Review Materials...

Transcript of Review Materials...

Review Materials Science

The development of BiFeO3-based ceramics

Ahmad Hussain • Xijun Xu • Guoliang Yuan •

Yiping Wang • Ying Yang • Jiang Yin •

Junming Liu • Zhiguo Liu

Received: 21 May 2014 / Accepted: 19 July 2014 / Published online: 16 October 2014

� Science China Press and Springer-Verlag Berlin Heidelberg 2014

Abstract The multiferroic properties of BiFeO3-based

ceramics were improved through optimizing their sintering

method and doping with certain rare earth elements in pure

BiFeO3. Some methods, especially liquid-phase sintering

method has largely decreased the densities of oxygen

vacancies and Fe2? in BiFeO3-based ceramics, and thus

their resistivity became high enough to measure the satu-

rated polarization and the large piezoelectric d33 coefficient

under the high electric field of [150 kV/cm. Besides,

multiferroic properties were improved through the rare

earth elements’ doping in pure BiFeO3. Magnetization

commonly increases with the proportional increase of Nd,

La, Sm and Dy contents up to *30 %, while ferroelectric

phase can transform to paraelectric phase at a certain

proportion. An improved magnetoelectric coupling was

often observed at ferroelectric phase with a relatively large

proportion. Besides, an enhanced piezoelectric coefficient

is expected in BiFeO3-based ceramics with morphotropic

phase boundaries as they are already observed in thin

epitaxial BiFeO3 films.

Keywords Multiferroic � FE–PE phase transition �Liquid-phase sintering method

1 Introduction

Multiferroics or multifunctional materials have become

one of the hottest topics of condensed matter physics and

materials science in recent years, in which two or more

than two ferroicities properties coexist. Coexistence of

simultaneous order parameters in multiferroics enhances

the novel physical phenomena and offers the possibilities

for new device functions. Some novel discoveries and

concepts are revived by recent research activities on mul-

tiferroics, which have been evidenced by both experimental

and theoretical way. In present study, we have outlined few

progressive developments for the single-phase multiferroic

BiFeO3-based ceramics where magnetism and ferroelec-

tricity can coexist. Initially, we have empathized on the

synthesis techniques and the modifications, which are

brought to achieve pure single-phase BiFeO3-based

ceramics and after that their behavior is summarized under

the influence of rare earth-doped materials. For the gen-

eration of multiferroicity, three novel mechanisms are

addressed with special care: first is the induced ferroelec-

tricity by the spin orders such as spiral and E-phase anti-

ferromagnetic spin orders which have the tendency to

break the spatial inversion symmetry. Second is the fer-

roelectricity, which is originated from the charge-ordered

states. Third is the ferrotoroidic system [1–5]. Multiferroics

allow the manipulation of magnetic ordering through the

switching of electric polarization and vice versa. Bismuth

ferrite (BiFeO3) is the most famous one among the well-

known multiferroic materials, because it is ferroelectric

below its Curie temperature (TC) of *1,103 K and is

SPECIAL TOPIC: Multiferroic Materials

A. Hussain � X. Xu � G. Yuan (&)

School of Materials Science and Engineering, Nanjing

University of Science and Technology, Nanjing 210094, China

e-mail: [email protected]

G. Yuan � J. Yin � J. Liu � Z. Liu

National Laboratory of Solid State Microstructures, Department

of Materials Science and Engineering, Nanjing University,

Nanjing 210093, China

Y. Wang � Y. Yang

Precision Driving Laboratory, Nanjing University of Aeronautics

and Astronautics, Nanjing 210016, China

123

Chin. Sci. Bull. (2014) 59(36):5161–5169 csb.scichina.com

DOI 10.1007/s11434-014-0648-0 www.springer.com/scp

antiferromagnetic below its Neel temperature (TN) of

*643 K [6, 7]. In BiFeO3 film on (111) SrTiO3 single-

crystal substrate, ferroelectric measurements confirm a

large polarization value of 90–95 lC/cm2. Magnetic mea-

surements show a weak, saturated magnetic moment of

8–10 emu/cm3, which is consistent with the magnitude of

the canting of the antiferromagnetic sub-lattices calculated

for BiFeO3 film. However, there exists a long-wavelength

spin spiral with the wavelength of *62 nm and thus the

macroscopic magnetic moment is zero in BiFeO3 single

crystals and ceramics [8].

Bulk BiFeO3 belongs to rhombohedral R3c space group,

and its spontaneous polarization directs along one of the

(111) axis of the pseudo-cubic structure (Fig. 1a). The fer-

roelectric polarization in BiFeO3 can have eight possible

orientations, corresponding to the positive and negative

orientation along the four cube diagonals, and the direction

of the polarization can be switched by 180� (Fig. 1b), 109�(Fig. 1c) and 71� (Fig. 1d) under an external electric field,

respectively [9]. According to the earlier first-principle cal-

culations of BiFeO3 epitaxial film, there is an easy magne-

tization plane for the orientation of the magnetic moments,

which is always perpendicular to the ferroelectric polariza-

tion. As a result, the polarization switching by either 109�(Fig. 1c) or 71� (Fig. 1d) changes the orientation of the easy

magnetization plane while that of 180� (Fig. 1b) it does not

[9]. In this case, there is a strong coupling between ferro-

electric polarization and easy magnetization plane. Thus, it is

necessary to find a relatively convenient method to measure

the easy magnetization plane in future.

Two important progresses are achieved to improve fer-

roelectric, piezoelectric, magnetization and magnetoelec-

tric coupling in BiFeO3-based ceramics. At first, due to the

fast evaporation of Bi3? and the easy transformation

between Fe2? and Fe3? ions when BiFeO3-based ceramics

were prepared with the conventional solid-state sinter

method, high densities of Fe2? and oxygen vacancies

commonly induce serious leakage current. As a result, it is

always difficult to achieve good ferroelectric and piezo-

electric properties [10]. In order to settle this problem, a

liquid-phase sintering method was proposed by Wang et al.

[11] and now it is extensively used to suppress oxygen

vacancies and Fe2? in BiFeO3-based ceramics. The poly-

crystalline BiFeO3 ceramics show a saturated polarization

(PS) of *40 lC/cm2, being consistent with the PS of

*100 lC/cm2 along the polar axis in the epitaxial BiFeO3

film on (111) SrTiO3 single-crystal substrate [12–17].

Besides, due to the space-modulated spin structure of

canted G-type antiferromagnetic order [18, 19], ferromag-

netism is weak and magnetoelectric coupling is poor in

pure BiFeO3 ceramics. Mathe et al. [20] and lots of other

researchers suppressed the space-modulated spin structure

or increased the antiferromagnetic canted angle of single-

phased BiFeO3 by the substitution of A-site ions with rare

earth ions for larger remnant magnetization and stronger

magnetoelectric coupling.

In this paper, we have summarized the prominent

development of BiFeO3-based ceramics. Many rare earth

ions such as A = Nd, La, Dy, Sm, Eu and Pr are doped to

achieve single-phase Bi1-xAxFeO3 ceramics, in addition to

BiFeO3-based composite (e.g., BiFeO3–PbTiO3 or BiFe-

O3–BaTiO3). Their crystal structure, ferroelectric, piezo-

electric and magnetoelectric properties are analyzed and

compared.

2 Modified synthesis techniques

Research on BiFeO3 ceramics is still facing several com-

plexities due to the easy formation of the second phase

during synthesis, which makes the observation of intrinsic,

well-PS versus electric field (P–E) hysteresis loop difficult.

Conventional solid-state reaction method is commonly

used for the fabrication of most of ceramics. BiFeO3

ceramics prepared with this method commonly show high-

density of conductive impurities, oxygen vacancies and

Fe2?, and thus their resistivity becomes too low to measure

their saturated P–E loops. In 2000, Kumar et al. [21] pre-

pared BiFeO3 ceramic with the conventional solid-state

Fig. 1 (Color online) Schematic diagram of (001)-oriented BiFeO3

crystal structure and the ferroelectric polarization (bold arrows) and

the antiferromagnetic plane (shaded planes). a Ferroelectric polari-

zation is perpendicular to an antiferromagnetic plane; b 180�polarization switching by an external electrical field does not change

the antiferromagnetic plane; c 109� and d 71� polarization switching

does change the antiferromagnetic plane. Reprinted from [9] by

permission from Nature Publishing Group, copyright (2006)

5162 Chin. Sci. Bull. (2014) 59(36):5161–5169

123

reaction method, removed most of its conductive impurities

(e.g., Bi2O2.75, Bi2O3, Fe2O3) in nitric acid, pressed of

acquired powder and then annealed the ceramic at 550 �C.

In this way, the ceramic showed an improved ferroelectric

polarization of 0.1 lC/cm2 at 12.5 kV/cm.

In 2004, Wang et al. [22] developed a rapid liquid-phase

sintering method to achieve single-phase and high-resistive

BiFeO3 ceramics. High-purity Bi2O3 (99.99 %) and Fe2O3

(99.99 %) powders were carefully weighed in stoichiom-

etric proportions (1:1 mole ratio) and thoroughly mixed in

an agate mortar. The average size of the obtained mixture

particles was \1 lm. The mixture was then dried and

pressed into slices with the thickness of \2 mm. Then

these slices were sintered for 5–30 min in air at *850 �C

with a very fast heating rate ([100 �C/s) and a fast cooling

rate ([50 �C/s). As the melting point of Bi2O3 is 817 �C,

therefore Bi2O3 liquid phase will accelerate the synthe-

sizing reaction and thus the single-phase BiFeO3 phase can

be obtained at *850 �C for 2–5 min. Besides, the fast

sintering process also suppresses the formation of oxygen

vacancies and Fe2?, and thus the ceramics show super-high

resistivity for further electric measurement under high

electric field. Later on, Yuan et al. [23] introduced how to

prepare highly resistive BiFeO3 ceramics with the rapid

liquid-phase sintering method in details. The comparison of

their phases, electrical resistivity, and porosity revealed

that the use of Bi2O3 and Fe2O3 powders of \1 lm size

and a rapid liquid-phase sintering process at 855 �C were

beneficial to synthesize poreless single-phase BiFeO3

samples with high electrical resistivity. Figure 2a shows

the X-ray diffraction (XRD) patterns of BiFeO3-1, BiFeO3-

2 and BiFeO3-3 ceramics, which were prepared with Bi2O3

(\1 lm) and Fe2O3 (\1 lm) powders, Bi2O3 (\1 lm) and

Fe2O3 ([1 lm for 1/3 component) powders, and Bi2O3

([1 lm for 1/3 component) and Fe2O3 (\1 lm) powders,

respectively. For BiFeO3-1 sample, no phase impurity was

detected due to the implementation of the above mentioned

perfect condition. Samples prepared under other conditions

showed the presence of impure phases such as Fe2O3 and

BixFeyO1.5x?1.5y with x [ y.

In 2006, Chen et al. [25] followed the rapid liquid-phase

sintering method to fabricate BiFeO3 ceramic samples in

which sol–gel refined powders were used. Ceramics were

found to be dense with the grains’ size of 2–6 lm in

diameter, and the leakage current density was reduced to

lower than 3.02 9 10-4 A/cm2 under the poling field

below 119 kV/cm. Remnant polarization (Pr) of *28 lC/cm2

was achieved under the applied field of 180 kV/cm.

Some wet chemical methods are also used for the fab-

rication of single-phase BiFeO3 ceramics. Co-precipitation

[26], hydrothermal method [27], combustion method [28]

and sol–gel method are parts of this technique. Sol–gel

method ranks high among these techniques. So with the

passing time, lots of modifications were made in the syn-

thesis techniques along with the useful changes in the

composition of the chemical reactants to make the samples

pure, free of a second phase, highly resistive and poreless.

3 BiFeO3-based multiferroic ceramics

3.1 Bi1-xNdxFeO3

Yuan et al. [24] prepared the bulk Bi1-xNdxFeO3 (BNFOx)

ceramics in the ferroelectric to paraelectric (FE–PE) tran-

sition region of x = 0–0.2 by an improved rapid liquid-

phase sintering method. Phase transformation behavior can

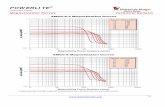

Fig. 2 (Color online) a XRD peaks for BiFeO3-1, BiFeO3-2 and

BiFeO3-3 samples, where Miller index (h l k) is on the basis of

pseudo-cubic structure. Reprinted with permission from [22]. Copy-

right 2004, AIP Publishing LLC; b XRD structural transformation

analysis of measured and simulated BNFOx=0-0.2, where Rp and Rwp

are two parameters of Rietveld simulation. Reprinted with permission

from [24]. Copyright 2006, AIP Publishing LLC

Chin. Sci. Bull. (2014) 59(36):5161–5169 5163

123

obviously be observed in XRD patterns and their Rietveld

refinement, where small Rp and Rwp values depict that the

simulation coincides well with experimental data (Fig. 2b).

Derived result from Rietveld refinement identifies that

BNFOx=0-0.2 were transformed from rhombohedral struc-

ture at BiFeO3 to triclinic structure at BNFOx=0.05-0.15 and

finally transformed to pseudotetragonal structure at

BNFOx=0.175-0.2. P–E loops are shown in Fig. 3a, and it is

clear that ferroelectricity with Pr of *9 lC/cm2 was found

in BNFOx=0-0.175 at 139 kV/cm, and paraelectricity was

found in BNFOx=0.2 with Pr of *0 lC/cm2 at 145 kV/cm

[28]. This abrupt drop in Pr confirms the FE–PE transition

and weak ferromagnetism. In Fig. 3b, magnetization versus

magnetic field (M–H) loops are demonstrated, and BNFOx=0

proves the antiferromagnetic behavior, which is converted

to weak ferromagnetic behavior with the small remnant

magnetization (Mr) of B0.227 emu/g in BNFOx=0.15-0.2.

The inset confirms the increasing Mr trend by increasing the

Nd concentration. Structural transformation from rhombo-

hedral to pseudotetragonal due to the increasing Nd con-

centration (x = 0–0.2) induces the continuing collapse of

space-modulated spin structure [29] and then increases Mr.

3.2 Bi1-xLaxFeO3

Yuan et al. [30] prepared the Bi1-xLaxFeO3 (BLFOx)

ceramics with x = 0–0.25 by the rapid liquid-phase sin-

tering method. In XRD analysis, Rietveld-refined crystal

structural parameters revealed the structural transformation

from the rhombohedral R3c structure in BLFOx=0 to a

triclinic P1 symmetry in BLFOx=0.5-0.15, to a pseudote-

tragonal P4 mm symmetry in BLFOx=0.2 and finally to a

pseudotetragonal P4/mmm symmetry in BLFOx=0.25. In

Fig. 4a, the maximum ferroelectricity with Pr of *9.8 lC/cm2

was observed. FE–PE phase transition occurred due to the

increasing La concentration. Abrupt changes of Raman

scattering spectra occurred in BLFOx=0.2 and BLFOx=0.25.

Piezoelectric coefficient (d33) of *25 pC/N was assured in

all compositions except BLFOx=0.25. Besides, weak ferro-

magnetism was established with Mr of *0.204–0.246 emu/g

in BLFOx=0.2-0.25 (Fig. 4b).

Zhang et al. [31] prepared BLFOx (x = 0–0.40)

ceramics by an optimized rapid liquid-phase sintering

Fig. 3 (Color online) a P–E loops and b M–H loops of BNFOx

(x = 0–0.2) ceramics, where inset shows the variation of Mr due to

the increase in Nd concentration. Reprinted with permission from

[24]. Copyright 2006, AIP Publishing LLC

0.00 0.05 0.10 0.15 0.20 0.25

0.0

0.1

0.2

0.3

–1.0

–0.5

0.0

0.5

1.0

–60 –40 –20 0 20 40 60

–150 –100 –50 0 50 100 150

–30

–20

–10

0

10

20

30

La concentration,

Mr (

emg/

g)

(a)

(b)

M (

emu/

g)

H (kOe)

x=0x=0.2

E (kV/cm)

P (

C/c

m2 )

x=0x=0.1x=0.2x=0.25

Fig. 4 (Color online) a P–E loops of La3?-doped BiFeO3 samples.

b M–E loops for BLFOx=0 and BLFOx=0.2 samples. Inset represents

the variation in the values of Mr with varying La concentration.

Reprinted with permission from [30]. Copyright 2007, IOP Publishing

5164 Chin. Sci. Bull. (2014) 59(36):5161–5169

123

method. It was described that rhombohedral to ortho-

rhombic phase transition had great influence on multifer-

roic properties. Magnetic and electric measurements

showed the enhanced multiferroic properties for

BLFOx=0.30 with two times the Mr and polarization of

*0.041 emu/g and *22.4 lC/cm2, respectively. These

enhanced multiferroic properties can be associated with

magnetoelectric interactions, which are created because of

the destruction of the spin cycloid of BiFeO3 for the

increase in La substitution.

3.3 Bi1-xDyxFeO3

Sun et al. [32] prepared Bi1-xDyxFeO3 (x = 0–0.2)

ceramics by the rapid liquid-phase sintering method. It was

reported that ceramics possess the rhombohedral structure

for x B 0.08. The coexistence of rhombohedral and

orthorhombic phases was observed for 0.11 B x B 0.17.

Finally, pure rhombohedral phase was achieved at x = 0.2.

It was also observed by Sun et al. [33] that Bi0.92Dy0.08-

FeO3 ceramic showed the rhombohedral phase at room

temperature, but it also allowed the coexistence of rhom-

bohedral phase and orthorhombic phase at 460–650 �C. At

room temperature, Bi0.92Dy0.08FeO3 ceramic shows the d33

of *35 pC/N (Fig. 5). The relative permittivity versus

frequency (er - F) curves of Bi0.92Dy0.08FeO3 samples at

various temperatures showed the strongest er anomaly, due

to the piezoelectric resonance. The er anomalies became

weak and finally disappeared with the increase in temper-

ature C550 �C.

Xu et al. [34] measured the maximum Pr of *55 lC/cm2

at the same concentration of Dy (x = 0.05). With the

increase in Dy content, Mr increased to *0.313 emu/g for

x = 0.15, clearly representing the weak ferromagnetic

behavior at 7 T.

3.4 Bi1-xEuxFeO3

Zhang et al. [35] prepared Bi1-xEuxFeO3 (x = 0–0.3)

ceramics by the rapid liquid-phase sintering method. Poly-

crystalline rhombohedrally distorted structures were char-

acterized from the diffraction peak patterns of x B 0.15

samples. Compounds with 0.2 B x B 0.3, showed approxi-

mately orthorhombic EuFeO3 [36] structures by their XRD

analysis, which proved the structural phase transitions at

x = 0.2. The refined data from Rietveld method indicated

the rhombohedral lattice with R3c space group for x B 0.15

samples and orthorhombic lattice with Pn21a space group for

x C 0.2 samples. So, a polar-to-polar R3c ? Pn21a struc-

tural phase transition at x = 0.2 in Bi1-xEuxFeO3 com-

pounds were induced due to Eu substitution. However, it is

difficult to achieve PS at room temperature. Uniyal and

Yadav [37] reported improved multiferroic properties with

Pr and Mr of *11 lC/cm2 and *0.0347 emu/g, respec-

tively, for Bi0.9Eu0.1FeO3 ceramic.

3.5 Bi1-xSmxFeO3

Chen et al. [38] prepared insulated Bi1-xSmxFeO3

(x = 0–0.25) ceramics by the rapid liquid-phase sintering

method. XRD patterns suggested that Bi1-xSmxFeO3

showed the ferroelectric rhombohedral phase for

x = 0–0.12. Diffraction peaks’ splitting suggested the

coexistence of two phases at x = 0.125–0.175. One was

ferroelectric triclinic phase and the other was anti-polar

orthorhombic Pbam phase. Finally, it transformed to para-

electric orthoferrite phase at x = 0.25. Strong ferroelectric

characteristics with Pr *12 lC/cm2 were observed due to

rhombohedral phase for x = 0–0.12. The dominating fer-

roelectric triclinic phase was observed for x = 0.125–0.15,

but then Pr gradually decreased to 4.2 lC/cm2 for

x = 0.175–0.20. According to Khomchenko et al. [39], this

small ferroelectricity in the samples was due to the exis-

tence of antiferroelectric orthorhombic Pbam phase. Thin

P–E loop proved the paraelctric behavior at x = 0.25.

Figure 6a shows the Sm concentration (x) dependent

piezoelectric (d33) and er in Bi1-xSmxFeO3 ceramics. The

value of d33 remained *35 pC/N for x = 0–0.10 and

achieved the maximum value *42 pC/N for x = 0.125 at a

possible morphotropic phase boundaries (MPB). The

existence of a tiny anti-polar orthorhombic Pbam phase at

MPB has increased the value of d33. Figure 6b shows the

room temperature d33 value after the polarized ceramics

were annealed at various temperatures (TN), suggesting a

ferroelectric phase existing at higher temperatures.

0 150 300 450 600 7500

10

20

30

40

Temperature (°C)

d 33

(pC

/N) Bi

0.92Dy

0.08FeO

3

BiFeO3

Fig. 5 (Color online) Room temperature piezoelectric d33 constant of

polarized BiFeO3 and Bi1-xDyxFeO3 samples after they were

annealed at various temperatures. Reprinted from [33]. Copyright

2012, with permission from Elsevier

Chin. Sci. Bull. (2014) 59(36):5161–5169 5165

123

3.6 Bi1-xPrxFeO3

Khomchenko et al. [40] prepared Bi1-xPrxFeO3

(x = 0–0.3) ceramics by the conventional solid-state

reaction method. XRD analysis of the samples proved the

structural transformation from rhombohedral phase

(R3c) to two orthorhombic (Pnam and Pnma) phases.

Rhombohedral structure was observed for x B 0.12 sam-

ples, and homogeneous Pnam structure was observed for

0.16 B x B 0.25 samples. Single-phase Pnma structure

was obtained for x C 0.28. Conclusively, the structural

investigation of Bi1-xPrxFeO3 with x = 0–0.3 showed

sequential phase transitions R3c ? Pnam ? Pnma. In

intermediate compositions (0.16 B x B 0.25), two-phased

structural state was observed.

Uniyal and Yadav [41] prepared Bi0.9-xLa0.1PrxFeO3

(x = 0.1 and 0.2) ceramic samples by the conventional

solid-state reaction method. The maximum magnetization

of *1.1 emu/g was observed, which could not be saturated

up to 7 kOe. Bi0.8La0.1Pr0.2FeO3 showed a Mr of

0.1688 emu/g and a magnetic coercivity (Hc) of 7.466 kOe.

Effects of various magnetic fields on P–E loops were also

analyzed. Variation in the value of Pr was observed after

the comparison with and without the effect of magnetic

field on the same values of electric field.

3.7 Bi1?xCexFeO3

Pradhan and Roul [42] prepared Bi1-xCexFeO3 (x = 0–0.15)

ceramics by the conventional solid-state reaction method.

For higher Ce concentration, no impurity and phase trans-

formation was detected in the samples. Relative permittivity

of the samples was improved from 85 for pure BiFeO3 to 930

for Bi0.85Ce0.15FeO3 at 100 Hz. It was suggested that the

substitution of Ce ion with high valance and small radii can

reduce the oxygen vacancy and suppress the leakage current.

It was also reported that the presence of Ce ions can com-

pensate the loss of Bi ions at high sintering temperature, and

induce structural distortion, thus enhance ferroelectric

properties.

Figure 7 summarizes the structural transformations and

ferroelectric-paraelctric transitions of doped BiFeO3 ceram-

ics, which are due to the increase of dopant’s concentration.

3.8 (1-x)BiFeO3–xBaTiO3

Recently Kumar et al. [43] has prepared (1-x)BiFeO3–x

BaTiO3 (BFO–BT) ceramics with x B 0.30 by the solid-state

reaction method. Gradual structural transformation from

rhombohedral (BFO–0.1BT) to cubic (BFO–0.3BT) phase

structure was observed [44]. Ferroelectric and magnetic

behaviors of the samples changed significantly with the

proportion of BaTiO3 increasing. BiFeO3–BaTiO3 ceramic

commonly shows low leakage current than pure BiFeO3

ceramics. 0.75BiFeO3–0.25BaTiO3 ceramic showed an

unsaturated hysteresis loop with the Pr of 12.95 lC/cm2 at a

maximum electric field of 22 kV/cm, a high TC temperature

of 310 �C and a weak ferromagnetism [45].

3.9 (1-x)BiFeO3–xPbTiO3

The structure of (1-x)BiFeO3–xPbTiO3 (BFO–PT) is

tetragonal P4 mm space group for x [ 0.31 and monoclinic

Cc space group for 0.10 B x B 0.27, whereas the two

phases coexist in the MPB region for 0.27 \ x \ 0.31 [46,

47]. Cheng et al. [48] reported the properties of Bi(GaxFe1-x)

O3–PbTiO3 (BGFO–PT) crystalline solutions. The coexis-

tence of tetragonal and rhombohedral ferroelectric phases

along with a multicell perovskite structure was observed

for 0.7BiGa0.1Fe0.9O3–0.3PbTiO3. Also, the modification

of Ga increases the electrical resistivity up to[1012 X cm,

and the ferroelectric TC of 0.4Bi0.6Ga0.4FeO3–0.6PbTiO3

was 540 �C. Amorin et al. [49] reported excellent piezo-

electric properties (i.e., crystal piezoelectric coefficient of

87 pC/N, a TC above 873 K and relative permittivity of

0.00 0.05 0.10 0.15 0.20 0.250

15304560 100

120

140

160

0 100 200 300 400 500 600 700 8000

10

20

30

40

50

d 33

r

x value of Bi1–xSmxFeO3

1 kHz10 KHz100 KHz1 MHz

(b)

(a)d 3

3

Anneal temperature (°C)

x=0 x=0.125x=0.145 x=0.165

x=0.2

Fig. 6 (Color online) a Sm concentration (x) dependent piezoelectric

d33 and er of Bi1-xSmxFeO3; b effect of annealing temperature on the

piezoelectric d33 values of Bi1-xSmxFeO3 after polarization. Rep-

rinted from [38]. Copyright 2012, with permission from Elsevier

5166 Chin. Sci. Bull. (2014) 59(36):5161–5169

123

335) in 0.675BiFeO3–0.325PbTO3 ceramic with the mor-

photropic phase boundary.

3.10 MPB in rare earth element-doped BiFeO3

ceramics

MPB is a region in piezoelectric materials where these

materials display the enhanced electromechanical behav-

iors due to abrupt complex structural transformations. Bi-

FeO3 crystal or ceramics show rhombohedral structure with

a pseudocubic lattice parameter a = b = c = 0.379 nm

and thus it may be possible to improve piezoelectric

properties through introducing MPB in BiFeO3-based

ceramics.

Zeches et al. [50] grew the epitaxial BiFeO3 on (001)

LaAlO3 single-crystal substrate with a = b = c = 0.379 nm

and found the formation of MPB in the highly strained Bi-

FeO3 film. Although the parent ground state is a rhombo-

hedrally distorted perovskite (R3c), a tetragonally distorted

perovskite phase (P4mm symmetry, with in-plane lattice

parameter a *3.665 A and out-of-plane lattice parameter

c *4.655 A) with a large spontaneous polarization has been

identified. Electric field-dependent studies show that a

tetragonal-like phase can be reversibly converted into a

rhombohedral-like phase, accompanied by measurable dis-

placements of the surface. Furthermore, Zhang et al. [51]

reported a reversible electric field-induced strain of over 5 %

in such BiFeO3 films, which was larger than those values of

traditional piezoelectrics (0.2 % in Pb(ZrxTi1-x)O3, 1.7 % in

ferroelectric relaxors and 0.06 % in lead-free ceramics).

Although rare earth element-doped BiFeO3 ceramics

show structure and phase transitions at a certain dopant

concentration and some of them have the coexistence of

ferroelectric phase and paraelectric phase at some con-

centration scope, there is no real MPB which can largely

increase the piezoelectric coefficient in rare earth element-

doped BiFeO3 ceramics until now.

4 Summary and prospects

Doping of rare earth ions Bi1-xAxFeO3 (A = Nd, La, Dy,

Sm, Eu and Pr) not only induces crystal structure, ferro-

electric phase and FE–PE phase transition, but also has tre-

mendous influence on AFM–FM phase transition and

magnetoelectric coupling effect. The structure transition

destroys the space-modulated spin structure and unlocks

magnetization in the samples, brings the coexistence of

ferroelectricity and weak ferromagnetism in rare earth-

doped BiFeO3 ceramics and allows significant magneto-

electric coupling. Since there is a strong coupling between

ferroelectric polarization and antiferromagnetic plane in

BiFeO3 film or some doped BiFeO3 ceramics where the

space-modulated spin structure disappears, it is necessary to

identify this antiferromagnetic plane with a relatively con-

venient method so that this special magnetoelectric coupling

can be applied in industrial electronic devices and sensors.

BiFeO3 with ferroelectric TC [ 800 �C is promising to

become a good high-temperature piezoelectric ceramic, if

its piezoelectric coefficients can be improved through

Fig. 7 (Color online) Crystal structure, and phase of Bi1-xAxFeO3 ceramics, where A is Nd, La, Pr, Sm, Eu and Dy [24, 30, 32, 35, 38, 40]

Chin. Sci. Bull. (2014) 59(36):5161–5169 5167

123

introducing MPB and its high-temperature resistance can

be increased through enlarging its energy band gap. MPB is

introduced in highly strained BiFeO3 film, and thus it is

necessary to acquire MPB in BiFeO3-based ceramics.

There is the coexistence of ferroelectric and paraelectric

phases, which is not typical MPB in rare earth element-

doped BiFeO3 ceramics such as Bi1-xSmxFeO3 until now.

Thus, one of the most important studies is to introduce

typical MPB in BiFeO3-based ceramics in future.

Acknowledgment The work was supported by the National Basic

Research Program of China (2012CB619406), the National Natural

Science Foundation of China (11134004, 51177072 and 11274174)

and the Fundamental Research Funds for the Central Universities

(30920130111018).

References

1. Wang KF, Liu JM, Ren ZF (2009) Multiferroicity: the coupling

between magnetic and polarization orders. Adv Phys 58:321–348

2. Teague JR, Gerson R, James WJ (1970) Dielectric hysteresis in

single crystal BiFeO3. Solid State Commun 8:1073–1074

3. Feng B, Xue H, Xiong Z (2010) Structure and multiferroic

properties of Y doped BiFeO3 ceramics. Chin Sci Bull

55:452–456

4. Venevtsev YN, Gagulin VV (1994) Search, design and investi-

gation of seignettomagnetic oxides. Ferroelectrics 162:23–31

5. Tatarenko AS, Srinivasan G, Bichurin MI (2006) Magnetoelectric

microwave phase shifter. Appl Phys Lett 88:183507

6. Kubel F, Schmid H (1990) Structure of a ferroelectric and fer-

roelastic monodomain crystal of the perovskite BiFeO3. Acta

Crystallogr B Struct Sci B46:698–702

7. Smolenskii GA, Chupis IE (1982) Ferroelectromagnets. Sov Phys

Usp 25:475–493

8. Ederer C, Spladin NA (2005) Weak ferromagnetism and mag-

netoelectric coupling in bismuth ferrite. Phys Rev B 71:060401

9. Zhao T, Scholl A, Zavaliche F et al (2006) Electrical control of

antiferromagnetic domains in multiferroic BiFeO3 films at room

temperature. Nature 5:823–829

10. Simoes AZ, Riccardi CS, Dos Santos ML et al (2009) Effect of

annealing atmosphere on phase formation and electrical charac-

teristics of bismuth ferrite thin films. Mater Res Bull

44:1747–1752

11. Wang YP, Yuan GL, Chen XY et al (2006) Electrical and mag-

netic properties of single-phased and highly resistive ferroelec-

tromagnet BiFeO3 ceramic. J Phys D Appl Phys 39:2019–2023

12. Wang J, Neaton JB, Zheng H et al (2003) Epitaxial BiFeO3

multiferroic thin film heterostructures. Science 299:1719–1722

13. Yun KY, Noda M, Okuyama M et al (2004) Structural and

multiferroic properties of BiFeO3 thin films at room temperature.

J Appl Phys 96:3399

14. Liu XH, Xu Z, Qu SB et al (2007) Microstructure and properties

of Ga modified 0.7BiFeO3–0.3BaTiO3 solid solution. Chin Sci

Bull 52:2747–2752

15. Yang SY, Zavaliche F, Mohaddes-Ardabili L et al (2005) Met-

alorganic chemical vapor deposition of lead-free ferroelectric

BiFeO3 films for memory applications. Appl Phys Lett 87:102903

16. Cazayous M, Malka D, Lebeugle D et al (2007) Electric field

effect on BiFeO3 single crystal investigated by Raman spectros-

copy. Appl Phys Lett 91:071910

17. Ravindran P, Vidya R, Kjekshus A et al (2006) Theoretical

investigation of magnetoelectric behavior in BiFeO3. Phys Rev B

74:224412

18. Li J, Wang J, Wuttig M et al (2004) Dramatically enhanced

polarization in (001), (101), and (111) BiFeO3 thin films due to

epitaxial-induced transitions. Appl Phys Lett 84:5261

19. Ruette B, Zvyagin S, Pyatakov AP et al (2004) Magnetic-field-

induced phase transition in BiFeO3 observed by high-field elec-

tron spin resonance: cycloidal to homogeneous spin order. Phys

Rev B 69:064114

20. Mathe VL, Patankar KK, Patil RN et al (2004) Synthesis and

dielectric properties of Bi1-xNdxFeO3 perovskites. J Magn Magn

Mater 270:380–388

21. Kumar MM, Palkar VR, Srinivas K et al (2000) Ferroelectricity

in a pure BiFeO3 ceramic. Appl Phys Lett 76:2764

22. Wang YP, Zhou L, Zhang MF et al (2004) Room-temperature

saturated ferroelectric polarization in BiFeO3 ceramics synthe-

sized by rapid liquid phase sintering. Appl Phys Lett 84:1731

23. Yuan GL, Or SW, Wang YP et al (2006) Preparation and multi-

properties of insulated single-phase BiFeO3 ceramics. Solid State

Commun 138:76–81

24. Yuan GL, Or SW, Liu JM et al (2006) Structural transformation

and ferroelectromagnetic behavior in single-phase Bi1-xNdxFeO3

multiferroic ceramics. Appl Phys Lett 89:052905

25. Chen F, Zhang QF, Li JH et al (2006) Sol–gel derived multif-

erroic BiFeO3 ceramics with large polarization and weak ferro-

magnetism. Appl Phys Lett 89:092910

26. Cushing BL, Kolesnichenko VL, O’Connor CJ (2004) Recent

advances in the liquid-phase syntheses of inorganic nanoparticles.

Chem Rev 104:3893–3946

27. Rajamathi M, Seshadri R (2002) Oxide and chalcogenide nano-

particles from hydrothermal/solvothermal reactions. Curr Opin

Solid State Mater Sci 6:337–345

28. Patil KC (1993) Advanced ceramics: combustion synthesis and

properties. Bull Mater Sci 16:533–541

29. Yuan GL, Or SW (2006) Enhanced piezoelectric and pyroelectric

effects in single-phase multiferroic Bi1-xNdxFeO3 (x = 0–0.15)

ceramics. Appl Phys Lett 88:062905

30. Yuan GL, Or SW, Chan HLW et al (2007) Structural transfor-

mation and ferroelectric–paraelectric phase transition in Bi1-

xLaxFeO3 (x = 0–0.25) multiferroic ceramics. J Phys D Appl

Phys 40:1196–1200

31. Zhang ST, Pang LH, Zhang Y et al (2006) Preparation, structures,

and multiferroic properties of single phase Bi1-xLaxFeO3

(x = 0–0.40) ceramics. J Appl Phys 100:114108

32. Sun C, Wang YP, Yang Y et al (2012) Multiferroic properties of

Bi1-xDyxFeO3 (x = 0–0.2) at various temperature. Mater Lett

72:160–163

33. Sun C, Chen XM, Wang YP et al (2012) Structure and piezo-

electric properties of BiFeO3 and Bi0.92Dy0.08FeO3 multiferroics

at high temperature. Solid State Commun 152:1194–1198

34. Xu J, Ye GL, Zeng M et al (2014) Structure transition and

enhanced multiferroic properties of Dy-doped BiFeO3. J Alloys

Compd 587:308–312

35. Zhang XQ, Sui Y, Wang XJ (2010) Effect of Eu substitution on

the crystal structure and multiferroic properties of BiFeO3.

J Alloys Compd 507:157–161

36. Li SZ, Huang YJ, Zhu JB et al (2007) XRD and Mossbauer

investigation of phase segregation in Eu1-xSrxFeO3. Phys B

Condens Matter 393:100–104

37. Uniyal P, Yadav KL (2009) Room temperature multiferroic

properties of Eu doped BiFeO3. J Appl Phys 105:07D914

38. Chen XM, Wang YP, Yang Y et al (2012) Structure, ferroelec-

tricity and piezoelectricity evolutions of Bi1-xSmxFeO3 at various

temperatures. Solid State Commun 152:497–500

5168 Chin. Sci. Bull. (2014) 59(36):5161–5169

123

39. Khomchenko VA, Paixa JA, Shvartsman VV et al (2010) Effect

of Sm substitution on ferroelectric and magnetic properties of

BiFeO3. Scripta Mater 62:238–241

40. Khomchenko VA, Troyanchuk IO, Karpinsky DV et al (2012)

Structural and magnetic phase transitions in Bi1-xPrxFeO3 per-

ovskites. J Mater Sci 47:1578–1581

41. Uniyal P, Yadav KL (2009) Pr doped bismuth ferrite ceramics

with enhanced multiferroic properties. J Phys: Condens Matter

21:405901

42. Pradhan SK, Roul BK (2012) Electrical behavior of high resis-

tivity Ce-doped BiFeO3 multiferroic. Phys B Condens Matter

407:2527–2532

43. Kumar M, Shankar S, Kotnala RK et al (2013) Evidences of

magneto-electric coupling in BFO–BT solid solutions. J Alloys

Compd 577:222–227

44. Wang TH, Ding Y, Tu CS et al (2011) Structure, magnetic, and

dielectric properties of (1–x)BiFeO3–xBaTiO3 ceramics. J Appl

Phys 109:07D907

45. Kumar M, Shankar S, Parkash O et al (2014) Dielectric and

multiferroic properties of 0.75BiFeO3–0.25BaTiO3 solid solution.

J Mater Sci: Mater Electron 25:888–896

46. Woodward DI, Reaney IM, Eitel RE et al (2003) Crystal and

domain structure of the BiFeO3–PbTiO3 solid solution. J Appl

Phys 94:3313

47. Bhattacharjee B, Pandey D (2010) Stability of the various crys-

tallographic phases of the multiferroic (1-x)BiFeO3–xPbTiO3

system as a function of composition and temperature. J Appl Phys

107:124112

48. Cheng JR, Li N, Cross LE (2003) Structural and dielectric

properties of Ga-modified BiFeO3–PbTiO3 crystalline solutions.

J Appl Phys 94:5153

49. Amorin H, Correas C, Fernandez-Posada CM et al (2014) Mul-

tiferroism and enhancement of material properties across the

morphotropic phase boundary of BiFeO3–PbTiO3. J Appl Phys

115:104104

50. Zeches RJ, Rossell MD, Zhang JX et al (2009) A strain-driven

morphotropic phase boundary in BiFeO3. Science 326:977–980

51. Zhang JX, Xiang B, He Q et al (2011) Large field-induced strains

in a lead-free piezoelectric material. Nature 6:98–102

Chin. Sci. Bull. (2014) 59(36):5161–5169 5169

123