Rhino Strap Cam 27JAN2015

-

Upload

peter-moore -

Category

Documents

-

view

66 -

download

2

Transcript of Rhino Strap Cam 27JAN2015

RHINO STRAPNEW AREAL COVERAGE SUPPORT THAT WILL INCREASE SAFETY IN

THE

MINING INDUSTRY

ABSTRACT

Oslo or Osro Straps have been used for years to provide areal support for South African mines. The straps are used to link tendons depending on the

support pattern of the mine or rock. The straps in conjunction with mesh are designed to contain the smaller rock that would otherwise fall from between

the tendons as well as to keep the mesh in place as a secondary support tool. We have design a new form of Oslo Strap called the Rhino Strap, it has been tested at South Deep Gold Mine, and Petra Diamonds koffiefontein, by Dr D van Niekerk and Dr BP Watson, proven that the Rhino Strap can carry double

the load, and is much easier to install due to its lighter mass. There are also other benefits of the new design associated with stacking and ease of

installation.

INTRODUCTIONOslo or Osro straps replace the traditional lacing used on the conventional mines. Their function, in conjunction with mesh, is to contain smaller falls of ground (FOGs) that would otherwise occur between tendons as well as to serve as a secondary support tool to increase safety. The Rhino Straps link between tendons in two orthogonal directions and generally terminate at a tendon. There is prodomanitly 3 sizes of the Rhino Strap on the market at the moment 3m,4.5m and 6m, all with a 10mm round bar. Due to the design of the Rhino strap, the strength has increased by double making the Rhino superior to the Oslo/Osro CSIR Test proved this fact. The Rhino Strap is also a lighter and easier product to install.

RHINO STRAP

EASY INSTALLATION BULLNOSE @ PETRA DIAMOND MINE

UNDERGROUND, THE RHINO STRAPS WOULD TYPICALLY BE STACKED AND CLAMPED, DEPENDING ON THE

SUPPORT STANDARD OF THE MINE, BY A TENDON WITH A DOME-SHAPED WASHER. ROCKS FALLING OUT

BETWEEN THE ANCHORS WOULD THUS BE CONTAINED BY THE MESH AND STRAP ARRANGEMENT. THE TENDON WOULD BE RESPONSIBLE FOR OVERALL STABILITY, WHILE

THE MESH AND STRAPS WOULD CATER FOR ANY BLOCKS BETWEEN THE TENDONS.

The new Rhino Strap is similar to the Oslo Strap but is significantly stronger due to a Stronger design. This article describes the design of the Rhino Strap and compares its performance to the traditional Oslo Strap.

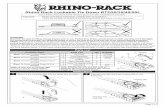

Design of the Rhino Strap

The Rhino Strap is designed in the shape of a hummock to ensure that all four of the 10mm diameter bars are clamped by the dome washer. The 6mm diameter “cross-bars” are replaced by 2mm thick flat-bar, as its function is to keep the 10mm diameter bars together and has little effect on the strength of the unit.

.

LOAD BEARING CAPACITY REQUIREMENTTHE SPHERE OF INFLUENCE OF A TENDON IS

CONICAL IN SHAPE UNDER HOMOGENEOUS ISOTROPIC ROCK MASS CONDITIONS (RYDER AND JAGER, 2002). HOWEVER, IN REALITY THE

SHAPE AND DIMENSIONS OF THE INFLUENCE ARE AFFECTED BY BEDDING AND OTHER

DISCONTINUITIES. UNDER IDEAL CONDITIONS, THEREFORE, THE MESH AND OSLO STRAP

CONSTRUCTION WOULD NEED TO SUPPORT THE SUPPORT PATTERN OF THE MINE AND ALSO THE SHAPE OF THE UNSUPPORTED ZONE. ASSUMING

ALL STANDARDS AND PROCEDURES ARE FOLLOWED. THE EFFECTS OF THE

DISCONTINUITIES COULD BE ACCOUNTED FOR BY USING A FACTOR OF SAFETY.

𝑽 =𝟏

𝟑𝒍𝒘𝒉 SHAPE OF THE UNSUPPORTED ZONE

BETWEEN SUPPORT ELEMENTS

3M DESIGN

4.5M DESIGN

6M DESIGN

RHINO VERSES OSLO

RHINO STACKING AND STORING

Advantage : Stacking of the Rhino strap when clamping is made easy by means of the more concentrated design, which creates a stable mounting.

Advantage : Due to the lighter wait of the Rhino strap it is easier to transport and store the product as well as issue it.

Advantage : If there is a need to bend the strap as a means to get it underground, it is a lot easier as to the change in the 2mm plate diagonal fittings

OSLO STACKING AND STORING

Disadvantage : Oslo makes use of a 6mm twirled round bar in the form of a pigtail, to tie the strands together, which creates an uneven and unstable mounting. This also takes up allot of mounting

area.

Disadvantage : The Oslo/Osro is a lot harder to store due to all the diagonal round bar which entangles into each other causing them to interlock.

Disadvantage : while installing the Oslo/Osro you need a person to hold each in position due to the wait. Which could be hazards to the employees.

POINT LOADING AND INSTALLING RHINO STRAP

Advantage : A spreaded load is formed with the mounting washer on the flat bar when clamping down. This method does not create a point load.

Advantage : It is a lot more visible to see where to pin.

Advantage : You will be able to use less people while installing the strap as the strap forms to the wall or supporting area.

POINT LOADING AND INSTALLING OSLO/OSRO STRAP

Disadvantage : Disadvantages of the Oslo is a point load which is created on the round bar when clamping down with the mounting washer i.e. the washer acts as a guillotine.

Disadvantage : Operators tend to struggle to find the correct place to pin the strap.

Disadvantage : You will need extra employees to insure correct installation.

COSTING OF RHINO STRAP

Advantage : Due to the improvement of the strap the costing of producing The Rhino Strap has decreased.

Advantage : We have over 2 factories that already manufacture for us which means there will not be a problem with delivery.

SUMMARY

RHINO ADVANTAGESAny bends or bullnoses will not affect the strength of the strap. The aperture between the strands is wider than the opposition and makes anchoring

penetration easier when stacking.

Due to the strap being lighter in weight, it makes for easier loading and installation.

Installation is also faster due the bigger apertures. The plastic tubes tend not to pinch with the bigger apertures and alleviate the previous

problem had with the grouting.

The 2 longitudinal flat bars can be clamped at any point along the length and will still be

above the safe load.

One less person is used during installation.

Bending the Rhino strap is easy when installing on corners and bullnoses.

The longer and bigger apertures allows for a more convenient pitch between the holes. A hammock effect is created due to the fact all strands are active.

OSLO DISADVANTAGES

• Bending the product and applying is difficult due to the

design.

• Small apertures makes positioning difficult when stacking

and clamping.

• The strap is much heavier and more cumbersome, that

makes installation more difficult.

• The smaller apertures creates a pinching problem with the

plastic tubes when clamping.

• The 2 longitudinal round bars will always have the

substandard load because of the area of the steel and the

point load problem.

• Strands are being cut off when anchoring is done due the

aperture.

CONCLUSION

In the mining industry, there are numerous strap designs which are in place to support the walls of a mine, yet they fail dismally with potentially lethal effects once a force greater than their intended design comes into play.

Rhino Industrial Solutions have developed the latest mine wall support strap known as the Rhino Strap which by far exceeds the current maximum force limit set by the 'Oslo Strap'. The maximum force limit set by the Rhino Strap is more than double that of the 'Oslo Strap'. The reason behind our re-invention of the mine wall support strap are as follows:

The short fall of the 'Oslo Strap' in terms Of its design and structural support, integrity led us to one conclusion, that the mine wall strap needs to be re-invented , CSIR testing on the 'Oslo Strap' presented many design flaws such as: The fact that the design on the mounting is incorrect, there is only clamping on the two strands, Whereas the Rhino Strap has clamping on all the strands. The ends curl up with fastening of the anchors by means of the round washer. On the Rhino Strap the ends forms a neat finish with no curled ends when the product is mounted. CSIR test conducted on the Rhino Strap has proven the fact that the Rhino Strap performed with far greater results and is unique on all accounts based on its design, functionality and performance. The advantages of the Rhino Strap is not only its strength but also the fact that it is lighter than the current product.

The Rhino strap is also more user friendly and easier to install. The manufacturing of the Rhino strap is a much easier process and cost effective. The product is easier to package and easier to transport. The Rhino Strap has been Internationally patented and has been designed with a unique feature to clamp all four strands equally.The Rhino Strap can be produced with or without the strapping ends at any length or width that would be required.

All CSIR tests and Certification are available on request.

Feedback on the installation / testing of the “Rhino” straps in the 95 3w tm³ areas by Eventspec.

We have briefly discussed the testing / installation progress of the “Rhino” straps in the underground environment and how the strap actually works / handles during the physical installation process.

According to “Jan Miller” the Eventspec support shift boss and “Adriaan Swanepoel & Johan Martiz” the drill rig operators, the “Rhino” strap has proven to work very well during the installation process and the secondary support crews also had the following to say regarding the straps:

The “Rhino” strap is physically lighter than the osro strap. The straps handles better when loading and off-loading. (Due to hand gripping area and weight) We currently use 1 x support worker less when installing the “rhino” strap due to the easy installation and weight of the strap. The “Rhino” strap trends to bend easily when it has to be bent for corner installation in the trackless ends. The installation process proved to be quicker and better due to the fact that the larger openings of the anchor for the installation process.

This proved that there is more space to drill the hole in the correct position and that it also ensures that the strap is pinned properly on the correct spacing’s.

The bigger openings also helps with sufficient space for the anchor pipes to come through and also helps stop / avoid the grouting problem that we have been experiencing when the anchors needed to be grouted. This was a problem for grouting of the anchors due to the lack of space for the pipes through the osro straps. This also caused for the support crews to cut some of the strands of the osro straps to ensure enough space for the anchor pipes. (This damaged the straps before the strap has done any work.)

The dome plate also covers all 4 strands of the “Rhino” strap when installed. The dome plate only covers two of the strands on the osro strap. This should help with the general strength of the “Rhino” strap.

The “Rhino” straps also nicely fit on top of each other when the “cross-over” of the strap lines per ring of the anchors are installed and tightened.

REGISTERED SUPPLIERS

ELECTRICAL WEB (PTY)LTD

Tel : 011 3148022

Cell : +27 731511515 ( Peter)

Cell : +27 82 534 6395 (Diane)

Email : [email protected]

Website : www.electricalweb.co.za