Rotating Cylinder Valve Engine Patented Project

Transcript of Rotating Cylinder Valve Engine Patented Project

K.S.RANGASAMY COLLEGE OF TECHNOLOGY

TIRUCHENGODE – 637 215

Department of

MECHANICAL ENGINEERING

Paper presented on

ROTATING CYLINDER VALVE ENGINE

A PATENT FILED PROJECT

Submitted by

V.LAKSHMANA SAMY

D.SRIRAM

Final Year

Contact: +91 9894024405, 9751254244

E-Mail ID: [email protected]

ABSTRACT

In present day global environment four stroke spark ignition engine are widely

used in automotives and aircraft application etc, over the last one century engines

continued to develop as our knowledge of engine processes has increased. In existing

competitive automotive scenario, the demand for high performance engine has grown.

So the recent research of development in automotive field gives emphasis to improve

thee efficiency and engine performance.

In order to meet the existing demand to increase the efficiency of the existing

engine, a modification of the valve system in existing engine is done. This paper

reviews the performance of the modified engine, termed as RCV engine

(ROTATING CYLINDER VALVE ENGINE) with the existing engine. The

numerical computer simulation done with RCV engine, shown considerable increase

in efficiency and performance of engine compared with the existing engine.

A Prototype 125 cc RCV Engine

CONTENTS

INTRODUCTION

HOW THE RCV ENGINE CONCEPT WORKS

PREMIUM PERFORMANCE AT LOW MANUFACTURING

COST

RCV OFFERS BETTER VOLUMETRIC EFFICIENCY

CYLINDER DRIVE SYSTEM

VALVE SEALING – A FUNDAMENTAL CHALLENGE

SOLVED

REDUCED EMISSIONS

ADVANTAGES

CONCLUSION

REFERENCE

INTRODUCTION

The ability of a reciprocating internal combustion engine to empty and fill its

cylinder efficiency is fundamental to its successful operation. The intake and the

exhaust operation of the engine with respect to the movement of the piston is done by

using valve systems. The valve train system consists of the valves and the mechanism

that opens and closes them. The opening and closing system is called as cam shaft.

The cam shaft has lobes on it that moves the valve up and down. Most modern

engines have what are called over head cams. This means that cam shaft is located

above the valves. The cams on the shaft activate the valves directly or through a very

short linkage. Older engines used camshaft located in the sump near the crankshaft.

Rods linked the cam below to valve lifters above the valve as shown in fig below.

The RCV engine shares the same induction, compression, power and

exhaust strokes as found in conventional four stroke engine, but its principle different

lies in the manner in which intake air exhaust gases are respectively induced into

expelled from the cylinder. True to its name RCV engine mounts its cylinder on

bearings and the entire system is geared to rotate at half crankshaft speed.

HOW THE RCV ENGINE CONCEPT WORKS:

While most of the components of the RCV engine are identical to those of

conventional four stroke engine, the principal difference lies in the cylinder. This

mounted on bearings and rotates exactly half of the crankshaft rotation speed and is

driven from the crankshaft either via a gear train or toothed belt drive system similar

to those used on other automotive engines. A single large cross-sectional area port

and combustion chamber is combined with in cylinder, the entrance to which forms

the rotating cylindrical valve together with the openings of the intake and exhaust

ports.

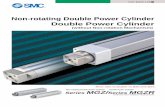

A CUTWAY OF THE NEW 125cc SCOOTER ENGINE DEVELOPED FOR MPI -

NOTE THE ADVANCED FACE GEAR DRIVE SYSTEM

The RCV 4-cycle engine has only one more moving component than a 2-cycle

engine –the rotating cylinder itself. The cylinder is suspended between two bearings

which allow it to rotate freely around the piston; the piston, and crank are entirely

conventional.

A gear formed around the base of the cylinder meshes with a 2:1 reduction

gear on the crank. As the piston reciprocates and the crank turns, the cylinder rotates

around the piston at half engine speed.

At the top rotating cylinder there is a single port leading to the combustion

chamber. This is surrounded by a fixed timing ring with three radically arranged

ports; inlet, ignition and exhaust. This simple valve arrangement serves the

combustion chamber as the engine cycles through the conventional 4-cycles:

induction, compression, power and exhaust. Ignition is achieved through a standard 4-

cycle glow plug exposed once only during each complete cycle.

A rotating cylinder is efficiency combined with the rotary valve in a single

component. A shaft attached to the cylinder rotates at half engine speed producing

high torque and facilitating use of larger and quieter scale propellers.

The four stroke of the RCV engine and how the rotating valve reacts to the

each stroke are explained above in the fig.

FOUR STROKES OF A RCV ENGINE

In RCV engine, the induction stroke entirely different from the normal

ordinary four stroke engine. With in the spinning cylinder lies a cavity on the same

plane as an inlet and exhaust port placed at scientific intervals on the cylinder’ path of

rotation. Air fuel mix is induced when the inlet port coincides (induction stroke) and

waste gases exit the cylinder when the exhaust port matches (exhaust stroke). During

compression and combustion strokes, the cylinder remains sealed. The rotating valve

inside the cylinder completes the full revolution per each cycle. The inlet and outlet

ports in the cylinder are should be in right angle.

PREMIUM PERFORMANCE AT LOW MANUFACTURING COST

The RCV engine concept has been shown to offer the potential for both high

performance and fuel economy, as well as for low emissions. While these are

attractive attributes for prospective customers of products powered by RCV engines,

it is important for manufacturers that these benefits can be delivered by a cost-

effective manner. The results of the detailed study carried out by RCV engines ltd

based upon manufacturing data provided by MPI, show that the projected

performance/cost trade-off of a similarly sized RCV engine is significantly better than

that of a range of existing successful products.

Based on this analysis there is a clear, near-linear relationship between

performance and manufacturing cost for the existing production engines. However,

the projected performance/cost trade-off of a similarly sized RCV engine is

significantly betters then this trend.

The analysis shows that it is of similar manufacturing cost to that of a

conventional single over head cam shaft, two-valve per cylinder air-cooled engine.

Crucially however, the RCV engine delivers more than 20% additional specific

power. Products powered by RCV engines are thus likely to have market appeal with

the ability to deliver premium power compared to competitor engines of similar

capacity and production cost.

RCV OFFERS BETTER VOLUMETRIC EFFICIENCY:

The RCV engine concept has a number of inherent advantages compared with

a conventional two or four-valve cylinder four-stroke engine. Firstly in terms of

combustion, an RCV engine’s configuration enables a much larger port cross-

sectional area than is practicable in port valve engine, which has the effect of

significantly improving its volumetric efficiency. The design of the port and

combustion chamber - including the large squish area at the piston crown – also

generates a very high level of intake air turbulence which is conducive to efficient

combustion. These advantages provide improvements in performance across the

speed range; in effect combining the positive attributes typically associated with two-

valve per cylinder four stroke combustion at low engine speed, with those of a four

valve per cylinder four-stroke combustion at low engine speed, with those of a four

valve per cylinder design at high speed.

Secondly the rotating cylinder valve and its seal, which rotate at half

crankshaft speed, are extremely dynamically stable. With adverse valve train

dynamics typically limiting factor for the maximum operating speed of four stroke

engines, it offers reliable and durable operation at which higher speeds than might be

the case for an equivalently sized conventional engine.

The combination effect of these advantages enables RCV engines to consistently

deliver performance in excess of (100PS/litre).

COMPARISON OF POWER OUTPUTS FOR THE RCV VERSUS A STANDARD

SOHC FOUR-STROKE ENGINE, BOTH 125cc

The stable and efficient combustion system of an RCV engine, combined with

the elimination of loses normally associated with operation of the valve train provides

the potential for improved fuel consumption in addition to superior performance.

Naturally, the balance of these benefits in a given product will be optimized in

accordance with each manufactures marketing strategy. Some for example may use

the advantage of RVC technology to enable aggressive down sizing in order to

deliver equivalent power and performance from a smaller capacity and more fuel

efficiency engine .Others however, may favour its use to deliver premium

performance characteristics over and above those of existing products.

CYLINDER DRIVE SYSTEM.

While the RCV engine does not require a valve train, a gear or toothed belt

drive system in needed in order to rotate a cylinder and cylinder valve exactly half

crankshaft rotational speed. The cylinder is driven via an advanced face gear drive

similar to those found in many helicopter and machine tool applications. The system

uses a three dimensional gear tooth profile which enables the drive to be transferred

through a 90 degree contact with the cylinder.

DETAIL OF THE ADVANCED FACE GEAR DRIVE USED IN THE NEW

125cc RCV PROTOTYPE ENGINE

With the ability to include counter balance weight with in the idler gear, this

arrangement offers exceptionally high standards of vibration refinement, facilitating

improved handling and driver comfort in scooter and ATV applications. With the use

of sintered gear blanks, it also offers a considerable production cost advantage over

alternatives such as bevel gear drives. Additionally, the face gear drive affords much

greater tolerance to the high levels of component thermal expansion typically found

with engine components.

VALVE SEALING –A FUNDAMENTAL CHALLENGE SOLVED

While many previous sleeve and rotary valve engines delivered benefits in

terms of breathing and performance, a common and fundamental problem was that of

effective valve sealing. Typically, close tolerance were relied upon in order to archive

sealing during engine operation. Such engines were hence both relatively expensive

to manufacturer and required lengthy and controlled engine warm-up procedures to

avoid seizure. With thermal expansion of the cylinder and reciprocating components

typically two orders of magnitude greater than the tolerances required for sealing, the

need for an effective, robust and low cost means of valve sealing was a fundamental

challenge which prevented more widespread and practical application of such

engines.

THE RCV CYLINDER VALVE SEALING SYSTEM

With the patented technology RCV engines ltd has solved this challenge through

highly innovative and yet fundamentally very simple cylinder valve sealing system

which employees essentially the essentially the same basic principle as used in piston

rings.

In order accommodate the thermal expansion typical of engine operation the

valve has an active SPRUNG SEALING MECHANISM.

This is augmented by a static seal which closes the gas path around

back of the sliding seal.

The sealing mechanism is designed such that combustion pressure

augments and hence reinforces the seal.

In addition to above, a means is required to maintain intake air

pressure stability and prevent the entrainment of lubricating oil within

the inlet and exhaust gases.

A secondary inlet and exhaust port sealing element is provided to act

as a gas seal while ports are closed.

Like a conventional piston ring pack, the RCV cylinder valve sealing

system is as simple in its design as it is effective in its operation. The

seal mechanism contains just four low cost components which together

enable the performance and emission benefits of an CV engine to be

delivered in a practical to manufacture, robust and cost-effective

design

REDUCED EMISSIONS

The stability and efficiency of combustion system also lends itself to naturally

low engine out emissions these benefits are likely to greatest when an RCV four

stroke is used in substitution for a piston ported two stroke engine, given the latter’s

much higher hydrocarbons and CO2 emissions. The physically compact and high

revving nature of RCV technology offers emissions performance of well engineered

four strokes while retaining some of the practical advantages typical of a small two

stroke. As such RCV technology is an ideal four stroke choice substitution of crank

case scavenged two strokes for application such as scooters and hand held forest and

garden equipment.

ADVANTAGES:

Shorter physical size

Excellent fit and finish to all parts

Great four stroke sound

Easy to setup and adjust

Fuel economy

Less parts =less maintenance (no valve train)

Excellence performance-great torque

CONCLUSION:

The RCV line of engine is amazing. Not only from a design

view point but also from the point of functionality, it is very easy set up and

adjusts, it performing flawlessly.

Comparing it to the other normally aspirated four strokes

we’ve flown, RCV 0.91s power is right up there: lots of torque and very

smooth.

One of the remarks we had from the engine sounded as if it had

a bit “snappier response” than most four strokes.

REFERENCE:

Gizmag article

English Tools & Die Castings Ltd