Roots Blower Operating Manual

Transcript of Roots Blower Operating Manual

-

8/10/2019 Roots Blower Operating Manual

1/15

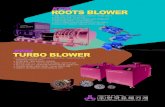

Three Lobes Roots Blower

Instruction Manual

Welcome to purchase the three lobes roots blower produced by us. You shall read this

instruction manual seriously before you use this product in order to ensure a long-time,

safe and highly efficient application.

Greentech International (Zhangqiu) Co., Ltd.

Address: Mingshui, Zhangqiu City, Shandong Province, China

Tel: 86-531-83117088

Email: [email protected]

http://www.china-blower.com

-

8/10/2019 Roots Blower Operating Manual

2/15

1

Operation Principle of the Three Lobes Roots Blower

The operation principle of the three lobes roots blower: the engine drives the blower

with narrow v-belt to discharge the air fed at the inlet port out of the air outlet through

rotary pressure boost of the three- lobe type impeller.

Installation Requirements of the Blower:

1. The foundation shall be solid with flat surface 10cm higher than the ground.

2. Sufficient room shall be arranged around the blower to satisfy the requirement for

overhaul and dismounting.

3.

The ambient temperature for the blower operation shall be within 40. If the

temperature is beyond that limit, certain measures shall be taken to reduce the

temperature; otherwise, the service life of the blower will be curtailed.

4.

Rain proof shed shall be set if the blower is mounted outside.

5.

The rated pressure boost value specified on the nameplate shall not be exceeded to

prevent the engine from over burning.

Requirements on the Pipeline

1.

The blower pipeline shall be connected tightly without air leakage and the support

shall be set at appropriate location.

2. The pipeline material can sustain exhaust temperature and pressure. (try to adopt

steel pipes)

3. The pipeline inside shall be clean and without foreign substance; certain measures

shall be taken to stop the foreign substance from coming into the pipeline.

4. Check valve shall be installed on the pipeline to stop the back flow created by the

blower reversion from entering into the blower.

Attention: the check valve shall be installed on the horizontal pipeline.

5. In the situation of parallel operation of many blowers, brake valves must be

mounted respectively on each branch pipeline (as one blower needs examine and

repair, the corresponding pipeline can be cut off).

6. Drain cock shall be mounted on the pipeline to prevent the blower from loaded

start-up; the drain cock shall not be shut down until the blower starts with no load,

and then the loaded operation of the blower begins.

-

8/10/2019 Roots Blower Operating Manual

3/15

2

7. As to the blower with water cooling system, regulation valve shall be equipped in

front of the cooling water inlet.

Notices Before the Start-up of the Blower

1.

Check whether the grounding bolts are connected tightly.

2. Wipe out foreign substance such as welding slag in the pipeline interior.

3.

Completely open the valve, otherwise, the blower will be damaged due to its

over-loaded operation.

4. Fill gear oil. As the blower leaves the factory, there is no gear oil in its oil tank, so

you shall fill it yourself. In stoppage situation, it is suitable to add the oil to the

center level of the oil window as more will cause oil leakage.

5. Fill grease lubricant with oil gun until the grease overflows out of the spill hole on

the gland (the blower has been filled with grease lubricant before delivery).

6.

Check the tightness degree of the narrow v-belt and the location of the pulley. The

location of the pulley can be regulated with ruler and the tightness degree of the

v-belt can be adjusted according to the following graph. The belt is loosened over

a period of usage when the readjustment is in demand.

Type of the Blower W (kg) & (mm)

50H 1~2 4

65H 1~1.7 4.5

80H 1.5~2.5 4.5

100H 2~3 5.5

125H 1.5~3 6.5

150H 3.5~5 7

175H 3.5~5 7

200H 4~5.5 8

250H 4~5.5 8

300H 4~5.5 8

7. Check whether the voltage and frequency of the power supply is in accordance

with the requirement of the rating plate.

8.

Check the rotation direction of the pulley in the face of it, finding that it rotates in

-

8/10/2019 Roots Blower Operating Manual

4/15

3

a counterclockwise direction.

9. Rotate the pulley by hand to make sure there is no abnormal phenomenon before

the blower start-up.

10.Open the cooling water switch before the blower start-up; at the time of stoppage,

turn down the blower before cutting off the water.

Operation Description

1. At the initial stage of operation, because of the sticky grease lubricant, there may

be such phenomenon as noise and over high current that can disappear after ten to

twenty minutes operation.

2.

The regulation of air flow rate can be carried out by changing the rotation speed of

the blower or the number of the flooding pipeline.

3. The blower shall work under the pressure rated by the nameplate. The switch of

the pressure meter shall be placed at the off position during the operation of the

blower. The switch can not be opened unless there is need of testing the pressure

and shall be closed immediately after the estimation.

4. There is even noise difference between the blowers of the same type. This can be

caused by the different location and piping of the blower in mechanical room.

5. Inspect whether the filter core of the inlet muffler is blocked during blower

application. The blockage may increase the motor

power and even damage the motor, hence prompt

cleaning is in demand.

6. As the boost pressure of the blower is higher than 58.8kpa, the user is advised to

install the water cooling system with cooling water 25, pressure 196-

294kpa, flow rate 8-13L/min. The blower with cooling system shares the same

appearance with the ordinary blower. The only difference is that the main and

auxiliary tanks are installed with water inlet and outlet interfaces which can be

connected the inlet and outlet water as required.

-

8/10/2019 Roots Blower Operating Manual

5/15

4

Routine Maintenance and Overhaul of the Blower

Item for

Maintenance

Overhaul

Overhaul Period

Remarks

Day to Day 3 Months 1 Year 34 Years

Pressure Below the Value

on the Nameplate

Flow Rate Within 10% of the

Nameplate Value

Noise No Abnormal

Noise

Vibration No Abnormal

Vibration

Inlet

Temperature

Below 40

Current Below the Motor

Nameplate Value

Voltage Within 10% of the

Motor Nameplate

Value

Tension of Belt

Location of

Pulley

Gear Oil

Capacity

To the Center

Position of Oil

Gauge

Sweep Air

Cleaner

Inspect Gear

Oil

Supplement or

Change

Inspect

Bearing Grease

Lubricant

Fill Once Every

Other Week and

Change Once

Every Three

MonthsChange V-belt

Change Filter

Core

Clean Once a

Month

Change

Bearing

Change Gasket

Oil Seal

Inspect and

Change Gear

Attentions: In the initial stage of operation, the gear oil must be renewed after one

-

8/10/2019 Roots Blower Operating Manual

6/15

5

month of application.

Gear Oil: N220 L-CKC

Kinematical Viscosity mm2/s (40): 198 242

Flashing Point (no less than): 200

Gear oil quantity table

Model Oil box Oil quantity Each blower

50H/65HGear end oil box 0.4L

0.7LDrive end oil box 0.3L

80H/100HGear end oil box 0.5L

0.85LDrive end oil box 0.35L

125HGear end oil box 0.8L

1.3LDrive end oil box 0.5L

Instruction of the Safety Valve

1. Notices for Application

Given that the safety valve shall work under low pressure, the interface between the

valve seat and valve body has gone through precision finishing. If there is foreignsubstance sticking around the valve seat, it will be attracted on the interface as the

valve body moves to lead to valve body leakage. In addition, please concern that

whether the safety valve suffers strike during the process of transportation which may

be another reason for valve body leakage.

2. Setting Method of the Safety Valve

Principle: the safety valve opens as the load surpasses its setting pressure so as to

avoid the blower failure.

Setting Method:

Start the blower.

Tighten the brake valve while watching the pressure gauge to make the

pressure exceed the setting pressure by about 10%.

Loosen the lock nut and revolve the regulation screw in a counterclockwise

direction until air is discharged out of the safety valve.

-

8/10/2019 Roots Blower Operating Manual

7/15

6

In the process of

tightening the brake

valve, if the safety

valve has discharged

air before the

pressure reaches the

setting value, please

revolve the

regulation screw

again in a clockwise direction to the position that the air can not be exhausted,

and then revolve it again in an opposite direction until the air is right

exhausted. (Clockwise rotation makes the setting pressure higher;

counterclockwise rotation makes the setting pressure lower).

Tighten the lock nut and regulation screw.

Loosen the brake valve to reduce pressure so that the safety valve does not

discharge air any more.

Inspect whether the safety valve operates under the setting pressure and

tighten the brake valve again to raise pressure.

Attention: actually as there is load on the exhaust side (water in aerator tank

reaches the fixed level), if the brake valve opens completely, the setting pressure

will be around10% higher than the practical load.

6

5

4

3

2

1

-

8/10/2019 Roots Blower Operating Manual

8/15

7

Reference Drawing of the Blower Piping

Attention: the check valve must be mounted on the horizontal pipeline and can

open and close normally.

-

8/10/2019 Roots Blower Operating Manual

9/15

8

Exterior Dimensional Drawing of the Drive Type V-belt

Unit: mm

Sign

Type

Caliber A B C D E F G H J K

50H 50A 250 150 120 895 185 179 560 410 100 -

65H 65A 250 150 130 970 205 202 650 450 100 -

80H 80A 290 180 145 1130 220 225 700 500 100 -

100H 100A 290 180 155 1255 260 265 780 580 100 -

125H 125A 345 195 190 1515 295 294 860 700 110 -

150H 150A 385 220 210 1730 375 377 1060 750 160 -

175H 175A 490 275 230 2163 470 412 1250 750 230 -

200H 200A 593 378 256 2210 525 550 1400 1000 180 500

250H 250A 760 400 425 2785 668 590 1900 1490 210 745

300H 300A 760 400 430 2820 756 677 1900 1490 210 745

Sign

Type

Caliber L M N O P Q n R S Weight

(kg)

50H 50A - 300 115 155 15 80 4 450 730 70

65H 65A - 340 135 175 15 80 4 500 780 81

80H 80A - 360 130 200 15 80 4 530 860 123

-

8/10/2019 Roots Blower Operating Manual

10/15

9

100H 100A - 470 170 270 15 80 4 600 930 157

125H 125A - 470 185 255 15 100 4 710 1230 235

150H 150A - 590 255 295 20 100 4 860 1335 394

175H 175A - 650 286 316 22 100 4 887 1600 695

200H 200A 500 755 360 345 25 120 6 1080 1765 900

250H 250A 745 950 390 500 30 160 6-26 1258 2400 1758

300H 300A 745 950 510 380 30 160 6-26 1433 2400 2256

Attention: The weight of motor is excluded.

Users can ask the company for the electronic CAD of the exterior dimension

according to the type of the order.

Exterior Dimension Drawing of the Direct-coupled Blower

Unit: mm

Sign

Type

Caliber A B C D E F G H J

50H 50A 570 179 135 895 152 230 540 420 60

65H 65A 610 202 145 970 192 230 600 440 80

80H 80A 700 225 165 1130 217 280 650 500 75

100H 100A 900 265 175 1255 234 280 850 630 110

125H 125A 945 294 205 1525 260 345 920 710 105

150H 150A 1155 377 225 1745 305 385 1150 950 100

175H 200A 1570 550 276 2230 405 593 1600 1300 150

-

8/10/2019 Roots Blower Operating Manual

11/15

10

200H 250A 1847 596 445 2570 520 680 2200 1800 200

250H 300A 2167 683 470 2820 520 670 2500 2000 250

Sign

Type

Caliber K L M N O P Q R n-1 Weight

(kg)

50H 50A -- -- 260 220 122 20 80 60 4 72

65H 65A -- -- 300 260 122 20 80 80 4 84

80H 80A -- -- 370 330 147 20 80 75 4 132

100H 100A -- -- 400 360 114 20 80 110 4 168

125H 125A 355 355 430 390 175 20 100 105 4 245

150H 150A 475 475 500 455 190 22.5 100 165 4 408

175H 200A 650 650 650 605 348 22.5 120 240 6 900

200H 250A 900 900 1020 950 250 40 200 250 6-26 1708

250H 300A 1000 1000 1020 950 240 40 200 270 6-26 2198

Attention: The weight of motor is excluded.

Users can ask the company for the electronic CAD of the exterior dimension

according to the type of the order.

-

8/10/2019 Roots Blower Operating Manual

12/15

11

Problem Shooting

Fault Cause Measure

Blower

Not

rotate

Can be reversed by

hand.

The motor is damaged. Repair or change the motor.

Can not be rotated

by hand.

The rotor is blocked. Take it apart to repair.

There is foreign substance inside. Take it apart to repair.

Rotate

Abnormal Noise or

Vibration

Be slippery and the v-belt is over

tight or loose.

Regulate the tension of the belt.

The pulley is not in right position. Resume the pulley to right

position.

There is friction between pulley

and belt cover.

Regulate the belt cover to right

position.

The bearing oil is inadequate or

aged.

Renew the oil.

The gear oil is inadequate or

aged.

Renew the oil.

The safety valve is leaking air. Regulate the safety valve.

Insufficient Foundation Strength Strengthen the foundation.

Pipeline Resonance Remove it with muffler and

support and so on.

Exhaust pressure goes up

abnormally.

Refer to theexplanation.

The grounding bolt is too loose. Tighten it.

Rotor Interruption Take it apart to repair.

There is foreign substance in the

case.

Take it apart to repair.

Check valve is damaged. Change a new one.

Over Heat

The exhaust pressure goes up

suddenly.

Refer to the explanation.

The temperature in the blower

room goes up (over 40)

Increase ventilation.

The suction muffler is blocked. Clean/ change the filter.

Insufficient Flow

Rate

Pipeline Leakage Tighten the joint.

The suction muffler is blocked. Clean/ change the filter.

The safety valve is leaking air. Regulate the safety valve.

The belt is slippery. Regulate the tension of the belt.

-

8/10/2019 Roots Blower Operating Manual

13/15

12

The exhaust pressure goes up

suddenly.

Refer to the explanation.

Exhaust pressure

goes up suddenly.

The valve is closed. Fully open the valve.

The water level increases. Regulate the water level.

The inlet pipe is blocked. Wipe out the foreign substance.

The pipeline is blocked. Wipe out the foreign substance.

The valve is broken or revolved

in the wrong direction.

Change or revolve it in the

opposite direction.

The airflow is over strong. Reduce the rotation speed or air

exhaust.

Oil Leakage There is too much gear oil. Fill the oil to the center of the oil

gauge (stalling).

Motor

Note

rotate

Can be reversed by

hand.

Improper Switch or Circuit

Connection

Connect or repair it correctly.

The fuse is disconnected or has

only one wire.

Examine and repair or renew it.

The power supply is abnormal. Improve the power supply

equipment.

The motor is damaged. Repair or change the motor.

Can not be rotated

by hand.

The bearing is damaged. Change the bearing.

The motor is damaged. Repair or change the motor.

Rotate

Reverse Wrong Connection Inspect the joint.

Over Heat

Overloading Regulate the air exhaust pressure.

The power supply is abnormal. Improve the power supply

equipment.

The temperature in the blower

room goes up (over 40)

Increase the ventilation.

Rotation speed is too

low.

The power supply is abnormal. Improve the power supply

equipment.

Overloading Regulate the air exhaust pressure.

-

8/10/2019 Roots Blower Operating Manual

14/15

13

After-sale Service and Maintenance

1. Under the circumstance of regular service, the one-year warranty for free

from the day of product delivery is available in the event of failure! However,

the maintenance in the following situations shall be paid:

The failure happens after the user conducts the repair by oneself during the

warranty period.

The failure is caused by the following facts: first, improper application;

second, the repair is not conducted by the professional maintenance personnel

designated by this company; third, the user reconstructs the machine by

oneself.

The failure is caused by natural disaster.

The failure is caused by the fact that the machine is not repaired or

maintained according to the requirement of this instruction manual.

The failure is caused by the fact that the user does not apply the standard

component designated by this company.

The change of easy workout parts.

The failure is not due to improper design or production.

2. In the event of blower failure, please contact with the agency that is

responsible for the order first and tell them the type, serial number and

purchase date of your product. You shall fill out the table below

according to the blower nameplate for the convenience of maintenance.

Type

Production Serial Number

Bearing Power

Rotation Speed

Pressure

Delivery Date

Name of the Client

-

8/10/2019 Roots Blower Operating Manual

15/15

14

Distinguished Users,

You are welcome to choose the Three Lobes Roots Blower produced by us. Thanks

for your trust and support to us.

To be responsible and provide timely service for you in future, we carry out qualitytracing towards all the products. After you receive the product, you are appreciated

to fill out the quality tracing card and mail it to our business department. Thanks for

your cooperation!

Name of the Company: Greentech International (Zhangqiu) Co., Ltd.

Address: Mingshui, Zhangqiu City, Shandong Province, China

Tel: 86-531-83117088

Email: [email protected]

http://www.china-blower.com

Quality Tracing Card

Postal Address Working

Unit

Contact Type of the

Product

Tel and Fax Serial No. of

the Product

Postcode Delivery

Date

Suggestion and Quality Situation

![IRB1400 – Positive displacement roots blower for road … 1400 min. 1/min 1800 max. 1/min 3000 Performance data – Pressure Unit IRB 1400 Roots Blower min-1 [rpm] 1800 2400 3000](https://static.fdocuments.in/doc/165x107/5acc0bf37f8b9a93268c046a/irb1400-positive-displacement-roots-blower-for-road-1400-min-1min-1800.jpg)