Roads #2, 2013 (Quester)

-

Upload

ud-trucks-corporation -

Category

Documents

-

view

224 -

download

1

description

Transcript of Roads #2, 2013 (Quester)

The Global UD Trucks Customer Magazine #022013

ANSWERING THE CALL:

INTRODUCING QUESTERP10 Delivering bread in Trinidad & Tobago

P20The Japanese way of making things

P22

The story behind the Quon cab

Go out for a run. With tons of cargo on your back.

Discover a truck with endurance like a long-distance runner.

The new heavy-duty hero Quester gets the job done efficiently

and reliably. With versatility and carrying capacity for any

type of mission, it cuts your costs and maximises your uptime.

Get ready, set and go at udtrucks.com

Quester. Made to go the extra mile.

291-0053_UD_P9103_Ad_ROADS_210x297.indd 1 2013-07-11 16:24

Go out for a run. With tons of cargo on your back.

Discover a truck with endurance like a long-distance runner.

The new heavy-duty hero Quester gets the job done efficiently

and reliably. With versatility and carrying capacity for any

type of mission, it cuts your costs and maximises your uptime.

Get ready, set and go at udtrucks.com

Quester. Made to go the extra mile.

291-0053_UD_P9103_Ad_ROADS_210x297.indd 1 2013-07-11 16:24

04 Cover Story

Introducing QuesterUD Trucks introduces Quester, a new heavy-duty truck range for South East Asia’s growth markets designed to maximize fuel economy and uptime.

10 Feature Story

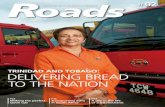

From Bakery to Basket: Tasty Trails in Trinidad and Tobago On the islands of Trinidad and Tobago, bread is a daily staple. Kiss Baking relies increasingly on its UD trucks to get the job done.

14 Feature Story

A Day in the Life of a UD MechanicFor Toshihide Hiranishi, a UD mechanic in Kanazawa Prefecture, Japan, a variety of unique challenges mean that no two days are alike.

16 Feature Story

The Milkman Cometh Clover, South Africa’s largest dairy company, uses UD trucks to navigate the logistical hurdles of transporting milk from farm to shop.

20 Tradition

Monozukuri – An Old Word that Keeps Up with the TimesThe Japanese approach to making things is evident in everything from cooking and traditional crafts to modern robotics, and indeed, trucks.

22 Engineering

Making the Perfect Quon CabKunihisa Shimura, chief cab engineer at UD Trucks, talks about attention to detail and why the Quon cab is more than the sum of its parts.

#02 | 2013

Torbjörn SelanderBased in Cape Town, South

Africa, Torbjörn Selander is a photojournalist and

contributor to publications in the region, Europe and the

United States.

David AgrenDavid Agren is a Mexico City-based freelance journalist who has written for USA TODAY, The New York Times and other publications.

Tony McNicolBased in Tokyo, Tony McNicol is a writer, editor and photographer who has written widely for publications in Japan and globally.

Contributors to this issue:

Cover photograph: Gerhard Jörén

Roads is published three times per year by UD Trucks Corporationudtrucks.com

PublisherPer Sundström [email protected] Tel: +81-48-726-7601

Editorial ProductionNext [email protected]: +81-3-6436-4270

Editor-in-Chief Kjell Fornander

Executive Editor Tyler Rothmar

Art Director Koichi Asano

Production ManagerKazumi Umezawa

Printed in Japan

Taizo MatsuoVice President

UD Trucks Product Management

Striking the perfect balance

By now it is clear that 2013 is a very exciting year for UD Trucks. At a time when so much is going on around the globe, it is my pleasure to

be able to address all of our customers by way of an introduction to this issue of Roads.

As part of our ongoing efforts to keep pace with the needs of interconnected markets around the world through innovation and evolution, we are very proud to announce the introduction in Thailand, Indonesia and Malaysia of a new heavy-duty truck, Quester, which you can read about in this issue.

Part of my job here at UD is to oversee the development of new products such as Quester. Based on the understanding that our customers’ needs are the engine of our business, we invest in research on the real-world conditions in which our trucks operate.

If I had to sum up our goal in one word, it would be “balance.” We strive to deliver a product that satisfies your needs at a competitive price, with the same durability and reliability that has become synonymous with UD Trucks worldwide.

The result is the mature and diverse range of products that we are proud to offer today. Much like this issue of Roads, I can truly say we have something for everyone.

In this issue you can also find two profiles of happy UD customers, read about a day in the life of a UD mechanic, and learn about monozukuri, the Japanese attitude toward aesthetics and production.

With that, I would like to bid you happy reading!

Introducing QuesterQuester draws on more

than 70 years of history and quality engineering. Read more about its genesis and the

thinking behind it on page 9.

Quester is available in an unprecedented array of

configurations and is highly customizable. Learn more about

the right combination for your business on page 6.

Moving ForwardUD Trucks takes a bold step into Asia’s growth markets on August 26, 2013, with the release in Bangkok, Thailand, of Quester, a versatile heavy-duty truck. Made to Japanese quality standards using global technology, Quester can be tailored to any segment or task, from mining and construction to long hauling. Durable and reliable, Quester has been designed from the ground up with the needs of the customer in mind.

Locally sourced and manufactured, Quester addresses the needs of operators in growth markets by striking a balance between high average speeds and good fuel consumption. With combined knowledge from Japan’s UD Trucks and the Volvo Group’s global resources, Quester is affordable, robust, adaptable and slated for released in major Asian markets.

“With the combination of the new product range and investments in the network to better serve our customers, we believe that we will obtain a much better position in such competitive markets”, says Taizo Matsuo, vice president of UD Trucks Product Management.

More Than Just a TruckThe purchase of a Quester buys more than just excellent vehicle technology. UD Trucks’ telematics system is configured for breakdown assistance, preventive maintenance analysis and corrective service scheduling. Combined with UD aftermarket support focused on maximizing fuel efficiency, minimizing operation costs and extending uptime, this means a support team is ready at all times to help a Quester truck, no matter where or when it might experience trouble.

Quester production for South East Asia is set for the third quarter of 2013 at the Thai Swedish Assembly plant in Bangkok, Thailand, and Quester is set to be manufactured in China and India for their respective markets in the near future.

04 #02 | 2013

Introducing QuesterText: Tyler Rothmar

Learn more about Quester’s aerodynamic cab design and the symbol that connects it to

UD’s past on page 9.

Quester is carefully made using the Volvo Group

production system. Find out more about how UD Trucks successfully exported Japanese

quality and attention to detail on page 8.

Quester has a host of new features designed to

minimize fuel consumption and maximize uptime. Read more

about these and other money-saving features on page 7.

05 #02 | 2013

Cover Story

hen we began developing Quester, we knew it would have to cover

all growth markets,” says Taizo Matsuo, vice president of UD Trucks Product Management. “This means we had to prepare a very diverse product line.”

Indeed, “diverse” hardly begins to describe it. For starters, the new Quester is available in seven different configurations, ranging from 4x2 to 8x4. “This is a first, not only for UD Trucks, but for any Japanese company, to introduce all configurations at the same time,” Matsuo says.

The truck is also totally customizable, with myriad options that make it an attractive choice for everything from long hauling to distribution, mining and construction. The spectrum ranges from big choices like engine, axle/wheel configuration and gearbox type, to small, such as the thickness of the steel on the side rail. There is also the choice of either a standard cab or one with a high roof for long hauls.

“Theoretically, any kind of combination is possible,” Matsuo says. “It depends on the uses in various markets. So we’ve prepared many puzzle pieces. How to mix and match them will depend on the market’s requirements.”

There are two engine choices, the 8-liter GH8E and the 11-liter GH11E, each available in three to four different horsepowers, depending on the configuration. “Each country has its own regulations for emissions, weight, noise, safety and so on. So we have tried to cover the many variations that might be in demand,” Matsuo explains.

There are also three kinds of gearbox—six, nine and 12 speed. The wheelbase can be tailored to the customer’s needs within a range of 3.2 meters to 5.6 meters. For heavy and off-road applications, Quester is the first truck from a Japanese

manufacturer to offer hub reduction axles. Two of the configurations have optional bogie lifting axles, which help to maximize fuel consumption and tire life.

“Simply put, developing this truck has been the ultimate balancing puzzle between performance and cost,” Matsuo says. The challenge has been to keep costs down, while “retaining the quality that UD Trucks is known for.”

The team at UD Trucks is convinced that Quester is the solution to that puzzle. The result is a sturdy, reliable and extremely versatile truck that is ready for the variety of challenges that customers face.

For UD Trucks and the Volvo Group, Quester represents the opening move of a strategy to expand into growth markets across Asia. It was clear from the early stages that the key to this strategy—which the Quester range exemplifies—is adaptability.

A Truck Range for Any Task

01

01. Quester’s tilted cab, with engine exposed. The roof hatch doubles as an escape route in case of accident or fire.

02. The real-time Fuel Coaching System helps drivers to capitalize on engine efficiency while using less fuel.

“Theoretically, any kind of combination

is possible.”Taizo Matsuo, Vice President of UD Trucks

Product Management

06 #02 | 2013

The one thing that is common among all operators around the world is they all feel they’re paying too

much for fuel,” says Product Management Director Ian Sinclair. “With Quester, we’ll save you money when you’re on the road,

and keep you there as long as possible.”Quester was designed specifically to optimize fuel efficiency and uptime.

“We’re very confident that we’ll be able to capture the imagination

of the market with the product

we have on offer,” says Sinclair, referring to a number of features aimed at realizing the best possible performance in these two areas.

First is a new Fuel Coaching System located in the truck’s information display. An on-board computer runs a constant analysis on the engine’s performance and gives the driver instant feedback on when to shift up or down to home in on the so-called sweet spot, or the optimal revolution range that uses the least amount of fuel.

“We noticed over many years that the driver actually has much more influence

on the fuel consumption than components and drivelines. The driver can influence the fuel consumption by up to 30 percent, so if we can help to train them to be better, we can save the customers on fuel,” Sinclair says. To compliment this hardware, Quester comes with “software” in the form of a professional driver training program.

On the issue of uptime, engineers and designers at UD Trucks have attacked potential problems from multiple angles. Both engine options feature Volvo Group technology, which means less frequent oil changes for most applications. The 11-liter GH11E engine also features an optional UD Extra Engine Brake “that will save us on

brake maintenance, because we’re able to use the engine to brake the truck, not just the wheel brakes all the time,” Sinclair notes.

There is also a new system in the driver information display that gives advance warning when regular

maintenance is needed, allowing for the planning of vehicle downtime, thereby maximizing uptime.

When it comes to the issue of reliability and durability, it’s in everyone’s interest

to invest in the cab, due to the correlation between strength and safety. “The Quester cab complies to the European ECE R29 cab crash

standard, which means it’s strong enough to stand up to those rough

roads, heavy loads or whatever stresses and strains you want to put on it,” Sinclair

says. This strength, of course, means increased safety for the driver.

“This truck has gone through both European and Japanese product development testing and standards, so it has been tested to the highest and most difficult standards that are in the industry today,” Sinclair adds. “We’re itching to roll Quester out for the customers, because we’re sure that they’re going to be very pleased with what they see.”

All of Quester’s features were designed with the same goal in mind: to give the customer a truck of solid quality that stays on the road, where it should be, at minimal cost. Quester is the embodiment of the UD Trucks brand promise, “Going the Extra Mile.”

Keeping an Eye on the Customer’s Bottom Line

02

“We’re itching to roll Quester out for the customers, because we’re sure that they’re

going to be very pleased with what they see.”Ian Sinclair, Product Management Director

07 #02 | 2013

Cover Story

Roads: Please tell us a bit about how Quester is made.Kyoji Funatsumaru: Of course now, we are using the Volvo Production System, which was influenced by the UD Production System when UD joined the Volvo Group. In order to realize an efficient, effective and lean manufacturing system at the Thai plant, we decided to introduce the Volvo and UD Production Systems to its assembly line.

R: What did that process involve?F: From a Japanese perspective, the core of the system is people. The foreman and the operators play key roles. The most important factor is not the hardware, but the software, meaning the people.

The kaizen mindset is very important. This

is a very famous word in the manufacturing world. It’s Japanese for “improvement,” a mindset of always making improvements.

R: What other steps were taken to ensure high-quality manufacturing at the Thai plant?F: To keep the workshop clean and develop skilled personnel, the five Ss and Ws are very important. In English the five Ss are: sort, set in order, systematic cleaning, standardize and sustain. The five Ws refer to the practice of always asking “why” until the root cause of a problem is found.

We also use a system called Quick Response Quality Control. If anyone detects a defect, they can discuss it with the management on a daily basis to solve it quickly.

Additionally, in anticipation of Quester production, we have been implementing shokiryudo activities. In English it means the Initial Quality Control Plan, which ensures speed and attention to detail in manufacturing.

Senior Vice President of Asian manufacturing Kyoji Funatsumaru was responsible for setting up Quester production at the Thai Swedish Assembly plant. He sat down with Roads to discuss how he and his team successfully exported Japanese production values to Thailand to make Quester a reality.

Exporting Japanese Craftsmanship

R: From a Japanese perspective, what is important for manufacturing?F: Japanese quality comes from the design of manufacturing and shokiryudo activities, from the quality control plan, and of course from gemba spirit. This is the baseline for everything.

Also, in my experience, the foreman is a very important person. It may sound strange, but my first teacher was a foreman. He was a very good person. When I was a newcomer, I spoke with him in his office on the shop floor everyday and he taught me many things. It was the foundation of my career. If I didn’t experience that, I probably wouldn’t be here right now. I think the foreman is the heart of manufacturing.

It’s important that workers learn through on-job training. It’s the most efficient way to learn a lean manufacturing spirit. For this reason, I made plans to send Japanese foremen to the Thai factory, and foremen from there also visited the Japanese plant in Ageo, Saitama.

R: How is the Japanese way of production transmitted to the workers at Thai Swedish Assembly?F: We have a special training and evaluation system. First, we train newcomers at a training center called a dojo in Japanese. There they learn basic skills, like how to handle parts, tighten bolts and avoid injury. Then they go to the assembly line, where the foreman trains them in kata, or the form, the standard operating procedure. They are evaluated, and when they are ready, they graduate.

R: It sounds like martial arts training.F: Yes, exactly. It is not so different.

“ My first teacher was a foreman. I think the foreman is the heart of manufacturing.” Senior Vice President Kyoji Funatsumaru

01. Quester production at the Thai Swedish Assembly plant, part of the Volvo Group’s global production system, located in Samut Prakarn, an eastern suburb of Greater Bangkok. [Photo: Gerhard Jörén]

Kyoji Funatsumaru

01

08 #02 | 2013

The story of Quester’s genesis begins just after the Volvo Group acquired UD Trucks in 2007. A management team comprising members from seven countries

was mulling a new project: “How will we create the next UD Trucks offering to meet the challenges of South East Asia?”

It was a daunting proposition. “The idea of creating a competitive truck for Asia is not new. It has been in the system for a while, probably 15 years,” recalls Mellinand. Yet a locally sourced truck for the South East Asian market has proved elusive. Twenty years ago, UD Trucks created an offering for Indonesia, Malaysia and Thailand, and other growth markets. These vehicles were put together using assembly kits in South East Asia. This offering needed to be renewed and the business model changed.

“We had to change our attitudes and our thinking,” adds Trombert. “We started from the customers’ needs and developed something for the markets we were targeting, at a competitive price. We needed something original, not a copy of an existing product.”

With this in mind, the group set about developing a truck that’s fully adapted to the Asian ecosystem. Mellinand explains: “To be competitive in Asia you need to be in Asia. You need to design the truck in Asia because the development drives the cost of the product. Then you need to source the product locally. You need a new supply base and you need to assemble in Asia.”

What followed was not easy, but it transformed the way UD Trucks operates. The planning and development of Quester

spanned three and a half years and involved 1.5 million engineering hours.

“There is the company, but the company does not really exist as such. It is made up of people. A group of individuals had to rise to the challenge, and when that happens, it is absolutely not business as usual,” says Mellinand.

Trombert agrees wholeheartedly: “The main thing is the human journey we have had. Thousands of people from something like 18 different nationalities at eight different sites have been involved. This really is a

sincere gift. Probably only once in a lifetime is there a big challenge with this many people involved, all focused on the same target, willing to make it happen, and opening doors in an organization where we have never done that before. This human journey has been amazing. Stressful, for sure, but the take-away is tremendous.”

Range Director Patrick Trombert and UD Trucks Global Brand Senior Vice President Loic Mellinand are two people who have ushered Quester from its early conceptual stages into reality. Both men took time out with Roads to explain the process and why Quester has been so revolutionary.

An Asian Odyssey

Design:

A Shape From the PastWith its more than 70-year history, UD Trucks has

earned a reputation for craftsmanship, simplicity and modern technology. Quester is no exception, and the

mark it bares on its front grill is a testament to a proud tradition. Product Design Complete Vehicle Director Toshio Shiratori

explains: “The hexagon goes all the way back to the shape found on the grill of UD’s first ‘Cab Over Truck’ in 1960. The shape is being

used modestly in the Quon and Condor, but now it’s very distinctive and prominent on Quester. The hexagon has six corners, each of which represents

an aspect of UD Trucks’ product design philosophy, ‘Dependable Tools with Soul.’ The six points are: tough, smart, distinctive, harmonized,

caring and supportive.”Another notable feature is the unique shape of Quester’s cab.

“Quester’s cab has a distinctive and dynamic exterior with a unique slanted form inspired by modern skyscrapers

and towers as a symbol of growth markets,” Shiratori explains. “As this form generates a rounder corner

shape, it is naturally aerodynamic. This is just one example of the smart solutions we

contributed to support our customers.”

“ Probably only once in a lifetime is there a big challenge with this many people involved, all focused on the same target and willing to make it happen.” Patrick Trombert, Range Director

01. Patrick Trombert, Range Director, and members of his team, in Bangalore, India.

01

Phot

o: N

amas

Bho

jani

09 #02 | 2013

Cover Story

01

an you send Kiss Cakes?”It was a simple request, but typical

of the Trinidad diaspora, recalls Anna Ackbarali, supply chain manager at Trinidad and Tobago’s Kiss Baking

Company Ltd., the largest commercial bakery in the Caribbean.

The request came from Canada three years ago when a friend of Ackbarali’s son learned that she had taken the position at Kiss. Such is the stature of Kiss Baking: a national icon whose treats are sold not only in Trinidad and Tobago, but across the Caribbean. Kiss delivers fresh bread to all corners of Trinidad and Tobago using a fleet of UD trucks to reach thousands of sales points, ranging from supermarkets to mom-and-pop shops and gasoline stations.

Ackbarali gives several reasons for Kiss Baking’s preference for UD trucks, including price, ease of maintenance and, crucially, reliability. These are no small matters in the baking business—the product is perishable and customers consider fresh bread a breakfast staple.

“We find that the reliability of the truck has become very important to us,” Ackbarali says. “It takes some of our distributors 2.5 hours to reach the end of their routes. We cannot afford to have them break down and not get there.”

Kiss Baking Company started in 1976 producing snack

cakes and later expanded into bread—the baking of which was previously a weekend task for Trinidadians, since baked goods weren’t readily available in stores at that time. Somewhere along the way, Kiss Baking’s heart logo and signature red trucks became ubiquitous. “Kiss doesn’t only distribute to places along the main routes,” Ackbarali says. “We go into the villages. We go to the extremes of Trinidad and Tobago.”

TRINIDADAND TOBAGO

VENEZUELA

COLOMBIA

CUBAMEXICO

“C

From Bakery to Basket:

Tasty Trails in Trinidad and TobagoText: David Agren Photos: Keith Dannemiller

10 #02 | 2013

The distribution challenges involved mean that Kiss Baking is in the logistics business as much as it’s in the baking business. While small, the main island of Trinidad covers 4,768 square kilometers, and the population of approximately 1.3 million people are spread out. The nation’s infrastructure can be problematic as well.

“Logistics is one of the major challenges we have, because our roads are still very small and some are not

well paved,” Ackbarali says. “There’s a lot of wear and tear on the trucks.” Kiss operates a fleet of 150 trucks. The bigger vehicles, mostly UD trucks, deliver bread, while smaller vans deliver snack cakes and custom-made cakes for events such as birthdays and weddings. The trucks head out six days a week, with some salesmen calling on up to 100 customers each day.

Dependability is a point of pride for Ackbarali and

01. One of Kiss Baking’s 60 UD trucks, painted in the company’s signature red, transports sliced bread, cakes and other baked goods for delivery.

In a country where fresh baked bread is a staple at the breakfast table, the delivery of such goods is serious business. Kiss Baking has been doing exactly that since 1976, carrying bread and cakes to the far corners of Trinidad and Tobago using a fleet consisting primarily of UD trucks.

11 #02 | 2013

Feature Story

01. Kiss distributors carry baked goods, a staple of the Trinidad and Tobago diet.

02. Kiss Baking Supply Chain Manager Anna Ackbarali.

03. Maintenance yard staff keep Kiss Baking’s UD trucks in good health.

01

part of what has made Kiss Baking so successful. “One of the things we boast about is that we’ve never had a truck stay in the yard on any day. Every single route has been serviced every single day. No truck has been left in this yard,” Ackbarali says. “We think of our business as national service because there are many people who depend on Kiss delivering bread for their family breakfast.”

Kiss Baking is still a young company, but it’s growing, and now boasts over 500 employees. Its fortunes mirror those of Trinidad and Tobago, which gained independence in 1961 and is home to a multicultural population that includes Africans, Indians and people from the Middle East. The nation is famous for giving the world calypso and steelpan music, and its economy has performed well over the past decade, with some bumps due to the 2008 world economic downturn. Per capita GDP tops $20,000, placing it among the best in the Caribbean, and double the figure from 2003.

The island of Trinidad, located just 11 kilometers off the coast of Venezuela, is the larger of the nation’s two islands and has an industrial economy underpinned by petroleum exploration, petrochemical processing and liquefied natural gas. The island of Tobago, meanwhile, has a population of just 60,000 and takes a more Caribbean feel from its beaches and turquoise waters.

The burgeoning economy brings both benefits and challenges, Ackbarali says. People have more disposable income and now purchase more pre-packaged items. But finding employees can be difficult in an expanding economy. “Our wages in the industry are some of the best,” Ackbarali says. “We try as much as possible to keep our employees for life.”

One unexpected benefit is the government’s heavy subsidization of diesel fuel, which sells for less than $1 US per liter. “That’s a huge advantage for us,” Ackbarali says. “It makes the overall running costs for the vehicle

Distributor Anand Ramdeo Likes His UD Truck Anand Ramdeo expresses pride in the way he

drives when delivering bread for Kiss Baking.

“[Recently] A woman came up to me and said,

‘I just try to drive the way you drive,’” Ramdeo

recalls after finishing a shift. Distributors

like Ramdeo take UD trucks to all corners of

Trinidad and Tobago, bringing fresh bread to

the people. Ramdeo operates in “one of the

bigger” Kiss Baking routes in the Princes Town

area of southern Trinidad.

The route winds its way around steep hilltops

and mudslides sometimes block the road. But

Ramdeo says the worst he’s experienced with

his UD truck is a flat tire. He likes his truck,

especially for its air-conditioned comfort—an

important consideration, as his workday is long.

“When you’re spending that kind of time on

the road, you need something comfortable,”

he explains.

Ramdeo’s job is more than just driving. Kiss

Baking’s distributors must learn the needs

of their customers. Of course they have to

introduce the right products, but they also

must deliver just enough bread, a tricky feat

considering the perishable nature of the

product. Ramdeo says he usually manages

this issue well, a sign that he’s doing his job

efficiently. “That’s the difference between

being just a deliveryman and being a Kiss

Distributor,” he says.

a whole lot less.” Surprisingly, tires are the biggest truck expense. “Our trucks are on the road a lot,” she says.

UD trucks are the workhorses of the bread delivery business. Kiss Baking previously used Mercedes-Benz trucks, “But as time went on, they became more and more expensive to maintain,” Ackbarali says. Kiss switched to UD Trucks six years ago and now has 60 vehicles, along with some remaining Mercedes-Benz trucks that are being phased out. “Cost-wise, it’s much better over time, and the initial price is lower, too,” she says of the UD trucks. “Also, parts are readily available.”

Kiss Baking puts priority on maintenance. All trucks are serviced according to OEM recommendations by their in-house Fleet Maintenance Department, oil is changed on schedule and the vehicles’ undercarriages are routinely inspected. Drivers are also encouraged to report any incidents that occur while on the road. Replacement vehicles are always available so that no delivery days are missed. “We keep an adequate amount of spare units to ensure that trucks are

12 #02 | 2013

“ We think of our business as national service because there are many people who depend on Kiss delivering bread for their family breakfast“ Anna Ackbarali

02

03

available to go out,” Ackbarali explains.The company cuts no corners, as exemplified by its

philosophy of spare parts. “Substitute parts don’t last,” says Amar Haniff, maintenance planner in the Fleet Maintenance Department. “The service life of genuine parts outperforms substitutes. Drivers like the UD trucks, too,” Haniff says. “They’re more comfortable and easy to handle.”

UD trucks are popular in Trinidad and Tobago, especially models for construction, according to Neal & Massy, the UD Trucks distributor in the country. There is competition, however. American imports have started to enter the market, along with used trucks from the United Kingdom. (Trinidad and Tobago, like the U.K. and Japan, drive on the left-hand side of the road.) Ackbarali plans to continue with UD trucks and has plans to purchase more. It’s a decision driven by the reliability of UD Trucks. “Our main goal is never to disappoint our customers,” she says.

13 #02 | 2013

Feature Story

UD Mechanic Toshihide Hiranishi

The workday at the UD Trucks dealership in Kanazawa, northwest Japan, starts at 8:50 a.m. with five minutes of stretching exercises guided by a radio broadcast outside the entrance. Among the 40 staff limbering up is Toshihide Hiranishi.Text and Photos: Tony McNicol

A Day in the Life

of a UD Mechanic

A “Quick” Mechanic’s Day

8:30 8:50 9:00 13:00

Arrival at work and

suiting up

Morning exercise and

assembly followed

by a customer center

meeting

Work begins. Regular inspection

and maintenance work;

diagnosing trouble, locating

malfunctions and other work in

the maintenance bay

12:00

Lunch break Work resumes.

Once work on a

vehicle is complete,

the maintenance bay is

cleaned up

14 #02 | 2013

The Kanazawa VISTA team takes a break in their busy day to pose for the camera: (from left) Toshihide Hiranishi, Mechanic; Naoki Nishida, Front; Jun Haruta, Mechanic; and Hiroshi Kontani, Mechanic.

Hiranishi joined UD Trucks Kanazawa 12 years ago at the age of 20. “I wanted to do something useful for society and the economy, and got interested

in trucks,” he recalls. “If we didn’t have trucks to transport goods with, how could we have economic development?”

Shortly after the exercises, all of the mechanics join in a morning greeting and team meeting. It’s a time to discuss what vehicles have come in, assign tasks for the day and share information on repair issues across the team. Following this, work begins in earnest.

UD Trucks Kanazawa has 12 maintenance bays where 22 mechanics work on as many as 40 vehicles a day. The mechanics work in two teams: one for shaken (legally mandated vehicle inspections) and another that does a wide variety of repair work, called “Quick,” of which Hiranishi is a member.

“These days we get a lot of electrical repairs to do,” says Hiranishi. The first step in dealing with such problems is to connect a laptop computer to the truck’s circuitry to run diagnostic software. It’s a far cry from the mostly basic knowledge and techniques he was taught during a two-year course at college, he says.

“There’s nothing to see with electrical problems. That’s the hardest thing,” he says. “Sometimes it’s like there’s a ghost in the machine.”

On the other hand, the challenge of solving such electrical conundrums is one of the job’s joys for Hiranishi.

“I really get into these problems and there’s a sense of achievement when I solve them,” he says.

The number of repairs Hiranishi might perform in a day varies. While some take just a few minutes, others, like an engine overhaul, can take up two or three days. Members of the repair team have

to be “all-rounders,” versatile and able to

cope with a variety of tasks, says Hiranishi. New mechanics at the dealership start off in the shaken team, as it’s a good place to pick up the job’s essential skills.

Hiranishi recalls the huge amount he had to learn when he first joined UD Trucks after college. “More than 90 percent” of what he needed to know had to be picked up on the job.

Back then he simply focused on getting through each day, with little time to think about his colleagues, he says. That’s another big difference; these days, he’s constantly aware of the need for teamwork.

“We spend more time together than

most families,” notes Hiranishi. “It’s extremely important for us to trust and respect each other.”

Some of the mechanics and office staff members are part of an informal social group called jimichi (a play on the Japanese words for “road” and “steady effort”). Their activities include kart racing and jet skiing. “Basically, we all like vehicles,” says Hiranishi.

Jimichi is also the name of the dealership’s successful VISTA (Volvo International Service Training Award) team, of which Hiranishi is a member. Having won the Japanese competition last year, the team is now preparing for the 2014 World Championship in Australia in April.

“If we work together as a team, we can do in Australia what we did in Japan,” he says with confidence.

The dealership’s end-of-the-day meeting is at 5:30pm, but Hiranishi doesn’t necessarily stop there. Recently, he and his three VISTA teammates have been practicing hard for the upcoming competition.

If an emergency repair comes in, such as a truck that has suddenly broken down nearby, the mechanics may work into the early hours. The end of the financial year in March can also be hectic, particularly for the shaken team. At such times, Hiranishi and the other repair staff pitch in to help their colleagues.

“I aim to put passion and energy into everything,” Hiranishi says, echoing the dealership’s slogan. “We aren’t just repairing vehicles. For our team, building a relationship of trust with the customer is the most important part of the job. That’s why I love doing this job.”

“ Building a relationship of trust with the customer is the most important part of the job. That’s why I love doing this job.”

17:30 19:00

End-of-day assembly

and appraisal of

remaining work; tasks

that need to be done

that day are completed

Return home

A “Quick” mechanic’s day is always different from the one

before. Work could be anything from simple jobs, like

changing oil, to complex maintenance procedures spanning

several days. Mechanics on call via the Hotline may be

dispatched to do urgent repairs at any time.

15 #02 | 2013

Feature Story

The Milkman ComethWhen Clover, South Africa’s largest dairy company, decided on a new slogan last year, they chose one that reflects the crucial role that transport plays in the milk industry: “Way better.”Text: Jette Kristiansen Photos: Torbjörn Selander

If you thought air traffic control was complicated, try transporting milk from farm to shop in South Africa. Not only does the milk have to be kept at a constant temperature of below 5˚C, but

every tanker route has to be meticulously planned to fit with the local farmers’ milking routines and milk volumes. These plans include details such as distances to the production plants, road quality, truck and driver availability, and seasonal demand in a vast country that sometimes experiences sweltering conditions.

Different truck combinations have to be considered, with fuel consumption being weighed against terrain difficulties and other complications. Indeed, the math involved in running an efficient milk procurement business seems to call for

nothing short of an Einstein. What’s more, similar conundrums result once the milk has been turned into a finished product and needs to be transported to the shop shelf – and all before the sell-by date is reached.

South African dairy company Clover is expert in exactly this field. So much so that its cold chain transport division has become the company’s fastest growing business area. Apart from their own products such as milk, cheese, butter and cream, they are also responsible for logistics and transport for a number of other local and international brands such as Danone, Unilever and Red Bull.

Clover has a 114-year history and a background in the co-operative movement. Its ultimate objective is to market the milk farmers produce, and demand for the

product dictates all supply chain activities.“At present we have 26 distribution

networks in Southern Africa. Outside South Africa, we also distribute in Swaziland, Lesotho, Botswana and Namibia,” says Clover’s Commercial Director Dr. Jimmy Botes.

“Chilled goods are more difficult to transport than frozen goods because of their limited shelf life. To solve this problem, our philosophy is to control every link in the supply chain. In this context, the vehicle is critical. Without a vehicle, all our other efforts are fruitless,” he points out.

“Our relationship with Clover goes back many years. In fact, Clover is one of UD Truck Southern Africa’s most loyal customers,” says Jacques Carelse, managing director of UD Trucks Southern Africa.

Dr. Botes explains: “The UD truck suits us

16 #02 | 2013

The Milkman Cometh

because it is not electronically complicated. Electronics became a liability to us in the past because we couldn’t assign the same driver to the same truck. Milk is collected and distributed 24/7 by drivers working in shifts, so any truck should be able to be driven by any one of our drivers without complications. Apart from that, they are also reliable work horses in difficult terrains and UD Trucks offer all the different combinations that we need.”

Tobie de Villiers, general manager at Clover’s Milk Procurement Division, adds: “In some of the more distant areas with bad roads and topography, we need to collect the milk in smaller trucks and pump the milk over into bigger tankers, which can transport the milk to the final destination more efficiently.”

Running such a tight ship also puts extra demands on the drivers.

“It is actually the driver who buys the milk. They are our ambassadors when they interact with the milk producers. On top of being put through rigorous driving training, the drivers must also learn how to handle and sample raw milk for later testing. Furthermore, we teach them social and communication skills, which prepare them for anything from conflict management to acting professionally under all conditions and looking presentable,” says de Villiers.

Once the milk has arrived at the factory, getting the product to the shops is the next challenge. Because of the limited shelf life, shops all over the country can place their order one day and expect delivery the next.

The production must more or less fit

demand, as perishable products can’t be kept in a warehouse for long. Stock is taken to distribution centres during the day, then

Dr. Jimmy Botes, Clover Commercial Director

17 #02 | 2013

Feature Story

packed into trucks at night that leave at 6:00 a.m. the following morning for the shops.

Planning distribution to the shops is another logistical puzzle.

“We go to most of the bigger stores all over the country six times a week and the delivery routes have to be planned every single day of the week, because they change constantly. We use the IDS

distribution software system, but you still have to be on your toes,” says Delivery Manager Brigette Willemse from the City Deep Secondary Distribution Branch.

Milk Farming in South AfricaClover’s milk suppliers cover a wide spectrum in terms of approach, size and topography. Most farms are situated along dirt roads where dust, mud and mountainous terrain make every milk truck’s journey a challenge. During winter, snow is a common phenomenon in some regions, and this is a real challenge for both driver and truck. Very few farms are located close to main infrastructure arteries.

One might still find a milk producer playing classical music to his cows during milking, but most producers have streamlined their production to an extent that it is almost factory-like. The fact is, the current economic climate in South Africa has created a situation in which smaller producers either sell or get bigger. As a result, Clover has seen its producer base shrink from more than 1,000 to 240 during

the last ten years.Since the global economic crisis hit four

years ago, bringing drastic price hikes in fuel and foodstuffs, about two-thirds of Clover’s milk farmers gave up and either sold their farms or changed to other more lucrative types of farming.

“It was typically the small farmers who couldn’t make ends meet,” says Manager of Milk Procurement Logistics Anton van den Berg. “Our milk volume has nevertheless remained constant, because the big farms that survived have expanded hugely. Today, the margins are so small that you have to be able to deliver more than 5,000 liters of milk per day to make a profit.”

Clover’s main milk producer in the Western Cape region currently produces 95,000 liters every day. He is also Clover’s biggest milk producer nationally. Three UD tanker-trailer combinations collect milk on the farm in the morning, noon and evening, seven days a week. Efficiency is at the heart of this business model.

Gone are the days when cows calved in the spring. Cows on this farm are

Tobie de Villiers, General Manager, Milk Procurement Division

01

“Chilled goods are more difficult to transport than frozen goods because of their limited shelf life…

in this contex t, the vehicle is critical.“ Dr. Jimmy Botes, Commercial Director

18 #02 | 2013

synchronised and calf all year round to ensure a steady flow of milk.

Gone too are the days when high quality milk equalled a high cream content. On this farm cows are fed a special diet of grass, corn, alfalfa and other food supplements to ensure a high quantity of milk output with a low fat content of about 3.5 percent, as it would be too expensive for Clover to separate the milk fat from the milk and transport it to their butter factory located more than 1600 kilometers away. Instead, it is sold locally as fresh milk.

These huge quantities of milk also put serious pressure on timing and truck reliability. It takes about an hour and a half to fill each truck, and subsequently the farmer needs an hour to clean his tank before he can start milking again. Once produced, the fresh milk has to be cooled down to below 5˚C before it can be loaded onto the truck. As everything has been precisely timed, there is no margin of error for a milk truck to break down or be late. Such an occurrence could create havoc on the farm as well as at Clover’s factory and

further down the supply chain.

Fleet Manager Riaan NaudeClover has 950 trucks in their fleet, of which 65 percent are UD trucks. Of the remaining 35 percent that are not UD trucks, most are trailers and small vehicles. The person responsible for it all is Fleet Manager Riaan Naude.

The company employs 941 drivers nationwide. Together they drive 60 million kilometers per year—a distance equal to that between the sun and the planet Mercury. These conditions put enormous demands on the fleet.

“I’m responsible for fuel consumption, drivers, insurance, branding on the trucks and research, in terms of fuel consumption, etc. I also do the specifications according to the topography of the terrain we’re in. We now use trucks with an automatic gearbox and double axle, which has been an improvement both for our drivers and in terms of damage to the trucks,” says Riaan Naude.

“We lease all of our vehicles from leasing company Eqstra, which is also responsible

for maintenance. But because we have been using UD trucks for so long, we also have a close relationship with them. For instance, I have been to see the assembly factory. I can send UD Trucks a list of my requirements, and they usually provide solutions,” says Naude, who has been with Clover for 24 years.

“I love my job, it’s never boring. To me, this is the best company to work for. I like the people and the brand. My colleagues are my friends. I have a passion for transport and I grew up on a farm, so to me this is the perfect job!” Naude concludes.

Milk and TransportAround 15 percent of the cost of producing a bottle of milk comes from transport costs. At the same time, transport is also a vital link in the supply chain. It is therefore imperative to Clover to have full control over its own logistics and transportation to ensure that it is run reliably and with optimum efficiency. The reliability of UD Trucks has made Clover one of UD Trucks Southern Africa’s biggest and most loyal customers.

01. Clover’s UD trucks regularly navigate dirt roads and rough terrain to reach dairy farms.

02. The source of Clover’s product, dairy cows on a farm in South Africa.

03. Fleet Manager Riaan Naude coordinates issues such as fuel consumption and insurance for 950 vehicles, 65% of which are UD trucks.

02

03

“Chilled goods are more difficult to transport than frozen goods because of their limited shelf life…

in this contex t, the vehicle is critical.“ Dr. Jimmy Botes, Commercial Director

19 #02 | 2013

Feature Story

The warlord Akechi Mitsuharu crossing a lake with his famous horse, Okage, in a woodblock print from 1883 by Utagawa Toyonobu.

The Japanese historical work Taikoki, first published in 1626, contains an account of a warlord named Akechi Mitsuharu. When his castle was besieged by a powerful enemy

and the situation appeared hopeless, under a truce, Akechi sent out works of art and tea ceremony implements, saying, “I cannot bear to see these pieces reduced to ashes. I give them into your keeping, so that they will remain among the living. Please accept them.” Akechi found it shameful to allow the pieces to be lost in the flames of his defeat. “I would be disgraced by posterity for deeds unworthy of our warrior traditions,” he was recorded as saying. “I therefore entrust them to your care.”

It may seem something of a paradox, but in those times, members of the warrior samurai class reconciled their martial spirit with a deep appreciation for beauty and respect for those who created it.

These sentiments are embodied in the Japanese word monozukuri, which is made up of mono (thing) and zukuri, the nominative form of the verb tsukuru (to make). Simply put, in its basic form the word means “making things.”

In English, monozukuri is defined as “manufacturing,” “craftsmanship” and “making things by hand.” Native speakers of Japanese typically relate it to such traditional occupations as sword making, ceramics or textiles, but it can be expanded to cover almost anything that is made with an artisan’s mindset and attention to detail, from the brewing of sake (rice wine) to food preparation by a master chef.

By implication, monozukuri also carries a sense of continuity. A creative genius who dies without leaving an heir to preserve his tradition may be remembered, but one who arranges to pass on his knowhow to future generations is admired even more. This is why it became a common practice for a craftsman without offspring to formally adopt a promising young apprentice into his family.

While the word is not always easy to define, people agree on certain key attributes. These include eye-pleasing design, a sense of refinement and other

qualities that evoke a synergy by which people form psychological or emotional attachments.

Canadian author Timothy Hornyak, author of Loving the Machine: The Art and Science of Japanese Robots (Kodansha International, 2006) offers this insight, using karakuri ningyo, the mechanical dolls of the Edo period, as an example:

“Karakuri ningyo are spectacular examples of how even centuries ago the Japanese were keen on using technology to inspire and delight,” he says. “In typical Japanese fashion, the remarkable clockworks craftsmanship that enabled a tea-serving doll, for example, to approach a guest, offer tea, and then return to its starting point was hidden behind a gorgeous exterior—the porcelain-white face and patterned kimono.

“So essentially monozukuri was the marriage of beauty and ingenuity.”

It is somehow reassuring to know that monozukuri and modernity are by no means mutually exclusive. A recent article in the Asahi Shimbun newspaper used the term “digital monozukuri revolution” when referring to 3D printing technology. And indeed, in the Japanese scheme of things, if computers can be harnessed to mass produce wondrously exquisite things that will synergize with their users, there is no reason why monozukuri cannot be used to describe them.

Monozukuri, the art of making things, touches everything from pottery and swords to robots and trucks. Text: Mark Schreiber

Monozukuri—An Old Word that Keeps Up with the Times

20 #02 | 2013

Monozukuri—An Old Word that Keeps Up with the Times

[monozukuri]

21 #02 | 2013

Tradition

01

01. Kunihisa Shimura sits in the cab of a Quon at the UD Trucks facility in Ageo, Saitama Prefecture, Japan.

02. Quon’s cab interior was engineered to put total control of the vehicle at the driver’s fingertips.

03. Quon’s passenger seat. Extra care was taken to strike a balance between comfort and support.

What does it take to make the perfect truck cab? If anyone knows, it’s Kunihisa Shimura, chief engineer of cab

engineering at UD Trucks HQ in Ageo, Saitama Prefecture, just north of Tokyo.

“The most notable aspect of this cab’s design is the balance between aerodynamics and comfort,” Shimura says.

Using computer simulations and wind-tunnel experiments with a scale model, the aerodynamic performance of the latest Quon was improved 5 percent to 6 percent compared to the model it replaced, thanks in part to the wind deflector on top of the cab. For operators, this equates to a valuable 2 percent to 3 percent improvement in fuel economy.

Of course, it could have been possible to improve aerodynamics further by streamlining the cab, but there was another crucial factor to consider—the comfort of the driver. A roomy, square-shaped cab might not be the most aerodynamic, but it

helps to keep the driver fresh and alert.In some markets, Quon drivers can be at

the wheel for 10 hours or more. “Of course, drivers will still get tired, but we can try to prevent it a little,” Shimura says.

To that end, the high-roof Quon model has a 188.8 cm-tall cab, allowing the average truck driver to stand in the passenger seat area to stretch or change clothes.

Another crucial factor in preventing driver fatigue is the seat. Here, the so-called

Goldilocks effect comes into play. If the polyurethane cushions are too hard, it will be uncomfortable. If they are too soft, it will be equally uncomfortable. They have to be just right.

The seat has its very own air suspension to reduce vibrations and bumps. If there is too much jostling, drivers can begin to feel pain in their backs. In fact, since both the cab and the truck itself also have suspension, there are three sets of suspension between the driver and the road—an invaluable asset in markets where road conditions leave something to be desired. No driver wants the local version of the infamous “African massage,” a nickname for the bumps and jolts of a particularly rough road.

In markets such as Australia, the huge distances involved mean drivers have to work in pairs, one sleeping while the other drives. The sleeping space behind the seats is bigger than it looks at first glance—200 cm by 60 cm—allowing drivers to stretch out comfortably.

Visibility was another consideration when designing the Quon cab, says Shimura. Generally speaking,

because trucks are so high, it can be difficult to see the area right in front of the cab. One solution is to position the driver as close to the windscreen as possible, but that can make the cab feel cramped.

In the Quon, the windscreen is specially angled for maximum visibility. Likewise, the side pillars are as narrow as possible and positioned to minimize blind spots. One distinctive feature unique to the Japan-market model is a small window, placed low on the passenger-side door, through which

drivers can see cyclists and pedestrians when the truck makes a left turn.

The visual environment inside the truck was another important consideration for designers. The interior needs to have muted colors to avoid tiring drivers’ eyes. It can’t be too shiny either, as it might cause distracting reflections on the windscreen. The interior also has to be a color that doesn’t easily show dirt or wear.

For those reasons, neutral grays were chosen, with a gentle silver tone for the dashboard area and a slightly brighter upper section to create a sense of space. “The color needs to be calming. It’s not like a normal car, which can be a bit brighter,” says Shimura.

In fact, all five senses were considered in the design of the Quon’s cab, which is the quietest in its class. Special materials

There is far more to the Quon cab than first meets the eye. Roads talks to cab engineer Kunihisa Shimura.

Text and Photos: Tony McNicol

Making thePerfect Quon Cab

“ The most notable aspect of this cab’s design is the balance between aerodynamics and comfort.” Kunihisa Shimura, Chief Engineer, Cab Engineering

22 #02 | 2013

were used to reduce vibrations and absorb sounds from the engine and air rushing past the cab. The aim, however, wasn’t to completely soundproof the cab. “If there was no sound at all, it could be quite frightening for drivers,” says Shimura. The Goldilocks effect comes into play yet again.

Even smell was considered. The cab was designed to meet newly introduced regulations on volatile organic chemicals (VOC). These are the chemicals in adhesives, resins and other substances that give the “new car” smell. They can make drivers of new cars feel queasy or cause headaches. VOCs in the Quon were reduced to one-tenth that of prior models.

So what were the biggest challenges for the Quon cab’s designers? According to Shimura, one was reducing the weight of the cab to an absolute minimum to

allow more cargo. Another was “fitting the heaters, pedal machinery, meters etc. into as small a space as possible, to leave maximum room for the driver.”

Lastly, there’s one aspect of the cab for which designers might be forgiven for having some ambivalent feelings: customization. Popular changes include the installation of CB radios, curtain changes

and other alterations. The area to the left of the dashboard uses German DIN standards to allow easy rearrangement or replacement of modules.

The Quon’s cab is an adept balance of efficiency, performance, comfort and safety, making it yet another demonstration of the designers’ focus on the most important consideration of all: the needs of the driver.

02

Making thePerfect Quon Cab

03

23 #02 | 2013

Engineering

Moving your business the extra mile

A complete transport solution UD Trucks is your business partner, fully committed

to offer you a total solution. Our complete

Genuine Aftermarket Support delivers quality and

value, making sure your truck always runs in

optimum condition.

UD Genuine Service and PartsOur service technicians and our specially designed

parts reduce unplanned stops and increase your

vehicle uptime.

UD Genuine Service agreementsUD Genuine Service agreements extend your

vehicle’s life cycle – cutting your costs in the

long run.

Explore UD Trucks’ Aftermarket offer

at udtrucks.com

291-0053_UD_P9103_Ad_ROADS_210x297.indd 2 2013-07-11 16:24