Ring gasket

description

Transcript of Ring gasket

10/27/2011 1

ASME/ANSI/API Gasket Workshop

10/27/2011 2

Presentation Objective

Give attendees a better understanding of the identification and problems associated with commonly used ASME and API gaskets.

How to Inspect Bolting to Specification requirements.

10/27/2011 3

Agenda Doing our Quality Part of the Team Gasket Standards used by Governing Codes. The Purpose of a Global Identification and Color Coding system for

Gaskets Specification Requirements for Spiral Wound gaskets ASME B16.20 Material requirements for Spiral Wound Gaskets Color Codes and Product Marking for Spiral Wound Gaskets Inspection of Spiral Wound Inspection of Ring Joint Gaskets Problems with Spiral Wound and Ring Joint Gaskets Non Metal gaskets Importance of proper bolt torque ASTM A320/A193/A194 bolting Questions and Answer/Discussion

10/27/2011 4

The Team Players All of us play an important role in the successful Operations of

the Pressure Systems on the FPSOs, Production Platforms or Ships. However, we cannot forget about the rest of the team in Operations and Maintenance

Maintenance Commissioning Operations

Receiving Inspection

Installation By Construction

Engineering Procurement Design

10/27/2011 5

Gasket “WIN WIN” Results No matter what area that your services are used we are all one Team and we need to think about the work now to avoid problems for other departments. Design: Pressure System Design. What the Owner Wants. Engineering: Engineer the Systems with the proper Materials to suit the

Process, Pressures and Temperatures Procurement: Purchase the different Materials and Equipment for Qualified

Contractors, Suppliers and Vendors. Receiving Inspection: To ensure that the Equipment and Materials are in

accordance with Contractor Requirements. Fabrication: Inspection and Installation by the Construction Teams Commissioning: to ensure all systems work as designed and Safely. Operations Department: Operate the end product in the installed locations

to produce the desired product to make profits. Maintenance Department: To maintain the pressure systems to operate

safely and efficiently.

10/27/2011 6

Doing Our Part as the Construction Inspection Team

The design and Construction Engineers generally have a lot of work and sometimes they are working several projects at one time. Small details may be missed or not addressed. This is why being a Team and having more than one pair of eyes review and inspect helps catch the small details that may have been missed by someone else. We all have different levels of experience.

Read the Project Specifications to know what type of Gaskets are required. Verify if there are any additional requirements in the specification over and above the gasket standards. The Piping Material Class will tell you what styles and materials are required for the Gaskets.

Find a Copy of the Gasket Standards, if you do not have it your Quality Manager can get you a copy through the Document systems.

Read all of the requirements in the Gasket Standards such as what type of material is required, if the material requires coating for corrosion protect, How is it properly identified.

Gasket Manufacturers do not all follow the Gasket standards for marking, coating and color coding for proper identifications.

Any doubt as to the received gaskets consult the Quality Manager and/or the Project Piping Engineer, they do not mind helping with material questions. That is part of their job. Even Good Piping and Equipment Inspectors should always review requirements and verify the results. There are too many variables concerning Gaskets to remember them all. Technology is always changing.

Improper manufactured Gaskets, Improper Gasket Materials and Gaskets installed with no Color Codes and Corrosion protection are setting the Operations and Maintenance departments up for FAILURE!

10/27/2011 7

Gaskets Standards used by Governing Codes

ASME Pressure Vessel Codes do include Gaskets Standards instead of specific gasket types due to too many variables dealing with Gasket types required for the pressure systems.

The ASME B31 Piping Codes for Pressure Pipe and Power Piping list the ASME B16.20, B16.21 and B16.47 (For Large Flanges) gasket standards to be used for ASME applications.

API Standards refer to ANSI ASME Type Gaskets without the standards being named and for High pressure Ring Joints list the API-6A.

There are many other Construction Codes used for fabrication of offshore platforms and equipment and all cannot be covered during this presentation so the Codes being used presently on this project are referenced.

10/27/2011 8

The Purpose for a Global Gasket Identification System

The major construction codes such as ASME and API determined many years ago that the quick and proper identification of Gaskets installed in pressure systems is required.

A Gasket Color Code systems was globally standardized and all Gasket Manufacturers are to use the same color code system. It does not matter what country the gaskets are made in if they are made to a standard, the color code of that standard is required.

The Color Code used on the Spiral Wound gasket is just as important as the Material and Style of the gasket. All need to be correct.

When Spiral Wound gaskets are not properly color coded as required by the gasket standards, it does not matter the experience level of the Inspector. there is no way an identification of the gasket can be made by looking into the fit-up flange.

When gaskets are properly color coded as required by the standards it only takes about 1 minute to identify the gasket in the flange and/or the replacement gasket for a leaking flange.

Ring Joint gaskets do not require color coding and you can verify the markings and material after installation.

Sheet gaskets such as Grafoil you can verify the color of the gaskets.

10/27/2011 9

Project Specification Requirements for Spiral Wound Gaskets

Verify the Project Specification to see if the material for inner and outer rings are specified. For most offshore applications the Project specification may required 316 Spiral Wound gaskets with 316 inner and 316 outer rings. Some project specifications may not state inner and outer ring materials.

When the specification states 316 material without referencing the inner or outer ring material this is only the material specified for the spiral wounding.

When inner and outer ring is not specified in the Project Specification then the Gasket Manufacturer is only required to follow the gasket standard for materials.

When the outer ring is not specified in the specification the manufacturer will use cheap Carbon Steel for the outer ring and for the inner ring. If the pressure system is a low temperature system the Project Piping Engineer should be consulted. A specification change may be needed.

The gasket filler material should be specified in the Project pipe material class sections.

10/27/2011 10

Material Requirements for ASME B16.20 Spiral Wound Gaskets

B16.20 (3.3) Centering/Outer Ring Requirements: The centering ring may be Carbon Steel that is painted, metal plated, or otherwise coated to inhibit atmospheric corrosion.

B16.20 (3.3) Metallic Winding Materials as specified in Table 19 or as required by the Project Specification.

B16.20 (3.3) The inner ring shall should be of a material that has the corrosion resistant characteristics equivalent to or better than that of the metal winding. However, if the inner ring is not specified by the purchaser Carbon Steel can be used for the inner ring.

B16.20 Table 19 list 5 filler materials used 1. Chrysotile Asbestos (ASB), not normally used any more on any Oil and Gas

Projects. 2. Poltetrafluoroethylene (PTFE) Telfon Type may be used in chemical systems. Not

good for high temperatures. 3. Mica-graphite (mfr’s designation) 4. Flexible-graphite (F.G) used a lot in the Oil and Gas Industry due to its heat and fire

resistance 5. Ceramic (CER) would be used in a very high temperature system, not normal to oil

and gas

10/27/2011 11

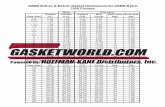

Color Codes for Spiral Wound per ASME B16.20

10/27/2011 12

10/27/2011 13

10/27/2011 14

10/27/2011 15

Spiral Wound Gasket

Marking

10/27/2011 16

Typical ASME B16.20 Gasket Marking

This example is from Flexitallic.com and shows the required gasket marking

10/27/2011 17

Inspection of Spiral Wound before Installation

A Spiral Wound Gasket should never be re-used. If it has flange face lines or looks used it should be rejected. If the gasket has been removed from the flange installation for any reason it should not be allowed to be used again.

Verify the gasket has all of the required markings The use of a Magnet is suggested to verify that the winding and inner ring are non

magnetic. This would apply to the outer centering ring if a non-magnetic material such as 304 or 316 is specified.

Check the gasket for flatness to make sure it has not been dented or bowed during shipment. If the gasket has been dented or bowed it may not be tightened properly and may not seal.

Check the filler surface for any scrapes or damage to the filler surface. There may be a few very small indications but anything that goes from the out edge of the filler to the inner edge of the filler may cause improper seating and a leak..

Check and count the outside filler windings B16.20 3.2.3 tells you how many windings are required to be visible without filler and where the windings shall be spot welded.

If the gasket is not color coded as required it should be rejected. If the gasket is not marked as required it should be rejected. There are many problems with the spiral wound gaskets in therefore as many as

possible should be inspected.

10/27/2011 18

Problems with Spiral Wound after installation

The Pipe flange styles should be matched such as a raised face to a raised face. If you have flange faces that do not match such as a raised face to a flat face consult the Piping Engineer to see what type of gasket should be used. This can happen sometime to a connection between pipe and equipment.

There should not be any tape residue left on the gasket grooves. This is common in that the grey sticky tape is used to protect the flanges during storage. We need to make them properly cover the flanges for storage or make them clean all of the tape residue off before flange up.

There should not be any sticky stuff used on the gasket or in the gasket groove to hold the gasket in place for flange up. Using a substance such as never seize to hold the gasket will affect the gasket seal.

Wrong Gasket size used. The centering ring should end up very close to the edge of the stud bolts. If there seems to be too much space between the stud bolt and the edge of the centering ring then the gasket is too small for the flange size. See ANSI B16.5 for picture details and dimensions.

Gasket is flatter on one side than the other. This can be caused for the flanges being out of alignment tolerances. It can also be caused from improper tightening sequence being used.

Gasket is cupped towards one flange side. The gasket has been over tightened and should be rejected and replaced. Over tightening damages the gasket seal and sometimes can cause the winding to spring into the inside of the pipe. You cannot see from the outside if the winding has been sprung. This can happen a lot when air wrenches are used for Tightening. Any cupping should be rejected.

10/27/2011 19

Example how the spiral wound should fit in a Flange and the clearance required from the stud bolts. If you have you have more clearance between the stud bolt and the centering ring, the gasket used could be the wrong size and should be investigated. The clearance between the stud bolt and the centering ring edge should be equal all around the flange.

10/27/2011 20

Specification Requirements for Ring Joint Gaskets

Piping Material Class will list the Class such as 1500lb. Gasket shape such as Oval or Octagonal Gasket Type such as type R, RX etc… Material Type Governing Standard such as ASME B16.20 or API6A Inspector should verify if any additional requirements are listed in the

Specification

10/27/2011 21

Ring Joint Gasket Identification

Remember Ring Joint Flanges require the corresponding R identification stamped On the Flange. This also applies to Ring Joint Valve Flanges.

10/27/2011 22

Typical Ring Joint Markings

Kukil R51S316 B16.20

10/27/2011 23

Inspection Of Ring Joints Ring Joints should never be re-used. If the ring joint looks like it has been

compressed even slightly reject it. Inspect for any dents of deformation due to improper shipping Verify that the ring joint is properly marked The R Number should be as required for the Pipe Material Class and should

correspond with the R-Number mark on the flange Verify that the material is correct per the pipe class Ring Joints should be stored on a flat surface with something in between each

gasket to protect from scratches. They should never be stored standing up or on nail.

10/27/2011 24

Problems with Ring Joint Installation Flanges using Ring Joint Gaskets should always be properly torqued. If the flanges

are not properly torqued it may not pass hydro testing or the Nitrogen testing performed by the commissioning group.

There should not be any tape residue left on the gasket grooves. This is common in that the grey sticky tape is used to protect the flanges during storage. We need to make them properly cover the flanges for storage or make them clean all of the tape residue off before flange up.

There should not be any sticky stuff used on the gasket or in the gasket groove to hold the gasket in place for flange up. Using a substance such as never seize to hold the gasket will affect the gasket seal.

10/27/2011 25

ASME B16.47 for Large Flanges

B16.47 does not give much detail for the materials, color coding and or filler materials for gaskets.

Section 6.6 states: 1. Ring Joint Dimensions to be per ASME B16.20 2. Non-Metallic Dimensions for Series A flanges with raised face shall conform to

ASME B16.20 3. Spiral Wound Gaskets and Double jacketed corrugated metal gaskets shall

conform to ASME B16.21. The gaskets being required to conform to these standards include the Materials,

Manufacture and Color Coding.

10/27/2011 26

Other Gasket Types

The Project Specification may list other Non Metallic type gaskets such as Grafoil or a Type of Rubber.

The Pipe Material class sheet will list the Gasket Standard that applies. Review the applicable standards and learn as much as possible about identifying

and installing these gaskets.

10/27/2011 27

Inspection Of Non Metallic Gaskets Gaskets should never be re-used. If it looks used reject it. To inspect Grafoil Gaskets verify that there is no squashing or cutting on the gasket.

The grafoil gasket has a stainless steel mesh inside the grafite. Check the gasket using a small magnet to make sure that Carbon Steel Mess has not be substituted for the stainless.

Rubber type gaskets should be in good pliable condition with no dry rotting. They should be clean. The gaskets should be marked with the material type, size and manufacturer. Sometimes the specification requires a certain hardness value and this should be verified with the manufactures test information.

Other porous material sheet gaskets should also be identified with the manufactures identification and the gasket type.

Check applicable standards for marking requirements.

10/27/2011 28

Bolt Torque It is very important to use proper torque sequences when bolting is tightened. Spiral wound and Ring Joint gaskets require the proper torque to seal. If the proper sequence

and torque is not used leaks can occur during hydro testing, commissioning or after the pressure systems has been put into service and has went through heating and cooling cycles.

Generally Spiral Wound gaskets require a minimum of 30,000 psi bolt stress for proper gasket seating.

Flanges leaking during hydro testing should never be torqued while under the test pressure. Bolting should be tightened evenly around the flange and not all at once Some Examples of Proper Bolt Tightening Sequence

10/27/2011 29

Bolting Bolting Material is as important as the Gaskets used in the Flange. Without the

proper bolting, the gasket may not seal or it will begin leaking a short time after being put into service.

Bolting Materials are always stated in the Piping Material Class The Inspector should review the bolting standards and know how to identify the

bolting and if the bolting is as specified. The ASTM standards used to manufacture the bolting is very clear on how the

bolting shall be marked.

10/27/2011 30

Common Bolting Material Issues Non ASTM Bolting is supplied Low temperature bolting is supplied without low temperature nuts Un-Marked Stainless Steel Bolting is supplied ASTM 193 Stainless Bolts Class 1 are supplied, instead of Class 2 Bolting supplied from the Valve Manufacturer have the same problems as above.

10/27/2011 31

Bolt Markings Stud Bolts require the manufacturer or symbol and the Grade stamped on the ends of the bolt.

If the stud bolt diameter is too small to stamp both on one end then the Manufacturers mark can be on one end and the grade on the other.

Machine (Hex Head) Bolts require the Manufacturer or Manufacturers symbol and the grade to be stamped on the head of the bolt.

Nuts require the Manufacturer or Manufacturers symbol to be stamped on one side of the nut. The nut should always be installed with this marking out.

Stud Bolts to ASTM A320 shall be marked with a L such as L7 Carbon Steel Bolts. Nuts for these bolts shall also be stamped with a L such as 7L. The specification usually list the grade of Low temp Nut only the L is never listed. The ASTM standards are very clear. If the bolt manufacturer is following the bolt standards the nuts will also have a L. If the nuts do not have the L the same as the stud bolts, impact testing was not performed on the bolt materials.

Stainless Steel bolts such as 304 are marked using a B8 for the grade. Clients generally require that ASTM A 193 stainless steel be Class 2 bolting. I have only seen one Project in 25 years that bought the class 2 stainless bolts the first time. If the specification calls for Class 2 or Strain Hardened bolting the grade marking is underlined such as B8. regular stainless steel bolting class 1 stretch when tightening and if the gasket seals it may not stay sealed after a few process cycles. Stainless Steel Bolting should always be inspected as soon as possible because if Class 2 is required they are more expensive and most contractors do not order class 2.

10/27/2011 32

Summary, How do we fix the Gasket and Bolt Material Problems

Reject and Correct. Improvement will not happen unless it is required. Explain and show where the requirements are in the specifications and standards. If we let gaskets and bolting be installed without the proper identification and color coding

system the Gasket and bolting manufacturers will never change and correct the problem because it cost money.

A Plan should be put in place to perform inspections while the gasket and bolt materials are in the warehouse so when these items require replacing it may not affect the schedule.

Gasket and Bolting manufacturers should be regularly Surveyed and materials verified at the manufacturing facilities where they know we mean business.

When Gaskets and Bolts are not correctly marked or color coded, do not allow the EPC Contractor to mark the items or color code. These items should be sent back to the Manufacturer.

Be consistent do not slack up on the inspection of these items if they are corrected. If you are not consistent they will go back to the cheaper ways.

10/27/2011 33

Where to Get More Information The Quality Manager has electronic files of the below standards for Company use

please let him know if you want a copy. ASME B16.20 ASME B16.21 ASME B16.47 ASME/ANSI B16.5 ASTM A320 ASTM A193 ASTM A194 MSS-SP-25 Please remember that these are Copy write Documents and are for Company use

only. No unauthorized distribution or photo copying is allowed. Additionally there is a lot of information on the internet. Two good websites

recommended is Garlock.com and Flexitallic.com If during your specification review other standards are needed let your Quality

Manager know and he will check the document system to see if it is available.