RSM · RSM . Author: RSM Indonesia Created Date: 5/17/2018 4:17:35 PM

Rsm Example

-

Upload

satwant-singh -

Category

Documents

-

view

79 -

download

4

Transcript of Rsm Example

324 JOURNAL OF THE INSTITUTE OF BREWING

Use of Response Surface Methodology to Investigate the Effectiveness of

Commercial Enzymes on Buckwheat Malt for Brewing Purposes

Blaise P. Nic Phiarais1,3, Beatus D. Schehl1,3, Jorge C. Oliveira2 and Elke K. Arendt1,4

ABSTRACT

J. Inst. Brew. 112(4), 324–332, 2006

The influence of two factors, total concentration and fraction of three pairs of commercial enzymes, which showed statistical significance (Biocellulase W with Hitempase 2XL, Biocellulase W with Amylo 300 and Amylo 300 with Hitempase 2XL), were studied for their overall effect on buckwheat wort quality using response surface methodology (RSM). This study revealed that the addition of increasing levels of Hitempase 2XL to the buck-wheat mash increased colour, extract levels, wort filtration, fer-mentability and total fermentable extract (TFE), along with de-creasing viscosity values. Results also determined a high level of fermentability when an enzyme combination of 30% Biocellu-lase and 70% Hitempase was added to the mash. The addition of increasing levels of Amylo 300 to buckwheat mashes resulted in increases in fermentability and total fermentable extract (TFE), along with increases in total soluble nitrogen (TSN), free amino nitrogen (FAN) and Kolbach index (KI). With regard to the pro-posed optimal regime, although no synergistic effect was found when the three enzymes were used together, the optimum condi-tions for the production of buckwheat wort with lowest viscosity, highest extract and optimal fermentability were achieved using a joint model. Overall, the findings of this study demonstrate the feasibility of producing wort suitable for the brewing of gluten-free beer from 100% malted buckwheat with careful optimisa-tion of enzyme types and dosage levels.

Key words: Buckwheat, enzyme activity, response surface methodology, wort quality.

INTRODUCTION There is a renewed interest in buckwheat as an alterna-

tive crop for organic cultivation as well as an ingredient for health food products22. Widely grown in Asia, Central

and Eastern Europe, Fagopyrum esculentum Moench (com-mon buckwheat) is traditionally used for pasta, blended bread and other types of flour11. Many positive physio-logical effects are associated with buckwheat. Due to the presence of soluble and insoluble fibres, antioxidants as well as the absence of glutenin-like proteins, buckwheat is considered a grain which can be used for preventative nu-trition. Soluble and insoluble dietary fibres have a positive effect on constipation and obesity12 whereas antioxidants may play an important role in lipid antioxidation and can-cer prevention20.

Coeliac disease is an autoimmune enteropathy trig-gered by the ingestion of gluten-containing cereals in sus-ceptible individuals7. The worldwide incidence of coeliac disease is predicted to increase over the next years due to reinforced awareness of the disease and improved diag-nostic and screening procedures8. Treatment involves a gluten-free diet that avoids ingestion of cereals that con-tain gluten and their products7. Therefore an increased demand for gluten-free products is expected. As it con-tains no glutenin-like proteins e.g. hordein, buckwheat is safe for patients who suffer from coeliac disease5.

Furthermore, buckwheat is becoming increasingly popular as a brewing ingredient. Maccagnan et al.14 re-cently used buckwheat, mainly as an unmalted adjunct in micro brewing, for the production of gluten-free beer. However, because of its low level of essential enzymes (e.g. �-amylase, �-amylase and �-glucanases), mashing using 100% malted buckwheat (without the aid of com-mercial enzymes) can lead to problems, such as low ex-tract yields, high wort viscosities, decreased rates of lau-tering and fermentation problems17. To overcome these problems, MacFadden and Clayton15 suggested various commercial enzyme additions. This involves the use of a range of proteases, �-amylases, �-amylases, �-glucanases, amyloglucosidases, and cellulases.

The purpose of this study was to determine the effects of increasing the dosages of the commercial enzymes Bio-cellulase W (a fungal cellulase), Amylo 300 (a fungal amyloglucosidase), Hitempase 2XL (a heat-stable �-amy-lase), Bioxylanase 10L (a fungal xylanase), Bioferm L (a fungal �-amylase), Bioglucanase B-10L (a bacterial �-glucanase) and Bioprotease N-100L (a bacterial protease) on wort quality when mashing with 100% malted buck-wheat (Fagopyrum esculentum Moench). The goal was to

1 Department of Food and Nutritional Sciences, National Universityof Ireland, University College Cork, College Road, Cork, Ireland.

2 Department of Process and Chemical Engineering, National Uni-versity of Ireland, University College Cork, College Road, Cork,Ireland.

3 Biotransfer Unit, National University of Ireland, University Col-lege Cork, College Road, Cork, Ireland.

4 Corresponding author. E-mail: [email protected]

Publication no. G-2006-1308-459 © 2006 The Institute of Brewing & Distilling

VOL. 112, NO. 4, 2006 325

identify the enzymic preparation that would result in an optimum brewing process. Response surface methodology (RSM) was used to investigate the effects of the total con-centration and the fraction of each pair of three enzymes, Biocellulase W, Amylo 300 and Hitempase 2XL, on wort quality. The three enzymes were chosen based on prelimi-nary results for the full set. The influence of total concen-tration and fraction of enzyme in a mixture on selected quality parameters was to be analyzed using a quadratic model to identify constrained and unconstrained points of optimum, which would then be related by subsequent experiments performed at the conditions predicted by the models to be optimum.

MATERIALS AND METHODS Raw materials

Unmalted common buckwheat (Fagopyrum esculen-tum) originating from an unspecified location in Eastern Europe and harvested in 2004 was obtained from Trouw B.V. (Rotterdam, The Netherlands). Malted buckwheat was found to have a moisture content of 6.1%, total nitro-gen of 1.9% and friability of 91.7%. In all mashing exper-iments, distilled water was used. The commercial enzyme preparations Bioxylanase 10L, Bioferm L, Bioglucanase B-10L, Biocellulase W, Bioprotease N-100L, Amylo 300 and Hitempase 2XL were kindly provided by Kerry Bio-sciences Ltd. (Kilnagleary, Carrigaline, Co. Cork, Ireland). Details regarding the enzymatic activities of the enzyme preparations are outlined in Table I. Throughout this pa-per, the enzyme amounts are expressed as the dosage per-centage (v/w) of grist.

The calcium level of the mash-in liquor was adjusted to 200 ppm using calcium chloride (CaCl2·6H2O) and hydro-chloric acid (HCL) was used to adjust the mash-in pH to 5.6, in order to increase the stability of the commercial enzymes. In-house research, yet to be published, deter-mined the optimum calcium and pH levels.

Malting procedure

Malting was carried out using optimised procedures for steeping26, germination25 and kilning17 using a micro malting machine (Joe White Malting Systems, Perth, Aus-tralia).

Milling

Malted buckwheat (Fagopyrum esculentum) was milled with a Bühler Miag laboratory-scale disc mill (Bühler GmbH, Braunschweig, Germany) set at a fine setting of 0.05 mm.

Mashing

Malted buckwheat was mashed according to the opti-mised buckwheat mashing program as suggested by Wijn-gaard et al.24 All enzymes were added at mash-in unless otherwise stated.

Wort analysis

EBC-methods 3.3.2 and 4.3.2 were used to determine the total nitrogen (TN) level in flour of unmalted and malted samples, respectively6. Total soluble nitrogen (TSN) determination was based on EBC-method 8.9.2 using a nitrogen analyzer (LECO type FP-528; LECO, St. Joseph, MI). Free amino nitrogen (FAN) in wort was mea-sured according to EBC 8.10. The extract (%) of resulting wort was measured with a Servo-Chem Automatic Beer Analyzer (SCABA) obtained from Tecator AB, Sweden. Wort viscosity was measured using a falling ball viscome-ter (Haake, Karlsruhe, Germany) at 20°C according to EBC-method 8.4. Colour was determined in accordance with EBC-method 8.5 and fermentability was based on EBC-method 8.6.1. The mash was filtered according to EBC-method 4.5.1, through filter paper (Schleicher & Schnell, Dassel, Germany) into graduated cylinders. The time taken for each wort sample to filter was recorded.

Preliminary screening of enzymes

Preliminary screening in a range of 0.05–1.5% concen-tration of enzymes was performed in triplicate to deter-mine the optimum concentration range and effectiveness of the various enzymes, to select the most promising ones for subsequent study. From the data obtained, three en-zymes were selected.

Experimental procedure and data analysis of preliminary experiments

All preliminary experiments were repeated three times. All samples were analyzed in duplicate. The results quoted are the mean of the three repeated experiments. Statistical data analysis (Student’s t-test, paired test) was performed using the SigmaPlot program (Systat Software UK Ltd, London, UK). P is the Probability and has a value from 0 to 1, where 0–0.25 is a significant difference.

Experimental design and data analysis

A response surface methodology (RSM) as described by Box et al.4 was applied to determine the relative contri-butions of two factors on the quality of buckwheat wort and beer. The two factors (process variables) considered were total enzyme concentration and fraction of enzyme in a binary mixture. It was decided to analyse separately

Table I. Commercial enzymes used in this study.

Code Commercial enzyme Derivative organism Description pH optima Temperature optima Activitya

A Biocellulase W Trichoderma reesei Cellulase 5.0 60°C 1,000 U /mLB Amylo 300 Aspergillus niger Amyloglucosidase 4.0 75°C 1,100 U /mLC Hitempase 2XL Bacillus licheniformis �-Amylase 4.0–8.0 90°C 120,000 U /mLD Bioxylanase 10L Trichoderma reesei Xylanase 3.0–7.0 55°C 10,000 U /mLE Bioferm L Aspergillus oryzae �-Amylase 4.3–6.3 55–60°C 600,000 U /mLF Bioglucanase B-10L Bacillus subtilus �-Glucanase 5.5–7.0 60°C 10,000 U /mLG Bioprotease N-100L Bacillus subtilus Protease 6.0 55°C 100,000 U /mLa Determined by Kerry Bioscience (Kilnagleary, Carrigaline, Co. Cork, Ireland) standard methods.

326 JOURNAL OF THE INSTITUTE OF BREWING

all mixtures of two enzymes rather than producing mix-tures of 3 enzymes, to duly study the possible synergistic effects. A circumscribed central composite design was defined for each of the 3 pairs of the 3 enzymes selected. This experimental plan was defined by considering first the maximum and minimum values of the chosen vari-ables on the basis of preliminary brewing tests, and these values were coded as 1 and –1, respectively. The arith-metic average between them defined the centre points of the solution space (coded value 0). The central composite experimental design requires two other settings of the variables, called star points, which for this variant of the design are located at the coded values ± 1/√2. Table II shows the experimental design applied for each pair of enzymes. It is noted that experiments were performed in random order to minimise bias, and not in the order shown in the table. The responses (quality characteristics) measured for each case were extract, fermentability, vis-cosity, wort volume, colour, total soluble nitrogen (TSN), total fermentable extract (TFE) and Kolbach Index (KI). Each response for each enzyme pair was analysed by fit-ting quadratic models to the data, as indicated in equation 1, with least square regression.

2cjk,i,

2cjk,i,ccjk,i,cjk,i,cjk,i,jk,i,jk,i, FfTeFTdFcTbaR +++++=

(1)

where Rk is the measured value for quality response k, Tc is the coded value of the total enzyme concentration, Fc the coded value of the fraction of enzyme i in the i + j mixture, and the model parameters a to f have the follow-ing meaning: a is the offset (average of all response val-ues); b and c are half of the individual linear effects of factors T and F, respectively; e and f are half of the indi-vidual quadratic effects of factors T and F, respectively, and d half of the interactive effect of the two factors. As the model parameters have these meanings, regardless of the goodness of fit it is possible to analyse which of the 5 effects have statistical significance. Dividing each effect by the corresponding standard error of the model parame-ter gives the standardised effect, and those that are statisti-cally significant are bigger than the t-Student value for 95% confidence level and 10 degrees of freedom (16 data points in each model – 6 model parameters = 10). This

information is neatly visualised in Pareto diagrams, but these are not shown for conciseness of the paper.

The goodness of fit of equation 1 for each response and pair of enzymes was evaluated by the coefficient of deter-mination R2, which is equal to the percentage of the vari-ance of the data that is explained by the model. In RSM, values above 88% are usually demanded for the model to be usable for predictive purposes with minimum confi-dence, albeit limited to the solution space (extrapolation beyond the range of values tested experimentally is not recommended). In those cases, 3-D graphs can be plotted to visualise the solution space and help identify regions of optimum. Optimum values (settings of the two factors that give an absolute minimum or maximum value of a re-sponse) can be calculated analytically by finding the zeros of the derivatives of equation 1. For constrained optimisa-tion (finding points of maximum or minimum of a re-sponse which obey specified limits of other responses), the Solver add-in of the Microsoft Excel software (XP version, Microsoft, Seattle, USA) was used, applying the Simplex algorithm of optimisation.

For predictive purposes, a global model was also ap-plied for each response, pooling all data together for the 3 pairs of enzymes, as indicated in equation 2. In this global model, the factors used were the actual concentration of each enzyme in v/w. It is noted that all enzyme concentra-tions are variables that range between 0 and 1, when ex-pressed in mL enzyme/100 g of grist.

2CkC,

2BkB,

2AkA,

CBkBC,CAkAC,BAkAB,

CkC,BkB,AkA,kk

CCC

CCCCCC

CCCR

δ+δ+δ+

γ+γ+γ+

β+β+β+α=

(2)

where again the k subscript indicates the respective re-sponse, CA, CB and CC are the concentrations of enzymes A, B and C, respectively, in mL/100 g grist (the enzymes corresponding to each letter are given in Table I) and the model parameters � (alpha) to � (delta) are evidently related mathematically to the parameters of the 3 models for each pair. However, to avoid error propagation, the model parameters were obtained by least square regres-sion of all data jointly for each response. This global model can be used for predictive purposes to identify which enzyme concentrations give an optimum result. It is

Table II. Circumscribed central composite experimental design used in this study.

Coded Value

Experiment no.

Total concentration

level

Level

Total concentration(mL enzyme / 100 g grist)

Fraction of i

in i + j mixture

1 –1 –1 0.1 0 2 –1 1 0.1 1 3 1 –1 1 0 4 1 1 1 1 5 0 –1/√2 0.55 0.15 6 0 1/√2 0.55 0.85 7 –1/√2 0 0.232 0.5 8 1/√2 0 0.868 0.5 9 0 0 0.55 0.5

10 0 0 0.55 0.5

Three pairs of enzymes were tested: i = A; ∧ j = B; i = A ∧ j = C; i = B ∧ j = C, where A is Biocellulase W, B is Amylo 300 and C is Hitempase 2XL. Experiments were performed in random order.

VOL. 112, NO. 4, 2006 327

noted that the model was built from experimental data with pairs of enzymes only and therefore it is only appli-cable to ternary mixtures if the three-level interactive ef-fect is negligible. In RSM, this would be a reasonable assumption, as it is a third order term.

RESULTS AND DISCUSSION Preliminary results

It is clear from Table III that enzyme additions of Bio-xylanase 10L, Bioferm L and Bioglucanase B-10L did not accelerate wort filtration or improve extract development, wort viscosity and fermentability significantly when com-pared to the control. Bajoma and Young1 using sorghum malt (20%) and unmalted sorghum (80%) with the use of these enzymes, reported similar results. Commercial en-zymes that gave significantly improved extract, fermenta-bility and TFE, when compared to the control to which no enzymes were added, were selected for further trials. These included Biocellulase W, Amylo 300 and Hitemp-ase 2XL. Although Bioprotease N-100L showed signifi-cantly improved extract, fermentability and TFE, the rate of filtration was adversely affected. According to Goode

et al.10, the decrease in filtration of the sample is related to the degrading effect that Bioprotease N-100L has on malt amylases thus resulting in a retarded efficient liquefaction.

Effect of the enzymes on quality characteristics

The effects that data analysis indicated to be statisti-cally significant are shown in Table IV. This table gives a condensed view of the full set of data, as it would be ex-cessive to show the Pareto diagrams for all responses and pairs of enzymes. It is noted that when the model provides a poor fit, the standard errors of the parameters are very large and therefore effects tend to be statistically negli-gible. However, the true meaning of this situation is that the system is influenced by other factors more, or as sig-nificantly as the two chosen, and it does not necessarily imply that the factors have no effect.

The responses that generally had better model fits were fermentability, FAN and TFE. Viscosity was well fitted for the pairs containing enzyme A, while colour was well fitted for the two pairs containing enzyme C. Interactive effects were often significant. Inspection of the nature of these effects showed that they were due to a synergistic effect between the two enzymes being significant only at

Table IV. Statistical significance at a 95% confidence level of the effects of all enzyme pairs on all quality characteristics measured.

Responses (quality characteristics)

Pair

Effect

Extract

Ferment-ability

Viscosity

Wort volume

Colour

TSN

FAN

TFE

KI

A + B T yes yes yes yes F (of A) yes yes yes yes yes T × F yes yes yes yes T2 yes yes F2 yes R2 (%) 36.3 97.3 89.8 91.5 34.9 32.1 98.8 99.7 31.6 A + C T yes yes yes yes F (of A) yes yes yes yes yes T × F yes yes yes yes T2 F2 yes yes R2 (%) 93.0 99.5 89.9 74.4 94.2 49.3 80.3 99.4 48.7 B + C T yes yes yes yes F (of B) yes yes yes yes T × F yes yes yes T2 yes F2 R2 (%) 76.5 93.4 67.6 65.7 94.9 86.4 92.5 97.9 85.1

Enzymes are denoted A, B and C as per Table I. T indicates the linear effect of total enzyme concentration, F the linear effect of the fraction of enzymei in the i + j mixture (I = A or B, j = B or C), T × F indicates the interactive effect and T2 and F2 the quadratic effects. The coefficients of determination (R2) are also shown, bold meaning sufficiently high value for the model to be acceptable for predictive purposes.

Table III. Preliminary enzyme trials showing the statistical significance of using enzymes according to the Student’s t-test, paired test.

Enzyme

Extract (% dry wt)

Viscosity (mPas)

Filtrate volume (ml)†

Fermentability (%)

TFE (g L–1)

A Positive3 None None Positive6 Positive3 B Positive1 Positive4 Positive4 Positive1 Positive1 C Positive1 Positive5 Positive5 Positive1 Positive1 D None None None None None E None None None None None F None None None None None G Positive2 Negative1 Negative1 Positive2 Positive2

The enzymes (A–F) are indicated in Table I. Enzyme concentrations where statistical significance was observed 10.05%–1.5%, 21.5%, 31&1.5%, 40.05%, 50.5–1.5%, 60.1–1.5%, †Filtrate volume after 30 min, TFE = Total Fermentable Extract.

328 JOURNAL OF THE INSTITUTE OF BREWING

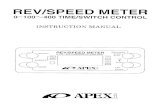

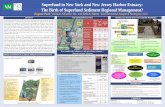

higher total concentrations. One quadratic effect on TFE was significant for all pairs, which may indicate that a point of optimum exists within the range of concentra-tions tested. Figures 1 to 3 show the 3-D surfaces for all cases where the surface fit is acceptable (R2 in bold in Table IV), enabling a better visualisation.

Extract

It can be seen from Fig. 1a, that there was an increase in extract associated with increasing the fraction and con-centration of Hitempase 2XL, when virtually no Biocellu-lase W was present. This supports the findings of Goode et al.10, where the extract increased significantly as the Hi-tempase 2XL levels of unmalted sorghum mashes were in-creased. The interactive effect of Biocellulase and Amylo 300, and Amylo 300 and Hitempase showed no significant effect on extract (data not shown).

Viscosity and filtration performance

A high viscosity makes beer filtration more difficult and may lead to starch hazes in the final beer13. It is as a result of this that low viscosity wort is a desirable attribute of worts. Fig. 1b depicts a decrease in viscosity as the concentration of Hitempase 2XL is increased. The lowest viscosity was observed when 100% of Hitempase 2XL was used. Also noted was a slightly higher wort filtration (data not shown). These results are in agreement with previous studies using Hitempase 2XL carried out on un-malted sorghum10. It was also noted that the lowest vis-cosity was associated with lowest concentration of Amylo 300, when no Biocellulase W was present (Fig. 2a). This supports the findings of Bajomo and Young1, who found

that the lowest viscosity was evident when the lowest con-centration of Amylo 300 was added to a mash containing 100% raw sorghum. An accompanying increase in wort volume was observed (Fig. 2b). This is in keeping with Siebert et al.21, who reported that viscosity impacted on wort filtration. The interactive effect of Amylo 300 and Hitempase showed no significant effect on viscosity and wort filtration (data not shown).

Colour

It is evident that with an increase in the fraction and concentration of Hitempase 2XL, there was an increase in the colour values of the subsequent worts (Figs. 1c and 3a). This increase in colour value of the worts was pre-sumably because of the increased extraction of solubles in the wort. This concurs with evidence from Goode et al.10 who also found that increasing the levels of Hitempase 2XL in the raw sorghum mashes, resulted in increased wort colour values. The interactive effect of Biocellulase W and Amylo 300 imparted no effect on wort colour (data not shown).

Nitrogenous fractions (TSN, KI, FAN)

Yeast growth involves the uptake of nitrogen, mainly in the form of amino acids, for the synthesis cellular proteins and other cell components18. Raw sorghum wort and bar-ley malt wort should not contain a FAN level less than 100–150 mg/L to ensure a healthy fermentation3. Previ-ous work has shown that when buckwheat malt was opti-mally mashed, similar levels were found, i.e. a FAN level of ~125 mg/L16.

Fig. 1. Effects of the total concentration of Biocellulase W and Hitempase 2XL and the fraction of Biocellulase W in a Biocellulase Wand Hitempase 2XL mixture, where 1.0 is 100% of Biocellulase W on (a) extract (R2 = 93%), (b) viscosity (R2 = 89.8%), (c) colour (R2 = 94.2%), (d) fermentablity (R2 = 99.5%) and (e) total fermentable extract (TFE) (R2 = 99.5%).

VOL. 112, NO. 4, 2006 329

Fig. 2. Effects of the total concentration of Biocellulase W and Amylo 300 and the fraction of Biocellulase W in a Biocellulase W andAmylo 300 mixture, where 1.0 is 100% of Biocellulase W on (a) viscosity (R2 = 89.9%), (b) wort volume (R2 = 91.5%), (c) free amino nitrogen (FAN) (R2 = 98.8%), (d) fermentability (R2 = 97.3%) and (e) total fermentable extract (TFE) (R2 = 99.7%).

Fig. 3. Effects of the total concentration of Amylo 300 and Hitempase 2XL and the fraction of Amylo 300 in a Amylo 300 and Hi-tempase 2XL mixture, where 1.0 is 100% of Amylo 300 on (a) colour (R2 = 95%) (b) total soluble nitrogen (TSN) (R2 = 86.4%),(c) kolbach index (KI) (R2 = 95.1%), (d) free amino nitrogen (FAN) (R2 = 92.5%), (e) fermentability (R2 = 93.4%), and (f) total fer-mentable extract (TFE) (R2 = 97.7%).

330 JOURNAL OF THE INSTITUTE OF BREWING

Results indicate that the highest levels in FAN were obtained from the maximum concentration of Amylo 300, with no other enzyme present (Fig. 2c). However, this does not correlate with previous work carried out with raw sorghum and Amylo 300, where Amylo 300 imparted little or no effect on the levels of FAN in the wort3. No significant effect was noted from the interactive effect of Biocellulase W and Amylo 300 with regard to TSN (data not shown).

However, it was found that the addition of Hitempase 2XL had a negative effect on TSN at high concentrations (Fig. 3b). This concurs with previous studies, using Hi-tempase 2XL, carried out on unmalted sorghum10. It was also noted that TSN levels were positively influenced by the addition of high levels of Amylo 300. This is further confirmed by values obtained for the Kolbach index (3c), which is the ratio of soluble protein to total protein, thus providing a reasonable index of the extent of protein deg-radation9. Results obtained for FAN levels reflect the same trend (Fig. 3d). This supports the idea that as more protein was solubilised, this protein was degraded to FAN (amino acids and peptides) during mashing.

Fermentability and total fermentable extract (TFE)

Previous studies indicate that the low levels of ferment-able sugars obtained from buckwheat malt were as a result of low amylolytic activity generated during germination. The quality of malt and wort is considerably compro-mised when malt contains low amylolytic levels16,17. The highest level of fermentability was obtained using ap-proximately 30% Biocellulase W in combination with 70% Hitempase 2XL (Fig. 1d). In addition, the curves appeared to approach limiting values. This implies that further additions of the enzymes would have had little effect on fermentability. Results obtained for extract and fermentability levels reflect the same trend observed in total fermentable extract (Fig. 1e).

It has been observed by many workers2,3,19,23 that an in-crease in the total concentration of Amylo 300 results in a corresponding increase in fermentability. The results pre-sented in Fig 2d support these findings. Amylo 300 de-grades dextrins into simpler fermentable carbohydrate moieties and complements intrinsic �-amylase acivity19.

Using Amylo 300 alone in the mash at an increased total concentration gave the highest fermentability. Correlating total fermentable extracts can be seen in Fig. 2e.

It was found that when Hitempase 2XL was combined with Amylo 300, it did not contribute significantly to fer-mentability (Fig. 3e), but did yield higher levels of fer-mentable extract (Fig. 3f) in mid range concentration. However at all times Amylo 300 when used alone pro-duced the highest levels of fermentability and total fer-mentable extract.

Prediction and validation of optimum conditions

Pooling all data from the 3 pairs of enzymes in a single regression using equation 2 for each response provided the results shown in Table V. Parameters that are statisti-cally significant at a 95% confidence level are indicated in bold typeface (i.e. whose value divided by the standard error is greater than the t-Student value for 95% confi-dence level and 14 degrees of freedom: 24 data points minus 10 model parameters).

It can be seen that this model predicts that Biocellulase W (enzyme A) does not influence the results significantly compared to the other enzymes, and its only effects of relevance are an interaction with Hitemase 2XL (enzyme C), when mixed with it, affecting colour, and with Amylo 300, affecting the extract. The concentration of both Amylo 300 and Hitempase 2XL affect the quality charac-teristics that are better fitted by the surface model: fer-mentability, colour, FAN and TFE, and quadratic effects are relevant in all cases, which suggests that points of optimum may exist. It can be seen that model predictions can be made with acceptable confidence for fermentabil-ity, colour, FAN and TFE.

A number of optimum search scenarios were defined. The concentrations of enzymes that according to the mod-els provide the best solution for each scenario are shown in Table VI. It is noted that the predictions for viscosity and extract objectives are made using models that have a low certainty (R2 below 88%, although above 73%), but given their importance, they were also considered. Further experiments were then performed using the enzyme con-centrations thus specified, with some replicates, and the results are also shown in Table VI. It can be seen that the model predictions were indeed very good, even in the

Table V. Parameters of the predictive global surface model relating quality characteristics to the concentration of the three selected enzymes.

Responses (quality characteristics)

Coefficient

Extract

Ferment-ability

Viscosity

Wort volume

Colour

TSN

FAN

TFE

KI

off-set 71.6586 69.0174 2.4778 285.9216 4.5061 825.186 144.269 49.3835 29.3056 CA 6.6333 –2.2595 0.1150 –44.6750 0.003292 45.730 6.0106 3.4408 1.9164 CB 8.0529 40.6605 0.01480 20.1980 –0.1298 287.874 44.5372 36.0893 10.5965 CC 12.0391 31.2610 –0.07178 –26.2906 0.8941 86.621 18.1170 31.8790 3.6361 CA × CB –32.4592 14.0727 –0.4353 65.3797 0.2944 –418.845 –21.9977 –16.3314 –16.3086 CA × CC –16.6995 2.0951 –0.7628 184.4113 –0.8496 –309.800 –21.9977 –11.2197 –11.7905 CB × CC –16.5666 –32.9141 –0.4167 22.0091 –0.01218 –75.628 15.7091 –36.1991 –3.3986 CA

2 –5.1077 –2.8493 –0.08970 16.2263 –0.03389 17.063 0.8256 –6.0488 0.3864 CB

2 –5.8852 –21.7692 0.008428 –15.6305 0.1098 –208.694 –24.4835 –20.5603 –7.6786 CC

2 –7.3490 –23.7362 –0.1157 45.2455 –0.4592 –155.427 –30.2383 –22.7902 –5.8916

R2 (%) 73.0 93.3 78.6 54.0 95.9 66.0 95.4 93.3 65.2

Parameters that are statistically significant are indicated in bold and shaded background. The coefficients of determination (R2) are also shown, bold meaning sufficiently high value for the model to be acceptable for predictive purposes.

VOL. 112, NO. 4, 2006 331

cases where the model R2 was lower. It can also be seen that the predictions of the global model (equation 2 with the parameters of Table V) were actually the best, and therefore this model is recommended.

CONCLUSIONS In this study, the effects of 7 individual enzymes (Bio-

cellulase W, Amylo 300, Hitempase 2XL, Bioxylanase 10L, Bioferm L, Bioglucanase B-10L and Bioprotease N-100L) on the quality of wort when mashing with 100% malted buckwheat (Fagopyrum esculentum Moench) were investigated. Further to this, the influence of two factors, total concentration and fraction of three pairs of enzymes, which showed statistical significance (Biocellulase W with Hitempase 2XL, Biocellulase W with Amylo 300 and Amylo 300 with Hitempase 2XL), were studied for their overall effect on the buckwheat wort quality using response surface methodology. This study revealed that the addition of increasing levels of Hitempase 2XL to the buckwheat mash increased colour, extract levels, wort filtration, fermentability and TFE, along with decreasing viscosity values. Fermentability and TFE appeared to ap-proach limiting values which was expected. The addition of Amylo 300 increased >20% the amount of fermentable carbohydrate in sorghum malt, which is due to the degra-dation of dextrins into smaller fermentable carbohydrate moieties and complements intrinsic �-amylase activity by an amyglucosidase enzyme2,19. As expected, the addition of increasing levels of Amylo 300 to buckwheat mashes resulted in corresponding increases in fermentability and TFE, along with increases in TSN, FAN and KI. Results also determined a high level of fermentability when 30% of Biocellulase and 70% of Hitempase was added to the mash.

In practice, the most important objective would be to achieve the highest TFE with fermentability in the range of 82–84%6. The response surface model predicted that this is achieved using Amylo 300 alone, in a concentration of 0.62 mL/100 g of grist, and this was validated experi-

mentally. The model predicts that fermentability is at the highest value of the range defined (84%), although the experimental results gave a higher figure. Therefore, a safety margin should be considered, lowering the concen-tration to 0.55 mL/100 g of grist. The viscosity of this wort is rather high. The mean value stated by EBC for wort viscosity is 1.867 mPas6. It can be decreased some-what by adding 0.36 mL/100 g grist of Biocellulase W, although this reduces the TFE and still results in a higher viscosity than desired.

This work shows the usefulness of a simple experimen-tal design and response surface methodology in identify-ing optimum conditions for brewing with a limited amount of experimental data. It is noted that the method is based on deterministic functions, that is, the effect of pro-cess variability is not considered. Other methods and more work would be required to minimise product vari-ability.

ACKNOWLEDGEMENTS

This project was funded by the Irish Government under the National Development Plan, 2006–2007. The authors gratefully acknowledge Eoin Lalor (Kerry Bioscience Ireland Ltd.) for kindly providing the commercial enzyme preparations and Dr. Helge Ulmer for his assistance with the experimental design and statistical analysis.

REFERENCES

1. Bajomo, M. F. and Young, T. W., Development of a mashing profile for the use of microbial enzymes in brewing with raw sorghum (80%) and malted barley or sorghum malt (20%). J. Inst. Brew., 1992, 98, 515–523.

2. Bajomo, M. F. and Young, T. W., Fermentation of worts made form 100% raw sorghum and enzymes. J. Inst. Brew., 1994, 100, 79–84.

3. Bajomo, M. F. and Young, T. W., The properties, composition and fermentabilities of worts made from 100% raw sorghum and commercial enzymes. J. Inst. Brew., 1993, 99, 153–158.

4. Box, G. E. P., Hunter, W. and Hunter, J., Statistics for Experi-menters, Wiley Inc: New York, 1978.

5. De Francischi, M. L. P., Salgado, J. M. and Da Costa, C. P.,

Table VI. Enzyme concentrations predicted by the models to fulfill the specified objective and results of the validation experiments.

Extract Fermentability TFE Viscosity Enzyme conc. (ml enzyme / 100 g grist)

Objective A B C

Model predic-

tion

Experi-mental result

Model predic-

tion

Experi-mental result

Model predic-

tion

Experi-mental result

Model predic-

tion

Experi-mental result

Lowest viscosity1 0.36 0.64 0 — — — — — — 2.22 2.25 Highest TFE2 0 0.98 0.02 — — — — 64.9 66.1 — — Highest extract with

fermentability constraint3

0

0.49

0

76.6

76.5

84.0

83.2

—

—

—

— Highest extract with

fermentability constraint3

0

0.49

0

76.6

76.9

84.0

83.0

—

—

—

— Highest TFE1 0 0.86 0 — — — — 65.3 65.7 — — Highest TFE1 0 0.86 0 — — — — 65.3 65.6 — — Highest TFE with

fermentability constraint1

0

0.62

0

—

—

84.0

85.9

64.0

65.0

—

— Highest TFE with

fermentability constraint1

0

0.62

0

—

—

84.0

85.7

64.0

64.5

—

— 1as predicted by the joint model, 2as predicted by the B + C model, 3as predicted by the A + C model.

332 JOURNAL OF THE INSTITUTE OF BREWING

Immunological analysis of serum for buckwheat fed celiac pa-tients. Plant Food Hum. Nut., 1994, 46, 207–211.

6. European Brewing Convention (EBC). Analytica EBC. Hans Carl Getranke-Fachverlag: Nürnberg, 1998.

7. Ellis, H. J., Freedman, A. R. and Ciclitira, P. J., Detection and estimation of the barley prolamin content of beer and malt to assess their suitability for patients with coeliac disease. Clin. Chim. Acta, 1990, 189, 123–130.

8. Fasano, A. and Catassi, C., Current approaches to diagnosis and treatment of celiac disease: an evolving spectrum. Gastro-enterology, 2001, 121, 636–651.

9. Fix, G. J., Principles of Brewing Science: A study of serious brewing issues, 2nd ed., Brewers Publications: Boulder, 1999.

10. Goode, D. L., Halbert, C. and Arendt, E. K., Optimization of mashing conditions when mashing with unmalted sorghum and commercial enzymes. J. Am. Soc. Brew. Chem., 2003, 61, 69–78.

11. Ikeda, K., Buckwheat: compostion, chemistry, and processing. Adv. Food Nutr. Res., 2002, 44, 395–434.

12. Li, S. Q. and Zhang, Q. H., Advances in the development of functional foods from buckwheat. Crit. Rev. Food Sci. Nutr., 2001, 41, 451–464.

13. Lowe, D. P., Ulmer, H. M., Barta, R. C., Goode, D. L. and Arendt, E. K., Biological acidification of a mash containing 20% barley using Lactobacillus amylyvorus FST 1.1: Its effects on wort and beer quality. J. Am. Soc. Brew. Chem., 2005, 63, 96–106.

14. Maccagnan, G., Pat, A., Collavo, F., Ragg, G. L. and Bellini, M. P. Gluten-free beer containing rice malt and buckwheat. Euro-pean Patent, EP 0949328B1, 2004.

15. Macfadden, D. P. and Clayton, M., Brewing with sorghum – Use of exogenous enzymes Brew. Beverage Ind. Int., 1989, 1, 71–81.

16. Nic Phiarais, B. P., Wijngaard, H. H. and Arendt, E. K., The impact of kilning on enzymatic activity of buckwheat malt. J. Inst. Brew., 2005, 111, 290–298.

17. Nic Phiarais, B. P., Wijngaard, H. H. and Arendt, E. K., Kilning conditions for the optimisation of enzyme levels in buckwheat. J. Am. Soc. Brew. Chem., 2006, 64, 187–194.

18. O'connor, E. S. C. and Ingledew, W. M., Wort nitrogenous sources – Their use by brewing yeasts: A Review. J. Am. Soc. Brew. Chem., 1989, 47, 102–108.

19. Pozo-Insfran, D. D., Urias-Lugo, D., Hernandez-Brenes, C. and Serna Saldivar, S. O., Effect of amyloglucosidase on wort com-position and fermentable carbohydrate depletion in sorghum la-ger beers. J. Inst. Brew., 2004, 110, 124–132.

20. Qian, J. and Kuhn, M., Evaluation on gelatinization of buck-wheat starch: a comparative study of Brabender viscoamylogra-phy, rapid visco-analysis, and differential scanning calorimetry. Eur. Food Res. Technol., 1999, 209, 277–280.

21. Siebert, K. J., Troukhanova, N. V. and Lynn, P. Y., Nature of polyphenol-protein interactions. J. Agric. Food Chem., 1996, 44, 80–85.

22. Skrabanja, V., Kreft, I., Golob, T., Modic, M., Ikeda, S., Ikeda, K., Kreft, K., Bonafaccia, G., Knapp, M. and Kosmelj, K., Nu-trient content in buckwheat milling fractions. Cereal Chem., 2004, 81, 172–176.

23. Urias-Lugo, D. and Serna Saldivar, S. O., Effect of amylo-glucosidase on properties of lager beers produced from sorghum malt and waxy grits. J. Am. Soc. Brew. Chem., 2005, 63, 63–68.

24. Wijngaard, H. H. and Arendt, E. K., Optimisation of a mashing program for 100% malted buckwheat. J. Inst. Brew., 2006, 112, 57–65.

25. Wijngaard, H. H., Ulmer, H. M. and Arendt, E. K., The effect of germination temperature on malt quality of buckwheat. J. Am. Soc. Brew. Chem., 2005, 63, 31–36.

26. Wijngaard, H. H., Ulmer, H. M., Neumann, M. and Arendt, E. K., The effect of steeping time on the final malt quality of buck-wheat. J. Inst. Brew., 2005, 111, 275–281.

(Manuscript accepted for publication November 2006)