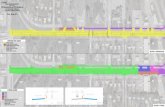

ROW TUBE LEGEND - GameChange Solar

Transcript of ROW TUBE LEGEND - GameChange Solar

100'0

200' 400'

2

1

2

" TYPICAL

TABLE SPACING

762'-3

7

8

"

510'-5"

510'-5"

630'-5"

630'-5"

16' TYPICAL

ROW SPACING

58'-0

1

4

"

33'-1

1

16

"

3

4

" TYPICAL

PANEL SPACING

LEGEND

TYPE WIND ZONE QUANTITY

STRINGS PER

TABLE

MODULES PER

TABLE

Exterior 242 2 38

Interior 92 4 76

GAMECHANGE SOLAR

730 Fifth Avenue, 16th Floor

New York, NY 10019

Tel:212-388-5160

www.gamechangesolar.com

Issue: By: Date: Description:

Array Information

PV Modules

Racking

Manufacturer JA Solar

Gamechange Racking

Model JAP6-72-315 Genius Tracker

Dimensions 77.00'' x 39.01'' x 1.8''Range of Rotation 90°

Weight

57.32 lbs

Ground

Clearance

29.03''

Quantity

18240

364 Actuator Posts

1920 Regular Posts

Design Information

Building Occupancy Category

I

Wind Exposure Category

C

Design Wind Speed 105 mph ASCE7-10

Design Snow Load 10 psf

Area of Array

20.52 acres

No. of rows 107

18,240 modules at 315W

5745.6 kW

GENERAL NOTES

The layout shown herein is based on site layout geometry

provided to GameChange Solar by the customer.

Any changes to the site that may affect the solar PV arrays

depicted herein shall be notified to GameChange Solar.

The layout and accompanying detail drawings herein are

specific to the module shown in the Array information table

above.

GameChange Solar cannot be responsible for errors

during installation caused by changes that impact the

layout as shown

Sheet #:

1 of 9

SITE PLAN

Customer:

Sample

Project:

Sample

Location:

Sample

1 SA 00-00-0000 Sample Layout

Interior Wind Zone

4 Strings

76 Panels

3

4

" TYPICAL

PANEL SPACING

3'-3"

PANEL WIDTH

253'-4

1

4

"

6'-5"

PANEL LENGTH

33'-1

5

8

"

33'-1

5

8

"

33'-1

5

8

"

25'-7

13

16

"

25'-7

13

16

"

33'-1

5

8

"

33'-1

5

8

"

33'-1

5

8

"

1'-7

1

2

"

1'-7

1

2

"

3'-3"

PANEL WIDTH

28'-11

5

8

"

28'-11

5

8

"

Exterior Wind Zone

2 Strings

38 Panels

127'-5

3

8

"

28'-11

5

8

"

3

4

" TYPICAL

PANEL SPACING

28'-11

5

8

"

5'-9

1

2

"

5'-9

1

2

"

6'-5" PANEL LENGTH

44'-3

1

2

"

39'

44'-3

1

2

"

0.25 TYPICAL

ROW TUBE GAP

39'

39'

39'

45'-5

3

4

"

45'-5

3

4

"

45'-5

3

4

"

0.25 TYPICAL

ROW TUBE GAP

1" TYPICAL

ROW TUBE OVERHANG

1" TYPICAL

ROW TUBE OVERHANG

PO

ST

S

PA

CIN

G

TU

BE

LE

NG

TH

TU

BE

LE

NG

TH

PO

ST

S

PA

CIN

G

ROW TUBE LEGEND

TYPE LENGTH TABLE USED COLOR

39'

2 String Table

Red

39'

4 String Table Light Green

44'-3

1

2

"

2 String Table Orange

45'-5

3

4

"

4 String Table

Dark Blue

Tube Squeeze Splices

GAMECHANGE SOLAR

730 Fifth Avenue, 16th Floor

New York, NY 10019

Tel:212-388-5160

www.gamechangesolar.com

Issue: By: Date: Description:

Sheet #:

2 of 9

TABLE

DETAIL

Array Information

PV Modules

Racking

Manufacturer JA Solar

Gamechange Racking

Model JAP6-72-315 Genius Tracker

Dimensions 77.00'' x 39.01'' x 1.8''Range of Rotation 90°

Weight

57.32 lbs

Ground

Clearance

29.03''

Quantity

18240

364 Actuator Posts

1920 Regular Posts

Design Information

Building Occupancy Category

I

Wind Exposure Category

C

Design Wind Speed 105 mph ASCE7-10

Design Snow Load 10 psf

Area of Array

20.52 acres

No. of rows 107

18,240 modules at 315W

5745.6 kW

GENERAL NOTES

The layout shown herein is based on site layout geometry

provided to GameChange Solar by the customer.

Any changes to the site that may affect the solar PV arrays

depicted herein shall be notified to GameChange Solar.

The layout and accompanying detail drawings herein are

specific to the module shown in the Array information table

above.

GameChange Solar cannot be responsible for errors

during installation caused by changes that impact the

layout as shown

Customer:

Sample

Project:

Sample

Location:

Sample

1 SA 00-00-0000 Sample Layout

11'-9

1

2

"

TYPICAL

LIGHT BLUE TO LIGHT BLUE

POST SPACING

7'-7

1

2

"

TYPICAL

BLUE TO LIGHT BLUE

POST SPACING

GAMECHANGE SOLAR

730 Fifth Avenue, 16th Floor

New York, NY 10019

Tel:212-388-5160

www.gamechangesolar.com

Issue: By: Date: Description:

Sheet #:

3 of 9

POST

DETAIL

Array Information

PV Modules

Racking

Manufacturer JA Solar

Gamechange Racking

Model JAP6-72-315 Genius Tracker

Dimensions 77.00'' x 39.01'' x 1.8''Range of Rotation 90°

Weight

57.32 lbs

Ground

Clearance

29.03''

Quantity

18240

364 Actuator Posts

1920 Regular Posts

Design Information

Building Occupancy Category

I

Wind Exposure Category

C

Design Wind Speed 105 mph ASCE7-10

Design Snow Load 10 psf

Area of Array

20.52 acres

No. of rows 107

18,240 modules at 315W

5745.6 kW

GENERAL NOTES

The layout shown herein is based on site layout geometry

provided to GameChange Solar by the customer.

Any changes to the site that may affect the solar PV arrays

depicted herein shall be notified to GameChange Solar.

The layout and accompanying detail drawings herein are

specific to the module shown in the Array information table

above.

GameChange Solar cannot be responsible for errors

during installation caused by changes that impact the

layout as shown

Customer:

Sample

Project:

Sample

Location:

Sample

1 SA 00-00-0000 Sample Layout

22'-6" TYPICAL

LEGEND

Heavier Gauge Purlins Area

Purlins Will Be Marked with Yellow

GAMECHANGE SOLAR

730 Fifth Avenue, 16th Floor

New York, NY 10019

Tel:212-388-5160

www.gamechangesolar.com

Issue: By: Date: Description:

Sheet #:

4 of 9

PURLIN

DETAIL

Array Information

PV Modules

Racking

Manufacturer JA Solar

Gamechange Racking

Model JAP6-72-315 Genius Tracker

Dimensions 77.00'' x 39.01'' x 1.8''Range of Rotation 90°

Weight

57.32 lbs

Ground

Clearance

29.03''

Quantity

18240

364 Actuator Posts

1920 Regular Posts

Design Information

Building Occupancy Category

I

Wind Exposure Category

C

Design Wind Speed 105 mph ASCE7-10

Design Snow Load 10 psf

Area of Array

20.52 acres

No. of rows 107

18,240 modules at 315W

5745.6 kW

GENERAL NOTES

The layout shown herein is based on site layout geometry

provided to GameChange Solar by the customer.

Any changes to the site that may affect the solar PV arrays

depicted herein shall be notified to GameChange Solar.

The layout and accompanying detail drawings herein are

specific to the module shown in the Array information table

above.

GameChange Solar cannot be responsible for errors

during installation caused by changes that impact the

layout as shown

Customer:

Sample

Project:

Sample

Location:

Sample

1 SA 00-00-0000 Sample Layout

GAMECHANGE SOLAR

730 Fifth Avenue, 16th Floor

New York, NY 10019

Tel:212-388-5160

www.gamechangesolar.com

Issue: By: Date: Description:

Sheet #:

5 of 9

ELEVATION

VIEW

Array Information

PV Modules

Racking

Manufacturer JA Solar

Gamechange Racking

Model JAP6-72-315 Genius Tracker

Dimensions 77.00'' x 39.01'' x 1.8''Range of Rotation 90°

Weight

57.32 lbs

Ground

Clearance

29.03''

Quantity

18240

364 Actuator Posts

1920 Regular Posts

Design Information

Building Occupancy Category

I

Wind Exposure Category

C

Design Wind Speed 105 mph ASCE7-10

Design Snow Load 10 psf

Area of Array

20.52 acres

No. of rows 107

18,240 modules at 315W

5745.6 kW

GENERAL NOTES

The layout shown herein is based on site layout geometry

provided to GameChange Solar by the customer.

Any changes to the site that may affect the solar PV arrays

depicted herein shall be notified to GameChange Solar.

The layout and accompanying detail drawings herein are

specific to the module shown in the Array information table

above.

GameChange Solar cannot be responsible for errors

during installation caused by changes that impact the

layout as shown

Customer:

Sample

Project:

Sample

Location:

Sample

1 SA 00-00-0000 Sample Layout

PARTS LIST

Item No. Description Part No. Material

1 Center Post GC61HGTGalvanized, G235+ Steel

2 Standard Post GC361WTGalvanized, G235+ Steel

3

Bearing Collar Bottom

GC1601

6005A / 6061 Al Alloy

4

Bearing Collar Top

GC1602

6005A / 6061 Al Alloy

5

Capture Ring

GC1603Galvanized, G90 Steel

6

Bearing Wheel

GC367 HDPE

7 Row Tube GC365Galvanized, G90 Steel

8

Squeeze Splice

GC1355Galvanized, G90 Steel

9 Purlin GC903Galvanized, G90 Steel

10 U-Bolt GC1325

Magnacoat Steel

11

Purlin Angle

GC378Galvanized, G90 Steel

12

Driving Arm (Upper, Lower) GC2375, GC2376 Galvanized, G90 Steel

13

Driving Arm Spacer

GC1361Galvanized G90, Steel

14 Controller GC2002

15 Controller Bracket GC2011Galvanized G90, Steel

16 Linear Actuator GC2003

17

Squeezer Plate

GC2301

Galvanized, G90, Steel

18

Squeezer Wrap

GC2399 EPDM

19 Wind Break Plate GC2029Galvanized, G90, Steel

20 Solar Panel GC2091

21 Master Controller GC2001

22 Pole GC2099 2" OD Galvanized Steel Tube

23 Pole U-Bolt GC2098

Magnacoat Steel

24

Panel Bracket Top

GC2104Galvanized, G90, Steel

25

Panel Bracket Bottom (Left, Right)GC2105L, GC2105R Galvanized, G90, Steel

26

Pole Angle

GC2106Galvanized, G90, Steel

27 Anemometer GC2102

28 Enclosure Attachment Bracket GC2107Galvanized, G90, Steel

29

Threaded Rod (1/2", 3/4") GC1351, GC1352Magnicoated Steel

30

Hex Bolt (1/4", 3/8", 1/2", 3/4") Magnicoated Steel

31

Hex Nuts and Lock Washers or Serrated Head Flange Nuts (1/4", 3/8", 1/2", 3/4") Magnicoated Steel: 3/8", 1/2", 3/4"; Stainless Steel: 1/4"

32

Washers (1/2", 3/4") Magnicoat or HDG Steel

33

Star Washer (1/4")

Stainless Steel

34

TEK Screw (1/4") Magnicoated or Stainless Steel

35

Grounding Strip

GC20 Stainless Steel

36

Jumper

GC1304 Aluminum

GAMECHANGE SOLAR

730 Fifth Avenue, 16th Floor

New York, NY 10019

Tel:212-388-5160

www.gamechangesolar.com

Issue: By: Date: Description:

Sheet #:

6 of 9

PARTS

LIST

GC Genius Tracker System

Use only GameChange parts. Use of other parts to complete the

installation as substitutes may void the warranty.

Make sure the ground structure is inspected and can support the loading

resulting from the GC Genius Tracker System and provided PV modules.

Follow all safety instructions that are required by relevant local, regional

and national organizations and procedures as outlined in the Install

Manual, both for mechanical and electrical aspects of the solar PV array

installation.

When encountering undocumented or unexpected obstacles requiring a

work around, they should be noted on working drawings and notified to

supervisor for evaluation. Work should then be completed in a manner that

ensures that the remainder of the array is not affected.

Customers are responsible for grade variations and making sure slope

tolerances support GameChange System. GC Genius Tracker System

ideally should be installed on flat, level and pre-compacted ground. This is

to avoid system settlement over time. Topsoil with loam content and

organics should be removed, and soil scraped down to subsoil level. If the

system is installed on new fill, the soil should be compacted with a

compacting roller prior to installation. However, due to vertical adjustability

of the Tubes on the Posts, the GC Genius Tracker System may be erected

on less than ideally prepared grounds when site conditions preclude

removal of topsoil. In that scenario, the Tubes should be adjusted to

appropriate heights on Posts during periods of operation and maintenance

visits.

Reference the Install Manual for detailed installation steps. Not following

the Install Manual may result in voiding warranty.

Material Storage

Make sure to install system within several days of receipt of components.

Storage of components in a damp or wet environment can lead to white

rust on galvanized parts as well as other damage on other protective

coatings which can lead to accelerated corrosion to components, and void

the warranty. Galvanization is especially prone to white rust when

components are still bundled because the zinc coating requires airflow

over its surface to establish its protective patina, otherwise water can

cause corrosion of the zinc and it has no protection against it in enclosed

spaces, such as those between parts that are bundled.

Tool Required

7/16”, 9/16", 3/4", and 1 1/8" Deep and Short Sockets

7/16”, 9/16", 3/4", and 1 1/8" Wrenches

Torque Wrench

Suggested finish torques : 1/4" hardware use 6 ft lbs

3/8" hardware use 35 ft lbs

1/2" hardware use 50 ft-lbs

3/4" hardware use 200 ft-lbs

String Line

Impact drill with interchangeable drivers

Must use anti-seize such as LocTite for bolts used to mount modules (most

bolts come pre-dip with anti-seize)

Tape Measure

48 inch long level

Assembly jigs for Driving Arm and Actuator Assemblies are optional

Preventative Maintenance

After Installation, installer must annually monitor for any surface rust that

may occur over time. Identify any rust areas, wire brush area to remove

rust, and coat area with 70%+ zinc rich or equivalent field life paint. This

step is not required if rust is limited to edges which were cut during

fabrication.

Clips must be checked annually and after storms with severe winds to

make sure their installation and torque settings remain correct.

Following extreme wind turbulences (in excess of 80% of designed wind

speed) and annually, inspections are required. Bolted joints and joints that

mechanically move shall be inspected for any loosened hardware or

component damage. Any impedance to mechanical movement must be

rectified.

Torque settings must be checked for all hardware.

All Clips must be checked to make sure there is no gap between side of

Clip and module.

Proper preventative maintenance must be conducted or warranty may be

voided. The Install Manual provides required maintenance steps and

diagnostic procedure for malfunctions. Follow steps and consult with

GameChange in case of maintenance issues.

Customer:

Sample

Project:

Sample

Location:

Sample

1 SA 00-00-0000 Sample Layout

3) Attach Bearing Collar Bottom to the Post Bracket. Leave connections loose. For Bearing Collar Bottom installation

onto the Center Posts, be sure that the center of the Bearing Collar Bottom is aligned to the center of the Center

Post to within +/- 0.5 inches. This is critical for the proper rotational range and performance of the tracker. Consult

with GameChange if this alignment is impossible for any reason.

4) Place two Bearing Wheel halves above and below the Row Tube. Then place the bottom Bearing Wheel onto the

Bearing Collar Bottom, slide the Bearing Collar Top over the Row Tube and Bearing Wheels into position flush with

the Bearing Collar Bottom. Position a Capture Ring on either side of the Bearing Collars and fasten them onto the

Bearing Collars using TEK screws.

5) Start with 2 Bearing Assemblies on the Center Post, and repeat 3 and 4 until Row Tube is properly supported by a

single Bearing Assembly on all Standard Posts.

6) Join one Row Tube to the next using Squeeze Splice. Go down entire tables attaching Row Tubes. Once all Row

Tubes for a single table are joined, tighten all hardware to specification.

7) Install U-bolts and Purlin Angles on either side of the Capture Rings to prevent lateral row movement (north-south).

At a minimum, there shall be lateral stops at the Center Post, first Standard Post, and last Standard Post. Consult

GameChange to determine if additional lateral stops are necessary based on site conditions.

Distance

1) Post Alignment Procedure and Specifications

Mark locations of Posts and for each table, set stakes past the first and last

Posts at the proper height. Install Posts in between the stakes to align the tops

of the Post to the line created between the stakes. Standard Post (GC361TW)

shall open to the South, and Center Post (GC61HGT) shall open to the West.

Drive Posts the specified distance apart. Be sure to meet to constraints:

Posts are square azimuthally to +/- 1.5 degree for Center Posts and +/- 3

degrees for Standard Posts

Posts are plumb, optimally +/- 1 degree for Center Posts and +/- 3 degrees

for Standard Posts

Make sure tops of Posts are leveled to be at a consistent height or slope

depending on the topography of the land (with a tolerance of 0/+1 for

Center Posts and +/- 1 inch for Standard Posts).

Not more than +/- 1 inch cumulatively (from the proper post location marked

on ground) in east to west direction at top of post

Not more than +/- 3 inches for Center Posts or +/- 4 inches for Standard

Posts cumulatively (from the proper post location marked on ground) north

to south direction at top of post

Note that embedment depth will vary to handle rolling ground variations.

Gamechange provides piles with additional length enabling an adjustment

range typically of 4" to 6". Be careful to always meet minimum embedment

depth and ground clearance requirement.

Make sure defined distance between foundations is measured from center of post to center of next post along

the ground (not from plan view). Otherwise foundation locations will creep if there is rolling terrain. since plan

view does not factor in dimensions differences caused by terrain. This may cause following installation steps

to be more difficult.

Proper Height

GC361

South

GC61HGT

West

Standard Post

Center Post

GAMECHANGE SOLAR

730 Fifth Avenue, 16th Floor

New York, NY 10019

Tel:212-388-5160

www.gamechangesolar.com

Issue: By: Date: Description:

Sheet #:

7 of 9

DETAIL

SHEET

2) Repeat Post Assembly and installation for adjacent tables. Position Post Assembly to the appropriate distance

apart as required by layout.

TOP TIP: Use vertical adjustability provided to make

Row Tubes level, and the site install look great.

GC Genius Tracker System

Use only GameChange parts. Use of other parts to complete the

installation as substitutes may void the warranty.

Make sure the ground structure is inspected and can support the loading

resulting from the GC Genius Tracker System and provided PV modules.

Follow all safety instructions that are required by relevant local, regional

and national organizations and procedures as outlined in the Install

Manual, both for mechanical and electrical aspects of the solar PV array

installation.

When encountering undocumented or unexpected obstacles requiring a

work around, they should be noted on working drawings and notified to

supervisor for evaluation. Work should then be completed in a manner that

ensures that the remainder of the array is not affected.

Customers are responsible for grade variations and making sure slope

tolerances support GameChange System. GC Genius Tracker System

ideally should be installed on flat, level and pre-compacted ground. This is

to avoid system settlement over time. Topsoil with loam content and

organics should be removed, and soil scraped down to subsoil level. If the

system is installed on new fill, the soil should be compacted with a

compacting roller prior to installation. However, due to vertical adjustability

of the Tubes on the Posts, the GC Genius Tracker System may be erected

on less than ideally prepared grounds when site conditions preclude

removal of topsoil. In that scenario, the Tubes should be adjusted to

appropriate heights on Posts during periods of operation and maintenance

visits.

Reference the Install Manual for detailed installation steps. Not following

the Install Manual may result in voiding warranty.

Material Storage

Make sure to install system within several days of receipt of components.

Storage of components in a damp or wet environment can lead to white

rust on galvanized parts as well as other damage on other protective

coatings which can lead to accelerated corrosion to components, and void

the warranty. Galvanization is especially prone to white rust when

components are still bundled because the zinc coating requires airflow

over its surface to establish its protective patina, otherwise water can

cause corrosion of the zinc and it has no protection against it in enclosed

spaces, such as those between parts that are bundled.

Tool Required

7/16”, 9/16", 3/4", and 1 1/8" Deep and Short Sockets

7/16”, 9/16", 3/4", and 1 1/8" Wrenches

Torque Wrench

Suggested finish torques : 1/4" hardware use 6 ft lbs

3/8" hardware use 35 ft lbs

1/2" hardware use 50 ft-lbs

3/4" hardware use 200 ft-lbs

String Line

Impact drill with interchangeable drivers

Must use anti-seize such as LocTite for bolts used to mount modules (most

bolts come pre-dip with anti-seize)

Tape Measure

48 inch long level

Assembly jigs for Driving Arm and Actuator Assemblies are optional

Preventative Maintenance

After Installation, installer must annually monitor for any surface rust that

may occur over time. Identify any rust areas, wire brush area to remove

rust, and coat area with 70%+ zinc rich or equivalent field life paint. This

step is not required if rust is limited to edges which were cut during

fabrication.

Clips must be checked annually and after storms with severe winds to

make sure their installation and torque settings remain correct.

Following extreme wind turbulences (in excess of 80% of designed wind

speed) and annually, inspections are required. Bolted joints and joints that

mechanically move shall be inspected for any loosened hardware or

component damage. Any impedance to mechanical movement must be

rectified.

Torque settings must be checked for all hardware.

All Clips must be checked to make sure there is no gap between side of

Clip and module.

Proper preventative maintenance must be conducted or warranty may be

voided. The Install Manual provides required maintenance steps and

diagnostic procedure for malfunctions. Follow steps and consult with

GameChange in case of maintenance issues.

30

32

31

2

3

6

5

33

4

1

2

8

4

31

30

10

11

31

Customer:

Sample

Project:

Sample

Location:

Sample

1 SA 00-00-0000 Sample Layout

GAMECHANGE SOLAR

730 Fifth Avenue, 16th Floor

New York, NY 10019

Tel:212-388-5160

www.gamechangesolar.com

Issue: By: Date: Description:

Sheet #:

8 of 9

DETAIL

SHEET

8) Preassemble Driving Arm halves. Torque to specification.

9) If Squeezer Plates not installed onto Linear Actuator, Actuator

Assembly shall be preassembled. Place Squeezer Wrap around

the Actuator housing at prescribed position. Place Grounding

Strip next to Squeeze Wrap. Clamp Actuator, Wrap, and

Grounding Strip together using 2 Squeezer Plates. Torque to

specification.

10) Put Actuator Assembly through window of Center Post (motor

end East). Install Actuator to the Post using threaded rod and

nuts. Be sure to stage nuts along the threaded rod so that there

are a nut on either side of both walls of the Posts and there are

separate double nut setups on either side of the Squeezer Plates

to keep the Actuator centered. Double nuts on either side of the

Squeezer Plates shall not be tight against the Plates.

11) Install Driving Arm Assembly onto Row Tube, in between the 2

Bearing Assemblies on the Center Post. With Bearing Wheel

halves above and below the Row Tube, install the Driving Arm

pointed up. Insert threaded rods through the Driving Arm holes

and Spacer tubes surrounding the Row Tube. Torque to

specification.

12) Once installed, rotate Driving Arm Assembly to the West. Driving Arm shall have the window for the Actuator facing

down. All Bearing Wheel halves shall be to the east or west of the Row Tube.

13) Attach the stroke end of the Actuator to the Driving Arm Assembly through the window.Be sure to stage nuts along

the threaded rod so that there is a nut on either side of both walls of the Driving Arm and there are separate double

nut setups on either side of the Actuator stroke to keep the Actuator centered. Double nuts on either side of the

Actuator stroke shall not be tight against the Plates.

14) Install Purlins onto Row Tube using U bolts and Purlin Angles.

Leave them loose until positions finalized as Wind Break Plate

and PV modules are installed.

15) Install Wind Break Plate centered on the Driving Arm on top of 2

Purlins. Torque Plate and Purlin hardware to specification.

16) Install small PV module onto center of Wind Break Plate.

TOP TIP: Use vertical adjustability provided to make

Row Tubes level, and the site install look great.

GC Genius Tracker System

Use only GameChange parts. Use of other parts to complete the

installation as substitutes may void the warranty.

Make sure the ground structure is inspected and can support the loading

resulting from the GC Genius Tracker System and provided PV modules.

Follow all safety instructions that are required by relevant local, regional

and national organizations and procedures as outlined in the Install

Manual, both for mechanical and electrical aspects of the solar PV array

installation.

When encountering undocumented or unexpected obstacles requiring a

work around, they should be noted on working drawings and notified to

supervisor for evaluation. Work should then be completed in a manner that

ensures that the remainder of the array is not affected.

Customers are responsible for grade variations and making sure slope

tolerances support GameChange System. GC Genius Tracker System

ideally should be installed on flat, level and pre-compacted ground. This is

to avoid system settlement over time. Topsoil with loam content and

organics should be removed, and soil scraped down to subsoil level. If the

system is installed on new fill, the soil should be compacted with a

compacting roller prior to installation. However, due to vertical adjustability

of the Tubes on the Posts, the GC Genius Tracker System may be erected

on less than ideally prepared grounds when site conditions preclude

removal of topsoil. In that scenario, the Tubes should be adjusted to

appropriate heights on Posts during periods of operation and maintenance

visits.

Reference the Install Manual for detailed installation steps. Not following

the Install Manual may result in voiding warranty.

Material Storage

Make sure to install system within several days of receipt of components.

Storage of components in a damp or wet environment can lead to white

rust on galvanized parts as well as other damage on other protective

coatings which can lead to accelerated corrosion to components, and void

the warranty. Galvanization is especially prone to white rust when

components are still bundled because the zinc coating requires airflow

over its surface to establish its protective patina, otherwise water can

cause corrosion of the zinc and it has no protection against it in enclosed

spaces, such as those between parts that are bundled.

Tool Required

7/16”, 9/16", 3/4", and 1 1/8" Deep and Short Sockets

7/16”, 9/16", 3/4", and 1 1/8" Wrenches

Torque Wrench

Suggested finish torques : 1/4" hardware use 6 ft lbs

3/8" hardware use 35 ft lbs

1/2" hardware use 50 ft-lbs

3/4" hardware use 200 ft-lbs

String Line

Impact drill with interchangeable drivers

Must use anti-seize such as LocTite for bolts used to mount modules (most

bolts come pre-dip with anti-seize)

Tape Measure

48 inch long level

Assembly jigs for Driving Arm and Actuator Assemblies are optional

Preventative Maintenance

After Installation, installer must annually monitor for any surface rust that

may occur over time. Identify any rust areas, wire brush area to remove

rust, and coat area with 70%+ zinc rich or equivalent field life paint. This

step is not required if rust is limited to edges which were cut during

fabrication.

Clips must be checked annually and after storms with severe winds to

make sure their installation and torque settings remain correct.

Following extreme wind turbulences (in excess of 80% of designed wind

speed) and annually, inspections are required. Bolted joints and joints that

mechanically move shall be inspected for any loosened hardware or

component damage. Any impedance to mechanical movement must be

rectified.

Torque settings must be checked for all hardware.

All Clips must be checked to make sure there is no gap between side of

Clip and module.

Proper preventative maintenance must be conducted or warranty may be

voided. The Install Manual provides required maintenance steps and

diagnostic procedure for malfunctions. Follow steps and consult with

GameChange in case of maintenance issues.

12

12

31

3031

29

17

16

3031

18

35

1

2931

31

13

29

12

29

31

12

11

31

10

9

30

31

19

20

Customer:

Sample

Project:

Sample

Location:

Sample

1 SA 00-00-0000 Sample Layout

TOP TIP: Use vertical adjustability provided to make

Row Tubes level, and the site install look great.

GC Genius Tracker System

Use only GameChange parts. Use of other parts to complete the

installation as substitutes may void the warranty.

Make sure the ground structure is inspected and can support the loading

resulting from the GC Genius Tracker System and provided PV modules.

Follow all safety instructions that are required by relevant local, regional

and national organizations and procedures as outlined in the Install

Manual, both for mechanical and electrical aspects of the solar PV array

installation.

When encountering undocumented or unexpected obstacles requiring a

work around, they should be noted on working drawings and notified to

supervisor for evaluation. Work should then be completed in a manner that

ensures that the remainder of the array is not affected.

Customers are responsible for grade variations and making sure slope

tolerances support GameChange System. GC Genius Tracker System

ideally should be installed on flat, level and pre-compacted ground. This is

to avoid system settlement over time. Topsoil with loam content and

organics should be removed, and soil scraped down to subsoil level. If the

system is installed on new fill, the soil should be compacted with a

compacting roller prior to installation. However, due to vertical adjustability

of the Tubes on the Posts, the GC Genius Tracker System may be erected

on less than ideally prepared grounds when site conditions preclude

removal of topsoil. In that scenario, the Tubes should be adjusted to

appropriate heights on Posts during periods of operation and maintenance

visits.

Reference the Install Manual for detailed installation steps. Not following

the Install Manual may result in voiding warranty.

Material Storage

Make sure to install system within several days of receipt of components.

Storage of components in a damp or wet environment can lead to white

rust on galvanized parts as well as other damage on other protective

coatings which can lead to accelerated corrosion to components, and void

the warranty. Galvanization is especially prone to white rust when

components are still bundled because the zinc coating requires airflow

over its surface to establish its protective patina, otherwise water can

cause corrosion of the zinc and it has no protection against it in enclosed

spaces, such as those between parts that are bundled.

Tool Required

7/16”, 9/16", 3/4", and 1 1/8" Deep and Short Sockets

7/16”, 9/16", 3/4", and 1 1/8" Wrenches

Torque Wrench

Suggested finish torques : 1/4" hardware use 6 ft lbs

3/8" hardware use 35 ft lbs

1/2" hardware use 50 ft-lbs

3/4" hardware use 200 ft-lbs

String Line

Impact drill with interchangeable drivers

Must use anti-seize such as LocTite for bolts used to mount modules (most

bolts come pre-dip with anti-seize)

Tape Measure

48 inch long level

Assembly jigs for Driving Arm and Actuator Assemblies are optional

Preventative Maintenance

After Installation, installer must annually monitor for any surface rust that

may occur over time. Identify any rust areas, wire brush area to remove

rust, and coat area with 70%+ zinc rich or equivalent field life paint. This

step is not required if rust is limited to edges which were cut during

fabrication.

Clips must be checked annually and after storms with severe winds to

make sure their installation and torque settings remain correct.

Following extreme wind turbulences (in excess of 80% of designed wind

speed) and annually, inspections are required. Bolted joints and joints that

mechanically move shall be inspected for any loosened hardware or

component damage. Any impedance to mechanical movement must be

rectified.

Torque settings must be checked for all hardware.

All Clips must be checked to make sure there is no gap between side of

Clip and module.

Proper preventative maintenance must be conducted or warranty may be

voided. The Install Manual provides required maintenance steps and

diagnostic procedure for malfunctions. Follow steps and consult with

GameChange in case of maintenance issues.

GAMECHANGE SOLAR

730 Fifth Avenue, 16th Floor

New York, NY 10019

Tel:212-388-5160

www.gamechangesolar.com

Issue: By: Date: Description:

Sheet #:

9 of 9

DETAIL

SHEET

17) Install Controller to the south of the Center Post using Enclosure

Brackets, U bolts, and Purlin Angles. The side of the Enclosure

with wires shall be pointing towards the Center Post. Connect MC4

connectors from the Enclosure to the PV module, but DO NOT

connect the wiring to the Actuator until the Master Controller is

set up.

18) Install Jumper Straps at the following location types:

a) Bearing Assembly (TEK screw) to nearby Purlin Angle (3/8"

flange nut)

b) Center Post (1/4" bolt & flange nut) to Squeeze Plate (3/8"

flange nut)

19) Install PV modules onto Purlins using hex bolts and nuts, spacing

Purlins appropriately. Of the 4 bolts used to mount each PV

module, 1 must include a star washer on the inside of the module

frame to bond the module to the system. Torque modules and

Purlin U bolts to specification.

20) Ground out system via commerically available grounding lug and 8 gauge copper wire from any Post The system is

rated to be able to ground out up to 25 A. Install appropriate number of ground points for the site.

21) Install Pole to mount the Master Controller and associated components just to the north of the arrays as not to cast

shading. The order of components to be installed on the Pole starting from the top are: Anemometer, small PV

module, and Master Controller. Use Pole Angles and Mounting Brackets with U bolts to mount all components.

1415

1131

10

36

36

9

313330

9

31

30

20

24

27

26

25

21

22

28

23

31

26 23 31

23

31

2331

Customer:

Sample

Project:

Sample

Location:

Sample

1 SA 00-00-0000 Sample Layout