ROFDA 2009 Spring - Effective Bench Marking Study Presentation

-

Upload

richard-kochersperger -

Category

Documents

-

view

37 -

download

0

Transcript of ROFDA 2009 Spring - Effective Bench Marking Study Presentation

Su

pp

ly C

hain

Con

su

ltan

ts1

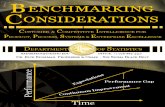

ROFDA Benchmarking Results - How do u rate?

Common factors that effect DC performance

Spring, 2009

Presented by

Keith Swiednicki

Senior Partner

KOM International

www.komintl.com

IQ-The Cognitive Reflection Test (CRT)

90 second test was developed by Shane Frederick, an assistant professor at MIT to predict whether a person would be good at managing money.

2

90 Second Quiz to Managing Money

(1) A bat and a ball cost $1.10 in total. The bat costs $1.00 more than the ball. How much does the ball cost? _____ cents

(2) If it takes 5 machines 5 minutes to make 5 widgets, how long would it take 100 machines to make 100 widgets? _____ minutes

(3) In a lake, there is a patch of lily pads. Every day, the patch doubles in size.If it takes 48 days for the patch to cover the entire lake, how long would it take for the patch to cover half of the lake? _____ days

3

Answers Correct Answers

(1) 5 cents (2) 5 Minutes (3) 47 Days

4

So – How do you do managing risk and money?

Cognitive Results

The CRT was administered to 3,428 respondents in 35 separate studies over a 26-month period. Respondents' ages range from 15-63 with the mean age of 24.

Overall mean CRT score = 1.24 Low (0 correct) = 33% (1 correct) = 28% (2 correct) = 23% High (3 correct) = 17%

5

6

Agenda Objective - ROFDA Ops Committee Summary of DC Productivity Survey Results– List of Participants– Profile of Participants– ROFDA Comparisons – ‘08 vs’09– Best of Breed Results (Top 3 Wholesalers) The Productivity “Drivers” Opportunities to Lower Operating Costs Bottom Line Potential DoMoreWithLess Case Study – Automating Slow Movers Questions?

7

Objective

Measure and report productivity facts.

Provide accurate benchmarks for participating ROFDA members to use when analyzing company DC operations.

Offer suggestions of how to improve operations through development of best practices.

Offer explanations for opportunities and issues challenging the industry and members.

Provide executive management with a summary of the most important points.

Identify and quantify the key costs of operating a food DC.

Su

pp

ly C

hain

Con

su

ltan

ts8

List of Participants – 11 Companies

8

1. Affiliated Foods Inc.

2. Associated Grocers of the South

3. Associated Grocers Inc.

4. Associated Wholesalers Inc.

5. Associated Food Stores

6. Associated Grocers of New England

7. Associated Grocers of Maine

8. White Rose Foods

9. Olean Wholesale Grocers

10. Merchants Distributors Inc.

11. URM Stores

“10 ROFDA Members included in this report”

9

Participant Profile

Characteristics Yes No

Union 73% 27%

Engineered Standards 0% 100%

Incentives 45% 55%

Computer Directed Putaway w/wo RF 91% 9%

Voice Technology 82% 18%

Characteristics Discreet Zone

Order Relationship 55% 45%

Characteristics Z Pick Street Add.

Selection Method 82% 18%

10

Participant Profile

Characteristic Average

Average Fill Rate 97%

Average Warehouse Scratches 2%

Average Labor issues 19%

Average Volume with Lumping services 74%

Average Typical Order Turnaround Time: 1.1

No Touch ReceivingYes No

9% 91%

11

Departmental Comparison

Participant Profile Cont’d

Department Averages 2008 2009

Dry

Cases Shipped 319,323 332,453Total Throughput 44 49Selection (Cases/Hour) 135 138Order Size 165 201Item Variety 9,305 9,971

Freezer

Cases Shipped 104,787 122,031Total Throughput 50 59Selection (Cases/Hour) 130 140Order Size 73 92Item Variety 3,535 2,550

Perishables

Cases Shipped 199,370 242,677Total Throughput 56 60Selection (Cases/Hour) 141 150Order Size 145 92Item Variety 3,521 3,244

12

ROFDA Dry ComparisonDry Grocery Cases/Man-Hour

Function2008 ROFDA Average 2009 ROFDA Average

Top 3 Average (Total Throughput)

Volume Volume Volume

Receiving 389,206 366,513 549,407Shipping 375,491 332,453 497,641

Total 764,696 698,966 1,047,048

Direct Labour Paid Hours Cases / Hour Paid Hours Cases / Hour Paid Hours Cases / Hour

Receiving 689 565 628 583 976 563Moving Stock 1,367 559 1,078 648 1,377 761Selection 2,893 130 2,403 138 3,081 162Loading 1,146 328 656 506 861 578Shipping 4,039 93 3,059 109 3,942 126Other 17 22,473 N/A N/A

Subtotal Direct 6,112 61 4,766 70 6,295 79

Indirect Labour Paid Hours Cases / Hour Paid Hours Cases / Hour Paid Hours Cases / Hour

Managers 510 1,499 406 819 408 1,219Clerks 289 2,648 229 1,450 320 1,555Inbound Checking 358 2,137 256 1,297 178 2,794Inventory Control 311 2,462 177 1,877 191 2,606Outbound Checking 115 6,642 49 6,812 47 10,687Housekeeping 1,026 746 439 757 432 1,152Maintenance 187 4,099 219 1,519 206 2,413Other 203 3,759 281 1,185 563 883

Subtotal Indirect 2,998 125 2,056 162 2,345 212GRAND TOTAL 9,110 41 6,822 49 8,640 58

13

ROFDA Freezer Comparison

Freezer Cases/Man-Hour

Function2008 ROFDA Average 2009 ROFDA Average

Top 3 Average (Total Throughput)

Volume Volume Volume

Receiving 129,458 178,129

Shipping 122,031 176,935

Total 251,489 355,064

Direct Labour Paid Hours Cases / Hour Paid Hours Cases / Hour Paid Hours Cases / Hour

Receiving 142 910 220 809 Moving Stock 345 728 360 986 Selection 875 140 1,009 175 Loading 150 813 217 817 Shipping 1,025 119 1,225 144 Other

Subtotal Direct 1,512 81 1,806 98

Indirect Labour Paid Hours Cases / Hour Paid Hours Cases / Hour Paid Hours Cases / Hour

Managers 125 975 116 1,530 Clerks 87 1,409 91 1,936 Inbound Checking 44 2,801 62 2,848 Inventory Control 57 2,156 82 2,154 Outbound Checking 24 5,001 38 4,674 Housekeeping 99 1,230 122 1,453 Maintenance 81 1,511 74 2,401 Other 31 3,929 80 2,212

Subtotal Indirect 547 223 665 266 GRAND TOTAL 2,060 59 2,470 72

14

ROFDA Perishables Comparison

Perishables Cases/Man-Hour

Function2008 ROFDA Average 2009 ROFDA Average

Top 3 Average (Total Throughput)

Volume Volume Volume

Receiving 237,814 184,131

Shipping 242,677 186,963

Total 480,491 371,094

Direct Labour Paid Hours Cases / Hour Paid Hours Cases / Hour Paid Hours Cases / Hour

Receiving 407 584 269 684 Moving Stock 603 796 387 958 Selection 1,623 150 885 211 Loading 242 1,005 88 2,124 Shipping 1,864 130 973 192 Other

Subtotal Direct 2,875 84 1,629 115

Indirect Labour Paid Hours Cases / Hour Paid Hours Cases / Hour Paid Hours Cases / Hour

Managers 223 1,089 185 1,011 Clerks 138 1,756 89 2,091 Inbound Checking 116 2,086 50 3,705 Inventory Control 120 2,018 99 1,893 Outbound Checking 35 7,032 10 18,696 Housekeeping 236 1,026 202 925 Maintenance 115 2,105 49 3,828 Other 112 2,174 0 -

Subtotal Indirect 1,095 222 685 273 GRAND TOTAL 3,970 61 2,314 81

Warehouse Labor – ROFDA Members

Warehouse Labor Expense Pie Chart

Indirect Labor, 11.1%

Receiving, 2.9%

Putaway, 8.3%

Stocking, 14.6%

Picking, 42.1%

Replenishment, 10.7%

Packing/Checking, 6.2%

Loading, 3.9%

Order picking is costly and accounts for 40-60% of warehouse labor expense

16

ROFDA Results

Total Direct Paid Hours – represents 70% of labor expense

“Focus on Selection travel and walk time”

Average

Order picking is costly and accounts for large % of warehouse labor expense

Design Considerations: Travel

Pick Line Length vs. Variety

Mom and Apple Pie

19

ROFDA Results

Total Indirect Paid Hours - represents 30% of total

“ A Clean Warehouse is a Productive Warehouse”

Average

Top 3 spend more time on Inventory control & clerical and less time on maintenance and inbound checking than the ROFDA average

Question For You Opportunity

Our facility appears dirty, we have allot of product damage, housecleaning is not our strong card.

Clean facilities

have higher morale and

better productivity

Our facility is reasonably clean but it is by no means spotless.

We are proud to take people on tours of our facility because it is immaculate. Our associates take pride in the cleanliness of the building.

The Basics – Facility cleanliness

September 24, 2004

“A clean facility is a productive

facility.”“A dirty facility is one of the most telling signs of

weak operations management.”

Facility Cleanliness

Question Opportunity

Our associates pick products that are heavier than 30 lbs from locations above ground-level.

Good ergonomics will reduce

worker injuries in the back,

neck, shoulder,

elbow, wrists, knees and

ankles

Our heaviest products > 30 lbs are always positioned at ground-level.

We have ergonomic pick locations to facilitate the way in which associates lift heavy products.

The Basics - Ergonomics

The Basics – Facility Lighting

“The dock is where the success or failure of distribution operations will be

determined”“Proper lighting technology will reduce energy

costs, and improve labor productivity,

accuracy and morale. ”

September 24, 2004

Ergonomics

“Reduce worker picking injuries by keeping heavy products at ground-level, or by

bringing the picker to the product.”

Productivity Drivers – effect on performance

Top Common Factors:

1. Volume2. Order size 3. Pick Line length 4. Hit Rate/Density

Opportunities to lower costs:

Engineered Standards Incentives Computer Directed Putaway Voice Technology Order Turnaround Order Relationship Selection Method Selection Accuracy Fill Rate Scratches Labor Turnover Lumping % No Touch Receiving

25

26

What is the Impact of Average Movement Weekly Cases Shipped

“Direct Correlation between Volume and Productivity”

50% of variation in logistics cost can be explained by volume alone

Volume >320,000 Volume <320,000

Cases Shipped/Week 573,901 131,247

Selection (Cases/Hour) 145 119

Direct Labor Throughput Rate 71 65

“The Drivers”

27

What is the Impact of Order Size

Order Size >244 Order Size <244

Cases Shipped/Week 483,637 206,467

Selection (Cases/Hour) 133 150

Direct Labor Throughput Rate 67 76

Indirect Throughput Rate 146 206

Total DC Throughput - Cases/Man Hour 46 55

“ Order Size impacts selection rate”

“The Drivers”

28

What is the Impact of Item Variety Unique Sku’s Stored in Facility

Sku’s >10,000 Sku’s<10,000

Cases Shipped/Week 446,811 195,224

Selection (Cases/Hour) 141 131

Direct Labor Throughput Rate 72 64

Indirect Throughput Rate 158 172

Total DC Throughput - Cases/Man Hour 50 47

“ More Variety less efficient”

“The Drivers”

Aside from the basics - facility cleanliness, lighting, ergonomics and safety

1) Measuring and improving labor productivity – standards and incentives

2) Warehouse Software and Equipment Technologies

3) Improving picking operations and strategic handling of small orders

4) Measuring product velocity and cube information

5) Layout development and fast / slow concepts

6) Optimized pick location management / slotting

7) Budgeting and accounting of distribution operations with ABC Costing

Opportunities to Lower Operating Costs

30

What is the Impact of Standards & Incentive Programs

Incentives No Incentives

Cases Shipped/Week 458,350 181,377

Selection (Cases/Hour) 137 144

Direct Labor Throughput Rate 71 66

Indirect Throughput Rate 161 164

Total DC Throughput - Cases/Man Hour 49 47

Errors 2/1000 4/1000

“ Incentives providing benefits?”

All participants have Standards

“The Drivers”

(1)Operators with incentives are more productive than those W/O

Question Opportunity

We do not measure labor productivity in our warehouse.

For distribution operations with high

wage labor expense or

militant unions,

standards and

incentives can reduce 5-15% labor

expense

We measure labor hours by function mainly for labor planning and budgeting purposes.

We have engineered labor standards in place for some of our job functions. We regularly inform associates of their productivity performance.

We have labor incentives developed against standards

Standards & Incentives

Standards and Incentives

One of the most significant productivity gains in a high volume distribution operation will be derived by:– Implementing and maintaining labor

standards• E.g. Red Prairie, Tom Zosel, In-House

– Implementing an incentive system

Incentive Systems Things we have learned:

– Paying for employee meals is a form of incentive that works well to reduce turnover

– Pay out incentives frequently (e.g. with pay checks)

– Base incentives on individual performance except for receiving, returns, salvage…

– Incentives should include penalties for errors, shorts and unsafe behavior (e.g. lose incentive if errors are encountered)

– Incentives should be based on industrial engineered labor standards, preferably by zone or aisle

– Incentives only paid if no absenteeism for the period

– Incentives should allow an operator to increase wages by a measurable amount (e.g. 20% or more)

Slotting Methodology

Question Opportunity

Our picking is random from all vertical levels of storage.

Optimized setup of a pick line will

often reduce order picking

hours upwards of 15%

Our primary fixed pick locations are not always at ground-level but we try to keep slow movers in locations that are not accessed from ground level

Our pick locations are all at ground level.

Our pick locations are assigned to products by slotting software to maximize picking efficiency.

Location Numbering Systems

X-Pick U-Pick Z-Pick

A = FASTEST ITEMS

B = FAST ITEMS

C = SLOW ITEMS

D = SLOWEST ITEMS

FREQUENT STOP POINT(FAST MOVERS)

A = FASTEST ITEMS

B = FAST ITEMS

C = SLOW ITEMS

D = SLOWEST ITEMS

FREQUENT STOP POINT(FAST MOVERS)

A = FASTEST ITEMS

H = SLOWEST ITEMS

FREQUENT STOP POINT(FAST MOVERS)

A = FASTEST ITEMS

H = SLOWEST ITEMS

FREQUENT STOP POINT(FAST MOVERS)

A = FASTEST ITEMS

B = FAST ITEMS

C = SLOW ITEMS

D = SLOWEST ITEMS

FREQUENT STOP POINT(FAST MOVERS)

A = FASTEST ITEMS

B = FAST ITEMS

C = SLOW ITEMS

D = SLOWEST ITEMS

FREQUENT STOP POINT(FAST MOVERS)

Location address systems should be intuitivee.g. AA-RR-LP (aisle-rack-level-position)

36

Bottom Line: Total Labor Savings

Cases Shipped Hours Staff* @ $35k

100,000 439 13 $ 455,000

250,000 1,098 31 $ 1,085,000

500,000 2,195 63 $2,205,000

Potential Savings realized by Wholesale Best of Breed• Total throughput savings of 9 cases/man-hour compared to ROFDA

* at a rate of 35 hours per week

37

Results – Payback 1yr

Alternative Total Capital One-Time Costs On-Going Savings Lifetime (years)

A $ (717,200) $ (321,310) $ 1,080,456 1.5 to 2.0

B $ (143,000) $ (172,810) $ 1,029,202 1.0

C $ (126,500) $ (167,310) $ 680,955 .8 to 1.0

Improved Productivity Projections

Cost/Savings Comparison

Labor Rate by Function (Cases per Paid Hour)

Benchmark(Kom Klinic)

Alternative A

Alternative B

Alternative C

Kom Klinic Average

Top 3 Kom Klinic

Moving Stock 653 847 791 741 1,019 1,127

Selection 144 179 182 169 190 257

Loading 482 482 482 482 1,020 1,208

Other N/A N/A N/A N/A 770 2,933

Total Direct Labor Rate 76 89 89 85 95 135

Total Indirect Labor Rate 287 287 287 287 227 297

Total Throughput 60 68 68 65 67 93

DoMoreWithLess

Milk your WMS for More

- can your WMS do more to reduce labor costs, improve inventory management, attain more accurate shipments, and improve space allocation?

- what else can your system do?

- have you looked into add-on capabilities?

Use challenging economic times as an opportunity to scrutinize operational efficiency to help weather the storm and reap benefits when the market turns

38

DoMoreWithLess Attack Freight Costs

- use analytical tools to identify how, why, when and where your costs are incurred. Manage freight more efficiently and gain net savings of 3-20%

Make use of Best Practices to Plan, Procure and Manage Freight

- scrutinize processes in planning, procurement and shipping revise or eliminate all those not ideal, innovative or well integrated with other functions

Cash in on ergonomics

- do you have lift trucks or racks with ergonomic features? … are you running regular programs to promote ergonomics and safety? … inform your insurance provider … you could see your premiums drop

39

DoMoreWithLess Stop Doing Things

- get end-to-end visibility on your operation and stop shipping, handling or warehousing anything unnecessarily… doing things 2x, 3x, 4x is costly

To-Automate-or-not-to …

- smaller footprint, productivity gains, reduced labor requirement, 18 month to 3 year ROI… may be worth having in place for when the recovery hits

40

C-Dock/RLP/FT to Cut handling and Inventory Carrying Costs

- select items to most easily bypass the storage racks and thereby increase efficiency

Question Opportunity

Our financial accounting of logistics expenses is weak. It is difficult to understand our cost structure and how the money is being spent.

Strong accounting, budgeting and ABC

costing are simple and inexpensive and ways to understand

costs

Our financial Accounting and Budgets are strong.

We use ABC Costing to understand the cost of transactions and logistics events.

Accounting/ABC Costing

September 24, 2004

ABC Costing Warehouse Productivity Scorecard

Direct Labor Function

MeasurementCriteria

Average Wage Rate

Including

Fringe Benefits

AverageThroughp

ut Rate/hour

Total Transactions/week

Total Paid

Hours/week

Total Labor

Cost/week

Cost per Transaction

Receiving Pallets Received

$17.37 28.0 5,816 208 $3,607 $0.62

Putaway Pallets Putaway

$22.44 12.7 5,816 458 $10,276 $1.767

Stocking/Stuffing

Cases Cut & Stocked

$22.32 125.9 102,375 813 $18,135 $0.177

Split Case Picking

Pieces Picked $13.97 586.0 1,857,496 3,170 $44,297 $0.0238

Full Case Picking

Cases Picked $14.73 107.0 56,433 527 $7,768 $0.138

Replenishment

Pallets Replenished

$17.93 9.3 6,904 742 $13,310 $1.93

Packing/Checking

Cases Packed & Checked

$14.97 107.7 55,520 516 $7,717 $0.139

Loading Pallets Loaded

$20.86 13.5 3,161 234 $4,884 $1545

Indirect Labor Pieces Shipped

$13.81 138.5 1,913,929 1,001 $13,820 $0.019

Total Pieces Shipped

$16.15 249.6 1,913,929 7,669 $123,814 $0.167

ABC Labor Costing by Process

Cost / Sales Order Line

FunctionCarousel4 pods

Carousel2 pods

Case Flow Rack

Pick to light

Split CaseConventiona

lFull Case

Conventional

DIRECT LABOR

Receiving $0.0051 $0.0051 $0.0051 $0.0051 $0.0051

Putaway $0.0158 $0.0158 $0.0158 $0.0158 $0.0158

Replenishment - Full Case $0.0203 $0.0203

Replenishment – PTL / Carousel $0.0506 $0.0506 $0.0506

Replenishment

Selection – Carousel 4 pods $0.0382

Selection – Carousel 2 pods $0.1291

Selection - Pick to Light $0.0714

Selection – Split Case Conventional $0.3272

Selection – Full Case Conventional $0.2276

Loading $0.2776 $0.2776 $0.2776 $0.2776 $0.2776

Subtotal Direct Labor $0.3822 $0.4732 $0.4155 $0.6409 $0.5413

Ambient Activity Profile

SKUs % cases % Cube % lines

Conventional

Floor 4300 93 95 90VNA 6457 7 5 10

Mechanized

Floor 2457 79 88 73 Active: 1283/52% Mini-Load 8300 21 12 27 Active: 3635/44%

Dynamic Pick Line: Slot only for one shift

ASRS: Dynamic Pick Line

Unit Load/Mini-Load drop required pallets to tunnel

drop required trays to pick face

based on shift or batch orders

restock above: based on history

maintain weight/stackability

Considerations set-up lead time

load stability

available slots and location

Dynamic Slotting: Benefits Picking

– Reduced labor, eliminating merge and travel time Replenishment

– Reduced labor requirements– Dynamic replenishment dependant upon daily SKU requirements– Increased accuracy– Reduce inventory

SKU Density– Higher than conventional racking solutions

Flexibility– Order driven system– Dynamic slots

• Recycle slot after pick• Can assign multiple slots to SKU

Modularity– Easily expandable

Mini-Load Module

Slow Movers: 77% SKUs, 21% Cases, 12% Cube, 27% Lines12’ aisle, pallet jack merge

Order picker truck backup; 35’ high

Mini-Load Input

“Decanting”Pay me now or pay me later

Ergonomic Decanting

Mezzanined StationPallet Lift to Slider Table

Mini-Load: Pick Path

Mezzanined infeed optional

Mini Load Pick Profile

Multiple Tray SizesSystem Controlled Slotting

Cost Comparison

Conventional ASRSBuilding $61,000,000 $46,000,000

ASRS unit load na $27,000,000 mini-load na $8,000,000

Other MH $8,000,000 $4,000,000

Capital $69,300,000 $85,000,000 Labor $12,000,000 $9,500,000

Payback: 8.5 yearsNot Exactly a Slam-Dunk….but

Option 2.5: Embedded Mini Load

Integrate modules within conventional layout

4 in Ambient, 3 in Frozen respect weight range/crushability group national /program accounts

$8mm investment enhanced ergonomics facilitates variety increase streamlined receiving picker merges all product reduced pick errors reduced dock delays reduced truck driver sort order-picker backup experience with automation best of both worlds can retro-fit other facilities

Other? Just Ask DICK

54

Supply Chain LabourTransportation

Vechicles

20%

Fuel

24%

Operating

17%

Labour

39%

Stores/Manufacturing

Other

25%

Labour

75%

Warehouse

Rent

25%

Utilities

5%

Computer

2%

Supplies

13%

Labour

55%

Returns

Other

35%

Labour

65%

55

What is the Impact of Union versus Non-Union

Union Non Union

Cases Shipped/Week 246,206 562,445

Selection (Cases/Hour) 125 158

Direct Labor Throughput Rate 63 80

Indirect Throughput Rate 141 195

Total DC Throughput - Cases/Man Hour 44 57

“ Non – Union operators are more productive”

“The Drivers”