooperation in internationalstandardisation committees and boardsREMBE has brought its knowledge intothe following European and internationalboards such as CEN, NFPA, ESMG, VDMA,WJI, VDI, ABNT and RosGORTECHNADZOR.

2. REMBE technical seminarsWe provide training of our productsincluding live demonstrations locally orin groups of up to 200 people on site.

3. On site consultationRequest a visit from our specialists.After taking a look at your site we willcreate an appropriate tailor-made conceptfor you. REMBE engineering relishes anexcellent worldwide reputation.

4. Optimised process safety -big cost savingsReduce your insurance payments byimplementing a comprehensive safetyconcept. If you are thinking about aninvestment in your safety concept -we will advise you.

Contact us! Well help you immediately.

-

arsnova

EP-P

SD-0

7082

/1-2

007-

11-1

5-5.

000

REMBE GmbHSAFETY+CONTROLGallbergweg 2159929 Brilon / GermanyT + 49 (0) 29 61 - 74 05 - 0F + 49 (0) 29 61 - 5 07 [email protected]

Proudly distributed thru:

The copyright of all contents in this catalogue with its design, text, photos and graphics are owned by REMBE GmbH SAFETY + CONTROL (except where

otherwise stated); all rights reserved. REMBE does not accept responsibility for any mistakes or technical changes which may occur due to progress in

research and development. All copies made of this catalogue are legally prohibited. REMBE reserves the right to change or update any information in

this catalogue without notice. REMBE will not accept any responsibility for mistakes that occur in the production or in the use of this catalogue. It is

the sole responsibility of the operator to ensure that all REMBE products are correctly used.

Single-Layer and Triple-Section Bursting DiscsERO Pat.-No. EP 07 73 393 / ODV /ODU / EDP / EX-GO-VENT

Indoor-Venting-SystemeQ-Rohr-3 Pat.-No. DE 38 22 012 /Q-Box /

Explosion IsolationEXKOP II Pat.-No. EP 05 59 968 /Q-Flap

Protection Conceptfor Bucket ElevatorsElevatorEX

Explosion SuppressionQ-Bic

Breather Valve forlow Response PressureELEVENT

Bursting Discs for allProcess Applications /IndustriesKUB Pat. pend. / TC(R)-KUB /ZW / ODV / UKB / IKB

Signalling Units

Safety Division

Explosion ProtectionProcess Safety

Weighing Systems andInventory Control for Silos,Mixers, Vessels,Microcell / LESICOM /Load Disc / LeverMount /MasterMount

Dry Bulk Level MeasurementBINDICATOR

BeltscalesUNIBAND

Dynamic Front-End-LoaderWeighing DeviceLOADRITE

Flow Metering Systemfor Bulk & SolidsC-LEVER IIC-LEVER II MINI

Flow MeteringDevice for PneumaticConveying SystemseMicroFlow

Emptying of Big-Bagsand barrelsDocking StationPump System

Weighing SystemsFlow Metering

Control Division