Rig Material to Location Using Crane

-

Upload

abdul-hakam-mohamed-yusof -

Category

Documents

-

view

213 -

download

0

Transcript of Rig Material to Location Using Crane

Talisman Malaysia LimitedHS&E Section

Job Safety Analysis

Doc. No: PM3-HSE-GEN-PR-F-00!

Re"ision: 0Date: J#ne $00%Pae: A''en(i) 3

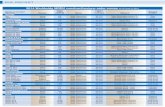

JOB SAFETY ANALYSIS WORKSHEETS

JOB SAFETY ANALYSIS DATE PERMIT NO:

JOB Rig up project materials to location using crane

WORK TEAM Rigging Crew

SEQUENCE OF BASIC JOB STEPS POTENTIAL ACCIDENTS OR HAZARDS RECOMMENDED SAFE JOB PROCEDURES

1. Raise Cold Work Permit for the job. Conf lict with others activities.

2. Removal of project material from cargo basket. Unorganied lifting. Plan material for lifting.

!. "ransferring the material b# crane. $oad swings% load sl ips% load falls. Communicationfailure.

Use tagline& do not stand under the load. Propercommunication with the operator.

'. $a#down the material at location b# crane. $oad swings% load slips% load falls. Use tagline& do not stand under the load. Propercommunication with the operator.

WHAT TO CHECK AND NOT LIMITED TO WITH REFERENCE TO APPENDIX 1 & 2 OF THE JOB SAFETY ANALYSIS SECTION OF MOGP MANUAL

EXPERIENCE YES NO YES NO

(ave #ou done this job before) * +re #ou knowledgeable with the job to beperformed)

*

(ave #ou referred to technical drawing*vendorprocedure*,,P)

* -s supervision*eperienced assistance re/uired) *

PPE YES NO YES NO

(ard hat) * Work vest) *

,afet# 0lasses) * +pron) *

,afet# shoes) * 0oggle) *

ar plugs) * ace shield) *

Right t#pe of gloves) * Respirator# protection) *

,afet# harness) *

POTENTIAL HAZARDS YES NO YES NO

,lipper# floor) * "rapped pressure) *

Congested area) * Pressuried e/uipment*vessel haard) *

"ripping) * ire*eplosion haards) *

3verhead work) * scape route) *

Working at height) * ,hock*electricit#*static) *

,caffolding) * 4reaker rack out) *

,ecure ladder) * 5alve isolation) *

TML MANAGING OPERATIONS WITH GENERAL PROCEDURES Rev. 0

Talisman Malaysia LimitedHS&E Section

Job Safety Analysis

Doc. No: PM3-HSE-GEN-PR-F-00!

Re"ision: 0Date: J#ne $00%Pae: A''en(i) 3

(eav# load) * 0uard rotating e/uipment) *

(ammer strikes) * Power tools haards) *

Pinch*trap finger% hand) * (igh noise area% double ear protection) *

4ack injur# haard) * ,park*hot slag) *

,winging object) * 4urn 6heat*chemical7) *

alling object) * 8ear radioactive materials*sources) *

3thers closeb#) * * nvironmental spill) *

,harp object) * * (ose connection) *

#e injur#) * Wind#) *

0rating*deck opening) * 9ust#) *

4locked drains) *

Prepared b#:;....................... ;; Reviewed b#: ;;;;;;;;;;.. Closed out: <<<<<<<<<<<<<<<<<<<<<<<<<

TML MANAGING OPERATIONS WITH GENERAL PROCEDURES Rev. 0