Rules of Thumb - Structural Engineering Other Technical Topics FAQ - Eng-Tips

-

Upload

seljakveseljak -

Category

Documents

-

view

12 -

download

1

description

Transcript of Rules of Thumb - Structural Engineering Other Technical Topics FAQ - Eng-Tips

-

5/29/2015 RulesofthumbStructuralengineeringothertechnicaltopicsFAQEngTips

data:text/htmlcharset=utf8,%3Cbr%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%20fontfamily%3A%20Tahoma%2C%20Arial%2C 1/9

PreliminarydesignRulesofthumb1.Thecostofreinforceconcrete(inplace)isusuallysomewherebetween$100/m3and$800/m3.Thisillustratesthefactthatfora"ruleofthumb"tobeanygood,thebackgroundforitsdevelopmentneedstobeknown.Thatinturnmeansthatmostofthe"rulesofthumb"aremostapplicablebytheengineerthatcameupwiththemandthateverybodyelsebetterbecarefulinusingthem.2.Ifplacingconcretedirectlyfromatruckorconcretepump,placeconcreteverticallyintothefaceofconcretealreadyinplace.Neverallowtheconcretetofallmorethan1to1.5metres.3.Thepossiblespans,andassociateddepths,dependontheloadingtowhichthebeamissubjected.Thefiguresgivenassume'normal'commercialbuildingloads.Theydonotapplytomoreheavilyloadedsituations(e.g.plantrooms)ortounconventionalloadingscenarios.4.Thisinformationisgivenwithoutprejudiceandisforguidancepurposesonly.Itissuitableforpossiblyinitialsizingofstructuralelementsforarchitecturalschemeorcostingpurposesforactualbuildingprojectsthesizeofstructuralelementsmustbeveri?edthroughdetaileddesignbyaquali?edstructuralengineer.5.Preparedrawingsproperly&accuratelyifpossiblelabeleachbarandshowitsshapeforclarity6.Indicatepropercoverclearcover,nominalcoveroreffectivecovertoreinforcement.7.Decidedetailedlocationofopening/holeandsupplyadequatedetailsforreinforcementsaroundtheopenings.8.Usecommonlyavailablesizeofbarsandspirals.Forasinglestructuralmemberthenumberofdifferentsizesofbarsshallbekepttoaminimum.9.Showenlargeddetailsatcorners,intersectionsofwalls,beamsandcolumnjointandatsimilarsituations.10.Congestionofbarsshouldbeavoidedatpointswheremembersintersectandmakecertainthatallrein.Canbeproperlyplaced.11.Inthecaseofbundledbars,lappedspliceofbundledbarsshallbemadebysplicingonebaratatimesuchindividualspliceswithinthebundleshallbestaggered.12.Makesurethathookedandbentupbarscanbeplacedandhaveadequateconcreteprotection.13.Indicateallexpansion,constructionandcontractionjointsonplansandprovidedetailsforsuchjoints.14.Thelocationofconstructionjointsshallbeatthepointofminimumshearapproximatelyatmidornearthemidpoints.Itshallbeformedverticallyandnotinaslopedmanner.

DONOT'SGENERAL:15.Bondedreinforcementshallnotextendacrossanexpansionjointandthebreakbetweenthesectionsshallbecomplete.16.Flexuralreinforcementpreferablyshallnotbeterminatedinatensionzone.17.Barslargerthan36mmdia.Shallnotbebundled.18.Lapsplicesshallbenotbeusedforbarslargerthan36mmdiaexceptwherewelded.19.Wheredowelsareprovided,theirdiametershallnotexceedthediameterofthecolumnbarsbymorethan3mm.20.Primarymovementjointsarerequiredtopreventcrackingwherebuildings(orpartsofbuildings)arelarge,whereabuildingspansdifferentgroundconditions,changesheightconsiderablyorwheretheshapesuggestsapointofnaturalweakness.Withoutdetailedcalculation,jointsshouldbedetailedtopermit1525mmmovementunlessseismicpoundingisanissuethenthisshouldbeincreasedtomin200mm.Adviceonjointspacingfordifferentbuildingtypescanbevariableandconflicting.Whilerulesofthumbareprovidedbesuretoseekguidanceofanexperiencedengineer.Expansionjointisamovement(functional)jointwhichisinstalledtoaccommodatevolumechangeduetotemperaturechanges,shrinkage,andchangeinmoisturecontent..Theothermembersofthisfamilyofjointsare:oControl(contraction)jointsoShrinkagestrips.

AccordingtoMARKFINTELtheuseofExpansionjointsinabuildingisacontroversialissue.Thereisagreatdivergenceofopinionconcerningtheimportanceofexpansionjointsinconcreteconstruction.Someexpertsrecommendjointspacing'saslowas30ftwhileothersconsiderexpansionjointsentirelyunnecessary.

Jointspacing'sofroughly100to200ftforconcretestructuresseemtobetypicalrangesrecommendedbyvariousauthorities.Forsteelstructuresaspacingof200ftisnormal.

However,thespacingismostofthetimesalsodictatedbythefollowingfactorswhichdeterminethelocationofsuchjoints:

NewbuildingadjoiningexistingbuildingLonglowbuildingabuttinghigherbuildingWingsadjoiningmainstructureLonglowconnectingwingsbetweenbuildingsIntersectionsatwingsof'L','T',or'U'shapedbuildings.Soilstratainlengthofstructurevaryinnaturebettertohavejoints(suchsituationisveryrare)

-

5/29/2015 RulesofthumbStructuralengineeringothertechnicaltopicsFAQEngTips

data:text/htmlcharset=utf8,%3Cbr%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%20fontfamily%3A%20Tahoma%2C%20Arial%2C 2/9

Differenttypeoffoundationsinstructure(i.e.buildingfoundedpilesandraft)

21.Actualconcretedeflectionsareinfluencedbymanyfactorswhichcannotbefullytakenintoaccount.Tensilestrengthofconcreteachangeinstrengthfrom2.7to2.1canincreasedeflectionsby50%Modulusofconcrete+/20%EarlyconstructionloadingShrinkagewrappingAlwaysrememberloadcanonlybeestimatedandevendeadloadscannotusuallybecalculatedtowithin5%accuracy.Withthisinmindnotcalculationneedhavemorethan2significantfigures.

22.Forhighrisksfacilitiessuchaspublicandcommercialtallbuildings,designconsiderationsagainstextremeevents(bombblast,highvelocityimpact)isveryimportant.ItisrecommendedthatguidelinesonabnormalloadcasesandprovisionsonprogressivecollapsepreventionshouldbeincludedinthecurrentBuildingRegulationsandDesignStandards.Requirementsonductilitylevelsalsohelpimprovethebuildingperformanceundersevereloadconditions.

Concrete:InitialEstimations:"Todesignevenasimplysupportedbeam,thedesignerneedstoguessthebeamsizebeforehecanincludeitsselfweightintheanalysis."

BEAMS:OVERALLDEPTHOFBEAMS:

MEMBERSPAN/OVERALLDEPTHRATIOreinforcedMaxrecommendedspanSPAN/OVERALLDEPTHRATIOPrestressed/posttensionedMaxrecommendedspanRectangularBEAMwidth>250mmorspan/15butlessthan5D.10TO14(con't2026)8m(con't12m)132012m(con't15m)Flangedbeams1218(con't1821)cantilever265mBandbeams(b?3D)orspan/51820812253014(18mcon't)FornonbandbeamsConcretebeams:2to1depthtowidthratiothewidth(b)ofarectangularbeamshouldbebetween1/3and2/3oftheeffectivelength(d).Thelargerfractionisusedforrelativelylargerdesignmoments.

BandwidthL/4toL/3maxatslabsoffit(Lforaveragetransversespan)Iwouldnormallytaperthesidesofthebandwitha1to1.5'taperfortheL/25ora2'taperfortheL/33tosaveweightbutthatdependsonformworkcosts)BanddepthL/25toL/30(Lforlongitudinalspan)

NotesNote:1.Beamsneedmoredepthtofitsufficientreinforcinginsectionsocheckdetailingearly2.Themaximumspanslistedherearenotabsolutelimits.Longerspansarepossiblewitheverytype,butmaynotbeeconomical.Asaruleofthumbforestimatesofthicknessabovethespanondeflectionratio'sshouldbemultipliedby"maximumrecommendedspan"/"actualspan")3.Thehighernumberaregivenforlightloadings(about1.5kpa)andthelowernumbersforheavyloadings(about10kpa)

-

5/29/2015 RulesofthumbStructuralengineeringothertechnicaltopicsFAQEngTips

data:text/htmlcharset=utf8,%3Cbr%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%20fontfamily%3A%20Tahoma%2C%20Arial%2C 3/9

Commonbandbeamwidthsare1200,1800and2400

bForflangedsectionswiththeratiooftheflangetotheribwidthgreaterthan3,theTablevalueforbeamsshouldbemultipliedby0.8.cFormembers,otherthanflatslabpanels,whichsupportpartitionsliabletobedamagedbyexcessivedeflectionofthemember,andwherethespanexceeds7m,theTablevalueshouldbemultipliedby7/span.dForflatslabswherethegreaterspanexceeds8.5m,theTablevalueshouldbemultipliedby8.5/span.eThevaluesmaynotbeappropriatewhentheformworkisstruckatanearlyageorwhentheconstructionloadsexceedthedesignload.Inthesecasesthedeflectionmayneedtobecalculatedusingadviceinspecialistliterature.Sizing:Fornoncantilevers:d(mm)=span(mm)/26+300,roundtheresulttonearest25mm.Forcantilevers:d(mm)=span(mm)/7+300,roundtheresulttonearest25mm.Fornoncantilevers:Ifspan

-

5/29/2015 RulesofthumbStructuralengineeringothertechnicaltopicsFAQEngTips

data:text/htmlcharset=utf8,%3Cbr%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%20fontfamily%3A%20Tahoma%2C%20Arial%2C 4/9

Note:Themaximumspanslistedherearenotabsolutelimits.Longerspansarepossiblewitheverytype,butmaynotbeeconomical.forflatplatesandflatslabswithdroppanels,thelongerofthetwoorthogonalspansisusedinthedeterminationofthespantodepthratio,whileforedgesupportedslabs,theshorterspanisused.minimumfireresistancenormallyrequireadepthofatleast125mm,150isbestforfittingthereoin.Thehigherspantodepthratiosareforlightloadings(about1.5kPa)andthelowerspantodepthratio'sforheavyloadings(about10kpa).Thespansassumeroughly1.50kPaforsuperimposeddeadloading(SDL).NotesFortwowayspanningslabs(supportedonbeams),thecheckontheratioofspan/effectivedepthshouldbecarriedoutontheshorterspan.Forflatslabs,thelongerspanshouldbetaken.Forflangedsectionswiththeratiooftheflangetotheribwidthgreaterthan3,theTablevalueforbeamsshouldbemultipliedby0.8.Formembers,otherthanflatslabpanels,whichsupportpartitionsliabletobedamagedbyexcessivedeflectionofthemember,andwherethespanexceeds7m,theTablevalueshouldbemultipliedby7/span.Forflatslabswherethegreaterspanexceeds8.5m,theTablevalueshouldbemultipliedby8.5/span.Thevaluesmaynotbeappropriatewhentheformworkisstruckatanearlyageorwhentheconstructionloadsexceedthedesignload.Inthesecasesthedeflectionmayneedtobecalculatedusingadviceinspecialistliterature.

1.Provideamaxspacingof250mm(8")formainreinforcementinordertocontrolthecrackwidthandspacing.2.Amin.of0.24%shallbeusedfortheroofslabssinceitissubjectedtohighertemperature.Variationsthanthefloorslabs.Thisisrequiredtotakecareoftemp.Differences.3.Spansaredefinedasbeingfromcentrelineofsupporttocentrelineofsupport.Althoughsquarebaysaretobepreferredongroundsofeconomy,architecturalrequirementswillusuallydictatethearrangementoffloorlayoutsandthepositioningofsupportingwallsandcolumns.Pinnedsupportsareassumed.4.Particularattentionisdrawntotheneedtoresolvelateralstability,andthelayoutofstairandservicecores,whichcanhaveadramaticeffectonthepositionofverticalsupports.Servicecorefloorstendtohavelargeholes,greaterloadsbutsmallerspansthanthemainareaoffloorslab.5.Eliminatingdropsresultsinsimplerfalseworkandformworkarrangements,enablesrapidfloorconstructionandgivingmaximumflexibilitytotheoccupier.6.Thebenefitsofusinginsituconcreteflatslabconstructionshouldbeinvestigatedattheconceptualdesignstage.Considernotonlythebenefitsintermsofpotentialdesignefficienciesbutalsothemajoradvantagesfortheoverallconstructionprocess,notablyinsimplifyingtheinstallationofservicesandthesavingsinconstructiontime.7.Tooptimisetheslabthickness,considerallfactorssuchasthemethodofdesign,thepresenceorabsenceofholes,theimportanceofdeflections,andpreviousexperience.8.Deflectionswillgenerallybegreatestatthecentreofeachpanel.However,aspartitionsmaybeplacedalongcolumnlines,itisusualtocheckdeflectionsherealso.Thepossibleeffectofdeflectionsoncladdingshouldalsobeconsideredcarefully.Edgethickenings,upstandanddownstandbeamsshouldbeavoided,astheydisrupttheconstructionprocess.9.Thereisevidencethatearlystrikingandearlyloadingthroughrapidfloorconstructionhassomeimpactonlongtermdeflections.10.Thinflatslabconstructionwillalmostcertainlyrequirepunchingshearreinforcementatcolumns.11.Minimumrecommendedthicknessforslabsforfireis120mm12.Drapeslabtendonstohighpointsatthefacesofthebandsattheslabsoffitandrunflatoverbandwidthatminimumtopcover,exceptatendcolumnswheretheyaredrapedtothecenterlineofthecolumnandcentroidoftheslab(Dslab/2fromthetopsurface).13.Whenopeningsinfloorsorroofsarerequiredsuchopeningsshouldbetrimmedwherenecessarybyspecialbeamsorreinforcementsothatthedesignedstrengthofthesurroundingfloorisnotundulyimpairedbytheopening.Dueregardshouldbepaidtothepossibilityofdiagonalcracksdevelopingatthecornersofopenings.Theareaofreinforcementinterruptedbysuchopeningsshouldbereplacedbyanequivalentamount,halfofwhichshouldbeplacedalongeachedgeoftheopening.Forflatslabs,openingsinthecolumnstripsshouldbeavoided.14.Whenisitanadvantagetousefabricmeshinsuspendedconcreteslabs?Designingslabswithmeshreinforcementisapropositionthatcanproducesubstantialcostsavingswhenconsiderationisgiventothefollowingpoints.

a)Meshshouldbesufficientforshrinkagecontrolwithoutadditionalreinforcement.

-

5/29/2015 RulesofthumbStructuralengineeringothertechnicaltopicsFAQEngTips

data:text/htmlcharset=utf8,%3Cbr%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%20fontfamily%3A%20Tahoma%2C%20Arial%2C 5/9

b)Thestructuralsystemshouldbepredominantlya"onewayslab"system,withextrabarsatthemaximummoment.

c)Lappingofmeshshouldbeminimal.

d)Lappinglocationsshouldbeclearlydocumentedsoastoeliminateanypossibilityoftopandbottomlapsbeingcoincidentandsoastomaximiseusageandminimisecutting.

e)Lappingshouldbeachievedusingbarsplicessothateachmeshremainsinthesameplane.

f)Meshlengthsshouldbefactorofthesheetlengthpreferablyusingfullsheetstominimisewastage.

PRESTRESS:1.Maximumlengthofslab50m,bondedorunbounded,stressedfrombothends.25m,bonded,stressedfromoneendonly.2.MeanprestressTypicallyP/A:Slabs:0.72.5mPaBeams:1.03.0mPa3.CoverTakeminimumcovertobe25mm.4.Allowsufficientcoverfor(atleast)nominalbendingreinforcementoverthecolumns,inbothdirections(typicallyT16barsineachdirection).5.EffectofrestrainttofloorshorteningAllconcreteelementsshrinkduetodryingandearlythermaleffectsbut,inaddition,prestressingcauseselasticshorteningandongoingshrinkageduetocreep.Stiffverticalmemberssuchasstabilitywallsrestrainthefloorslabfromshrinking,whichpreventstheprestressfromdevelopingandthusreducingthestrengthofthefloor.Thisshouldbeconsideredinthedesignofthestabilitysystemorallowedforinthemethodofconstruction

COLUMNS:1.Usehighergradeofconcretewhentheaxialloadispredominant.2.Goforhighersectionpropertieswhenthemomentispredominant.9.Restrictthemaximum%ofreinforcementtoabout3%.Inaninsitucolumntheabsolutemaximumreinforcementis6%or10%atlaps.3.Approximatemethodforallowingformoments:multiplytheaxialloadfromthefloorImmediatelyabovethecolumnbeingconsidered)by:1.25interiorcolumns(allowsforpatternloading)1.50edgecolumns2.00cornercolumnsButtrykeepthecolumnstoconstantsizeforthetoptwostoreys.4.Preliminarysizingbesttoaimforcoulmnswith1to2%reinfcoing

oColumnH/1020,oedgecolumnsH/79,ocornercolumnH/68oAccanbeestimatedforstockycolumnsbyAc=N/15(1%reo),Ac=18(2%reo)orN/20(3%reo)forN32concrete.(Ninnewtons)5.Acolumnshouldhaveminimumsection200250sq,ifitisnotanobligatorysizecolumn.6.Inaddition,allcolumnsshallbedesignedforminimumeccentricityequalto[(unsupportedlengthofcolumn/500)+(lateraldimension/30]subjecttominimumeccentricityof20mm.7.Areinforcedcolumnshallhaveatleastsixbarsoflongitudinalreinforcementforusingintransversehelicalreinforcement.forCIRCULARsections.8.Aminfourbarsoneateachcornerofthecolumninthecaseofrectangularsections.9.Keepouterdimensionsofcolumnconstant,asfaraspossible,forreuseofforms.10.Whendoesacolumnchangetowall?generallythisconsideredatabout4timesthethickness,howeverforfirepurposesifthefirecangettoallfoursidesitshouldbeconsideredasacolumn.11.Forserviceloadkeepthetotalstressabout0.3fc'forgravityloadkeepthisabout0.15f'c.12.REINFORCEDCONCRETECOLUMNS:Sizing:Forpreliminarydesignusesquarecolumns.Ifthebuildingheightis3storiesorless:

-

5/29/2015 RulesofthumbStructuralengineeringothertechnicaltopicsFAQEngTips

data:text/htmlcharset=utf8,%3Cbr%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%20fontfamily%3A%20Tahoma%2C%20Arial%2C 6/9

Ifbeamspan

-

5/29/2015 RulesofthumbStructuralengineeringothertechnicaltopicsFAQEngTips

data:text/htmlcharset=utf8,%3Cbr%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%20fontfamily%3A%20Tahoma%2C%20Arial%2C 7/9

1.Withthefollowingreinforcement:100mmonelayerSL72WWF6x6W1.4xW1.4125150mmonelayerSL82WWF6x6W2.9xW2.9180mmonelayerSL92WWF6x6W2.9xW2.9200mmtwolayers(SL72)WWF6x6W1.4xW1.42.Jointsspacing:Ruleofthumbis24to36timesthethickness(givesthespacinginmm/inches).Keepthethicknessvariationto5mm(1/4")/+10mm(3/8"),andthesubgradeasflataspossiblewithnoabruptchangegreaterthan15mm(1/2")inabout1.2m(4').Thiskeepsthe"sudden"restraintpotentialdown.3.Forslabs180mmgreateracrackinitiatorissuggested.4.Nogreaterthan21m(70')betweenDowelsawnjoints5.Nogreaterthan8m(27')betweenjoints6.Makeyourjointpatternassquareaspracticableandwithnomorethana2to1ratiooflengthtowidth.7.AlwayscheckwithclientattopreferredJointssystem8.ForsmallmediumprojectsMaxareainpour:600m^2(60000sqft)Maxjointsspacingforexternalexpansionjoints4050m,internalstoppourslabjoints:60m(200').9.ForlargeprojectMaxareainpour:800m^2aimfor600m^2(60000sqft)Maxjointsspacingforexternalexpansionjoints60m(200'),internalstoppourslabjoints:80m(250')

.

STEELBUILDINGS(NONCOMPOSITE)ChoiceofbeamsystemElementTypicalSpan/depthTypicalSpan(m)Span/depthMaximumspanPlategirder101225m(80')FloorJoist(steelonly)1769m(2030')CastellatedUB's*14171220m(4070')Rooftrusses(pitch>20)141517m(55')SpaceFrames1530100m(300')Primarybeams(supportedbycolumns)101512m(40')Secondarybeams(supportedbyotherbeams)152510m(33')Portalframeleg354060m(200')Simplespanrafter2430m(100')Simplespanroofbeam1525m(80')Con'tbeamorjoist.85*simplespanvalue*AvoidifhighpointloadsincreaseIreqby1.3Asaruleofthumb,thedefectionofacastellatedbeamisabout25%greaterthanthedeflectionofanequivalentbeamwiththesamedepthbutwithoutwebopenings.

ExpansionjointsSteelindustrialbuildings100mtypical150mmaximumc/c.Steelcommercialbuildings50mtypical100mmaximumc/cSteel/Tiltupbuilding50mtypicalSteelroofsheeting20mc/cdowntheslope,nolimitalongtheslope.1.Deeperischeaper.Allotherthingsbeingequal,adeeperwideflangebeamwillbemoreeconomicalthanashallowerone.Thereareexceptionstothisrule,butitisgenerallycorrect.2.Onecommonmisconceptionisthatallsteelmembershaveanactualdepthequaltotheirnominaldepth.3.Thebracesmaybedesignedforacapacityof2%oftheforceresistedbythecompressionportionofthebeam.

4.Cantilever"onetothree".Cantileveredsteelbeamsarecommonlyusedtosupportarchitecturalfeatures,givingtheillusionofanunsupportedor"flying"edge.Howfaristoofarforacantilevertostickout?Generallyspeaking,ifacantileverexceeds1/3ofthetotalbackspan,economyislostandmayleadtodesigndifficulties.Soifyourbeamhasa9m(30')backspan,trytokeepanadjacentcantilevertolessthan3m(10')long.

-

5/29/2015 RulesofthumbStructuralengineeringothertechnicaltopicsFAQEngTips

data:text/htmlcharset=utf8,%3Cbr%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%20fontfamily%3A%20Tahoma%2C%20Arial%2C 8/9

5.TRUSS:Anoptimaldepth/spanratioforaplanartrussisapproximately1/10.AlthoughforcesintheCHORDSdecreasewithincreasingdepth,forcesintheWEBarepracticallyUNCHANGEDandincreasingthedepthincreasesthelengthsofthesemembers.ApproximatelyhalfthewebmembersareinCOMPRESSIONandincreasingtheirlengthsreducestheirefficiencyduetotheincreasedsusceptibilitytoBUCKLING.

6.StrutsandtiesSlendernesslimits:Membersresistingloadotherthanwind:8#180Membersresistingselfweightandwindonly:8#250Membersnormallyactingasatiebutsubjecttoloadreversalduetowind:8#350

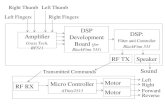

STORIESLATERALLOADRESISTINGSYSTEM

-

5/29/2015 RulesofthumbStructuralengineeringothertechnicaltopicsFAQEngTips

data:text/htmlcharset=utf8,%3Cbr%20style%3D%22color%3A%20rgb(0%2C%200%2C%200)%3B%20fontfamily%3A%20Tahoma%2C%20Arial%2C 9/9

(a)Connectionsimplicity(b)Numberofmembers(c)Numberofboltsand/oramountoffieldwelding(d)Sizeandefficiencyoferectioncrew,andtheequipmentattheirDisposal(e)Timelysupplyofsteel.

17.Theuseofthetransportationlengthmayhavetobecurtailedtoavoiddamageduringtransportationtrytokeepmemberlengthslessthan15m.18.Oneruleofthumbfor?lletweldsonbothfacesoppositeeachotheristomakethegussetthicknesstwicetheweldsize.

19.Simpleconnectionsusegrade8.8,20mmdiameterboltsfinplates}t=8mmforUB's