RT&S 0713

-

Upload

railway-track-structures -

Category

Documents

-

view

276 -

download

12

description

Transcript of RT&S 0713

July 2013 | www.rtands.com

Special Trackwork

Fasteners

And AlSo

AREMA news p. 39

plus

heatWelding brings the

www.rtands.com Railway Track & Structures July 2013 1

July 2013

Contents News

5 Industry Today 5 Supplier News

11 People

Columns

3 On Track Technology solutions to improve rail operations

12 NRC Chairman’s Column Safety first, then

conferences

Features

19 Finding security in fastening systems

Fasteners may be tiny in size, but they pull their weight in importance for North American railroads .

29 Rail welding sparks new developments

Rail welding suppliers, both flash butt and thermite, make advancements in order to offer a longer service life.

35 Special trackwork update Specialized trackwork

components are no cheap buy for the railroad; manufacturers offer these important pieces with a long lifespan.

29

RAILWAY TRACK AND STRUCTURES

Holland L.P. is one company working to provide the industry with quality, reliable rail welds. Story on page 29.

Departments13 TTCI R&D

39 ARemA News

44 Products

45 Advertisers Index

45 Sales Representatives

46 Calendar

47 Professional Directory

48 Classified Advertising

19

35

FOLLOW US on Twitter

LIKE US on Facebook

www.rtands.com Railway Track & Structures July 2013 3

Vol. 109, No. 7Print ISSN # 0033-9016, Digital ISSN # 2160-2514

EDITORIAL OFFICES20 South Clark Street, Suite 1910

Chicago, Ill. 60603Telephone (312) 683-0130

Fax (312) 683-0131Website www.rtands.com Semih Kalay/Guest Editor

Mischa Wanek-Libman/Editor, [email protected]

Jennifer Nunez/Assistant Editor, [email protected]

CORPORATE OFFICES55 Broad St 26th Fl.

New York, N.Y. 10004Telephone (212) 620-7200

Fax (212) 633-1165Arthur J. McGinnis, Jr./ President and Chairman

Jonathan Chalon/PublisherGeorge S. Sokulski/Associate Publisher Emeritus

Mary Conyers/Production DirectorWendy Williams/Creative Director

Maureen Cooney/Circulation DirectorJane Poterala/Conference Director

Railway Track & Structures (Print ISSN 0033-9016, Digital ISSN 2160-2514), (USPS 860-560), (Canada Post Cust. #7204654), (Bluechip Int’l, Po Box 25542, London, ON N6C 6B2, Agreement # 41094515) is published monthly by Simmons-Boardman Publ. Corp, 55 Broad St 26th Fl., New York, N.Y. 10004. Printed in the U.S.A. Periodicals postage paid at New York, NY and Additional mailing offices. Pricing, Qualified individual in the railroad employees may request a free subscription. Non-qualified subscriptions printed or digital version: 1 year Railroad Employees (US/Canada/Mexico) $16.00; all others $46.00; foreign $80.00; foreign, air mail $180.00. 2 years Railroad Employees US/Canada/Mexico $30.00; all others $85.00; foreign $140.00; foreign, air mail $340.00. BOTH Print & Digital Versions: 1 year Railroad Employees US/Canada/Mexico $24.00; all others $69.00; foreign $120.00; foreign, air mail $220.00. 2 years Railroad Employees US/Canada/Mexico $45.00; all others $128.00; foreign $209.00; foreign, air mail $409.00. Single Copies are $10.00 ea. Subscriptions must be paid for in U.S. funds only. COPYRIGHT © Simmons-Boardman Publishing Corporation 2013. All rights reserved. Contents may not be reproduced without permission. For reprint information contact: PARS International Corp., 102 W 38th St., 6th Floor, New York, N.Y. 10018 Phone (212) 221-9595 Fax (212) 221-9195. For Subscriptions & address changes, Please call (800) 895-4389, (402) 346-4740, Fax (402) 346-3670, e-mail [email protected] or write to: Railway Track & Structures, Simmons-Boardman Publ. Corp, PO Box 10, Omaha, NE 68101-0010.POSTMASTER: Send address changes to Railway Track & Structures, PO Box 10, Omaha, NE 68101-0010.

RAILWAY TRACK AND STRUCTURESOn Track

Technology solutions to improve rail operations

Over the past several decades, Transportation Technology Cen-ter, Inc. (TTCI), and industry

collaborators have been busy executing the collectively designed Association of American Railroads’ Strategic Research Initiatives (SRI) Program. The purpose of the research is to understand the safety, technical and economic issues related to track performance for high-tonnage freight traffic and heavy-axle-loads. Much of the research has been conducted at the Facility for Accelerated Service Testing (FAST), in Pueblo, Colo. The oval-shaped High Ton-nage Loop at FAST, where a 17,000-ton train operates under computer control, provides the industry a test bed for tech-nology development and evaluations.

With research support under this program, North American railroads have significantly increased rail life using cleaner and harder premium rai l steels. The Nor th Amer ican railroads have continued this progress by increasing the utilization of existing assets through effective implementation of technologies like friction control and preventive grinding procedures and by the acceleration of the development of wear and fatigue-resistant premium rails.

Collaborative efforts have significantly extended the service life of special trackwork under heavy-axle-loads. TTCI, railroads and suppliers have teamed to develop, test and implement innovative designs, including improved running surface profiles, flange bearing diamonds, partial flange bearing turnouts, one way low-speed crossing diamonds, conformal switch points and, most recently, continuous rail turnout designs.

Better assessment tools for bridge repair and life extension are being used and plans are underway to evaluate new bridge designs, such as one design referred to as hybrid composite concrete. The addition of a 100-year-old riveted girder span at FAST is serving as a proving

ground for studying the effectiveness of various repair and life extension methods. In 2014, steel girder bridge tests will be expanded at FAST and in revenue service to develop and demonstrate various bridge life extension methods.

Maintaining fastener hold-down strength over the life of ties is a challenge for all railroads. Through the SRI program a variety of wood and concrete tie/fastener systems are being tested. Frame ties are one innovation currently being evaluated at FAST and in revenue service for improved performance under heavy-axle-loads.

The condition of railroad track substructure can strongly influence track performance. TTCI’s track substructure research is focused on ballast condition assessment and development of ballast maintenance and remediation guidelines. This research aims at determining the root causes of poor track substructure problems and implementation of remedial procedures to improve track performance.

The thermite weld performance has been significantly improved by collaborative efforts undertaken by TTCI and the suppliers. The accelerated development of wide gap welds has led into an industry wide implementation of this technology.

TTCI eng ineers are currently working on the development of a matrix-based phased array rail inspection system. If successful, it is expected to significantly improve inspection reliability in North America.

The Federal Railroad Administration reports that 2012 was the safest year ever for U.S. railroads. Technological improvements undertaken by the AAR’s SRI program have extended the life of track components, enhanced inspection and maintenance capabilities and helped reduce track-caused derailments.

Semih Kalay, sen ior v ice president of TTCI.

Guest editor’s appearance should not be viewed as an endorsement of products, advertisements or opinions found within this issue.

www.rtands.com Railway Track & Structures July 2013 5

ACF InduSTRIeS’ rail car manufacturing plant in Milton, Pa., reopened its doors June 5, 2013, after four years of being shut down.

MonTAnA HydRAulICS has been awarded a contract to manufacture and deliver 54 bi-directional ballast plow units to FreightCar America.

RAIlCoMM has provided its yard control system to a yard in Geismar, la.

RITRon, InC., has delivered an order for 350pcs of the Ritron nXdn digital locomotive radios to the Southeast Pennsylvania Transit Authority.

Santa Clara Valley Transportation Authority’s (VTA) Board of directors awarded the Granite Rock Company, doing-business-as PAVeX ConSTRuCTIon dIVISIon, a $16.8 million construction contract for the continued improvements planned along Capitol expressway and future VTA rapid transit and light-rail corridor.

SIeMenS is currently installing its Sitras SeS energy Storage unit with supercapacitor technology in the u.S. on the new TriMet Portland-Milwaukie light Rail Transit line.

I l l i n o i s Tr a n s p o r t a t i o n Secretar y Ann Schneider, Springfield Mayor Michael Hous ton and Sangamon County Cha i r man Andy Va n M e t e r s i g n e d a n Intergovernmental Cooperation Agreement (IGA) to advance design work as a par t of the 10th Street Rai lroad Consolidation Plan.

Under the IGA, the Illinois Department of Transportation (IDOT) will commit up to $8.65 million to support approximately half of the total design cost for the 10th Street corridor rail improvements.

The 10th street corridor consolidation project through Springfield and the needed flyover project just south of Springfield are identified as part of the Chicago to St. Louis High-Speed Rail project. Currently, no funding has been identified for construction of these projects; however, the state of Illinois is funding a detailed environmental analysis of the flyover project. The project would include a new track alignment and railway flyover to grade separate the Union Pacific/Amtrak operations from the Norfolk Southern operations to eliminate train congestion and

improve crossing delays for vehicular traffic.The immediate improvements will

include the 3rd Street corridor safety enhancements that will consist of four-quadrant crossing gates that will prevent cars from driving around lowered gates, as well as new grade-crossing approaches, fencing and bridge upgrades to improve rail traffic flow and increase safety in the area until construction is complete on the 10th Street corridor.

Approximate ly $1.75 b i l l ion in improvements are being completed by IDOT, Union Pacific and the Federal Railroad Administration, pursuant to a Cooperative Agreement funded by the American Recovery and Reinvestment Act.

Supplier NewS

FRA issues grade-crossing iPhone/iPad appThe Federal Railroad Administration (FRA) launched the Rail Crossing locator, an ioS smartphone mobile application that provides easy access to safety information about grade crossings. The app is free through Apple’s App Store and can be used on any iPhone or iPad.

The app works by prompting users to enter a specific location, which allows them to locate grade crossings in their area and retrieve information, such as the physi-cal characteristics of a crossing and the type of traffic control devices used. The app allows users to report information about grade crossings to the FRA to ensure the most accurate and up-to-date information is available.

Throughout the past decade, highway-rail incidents have declined by 34 percent and deaths resulting from these events have fallen 30 percent. However, while the total number of incidents has been trending downward, collisions at crossings remain a challenge to safety, the FRA said. last year alone, grade-crossing collisions account-ed for nearly 20 percent of all reportable rail accidents and incidents and represented nearly one-third of all rail-related fatalities.

“While we’ve made significant progress in the reduction of highway-grade crossing incidents over the past decade, much more work remains to be done,” said Federal Railroad Administrator Joseph Szabo. “This technology will be one more tool to help us reach our goal of zero fatalities.”

INDUSTRY TODAY P

ho

to co

urtesy o

f Ido

T H

SR

web

site

illinois officials sign intergovernmental Cooperation Agreement

INDUSTRY TODAY

www.rtands.com Railway Track & Structures July 2013 7

Supplier NewS

Norfolk Southern dedicated the Franklin County Regional Intermodal Facility in Pennsylvania on June 11. The $97-million terminal connects Central Pennsylvania, Western Maryland and Northern Virginia to domestic and world markets, while creating 126 jobs at the site. The facility, a public-private partnership involving $52 million in NS funds and supported by a $45-million investment by Pennsylvania, is part of NS’ Crescent Corridor series of projects, a 2,500-mile network of rail and terminals that helps moderate truck traffic on congested roadways and reduce carbon emissions.

CEO Wick Moorman said, “This terminal represents a milestone for Norfolk Southern and Franklin County. It is creating jobs here in Central Pennsylvania, positioning Norfolk Southern as the green transportation choice and serving the region’s freight transportation needs. This important endeavor would not be possible without the dedicated support of people in Washington, Harrisburg and here in Franklin County.”

The terminal, with its 670 paved trailer/container parking spots, will be a major gateway for freight in the Mid-Atlantic. The Franklin County Regional Intermodal Facility is the third Crescent Corridor intermodal terminal NS has opened since mid-2012, with facilities in Birmingham and Memphis having started last year. A fourth Crescent Corridor intermodal terminal, located in Charlotte, N.C., will open later this year. NS also is expanding capacity at two intermodal terminals in Harrisburg, Pa.

While NS celebrated its newest terminal, CSX broke ground on a new 89-acre intermodal terminal in Salaberry-de-Valleyfield, QB, Canada, on June 3; the terminal is expected to open in 2015.

The $107-million project will expand CSX’s presence in the market and connect the greater Montreal region and Quebec with CSX’s 21,000-mile rail network in the United States.

Located in the Perron Industrial Park, the terminal will be close to the newly-completed Autoroute 30, providing easy market access to the greater Montreal distribution and consumption market. Trains serving the terminal will connect through CSX’s Nor thwest Ohio intermodal hub.

When fully operational, the terminal is expected to handle up to 100,000 containers per year, using modern rubber-tire gantry cranes to transfer containers between trains and trucks.

“We believe the intermodal terminal we are building here will quickly become a positive asset for Quebec and the Salaberry-de-Valleyfield community for years to come,” said CSX Intermodal Terminals Inc. president Wilby Whitt.

T h e Q u e b e c M i n i s t r y o f Transportation is also supporting the project through a $6 million grant for the reduction of greenhouse emissions.

CSX is relocating a portion of its track from a residential area of Salaberry-de-Valleyfield to a location east of Autoroute 530 along side the new terminal in the industrial park. Once the track is relocated, the right-of-way will be sold to the city of Salaberry-de-Valleyfield for recreational use.

NS dedicates intermodal facility, while CSX begins construction on one Metropolitan

Transportation Authority new york City Transit awarded a $208.4 million contract to 86TH STReeT ConSTRuCToRS JoInT VenTuRe, a joint venture of Schiavone Construction Co. llC and John P. Picone, Inc., for station finishes, mechanical, electrical, plumbing, ancillary buildings and entrances for the 86th Street Station of the Second Avenue Subway.

Pacific Imperial Railroad, Inc., has entered into a services agreement with J.l. PATTeRSon & ASSoCIATeS, InC. for the railroad’s desert line.

INDUSTRY TODAY

www.rtands.com Railway Track & Structures July 2013 9

The Federal Railroad Administra-tion’s (FRA) Railroad Safety Adviso-ry Committee (RSAC) voted unani-mously on implementing new crash-worthiness performance standards for next generation high-speed pas-senger rail equipment that will oper-ate in the United States.

“Today’s vote is another impor-tant step in advancing high-speed and intercity passenger rail in Amer-ica,” said U.S. Transportation Secre-tary Ray LaHood. “This vote brings us closer to new jobs and manufac-turing opportunities to make high-speed rail equipment for use here at home and abroad.”

The standards, which FRA is developing now before they are pub-lished later this year in a Notice of Proposed Rulemaking, will provide baseline safety requirements for next-generation rail equipment that would travel up to speeds of 220 mph on high-speed rail tracks, while providing the flexibility to operate with existing freight and passenger systems up to speeds of 125 mph. Once finalized through the FRA’s rulemaking process, the new stan-dards would be employed along the Northeast Corridor and in Cali-fornia, regions both designated for high-speed rail service.

“Today’s act ion by RSAC is a cont inuat ion of FRA’s move away from prescriptive regulations towards more performance-based regulatory environment,” said Joseph Szabo, FRA administrator. “I’d like to commend all members of RSAC for advancing these standards for-ward. They will better align our approach to passenger safety and the use of rail equipment with the rest of the world.”

The proposed standards are intended to provide an alternative approach to existing railcar crash-worthiness requirements that have influenced the type of passenger equipment built and used in the U.S. market for nearly a century. The proposed standards would establish performance-based requirements for

an interoperable rail network, per-mitting the use of “service proven” designs and advanced technologies, while ensuring a consistent, system-atic approach to safety.

Since 2009, members of the RSAC have undertaken a review of existing crashworthiness requirements in order to identify a new, technology-neutral,

performance-based approach that employs modern and advanced design techniques, such as crash energy man-agement. Consensus on the proposed standards was reached by the RSAC Engineering Task Force, which is made up of a cross section of the domestic and international railcar supply indus-try, including 12 railcar manufacturers.

FrA committee OKs high-speed rail crashworthiness standards

Correction: On page 12 of RT&S June 2013, Calculating maximum allowable curve speeds using new FRA rules scheduled to become effective July 11, 2013, by Louis Cerny, Calculation (A) was not included in the article. Below is the calculation.

www.rtands.com Railway Track & Structures July 2013 11

peOple

AlAskA RAilRoAd CoRpoRAtion named Bill o’leary chief operating officer, Jon Garner transportation superintendent, Clark Hopp vice president engineering, Wendy lindskoog vice president business management and corporate affairs and Barbara Amy chief financial officer.

CAnAdiAn pACifiC appointed the Hon. Jim Prentice to the company’s board of directors.

CRouCh EnginEERing named Richard Brann vice president and general manager; Harvey Crouch, founder of Crouch Engineering, will continue his responsibilities as president and CEO, as well as manager of business development.

CtlgRoup named Timothy Tonyan, Ph.D., interim president and CEO; President and CEO Jeffrey Garrett, Ph.D., S.E., has resigned.

dElCAn promoted Susan Cox, Sameh Salib, P.E., Paul Croft, MCIP, RPP, and Patrick Cruickshank, P.E., to principal; Yousef Kimiagar, P.E., to senior principal and Sylvain Montminy, P.E., to vice president.

J.l. pAttERson & AssoCiAtEs, inC., hired Harry Steelman as senior construction manager.

skAnskA usA promoted Jessica Murray to head of communications and marketing for Skanska Infrastructure development north America.

tRAnsystEms hired Robert Ryan as senior vice president and market sector leader for its national passenger rail and transit practice areas.

WAtCo tRAnspoRtAtion sERViCEs named Brit Sonnier as general manager for the Baton Rouge Southern Railroad and promoted Mike Stickel to vice president sales and marketing, east Region; WAtCo tERminAl And poRt sERViCEs hired Myles VanGorder as terminal manager at its Pecos, Texas, facility and WAtCo WEstERn AustRAliA RAil promoted Grant Thompson to senior vice president operations.

obituARy Former bAy AREA RApid tRAnsit General Manger B.R. (Bill) Stokes, passed away on May 15.

12 Railway Track & Structures July 2013 www.rtands.com

NRC CHAIRMAN’S COLUMN

The National Railroad Construction & Maintenance Association, Inc. 500 New Jersey Ave., N. W. Suite 400 Washington D. C. 20009

Tel: 202-715-2920Fax: [email protected]

As I read the industry news from several sources, I realize how fortunate I am to be involved in this industry. What great foresight I had as a teenager 40 years ago when I hired on to the Rock Island.

The railroad industry has been strong and demonstrated great resilience through the uneven economy of the past six years and continues to get stronger. Every day we are reading about new facilities for intermodal, petroleum, frac sand and grain being planned, going into construction or opening. Railroads are rehabilitating lines that have seen only marginal traffic for years but are now running unit trains, or soon will be. Opportunities abound.

Railroads, contractors, material suppliers and equipment suppliers are all busy scheduling and working to meet the demands and deadlines of our customers. With all of the positive aspects of these opportunities, we have to be aware of the possible side effects on our employees that are associated with long hours and stress.

When employees operate under extreme conditions for any sustained period of time, the possibilities of mistakes and injuries increase. It is imperative that we keep our employees safe throughout the year. Proper training and observation after training is the key to their safe return home every day. Don’t forget that the NRC

has many safety tools for use by its members, including 14 Safety Training DVDs, more than 100 safety toolbox talks, a pocket safety manual, Roadway Worker Protection safety training materials, safety seminars at the annual conference and an annual safety awards contest. 2012 was the safest year in railroad history. Let’s make 2013 a better year yet.

I hope to see everyone at the joint AREMA/REMSA/RSI/RSSI Railway Interchange event in Indianapolis, Ind., from September 29 - October 2. The show is a biennial industry highlight and is not to be missed.

And don’t forget to save the date: the 2014 NRC conference will be held at the J.W. Marriott in Palm Desert, Calif., from Sunday, January 5, 2014, through Wednesday, January 8, 2014. Updated information will be posted shortly on www.nrcma.org/go/conference and conference registration and booth sales will begin this summer. We’ll again expect to have senior engineering and procurement executives from the major freight railroads, commuter railroads and rail transit agencies presenting the details of their organization’s upcoming capital investment plans.

Work safe and keep those around you working safe.

by Terry Benton, NRC Chairman

Safety first, then conferences

www.rtands.com Railway Track & Structures July 2013 13

TTCI R&D

Transpor tation Technology Center, Inc., evaluated the potential load environment of flange-bearing frogs (FBF) under heavy-axle-load service to assess the potential for operating

various types of FBFs at speeds above 10 mph for freight trains (and 15 mph for passenger trains) in accordance with track safety standards established by the U.S. Department of Transportation, Federal Railroad Administration (FRA).1 Results showed that 25-mph operation, over turnout frogs designed to be flange bearing for most wheels, except those with shorter flange heights, will be similar to full FBF crossing diamond operations at this speed.

Full FBF crossing diamonds are currently

allowed for track speeds up to 80 mph for freight trains and 90 mph for passenger trains under a waiver of the FRA Track Safety Standards.1 The first full FBF diamond was installed by CSX in Shelby, Ohio, in 2006.2 Freight railroads began using FBFs for turnouts the same year. These frogs have been nicknamed “lift” frogs because of the way they work. They function by lifting the wheels of the crossing line over the mainline rail. This is accomplished with a tread-bearing ramp at the toe of the frog and a flange-bearing ramp at the heel. The wheel also crosses a flangeway and is flange bearing on the mainline rail. Figure 1 shows a lift frog in track at the Facility for Accelerated Service Testing (FAST). There are an estimated

1,000 lift frogs in revenue service today. This frog has brought significant increases in service life for locations in mainline turnouts where diverging traffic is low speed and low volume. They also have improved ride quality by eliminating any impacts or joints on the mainline route. The high-angle version of this design is used in the OWLS (One Way Low Speed) crossing diamonds. However, it has flange-bearing ramps on both sides of the flangeway gap.

A second design has been in service since 2010. The partial f l ange-bear ing se l f -guarded solid manganese (SGSM) frog (Figure 2) is similar to the full FBF crossing diamonds because it allows flange bearing for both routes. SGSM frogs are built so that most wheels will be flange bearing through each route of the frog. Wheels with shorter flanges

TTCI researchers evaluate flange-bearing frogs under heavy-axle-loads.

by David D. Davis, senior scientist, Rafael Jimenez, senior engineer I, and Xinggao Shu, principal investigator I, TTCI

Evaluation of load environment of flange-bearing frogs

Figure 1: Lift frog in High Tonnage Loop at FAST.

TTCI R&D

14 Railway Track & Structures July 2013 www.rtands.com

may be tread bearing or tread and flange bearing in the wheel transfer (i.e., wing to point) zone. SGSM frogs are installed in heavily-used yard turnouts, such as switching leads and ladder tracks. For these applications, having the ability to operate above 10 mph (in the range of 15 to 20 mph) is essential to productivity. The FRA’s current Track Safety Standards limit flange bearing through turnout frogs to Class 1 speeds.1 This limits applications to 10 mph speed for freight operations.

There are potential wheel and train operation issues with FBFs. The railway industry studied these issues at length from 1995 to 2002 with a series of analytical studies and full-scale tests by the Association of American Railroads.3-10

Revenue service operations of full flange-bearing crossing diamonds began in 2006, with a waiver of the Track Safety Standards for minimum flangeway depth. Since then, approximately 11 million car passes have been successfully operated at three FBF crossing diamond locations. There have been no flange-bearing related wheel failures nor did any FBF caused derailments under this waiver.

Service environmentDuring TTCI’s feasibility studies, an assessment of the service environment for conventional tread-bearing frogs and the proposed FBFs was conducted. The studies compared predicted and actual vertical wheel loads for each type of frog.3-10

The tread-bearing diamond frogs normally used today are well-known to be one of the most severe load environments in the railway. The unsupported flangeway gaps on high-angle frogs cause wheel impacts that have been measured at three to five times static wheel loads for 40 mph speed. Less well-documented is the dynamic loading on typical turnout frogs. These can often be 1.5 to three times static wheel loads for 40 to 60 mph speeds. While a wheel can span the flangeway gap on the low-angle frogs, there is often a dynamic load due to significant changes in running surface elevation and shape, as well as track stiffness across the frog. Figure 3 shows the maximum dynamic load factors measured from heavy-axle-load testing of the frogs at FAST.11

Figure 2, Top: Partial flange-bearing self-guarded solid manganese frog in revenue service.

Figure 3: Measured dynamic load factors for tread-bearing frogs.

www.rtands.com Railway Track & Structures July 2013 15

Predicted flange-bearing frog forcesA ser ies of s imulat ions were made to develop recommendations on ramp rates for FBF frogs.11 Figure 4 shows the results of the study. Ramp rate recommendations were developed with the requirement that dynamic wheel loads remain below 1.5 times static wheel load for typical bulk commodity freight cars.

The predicted forces for flange bearing are significantly lower than forces for high-angle tread-bearing frogs at mainline track speeds. Additional measurements of prototype FBF diamonds showed these predictions to be accurate.10 Additional issues, such as cross grooving in full FBF diamond frogs, were studied. Cross grooves are likely to be smaller than flangeway gaps.

An additional item was evaluated for the SGSM frogs. This issue may occur at the point of frog for wheels with shorter flanges. These wheels may remain tread bearing, if the frog is worn, until the flangeway gap. At this point, the wheel flange may contact the flangeway floor. This case was simulated by welding some rods in the flangeway of a tread bearing No. 10 frog.

The frog was custom made for the load measuring wheelsets, so that they would contact the flangeway floor only at the point of frog. Figure 5 shows the frog and wheel contact situation. The test scenario in this situation has been observed at Shelby, Ohio, and Moorhead Junction, Minn., where a new wheel is tread bearing through the diamond until it reaches the frog flangeway gaps. The wheelset drops until it contacts the flangeway floor. This scenario will also occur on SGSM FBFs. It is also a milder version of what every wheel potentially sees on an OWLS diamond, where the wheel crosses a full flangeway gap unsupported. Note that with tread bearing frogs, all wheelsets drop until the tread contacts the far side of the flangeway gap.

Measured frog forcesFigure 6 shows the average wheel force from two runs over this modified frog with a loaded 315,000-pound car at 10, 25 and 40 mph. The dynamic loads on the flange average about 55,000 pounds at 25 mph. This is a dynamic load factor of ~1.4. While this flange impact is not ideal, it is likely to only happen to short (i.e., new and presumably thicker) flanges. These forces are also within the 1.5 dynamic load factor used to design the ramps used on full FBF diamonds.

Figure 7 shows the wheel drop flange impact event at 25 mph as compared to the intended flange impact from the flange-bearing ramps at each end of the frog. The flange-drop dynamic load is in the range of that expected for wheel flange-ramp engagement on the designed ramps. In effect, the wheel drop event replaces the ramp engagement event for short-flange wheels. Wheels in revenue service using tread-bearing frogs, full FBF diamonds and OWLS currently experience this level of dynamic loading.

Industry experience with wheel performance on full FBF crossing diamond crossings has been successful. Test

Figure 4, Top: Predicted dynamic forces versus speed for flange-bearing ramps.

Figure 5, Middle: Wheel/frog contact in flange-bearing on modified number 10 frog.

Figure 6: Maximum dynamic wheel/rail force versus speed over simulated partial flange bearing frog.

16 Railway Track & Structures July 2013 www.rtands.com

results indicate that partial FBFs for turnouts will provide longer service lives and improved operations in terms of safety and efficiency. These test results will be useful if railroads choose to seek waivers of FRA Track Safety Standards that currently limit flange-bearing operations to Class 1 track (10 mph for freight and 15 mph for passenger service). There are many locations, such as switching lead tracks, where 15 to 20 mph operations would allow successful use of partial FBFs.

AcknowledgementsJohn Bosshart and Seth Ogan of BNSF contributed to the planning and testing of FBFs for turnouts reported here. They have been pioneers in the development and implementation of these concepts.

References1. U.S. Department of Transportation, Federal Railroad Administra-tion. U.S. Federal Register, 2011. Code of Federal Regulations, CFR 49, Part 213, Track Safety Standards, Washington, D.C.2. Davis, D., Jimenez, R., Clark, D. and Beyerl, J. May 2007. “Imple-

mentation of a Flange-Bearing Crossing Diamond in Revenue Service.” Railway Track & Structures, 17-20, Chicago, Ill.3. Reiff, R. et al. March 1997. “The Effect of Flange-bearing frogs on Locomotive Operation,” Technology Digest TD-97-009. Associa-tion of American Railroads, Transportation Technology Center, Inc., Pueblo, Colo.4. Davis, D. et al. April 1997. “Effect of Flange-Bearing Frogs on Train Forces,” Technology Digest TD-97-012. Association of American Rail-roads, Transportation Technology Center, Inc., Pueblo, Colo.5. Davis, D. et al. August 1997. “The Effects of Cross Grooves in Flange-Bearing Frogs,” Technology Digest TD-97-032. Association of American Railroads, Transportation Technology Center, Inc., Pueblo, Colo.6. Davis, D. et al. September 1997. “Load and Ride-Quality Assess-ment of Crossing Diamonds,” Technology Digest TD-97-036. Asso-ciation of American Railroads, Transportation Technology Center, Inc., Pueblo, Colo.7. Davis, D. et al. October 1997. “The Effects of Wheel Braking on Flange-Bearing Frogs,” Technology Digest TD-97-042. Association of American Railroads, Transportation Technology Center, Inc., Pueblo, Colo.8. Davis, D. et al. April 1999. “Initial Performance Evaluation of Flange-Bearing Frog Crossing Diamonds at FAST,” Technology Digest TD-99-012. Association of American Railroads, Transportation Tech-nology Center, Inc., Pueblo, Colo.9. Davis, D., Guillen, D. and LoPresti. J. August 1999. “Evaluation of a Prototype Flange-Bearing Frog for Heavy Haul Service,” Technology Digest TD-99-031. Association of American Railroads, Transportation Technology Center, Inc., Pueblo, Colo.10. Davis, D. et al. December 2009. “Flange-Bearing Frog Wheel Work Summary,” Research Summary RS-09-002. Association of American Railroads, Transportation Technology Center, Inc., Pueblo, Colo.11. International Heavy Haul Association. 2009. Best Practices for Heavy Haul Track and Structures, Norfolk, Va.12. Davis, D., Jimenez, R. and Kalay, S. July 2011. “Implementation Guidelines for Flange-Bearing Frogs,” Technology Digest TD-11-018, Association of American Railroads, Transportation Technology Center, Inc., Pueblo, Colo.

Figure 7: Wheel/flange dynamic load from flange-bearing ramps and wheel drop events.

www.rtands.com Railway Track & Structures July 2013 19

by Mischa Wanek-Libman, editor

line of complementary products to its resilient bonded direct fixation fasteners, such as embedded block, embedded rail systems and resilient Trackelast pads.

The company continues to manufacture bonded fastening systems, such as the System Wide series, which is engineered for standard direct fixation applications and specialty fasteners, such as the Egg and Loadmaster, which were designed for high attenuation and heavy-axel-load environments. Additionally, Amsted RPS says it continues to evolve its MACRO Armor line, developed to repair abraded and protect new concrete ties with the ultra abrasion resistant and highly-durable MACRO material. An added benefit of the material is that it can be molded into shapes that act as a form, allowing epoxy to be pumped through the MACRO Armor repair plate to fill the void created by rail seat abrasion.

The company’s Atchison, Kan., manufacturing facility will be expanded to accommodate capacity for new products, as well as meet “Buy America” compliance requirements.

“Over the past five years, we have invested in a number of process improvements for rail anchors, added a new flat stock clip line to make our 2000 and 6030LR Safelok style clips, built a state-of-the-art test laboratory and we are now building a round bar clip line for ME1 production to support our customer’s need for high quality, U.S.-based manufacturing,” said Wes Hodges, vice president and general manager.

I ncreased traffic along freight lines and ridership growth on transits is fueling a healthy demand for track fastening systems. Manufacturers are allying resources among organizational

divisions and across companies to speed up production, develop new solutions and control cost, while extending service life.

Amsted RPSCollaboration has been a valuable tool to Amsted RPS, allowing the company to enhance and expand its product offering. The company recently announced a joint venture with Switzerland-based Schwihag AG, which specializes in the development and manufacturing of advanced switch and rail fastening technologies. Amsted RPS says this combined effort will result in the manufacture of “Skl”-style rail fastening systems for the worldwide heavy-haul market.

The first product launch from this new “Skl” system is the ME63. The system includes the ME1 clip, rail pad, abrasion plate, field guide plate, gauge guide plate, screw spike and dowel.

“An advanced manufacturing technology is used, resulting in less stress present in the clip and a higher fatigue limit, resulting in longer life and reduced maintenance costs,” said Jose Mediavilla, director of engineering.

Last year, Amsted RPS partnered with edilon)(sedra, a Netherlands-based company known for its noise and vibration reducing products. The partnership allows Amsted RPS to provide a

Pandrol’s VICTOR system on a bridge using FASTCLIP fastening.

the fastener

fIxatIon

Suppliers have done thier homework when it comes to developing fastening systems to keep track secure and railroad budgets in line.

20 Railway Track & Structures July 2013 www.rtands.com

the fastener fixation

Amsted RPS says l i s tening to its customers is what steers product development initiatives and as those customer needs evolve, so do the products offered.

Amsted RPS points to its 6030LR rail clip as one example of this development. The company says the 6030LR has a longer reach than the 2000 or standard Safelok-style clips, a higher toe load and a higher fatigue limit. The company has also introduced two products in response to industry needs. The first, the Amsted RPS Under Tie Pad (UTP) by edilon)(sendra, consists of elastic polymer layers affixed or integrated on the underside of the concrete or wood ties for use in ballasted track to prevent degradation, protect railroad structures and provide noise and vibration attenuation.

“The benefits of our UTPs include: easy in-plant installation, reduction of vertical track modulus, resistance to deterioration in harsh environments, extended life of ballasted track bridge decks and prolonged tie life,” said John Stout, director of sales.

The second new product is the Loadmaster Timber Tie Fasteners. Amsted RPS said its engineers took the technology of the Loadmaster and adapted the product for use on open-deck timber bridges. The company says Loadmaster Timber Tie Fasteners can be used to match the track modulus of the adjacent ballasted track with that of open deck bridges thereby increasing the life of the structures and reducing

maintenance on the ties and bridge ends.“We are constantly looking for new

materials and manufacturing techniques that move our products toward the optimal performance combination of durability and resilience, while still being easy to install and maintain,” said Mediavilla.

L.B. FosterMarkets for the company’s various direct fixation fastening systems in late 2012 and 2013 continue to slowly improve.

Per L.B. Foster, passage of the latest U.S. transportation legislation, Moving Ahead for Progress in the 21st Century (MAP-21), last summer, gave some stability to federal funding of transit projects across the U.S. However, as this bill expires in September 2014, it does not give the length of time wanted as the successor to the six-year SAFETEA-LU and it kept funding essentially flat rather than increase spending, but it will encourage a number of projects to come forward. In addition, mass transit ridership in general and the use of heavy, commuter and light-rail modes in particular, continues to grow. According to the American Public Transportation Association, ridership on those three forms of rail grew by 1.6 percent in 2012 and had increased in 10 consecutive quarters before slipping slightly the past two quarters. Use of mass transit continues to expand as U.S. demographics shift towards a younger population.

Specifically, the company’s Transit Products team participated in a number of projects in supplying Direct Fixation Fasteners to New York City Transit,

Washington Metropolitan Area Transit Authority, Bay Area Rapid Transit (BART) and other agencies.

Last year, the company also won the largest award of business in L.B. Foster history for rail and related accessories for Honolulu Area Rapid Transit. Included in that award are approximately 170,000 Direct Fixation Fasteners. Shipment of those fasteners will begin later this year, continuing into 2014. L.B. Foster worked closely with the contractor, Kiewit/Kobayhashi, on this project.

The company also continues to develop new fastening technologies to meet changing industry demands. Per Korhan Ciloglu, R&D manager, Rail Products, stray currents in track cause numerous headaches for transit operators, including interference and premature track degradation due to corrosion.

“Based on feedback from our customers in North America and abroad, we are in the midst of developing new solutions that will mitigate stray currents. These solutions will provide significant operating and maintenance benefits to our customers,” said Ciloglu.

The Transit Products team also continues to work quite closely with other product teams within L.B. Foster to bring new designs forward. Resilient Ties were supplied to BART with the support of the CXT® Concrete Ties team. And utilizing the unique talents and technical consulting capabilities of the UK team in Sheffield, the company continues to establish a growing presence in global transit markets. As a result of steadily growing markets and internal collaboration to develop unique technical solutions, L.B. Foster remains quite optimistic about the future of fastening products.

Lewis Bolt & Nut“We’re continually looking to innovate with new products and to improve those already on the market. An example is the patented Evergrip™ Spike. Since its introduction, we’ve made numerous improvements to extend the service life and improve production times for our customers,” said Dave Barry, vice president-sales at Lewis Bolt & Nut Company.

Bar r y named severa l o f these improvements, including a refined point for installation ease, the addition of a double head for removing with a spike puller and increasing the strength properties.

Realizing that some customers prefer to use typical AREMA square hole tie plates,

L.B. Foster fasteners out on track.

22 Railway Track & Structures July 2013 www.rtands.com

the fastener fixation

Lewis Bolt used the Evergrip concept and applied to it to the new Permagrip™ Spike meant to be used in square holes.

“With an 11/16-inch diameter and lengths to 6-3/4 inches, the Permagrip really is filling an important need by offering a tremendous improvement in gauge control without the need to change to round hole plates,” said Barry. “Like the Evergrip, the patented Permagrip can be driven or turned in. The built in fins lock the spike in place, thus preventing backout. The part is now being produced with or without a 13-degree beveled washer to go against the rail base or to use in gauge holes.”

Citing customers’ need for quick product turnaround, Barry points out the company has expanded operations by adding primarily warehouse space, which will help the company to inventory more material to meet the demand.

Pandrol USAPandrol USA says 2013 has continued the strong demand for high performance elastic fastening systems the company experienced in 2012.

“North American railroads continue to improve their track systems and increase their capacity to take advantage of the benefits provided by the lower fuel costs to move freight by rail and to meet the needs of shifts in demand, including the increasing need to transport crude oil by rail as a result of the boom caused by the availability of shale oil,” said Pandrol.

The company says i ts fastening systems are finding a place among track in heavy-haul freight service in territories

with high degrees of curvature and grade. According to Pandrol, railroads are looking for fastening systems that can withstand the challenges presented by these operating conditions, providing both the holding power and durability required. Additionally, Pandrol says the stiffer track modulus provided by its fastenings increase locomotive fuel economy.

Pandrol USA also notes it continues to upgrade and improve its product line and its manufacturing facilities, such as adopting changes in its fastening manufacturing facility that streamlined its production and increased efficiency.

The company has also invested a significant amount of money in a captive plastics plant located near its facility in Bridgeport, N.J. This investment has added machinery to increase production of tie pads and insulators, as well as undertake a research and development program to determine the best plastic materials for insulators and pads in differing operating conditions. Both railroads and resin manufacturers are providing assistance to this program, which has involved the development of new testing

Vossloh Fastening Systems’ W 40 HH is specifically designed for the extreme U.S. heavy-haul market.

26 Railway Track & Structures July 2013 www.rtands.com

the fastener fixation

rigs and new and revised material formulations. Pandrol says the development program is expected to result in parts designed to better meet tough operating conditions, as well as increasing the life for the plastic parts that are an integral part of today’s fastening systems.

“Pandrol has always been on the forefront of development of new fastening systems for the railroad industry. We are committed to a program of new product development and the constant review of our

existing products to modify them where appropriate,” said the company.“As part of this ongoing effort, we are currently making

improvements to the Pandrol VICTOR plate system for wood ties that has seen a rapid increase in market share. The improvements, which include modifications to the shoulder design, strengthen the system and alleviate torque and turning issues that could occur under severe operating conditions. The Pandrol VICTOR system combines the durability of an AREA tie plate with the benefits of resilient fastenings. The flat tie plate provides a bearing area 37 percent greater than existing tie plates for resilient fastenings,” said Pandrol. “The use of Pandrol’s fastenings provides all of the advantages of resilient fastenings – holding power, prevention of rail rollover and reduced maintenance. Testing, with 39-ton-axle-loads, has shown a five-fold decrease in gauge widening when using resilient fastenings on wood ties. The Pandrol VICTOR system is demonstrating its value on bridges and curves with significant annual tonnage.”

Rail ForgeRail Forge LLC manufactures screws and fasteners that have been developed with installation ease in mind.

“Rail Forge manufactures GageLok screws with a unique design, which allows for insertion into wooden ties without pre-drilling,” said Keith Ishaug, the company’s CEO. “Customers have long-enjoyed the benefits of the GageLok 11/16 as fasteners for use in standard double-

Denver Regional Transportation District is using Amsted RPS’ Loadmaster on its Eagle P3 line.

www.rtands.com Railway Track & Structures July 2013 27

shoulder plates. Working with our customers, we have developed several new screws that bring the same easy installation to other applications. GageLok 3/4 Plus and GageLok 3/4 PL were developed for use in roll plates, switch stands and other plates with round holes up to one inch. GageLok 3/4 LS was developed with a longer shank for use with insulating bushings on electric tracks systems.”

Rail Forge, which entered the North American market in 2010, recently opened a new 42,000-square-foot manufacturing facility in Morton Grove, Ill. Ishaug says this plant gives the company a centrally-located facility to supply North American railroads and contractors with its rail fasteners, while also housing the company’s product development, testing and demonstration centers to drive Rail Forge innovation and quality that is required by the rail industry.

“The rail industry is driven by performance and safety requirements and our products help them achieve those goals,” said Ishaug. “For example, using GageLok 11/16 to replace cut spikes allows railroads to significantly reduce gauge and rail rollover issues at a very low cost, improving both performance and safety for our customers. These fastening applications require the proper combination of strength and ductility in the fastener. We work closely with track standards engineers, suppliers and independent testing laboratories on our product design, material selection and production processes to ensure the reliability of GageLok fasteners.”

Vossloh Fastening SystemsVossloh Fastening Systems, part of the Vossloh Group, relies on research and development rather than a “one-size fits all” approach to fastener design.

“Vossloh Fastening Systems is constantly assessing our products, how they perform in our lab and in the field and what we can do to achieve a lower life-cycle cost for our partners. With systems in more than 100 countries and on applications from extreme heavy haul to high speed and urban transit operations, we are educated on all types of operations and have helped develop cost-effective solutions for all users,” said the company. “With our extensive laboratory capabilities and constant field presence, we are able to research the best dynamics for any applications requirements and develop the correct system as a solution, whether that be low-axle weight and noise suppression or extreme heavy-haul with tight curves and steep grades.”

The company points to its W 40 HH, which was specifically designed for the extreme U.S. heavy-haul market, as one example of its focused research efforts. According to Vossloh, the W 40 HH, maintains the toe load forces longer and enhances the lateral and vertical holding forces, while providing higher fatigue limits to ensure a longer working life and reduced life-cycle costs.

“While accomplishing these goals, we were also able to increase the horizontal forces to ensure a higher level of rail creep resistance. We also developed new support components that help enhance the performance of the whole system and extend its life cycle and reliability,” said Vossloh.

Vossloh Fastening Systems believes all its products achieve the goal of high reliability and provide the best performing systems, while controlling the cost of ownership.

“[Our partners have] asked for the most reliable, robust and easiest to maintain systems possible and we’ve given them what they want,” said Vossloh. “As the market here and internationally changes and develops, new and more complex issues to be resolved, like rail life performance, rolling contact fatigue and its relation to the track structure influence and tie life issues, like rail seat abrasion issues, Vossloh will continue to be on the cutting edge of new developments to resolve or minimize the impact of these issues.”

www.rtands.com Railway Track & Structures July 2013 29

by Mischa Wanek-Libman, editor

T he industry’s rail weld providers are putting extra energy behind their research and development efforts in order to improve upon existing technology and

equipment, as well as develop new implements.

ChemetronChemetron Railway Products, a division of Progress Rail Services, acquired the mobile welding units from RibbonWeld LLC in 2012. The company says this addition allows for an expanded product offering and allows a broader mix of welding equipment to match customer requirements.

“Our 110-ton welders are ideal for joint elimination and portable welding and the 180-ton integrated pullers or 72-ton with puller are ideal for rail installation work,” said Mark McLean, manager sales. “We recently commissioned our first track welder. This Cat track-hoe based unit has a self-contained welding system, allowing us to access remote locations for rail and special trackwork welding. The unit has high-speed, hi-rail capability for use in a gang consist.”

McLean points out that Chemetron has also added another train to its welded rail train fleet, complementing the existing fleet and strengthening the company’s capability to provide rail, rail welding and equipment to deliver CWR to customers.

“As part of our continuous improvement process, Chemetron is refining the uniformity of the heat-affected-zone (HAZ), while we continue focusing on reducing the size of the HAZ. These advances will be implemented in both our fixed plant and mobile welding systems. The

improved uniformity and reduction in size of the HAZ will extend the life of our welds,” said McLean.

E.O. PatonE.O. Paton (Hong Kong) Ltd. is in the final stages of bringing a new narrow profile welding head to market. The weld head is interchangeable with existing Paton containers and will allow welds to be performed within turnouts, crossings and in third rail systems without removing the power rail.

Charles Ewing, managing director, says the machine will offer complete welding of large turnouts in one shift and its compact size will allow more work to be performed during tight work windows experienced on transit systems.

Responding to operational requests, Ewing says the company is refining the design of its high pull, self-shearing (distressing/joint elimination) welding head.

Ewing notes that most customers have the same concerns as they pertain to rail welding: minimum rail usage, narrow heat-affected zone, uniform hardness, lack of grey spots/inclusions and asking to weld to high-speed rail standards.

“Working with our partners in the Ukraine (Paton Welding Institute), processes have been developed to meet the foregoing requests,” said Ewing. “Construction of the machines ensures that the highest standards of alignment are achieved. The processes developed virtually eliminate the grey spots.”

Ewing continued, “Ongoing research is being done in conjunction with our partners (Paton Welding Institute) in Kiev involving rail steel producers. Process design is an

The

sparkof innovaTion

Beefed up R&D efforts resulting in stronger, more reliable welds.

Holland L.P. mobile welder on track performing welds.

30 Railway Track & Structures July 2013 www.rtands.com

rail welding

ongoing task and follows the new steel technology that is introduced. It is our belief that our welding process is by far the most advanced in the field. More physical field testing is required to supplement the analysis carried out from the weld monitoring systems currently in use. Current physical testing data is being compiled to examine relationships between weld parameters variation and actual bed test results. We maintain close contact with users and report concerns/suggestions to the institute, to help determine the best course of action in coming up with new designs/process.”

HollandHolland L.P. continues the development of its Flash Butt Head Defect Repair Weld, which it says enables its customers to remove and replace a defect in the head of the rail with a rail plug matching the hardness of the rail steel and without disturbing the rail neutral temperature.

“We are continuing to expand our capabilities for flash-butt welding joints in turnouts. Since the turnouts are the more expensive portions of the track structure, it only makes sense to have the highest quality flash-butt welds. Utilizing new equipment configurations will enhance our abilities and improve productivity in this welding application,” said Kevin Flaherty, vice president, maintenance-of-way sales.

Additionally, this year is the beginning of the Holland Turnkey, Engineering & Construction Division, which enables Holland to provide turnkey welding solutions to its customers, such as crop and weld, repair welding, roller line and other applications.

Flaherty points to one of Holland’s core values, improvement, as a driving force behind the company’s quest to better flash-butt welds and applications. He says ongoing improvements include new and upgraded welding control systems, slip detectors and weld process refinements, which all contribute to higher quality finished weld products.

“Our customers continue to request improvements in flash-butt welds that produce lower installed cost, more durable welds (last the life of the rail without surface defects), ability to flash-butt weld rail to frogs and more. Our improvement drive is producing many of these outcomes,”

said Flaherty. “Work to reduce the HAZ, harder welds matching the parent rail steel, increased reliability and improving weld quality are areas that Holland continually works to improve.”

Another aspect of continued product improvement is research and development, which Holland believes holds the key to its ongoing success in the rail welding business.

“Holland’s R&D efforts are derived from a myriad of sources. First and most important, we listen to our customers to learn their needs. We work with the rail manufacturers to develop weld programs of all rail types, hold brain-storming sessions both within Holland and outside our organization,” said Flaherty. “We conduct market studies to gather information on rail welding needs from throughout the rail industry, both in North America and internationally.”

Flaherty also notes that Holland encourages and engages in technology partnerships to expand the source of information for rail welding development from beyond the rail industry and gives the example of Holland partnering with the Edison Welding Institute on the development of its Head Defect Repair Weld.

“Holland’s leadership position within the rail welding field has been built upon our continued efforts to improve our technology, process and process control, equipment and quality of the complete flash-butt weld,” said Flaherty.

Lincoln ElectricIn 2012, Lincoln Electric began a program partnering with railroad customers to locate manganese welding crews with a basic understanding of welding on manganese frogs and crossing diamonds in regions where training schools were not available.

The company administered two-day classes, one-day classroom, the next day hands-on welding, at more than a dozen locations. These classes trained welders on how to set up the Lincoln equipment at the proper settings, check for trouble spots in the system and tips on how to service every part of the equipment chain. According to Lincoln Electric, application of consumables at the required voltage and the proper technique in welding brought the welders to a higher level of understanding.

In 2013, Lincoln Electric will go to the same locations to elevate the skill to a second level.

“The first time at the locations, we covered basic things,” said Brian Meade, Lincoln Electric’s manager of railroad technical services, global accounts. “We worked hard communicating with our engineers at our main plant in Cleveland, Ohio, and gathered the welders to come up with new techniques and a higher understanding to teach the second time around.”

Meade continued, “We have improved the welding machine, feeding systems, consumables, packaging and have added new products like the Magnum Pro welding gun.

Chemtron, the welding division of Progress Rail Services, offers its 110-ton mobile welder.

www.rtands.com Railway Track & Structures July 2013 31

rail welding

These improvements have made it easier for the welders, giving them more of an edge to increase their skill level.”

According to Meade, railroad welding crews in the field have taken advantage of Lincoln Electric’s improvements and training to reduce train delays and make better weld repairs to manganese castings, which will last longer under the increased loading of today’s train traffic.

Orgo-Thermit“The current metallurgical development of rail steels, with high running surface hardness, has made it necessary for Orgo-Thermit, Inc., to develop a suitable Thermit® welding technology, to join these high-strength rail steels and to keep abreast with the current global rail steel metallurgies and latest rail rolling technologies,” said Dave Randolph, president of Orgo-Thermit, Inc. “The industry is demanding a better surface wearing weld that better matches the surface hardness of these high-strength rails, while still maintaining toughness in the base of the weld.”

The company’s answer to the industry need is the patented Head Alloyed Welding (HAW) process, which allows welding of high-strength rails with more compatible weld running surface hardness and a ductile base. According to the company, the welding procedures and

tools used to execute the HAW are identical to that of a standard weld, except that a patented diverting plug that contains micro-alloys is used, instead of a conventional diverting plug.

“This feature makes it very easy for the customer to employ the HAW process, with minimal training and no outlay of additional costs for any special tooling. The HAW process is simple and can be performed by any trained welding crew with the current tools they have on their welding vehicles,” said Randolph.

In February 2011, after successful laboratory metallurgical and physical testing evaluations, 10 Head Alloyed Thermit® Welds were installed at TTCI’s Facility for Accelerated Service Testing Heavy Tonnage Loop. Seven of these Head Alloyed Welds were used to join high-strength rails with an initial hardness of around 390 BHN. Two of the Head Alloyed Welds were made in intermediate strength rails with a hardness of 340 BHN and one Head Alloyed Weld was made to join an intermediate strength rail (340 BHN) to a high strength rail (390 BHN).

“Although Orgo-Thermit Inc. does not recommend using the Head Alloyed Welds in mixed strength or standard strength rail welding, this test was performed to investigate how unintended application of the micro-alloyed diverting

32 Railway Track & Structures July 2013 www.rtands.com

rail welding

plugs can affect the weld service performance. Orgo-Thermit Inc. recommends that when welding a high-strength rail to a lower strength rail, the welding portion for the lower-strength rail is used,” said Randolph.

T T C I c o n d u c t e d h a r d n e s s measurements, visual inspections and longitudinal profiles of the entire weld running surfaces throughout the duration of the test. The Head Alloyed Welds have accumulated more than 324 mgt of heavy-axle-load (HAL) traffic, with no service failures. In the intermediate strength rail (340 BHN); the Head Alloyed weld was significantly harder than the adjacent rail. The Head Alloyed Weld experienced a lower wear rate than that of the rail. The weld centerline of Head Alloyed Welds, employed to join the high-strength rails (390 BHN), have shown approximately 50 percent

reduction in wear/batter compared to standard welds, despite any of the Head Alloyed Welds not having received maintenance grinding of any kind since the commencement of the test.

“We believe that the success of our research and development efforts will ensure that our unique Thermit®

welding products will have a future in the heavy-axle-load railroad industry, for many years to come,” said Randolph.

Railtech BoutetRailtech Boutet is focusing its efforts this year on commercializing three new products: The QP Hybrid Welding System, Head Wash Repair (HWR) welding and the Startwel® Ignition System. The three products were created to meet customers’ requests in improving the overall aluminothermic welding process.

“Our patented QP Hybrid molds have been a customer favorite this year and we are working hard on meeting the increasing demand for this product,” said Oliver Dolder, executive

Lincoln Electric’s Magnum Pro welding gun.

www.rtands.com Railway Track & Structures July 2013 33

rail welding

vice president and chief operating officer. “The QP Hybrid molds use a compressible lining in order to get a perfect fit on the rail. This allows the welders to make a great quality weld by drastically reducing the chances of any flashing to occur during the welding process which in turn significantly increases the life of the weld.”

Dolder says the company’s HWR weld has found success among customers in the repair of transverse defects, corner gauge defects and minor shelling. He calls the HWR a great “preventative maintenance weld,” which gives the customer an opportunity to repair a small defect before it grows and leads to a break in the rail.

Railtech Boutet notes that its Startwel® Ignition System allows the welder to easily ignite the weld charge

to initiate the pour process for the Railtech Aluminothermic Weld System, replacing the traditional “sparkler” igniter design.

“This new electric ignition system is safer than today’s traditional igniters,”

said Dolder. “In addition, Startwel® is classified as non-hazardous for transport, therefore there are no shipping restrictions (can be shipped overnight if there was an emergency) and provides more accurate and consistent tap time.”

The company’s trio of new products wouldn’t be possible without the research and development team, which is done by Railtech Boutet’s parent company, Railtech International.

“Between our internal R&D and working closely with our customers, we are able to develop new and innovative products, which have and will continue to improve the aluminothermic welding process,” said Dolder.

Railtech Boutet’s Head Wash Repair is designed to repair small defects before they grow.

www.rtands.com Railway Track & Structures July 2013 35

special trackwork

l ike the name suggests, special trackwork requires extra care and attention. Suppliers and scientists

have collaborated to offer the railroads these distinctive components at a low cost with a long service life.

atlantic track & turnoutAt Atlantic Track and Turnout Co., the focus has been on expanding its infrastructure to enhance technology and to expand capacity to produce special trackwork to Class 1 railroad standards. In the past 12 months, the company has made significant capital investments as part of its commitment to maintain its present customer base, as well as meet the demand with better delivery times.

Atlantic Track added 25,000 square feet of additional space to house new machiner y, increase layout and assembly area and expand the engineering department at its trackwork manufacturing plant in

Memphis, Tenn.; added a new CNC mill in Memphis, Tenn., and a gantry type, CNC mill at its special trackwork plant in Richmond, Ill.; installed a new CNC plate mill at its plant in St. Clair, Pa., and purchased a mobile flash-butt welder.

“Railroad budgets and spending for special trackwork material have been at a high level during the past several years and, so far, seem to be stable,” explained Jeff Grissom, director of engineering. “We expect that as the general economy continues to improve, demand for railroad products will stay at a high level or increase as railroads of all sizes expand their ability to move more freight.”

At Atlantic Track’s St. Clair, Pa., facility, the company has installed an enhanced electr ic third rai l manufactur ing , process ing and assembly work center. With the nations renewed interest in passenger rail service, Grissom says this will better position the company to service that

part of the special trackwork industry, as well as maintaining a domestic-based supply chain for those components.

Atlantic Track is a joint venture partner in MRT Track & Services Co., Inc., with ThyssenKrupp GfT, a manufacturer of special trackwork and provider of railway materials to transit systems throughout the world. This joint venture has developed a heavy-haul steel railroad crosstie that is based on an existing German design and is currently under testing and evaluation at the TTCI test track in Pueblo, Colo.

“From an engineer’s perspective of the special trackwork community, turnout geometry in the area of entry at point of switch and mainline speeds through turnouts seem to be at the forefront of discussion,” Grissom noted. “In addition, as an industry, we are learning and defining the parameters for full flange-bearing crossings and their correct usage, as it would pertain to crossing angle and signalization.”

DiamonDs, frogs,

turnouts anD other

by Jennifer Nunez, assistant editor

Researchers and manufacturers use materials and know-how to help railroads complete special trackwork projects.

Conformal switch point profile measurements. Photo courtesy

of TTCI.

36 Railway Track & Structures July 2013 www.rtands.com

special trackwork

Cleveland Track MaterialA recent Cleveland Track Material (CTM) venture is the production of flange-bearing crossings for TriMet in Portland, Ore. This crossing has been designed to reduce maintenance costs and improve ride quality, notes CTM.

“We are actively and aggressively quoting passenger rail bids,” explained Jim Remington, vice president of engineering. “We are also focusing on new designs related to passenger rail, which is a coordinated effort between engineering and sales.”

Remington says commuter rail companies are looking for greater after-sales service, including installation and maintenance instructions. CTM is currently providing this type of after-sales service for the TriMet project. This includes deploying engineers for onsite installation.

Nortrak-DamyNortrak-Damy has introduced a number of products in Mex-ico during the past three years. The company says it supplied the first European specification turnouts for passenger service in Mexico City, its Vangaurd® guardrail with UIC profile is now standard for Ferromex and Ferrosur and its voestalpine Nortrak-produced pad concrete tie insulators have been stan-dard for Kansas City Southern de Mexico since 2009.

The company’s WBM frog is a welded, boltless frog that has no bolts or drill holes; it was introduced with Ferromex in 2010 as a field test. Nortrak-Damy notes these frogs require less maintenance, there is no rail breaking due to drill holes and it is welded to the track (no joints or transitions).

Nortrak-Damy’s JUMP FROG® is meant for mainline application in which traffic is mixed 90 percent on the mainline and 10 percent on the deviation. There are no gaps or joints in the mainline, providing increased safety and higher speeds on the mainline, Alejandro Damy, CEO, notes.

“We are supplying transition rails to Class 1 railroads in Mexico, which are manufactured by voestalpine Nortrak with the highest quality and technical specifications available in

North America. We have seen increasing activity in Mexico from the Class 1s and industrial market due to the strength in the Mexican economy and the growth of the ivestments in the railroad industry.”

Progress Rail ServicesProgress Rail Services (PRS) is a full-line manufacturer of special trackwork, including turnouts, crossing diamonds and replacement maintenance items for all sizes and designs for railroad and transit industries.

Turnouts and crossing diamonds are subjected to high-impact use that affects the overall life-cycle cost of the components. Progress Rail Services says it is continuing to design products that eliminate or minimize these impacts to reduce maintenance and increase the overall product life.

“In 2006, we introduced the lift frog and we now have more than 1,000 units in track and counting,” said Russ Hein, manager of engineering services for the Engineering and Track Services Division. “To complement the lift frog, we recently introduced the vertical switch and, when combined with the lift frog, makes the turnout virtually invisible to mainline traffic. The turnout was installed at TTCI for industry testing and is now installed in a Class 1 track.”

The OWLS design eliminates the flangeway gap on the mainline heavy run and is said to greatly reduce crossing maintenance. PRS says it has OWLS castings that will accommodate a wide range of angles to reduce lead-times. The company is continuing work on improving its full-flange-bearing design. To date, there have been three full-flange-bearing crossings installed on Class 1 railroads.

“Through our continued efforts to reduce wheel impacts within turnout and crossing components, we are striving to achieve the railroad industry’s goal of reduced maintenance and overall lower product life-cycle cost,” explained Hein. “Providing a quality product is a given and we continually work toward developing designs that will reduce the overall cost of ownership. Further, reducing lead times and meeting

Left, Common standard number 9 with RBM frog, manufactured at Atlantic Track’s Richmond, Ill., facility. Nortrak-Damy’s Jump Frog with Vanguard guardrails.

www.rtands.com Railway Track & Structures July 2013 37

special trackwork

delivery commitments is important to us too, so as not to impact our customers’ project schedules.”

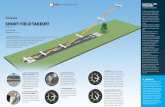

TTCITransportation Technology Center, Inc. (TTCI), has assisted Association of American Railroads (AAR) member railroads in implementing new turnout features in 2012-2013. These include the conformal profile switch points and the continuous mainline rail turnout. Several others are currently in prototype testing at the Facility for Accelerated Service Testing (FAST) at TTC in Pueblo, Colo.

The conformal profile switch point was developed with the help of BNSF, Union Pacific (UP), CSX, Progress Rail Services and voestalpine Nortrak Inc. The cross-section profile of the switch point was altered to more closely match the canted rail profile seen in the rest of the track. This change in profile has reduced the occurrence of rolling contact fatigue and reduced initial wear rates by 50

percent in revenue service prototype testing. Based on these results, the design is being adopted as the standard profile for BNSF, UP and CSX.

The continuous mainline rail turnout was developed by BNSF, Progress Rail Services and TTCI to address the currently used split switch failure modes. As the name implies, the mainline running rails of this turnout are continuous and fixed. Both switch points are on the diverging route. TTCI notes that this turnout has improved performance for the mainline route in terms of forces and ride quality. The intended use of this design is at set-out tracks and mainline industrial sidings; where the diverging traffic is low speed and low tonnage.

“Demand is increasing among freight railroads and transit systems for premium performance products,” said David Davis, senior scientist at TTCI. “Our approach is to put the premium performance capabilities where they are most needed. The continuous mainline rail turnout is a

good example in that the performance of the mainline route, which will carry 99 percent of the traffic, is greatly improved. This is essential to operations that carry either heavy-axle-loads or high-speed service.”

Davis explains that the trend continues to be in improved dynamic performance and results in improved safety and efficiency for the railways. Smooth ing and /or e l iminat ing discontinuities will result in better performing designs, he notes.

“This involves changes large and small, such as the removal of flangeway gaps and switch points from the mainline route of the turnout to relatively small changes in running surface profiles in frogs and switches,” he noted.

Prototypes in test at FAST include an improved steering switch for mainline crossovers. The switch will help vehicles steer away from the switch point tip on either route, Davis says, and should result in lower maximum vehicle forces and longer switch point

38 Railway Track & Structures July 2013 www.rtands.com

special trackwork

life. Another prototype at FAST are turnout foundations (e.g., pads for the tie-ballast interface) that will smooth out vertical stiffness in turnouts. This is expected to reduce required surface and alignment maintenance, as well as lower vehicle forces.

Unitrac Unitrac Railroad Materials, Inc., has been drawing on more than 85 years of experience in the railroad industry. The company distributes new rail and relay rail, OTM and does track removals, as well as buy and trade rail and other track materials. The company says it has experienced an increase in the special trackwork business, especially in the oil and gas markets, a nod to the recent energy boom in North America.

voestalpine Nortrak voestalpine Nortrak Inc.’s Hytronics Division continues to expand its product offering of “Buy America” compliant switch drives for transit

and freight applications. The new HY-100 Automater™ features a dual-control user interface, trailability, hydraulic actuation and a solar power source. A new line of fixed and rolling asset monitoring technology is also being introduced.

“ O u r t e c h n i c a l s t a f f i s collaborating closely with freight ra i l roads to improve both the functionality and durability of our synthetic pads and insulators,” said Brian Abbott, executive vice president

engineering. “We continue to see a healthy demand for special trackwork in both the freight and transit sectors. All indications are that that demand wil l remain strong through the current year.”