Row Crop Harvest Logistics for Single Harvester/Grain Cart ...

Transcript of Row Crop Harvest Logistics for Single Harvester/Grain Cart ...

Row Crop Harvest Logistics for Single Harvester/Grain Cart Operations

John Evans, MSPh.D. Candidate

Joe Luck, Associate Professor Santosh Pitla, Assistant Professor

Department of Biological Systems Engineering University of Nebraska Lincoln

1

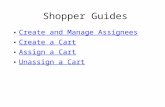

• Project Motivation • Objectives • Harvester Modeling • Grain Cart Modeling• Decision Support Tool

2

Outline

Shrinking Profit Margins§ Cost of equipment ↑§ Cost of inputs ↑§ Commodity prices ↓

Higher in-field efficiency is needed to reduce cost and increase productivity § Equipment selection § Time and compaction reduction

3

Project Motivation

Create a practical and feasible harvest logistics model with decision support tools for single harvester, single grain cart operations. • User Inputs

§ Yield Monitor Data § Machine Capacities

- Harvester- Grain Cart

• Outputs§ Optimized Paths

- Productivity- Bottlenecks- Economics

4

Project Objective/ Scope

5

Harvester Logistics Modeling

6

ObjectiveDevelop a mathematical model of single harvester operation in headland field patterns capable of the following:1.Minimizing the non-working in-field travel of the harvester in

irregular shaped fields.2.Producing solution that allows for unloading on the go. 3.Calculate the possible reduction in non-working travel compared to

actual harvest data.

7

Project Objective/ Scope

OptimizationAlgorithm

PassesThatTheHarvesterMustComplete OptimalRouteMinimizingTime

1 2 4 5 3 7 6 8 11 9 10 14 15 13 12 16 17 18 19 20↓↑↑↓ ↓↓↑↑↓↓↑↑↓↓↑↑↓↑ ↓ ↑

General Models • Bochtis, D. D., & Vougioukas, S. G. (2008). Minimizing the non-working distance travelled by

machines operating in a headland field pattern. Biosystems Engineering, 101(1), 1–12. https://doi.org/10.1016/j.biosystemseng.2008.06.008

• Oksanen, T., & Visala, A. (2009). Coverage path planning algorithms for agricultural field machines. Journal of Field Robotics, 26(8), 651–668. https://doi.org/10.1002/rob.20300

Harvest Modeling• Hansen, A. C., Zhang, Q., & Wilcox, T. A. (2007). Modeling and analysis of row crop

harvesting patterns by combines. Transactions of the ASABE, 50(1), 5–12.

• Ali, O., Verlinden, B., & Van Oudheusden, D. (2009). Infield logistics planning for crop-harvesting operations. Engineering Optimization, 41(2), 183–197. https://doi.org/10.1080/03052150802406540

8

Past Work

Need spatial data to validate and compare against harvest optimization model.• Desired Data:

§ Spatial Machine Data - Engine Speed - Fuel Usage - Unload Auger Status

§ Spatial Agronomic Data- Yield

~ 3600 acres of data collected from two producers

9

Harvester Data Collection

• Loop

For w < 2r, theta is given by: 𝜃 = cos'( )*+

𝐿𝑜𝑜𝑝𝑇𝑢𝑟𝑛𝑑𝑖𝑠𝑡𝑎𝑛𝑐𝑒 = 𝜋 ∗ 𝑟 ∗ (𝜃 + 90)

90 + ∆𝑦

• U-Turn

𝑈_𝑇𝑢𝑟𝑛𝐷𝑖𝑠𝑡𝑎𝑛𝑐𝑒 = F𝑑GH

�

G∈H

+ ∆𝑟𝑖 + ∆𝑟𝑗

10

Turning Distance Calculation

• Plotted actual vs. predicted of every turn in real field path

• Predicted was almost always less than actual because predicted is perfect turn at tightest turning radius.

11

Turning Distance Verification

Min ∑Harvester_Non-Working_Distance

With respect to:

1) Unload Auger Position2) Unloading Rate 3) Bin Capacity

12

Optimization Equation

Genetic Algorithm§ Generate Random Population (Set of Paths)

- Paths were created from permutation of passes- Direction of passes was based on order from first

pass§ Calculate Route Length

- Check constraints - add penalty if necessary - Distance between passes was calculated and

summed§ Selection of Best Routes

- Top 10% of shortest paths are selected as “parents” and are crossed and mutated to generate a new population of “children”

§ Settings - Elitist Selection - Population (group of paths) size = 600- Max iterations = 100

13

Optimization Method

Passes

Path

14

ResultsActual vs. Optimized • Irregular shaped fields*• Harvest unload

consideration • 29.1% average

reduction of non-working travel

Field Crop Area (m2)[ac]

Actual Path Order w/ Modeled Turns

Optimized Route Distance (m)

% Non-Working Travel Reduced

EFE Soybeans 22070 [54.53] 2705 1880 30.50

R Soybeans 35360 [87.38] 3019 2067 31.53

H Corn 3349 [8.27] 1317 984 25.28

* Continuous AB passes required

15

Grain Cart Modeling

Calculate cycle time of the grain cart § Account for cart unloading § Avoid obstacles (unharvested crop, fence lines, etc..)

Inputs: § Harvester path§ Harvester unloading points§ Cart unloading location§ Speed

- Loaded - Unload

Outputs:§ # of harvester waiting events§ Total harvester waiting time § Total grain cart travel distance

16

Grain Cart Model Objective

Need grain cart data to determine if it is a limiting factor• Desired Data: Spatial Machine Data and Bin Level (Grain

Mass)• Gap in current data collection methods:

§ Scale data is separate from machine data. § Scale data is usually only recorded when off loading to truck. § Machine data not usually recorded at all. § GPS is not available because units are often shared between tractor and

combine.

17

Grain Cart Data Collection

18

Grain Cart Data Collection• Initial Solution

§ Publish Scale Data on CAN Bus- Instrumentation Amplifier - CAN Node

§ CAN Data Logger w/ GPSSCALE DISPLAY

INSTRUMENTATIONAMPLIFIER

CAN NODE

J1939 CAN LOGGER

POWERCONTROL

TRACTOR DATASIMULATOR

(TESTING ONLY)

TEST LOAD CELL

Bench Test Spatial Variation of Grain Cart Weight

LegendGrain_CartWieght__lb

< 15550

15499 - 32800

32799 - 48500

48501 - 61800

> 61800

Unloading Location

Weight lbs.

19

Boundary Generation

Coverage map using polygons Binary representation

Binary Mask Legend▪ RestrictedTravel▪ UnrestrictedTravel−CartPath

Legend▪ HarvesterCoverage○ HarvesterUnload− Boundary

20

Grain Cart

Binary Mask Legend▪ RestrictedTravel▪ UnrestrictedTravel−CartPath

21

Grain Cart Simulation

Binary Image

22

Grain Cart Simulation

80536 Meters (~50 Miles) of Cart Travel

Actual Grain Cart Travel Data

Legend− HarvesterUnloadPath−ActualCartPath

Simulated Grain Cart Travel Data

54305 Meters (~34 Miles) of Cart Travel

Legend− HarvesterUnloadPath−ActualCartPath

23

Grain Cart Model Example Output

§ # of harvester waiting events = 2§ Total harvester waiting time = 4.56 min § Total grain cart travel distance = 51.0km

24

Decision Support Tool

Tool capable of identifying/calculating: • Bottlenecks • In-field travel • Cost per bushelVarying:

§ Header width § Bin capacities

- Harvester - Grain cart

§ Unloading rate - Harvester - Grain cart

§ Economic factors

25

Objective

Purpose:Define the passes the harvester needs to complete based on:

- Header width- AB pass orientation

26

Pass Generation

• Split passes§ Distance § Heading§ Swath width

• Find straight passes§ STD of heading

• Find AB pass§ Fuzzy subtractive clustering

27

Pass Generation

- AB PASS

- HEADLAND

• Find baseline pass using boundary, AB pass heading, and new header width

• Offset new lines • Interpolate yield to new

points on 1hz interval

28

Pass Generation (Header Width Change)

AB Baseline

Start Simulation

29

Decision Support Tool GUI

Data Import

Economic Values

Grain Cart Parameters

Harvester Parameters

30

Decision Support Tool Results

Harvester 1 2HeaderWidth(ft) 40 40

Area(ac) 43.06 43.06Distance(mi) 9.06 9.06

Productivity(ac/h) 23.78 20.45Efficiency 0.9 0.9Fuel($/ac) 2.7 3.4

TotalCost($/ac) 13.26 19.52TotalCost($/bu) 0.31 0.45

GrainCart 1 2Binsize 1282 880

#ofwaitevents 1 5

CumulativeWaitTime(min) 2.43 13.65

• Harvest Logistics Model§ Real field data § Irregular shape fields* § Optimized path

• Grain Cart Model § Calculate

- Cycle time- Total distance

§ Identify - Limitations- Current Efficiency

• Decision Support Tool§ Economics of equipment sizing

31

Project Outcomes

CLAAS OmahaMaury Salz

University of Nebraska LincolnDr. Santosh Pitla

Dr. Joe Luck

32

Special Thanks

33

Thank You

34

Grain Harvest Logistics Modeling

• Loop

For w < 2r, theta is given by: 𝜃 = cos'( )*+

𝐿𝑜𝑜𝑝𝑇𝑢𝑟𝑛𝑑𝑖𝑠𝑡𝑎𝑛𝑐𝑒 = 𝜋 ∗ 𝑟 ∗ (𝜃 + 90)

90 + ∆𝑦

35

Turns

36

Pass Generation from Planter Path Files

• U-Turn

𝑈_𝑇𝑢𝑟𝑛𝐷𝑖𝑠𝑡𝑎𝑛𝑐𝑒 = F𝑑GH

�

G∈H

+ ∆𝑟𝑖 + ∆𝑟𝑗

37

Turns

38

Simulation

Min ∑Harvester_Operation_Time

With respect to:

1) Unload Auger Position2) Bin Capacity 3) Boundaries4) Grain Cart Cycle Time

39

Optimization Equation

1 2 4 5 3 7 6 8 11 9 10 14 15 13 12 16 17 18 19 20↓↑↑↓ ↓↓↑↑↓↓↑↑↓↓↑↑↓↑ ↓ ↑

40

Project Objective/ Scope

1 2 4 5 3 7 6 8 11 9 10 14 15 13 12 16 17 18 19 20↓↑↑↓ ↓↓↑↑↓↓↑↑↓↓↑↑↓↑ ↓ ↑

Scenario Analysis§Change Machine Parameters§Re-run Harvest Simulation §Compare

- Time to Complete- Field Efficiency - Limiting Factors