Rev 1 to 'Diablo Canyon Unit 1 Independent Design Verification Program Electrical ... · 2017. 2....

Transcript of Rev 1 to 'Diablo Canyon Unit 1 Independent Design Verification Program Electrical ... · 2017. 2....

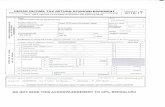

Robert L. Cloudand Associ'ates, Inc.

Interim Technical Report

DIABIO CANYON UNIT 1INDEPENDENT DESIGN VERIFICATION PROGRAM

ELECTRICAL EQUZBKHZ ANALYSISITR f33

REVISION 1

Docket No. 50-275License No. DPR-76

Pro ec >neer eT cal Review

830503 058i 830429PDR ADDCK 05000275

PDR

s ~closect Manager te

Appmved P 105-4-839-033

8

0A TELEDYNE

ENQINEERINQ SERVICES

PROGRAM MANAGER'S PREFACE

DIABLO CANYON NUCLEAR POWER PLANT - UNIT 1

INDEPENDENT DESIGN VERIFICATION PROGRAM

INTERIM TECHNICAL REPORT

ELECTRICAL EQUIPMENT BY ANALYSIS

This is Revision 1 to the thirty-third of a series of InterimTechnical Reports prepared by the DCNPP-IDVP for the purpose ofproviding a conclusion of the program.

The original issue of this report contained the analytical methods

and results of the independent analyses, the concerns, recommendations,and conclusions of the IDVP with respect to the initial sample forelectrical equipment qualified by analysis. This revision contains,along with the initial sample results in the original report, theresults of the additional verification effort. All EOI files initiatedfor this sample category, both in the initial sample and additionalverification evaluations, have been closed or identified as an error.

As IDVP Program Manager, Teledyne Engineering Services has approvedthis Revision 1 to ITR-33, including the conclusions and recommendationspresented. The methodology followed by TES in performing this reviewand evaluation is described in Appendix 0 to this report.

ITR Reviewed and Approved

IDVP Program Manager

Teledyne Engineering Services

R. Wray

Assistant Project Manager

I ~

ELECTRICAL EQUIPI1ENT ANALYSIS

REVISION 1

Contents

Program Hanager's PrefaceList of TablesList of Figures

1.0 IntroductionPurpose and ScopeSummaryBackground

2.0 Independent Design Verirication I!ethods

2.1 Procedures2.2 Licensing Criteria

3.0 Verification Analysis of Initial Sampleof Electrical Equipment

1ivv

3.1 Hot Shutdown Remote Control Cabinet 5

3.1.13.1.23.1.33.1.4

3.1.5

3.1.6

llethod of Verification AnalysisResults of Verification AnalysisDesign Analysis blethodsComparison of Verification andDesign Analysis HethodsComparison of Verification andDesign Analysis ResultsError and Open Item Reports

8141414

16

17

3.2 Nain Annunciator Caoinet 18

3.2.13 ~ 2 ~ 23 ~ 2 ~ 33.2.4

3.2.5

flethods of Verification AnalysisResults of Verification AnalysisDesign Analysis NethodsComparison of Analysis andDesign Analysis hletnodsError and Open Item Reports

21232426

27

4.0 Evaluation of Electrical Equipment Analysis 28Initial Sample

4.1 Interpretation4.2 Recommendations

2828

11

5.0 Additional Verification of ElectricalEquipment

5.1 Scope of Review5.2 Results of Review5.3 EOI Reports Issued

29

292929

6.0 Conclusion

7.0 References

8.0 Appendix A—

Appendix B-Appendix C—

Appendix D—

30

31

EOI Status — Electrical EquipmentAnalysisKey Term DefinitionsHosgri Response Spectra Consideredin IDVP Electrical Equipment AnalysisProgram l1anager's Assessment

ELECTRICAL EQUIPfiENT ANALYSIS

List of Tables

Comparison of Computed andAllowable Loads and Stressesin the Hot Shutdown RemoteControl Cabinet

12

Comparison of Verification andDesign Analysis Stresses for theHot Shutdown Remote Control Cabinet

16

Comparison of Computed and Allowable 23Loads and Stresses in the HainAnnunciator Cabinet Assembly

l 1

V

ELECTRICAL EQUIPMENT ANALYSIS

List of Figures

Hot Shutdown Remote ControlCabinet Overall Configuration

Hot Shutdown Remote ControlCabinet Support

STARDYNE llodel of InstrumentPanels in Hot Shutdown RemoteControl Cabinet

10

Design Analysis Dynamic Hodel for 15Hot Shutdown Remote Control Cabinet

llain Annunciator Cabinet Assembly 19Elevation View Looking Nest

~ 8

Truss Bracing — Plan View andCross Section

Verification Analysis Model forllain Annunciator

Cabinet'esign

Analysis Computer liodel

20

22

25

1 ~ 0 INTRODUCTION

This interim technical report summarizes theindependent analysis and verification of the initialsample of electrical equipment qualified by analysisat Diablo Canyon Nuclear Power Plant Unit 1 (DCNPP-1).The electrical equipment sample consists of the hotshutdown remote control cabinet and the main annunciatorcabinet.

In addition, this report summarizes theverification of the natural frequencies for anadditional sample of electrical equipment qualified byanalysis at DCNPP-1. The sample consists of the localinstrument panels and the instrument AC panels.

Verification and specification of additionalsamples is described in the Interim Technical Report(XTR) Ol, Revision 1 (Reference 1). The XDVPdetermined that instrument panels PXA, B and Cgthough specified in XTR Ol, Revision 1, wereanalyzed by the manufacturer, and thus were not partof the IDVP review scope.

This report is one of several interim technicalreports of the Independent Design VerificationProgram (IDVP). Interim technical reports includereferences, sample definitions and descriptions,methodology, a listing of Error and Open Xtems, andexamination of trends and concerns, and a conclusion(Reference 2). This report presents the results ofthe IDVP electrical equipment analysis and serves asa venicle for NRC review. It will also be referencedin the Phase I Final Report.

This report does not include the independentverification of Class lE electrical components which aremounted to the hot shutdown remote control cabinet ormain annunciator cabinet. These items were qualifiedby shake table testing. The verification of theelectrical equipment qualified by shake table testing isthe subject of a separate interim technical report(Reference 3).

Also not included here is the verification ofClass lE electrical components mounted to localinstrument panels or instrument AC panels. These itemswere qualified separately.

I

Robert L. Cloud and Associates Inc. (RLCA) hasperformed verification analyses for the Phase Iinitial sample of electrical equipment qualified byanalysis. Loads and stresses were calculated andcompared to allowables. llethods and assumptions usedin the design analyses were compared to those in theverification analyses. Allowable criteria were metfor the hot shutdown remote control cabinet, but wereexceeded for the main annunciator cabinet assembly.A generic concern with regard to frequency assumptionswas identified and recommendations were made.

As a result of the initial sample comparison, theIDVP reviewed natural frequency assumptions for anadditional sample of electrical equipment qualified byanalysis. An error was identified in the designnatural frequency calculations. However, both the localinstrument panels and instrument AC panels were found tomeet the frequency criteria for rigid equipment.

On September 28, 1981 PGandE reported that adiagram error had been found in a portion of theseismic qualification of the Diablo Canyon NuclearPower Plant Unit 1. This error resulted in an in-correct application of the seismic floor responsespectra for sections of the annulus of the. Unit 1containment building. The error originated whenPGandE transmitted a sketch of Unit 2 to a seismicservice-related contractor. This sketch containedgeometry incorrectly identified as Unit 1 geometry.

As a result of this error, a seismic reverif-ication program was established to determine if theseismic qualification of the plant was adequate forthe postulated Hosgri 7.5N earthquake. This programwas presented orally to the NRC in a meeting inBethesda, Haryland on October 9, 1981.

Robert L. Cloud and Associates (RLCA) presenteda preliminary report on the seismic reverificationprogram to the NRC on November 12, 1981 (Reference 4) .This report dealt with an examination of theinterface between URS/Blume and PGandE.

2

The NRC commissioners met during the week ofNovember 16, 1981 to review the preliminary reportand the overall situation. On November 19, 1981 anOrder Suspending License CLI-81-30 was issued. whichsuspended PGandE's license to load fuel and conductlow power tests up to 5% of rated power at DCNPP-1.This suspending order also specified that anindependent design veri'fication program be conductedto ensure that the plant met the licensing criteria.

PGandE retained Robert L. Cloud and Associatesas program manager to develop and implement a programthat would address the concerns cited in the ordersuspending license CLI-81-30. The Phase I Plan forthis program was tranmitted to the NRC staff inDecember 1981 and discussed on February 1, 1982.Phase I deals with PGandE internal activities andseismic service-related contractors prior to June1978.

On llarch 19, 1982 the NRC approved TeledyneEngineering Services (TES) as program manager toreplace Robert L. Cloud and Associates (RLCA).Flowever, RLCA continued to perform the independentreview of seismic, structural and mechanical aspectsof Phase I.

The NRC approved the Independent DesignVerification Program Phase I Engineering Program Planon April 27, 1982. This plan dictates that a sampleof piping, equipment, structures and components beselected for independent analysis. The results ofthese analyses are to be compared to tne designanalyses results. If the acceptance criteria isexceeded, an Open Item Report is to be filed.Interim technical reports are to be issued to explainthe progress of different segments of the technicalwork.

ITR 033, Revision 0 was issued in February, 1983to describe the IDVP verification of an initialsample of electrical equipment qualified by analysis.Two concerns were noted and recommendations were madefor additional verification. Results and conclusions ofthis additional verification are reported in Section 5of this ITR.

2.0 INDEPENDENT DESIGN VERIFICATION llETHODS

2.1

The verification analysis used the followingprocedures to analyze the seismic qualification of thehot shutdown remote control cabinet and main annunciatorcabinet.

First, the equipment's physical dimensions wereverified in the field. Next, the equipment wasmathematically modeled to represent the equipment's massand stiffness characteristics. From this model, naturalfrequencies were determined. Applicable seismicaccelerations were obtained using the natural frequenciestogether with the appropriate Hosgri response spectra.Forces and moments were calculated for the key areas.Stresses were determined from the forces and moments.These computed stresses were compared to the allowablestresses. Finally, the stresses computed by the IDVPwere compared to the stresses from the design analysis.2.2

The IDVP used the Diablo Canyon Nuclear Power PlantUnit 1 licensing criteria to analyze the hot shutdownremote control cabinet and the main annunciator cabinetassembly. This criteria is contained in the FSAR and theHosgri Report (References 5 and 6) .

Allowable criteria have been taken from the "SteelConstruction Handbook, Seventh Edition" (Reference 7).Allowable criteria for concrete expansion anchors havebeen taken from PGandE Drawing 054162, Revision 3,"Concrete Expansion Anchors for Seismic and StaticLoading," (Reference 8). Loading combinations are alsoincluded in Attachment 1 of the Phase I EngineeringProgram Plan (Reference 9).

3.0 VERIFICATION ANALYSIS OF ELECTRICAL EQUIPMENT

3.1

The hot shutdown remote control cabinet(called a panel in the Hosgri Report) is located atthe West end of the Unit 1 auxiliary building atelevation 100 feet. The cabinet containsindicators and manual controls for various pumpsand valves in the auxiliary feedwater, borationcontrol, and containment ian cooler systems.

The hot shutdown remote control cabinet isdesigned to act as backup to the control roominstrumentation and controls and allows the plantto be brought to a hot shutdown condition. Theoverall cabinet configuration is shown in Figure 1.Figure 2 shows the cabinet base and supportdetails.

The cabinet is made of ll gauge steel. Itsdimensions are approximately 5 feet 10 inches wide,6 feet 6 inches high, and 3 feet deep. The cabinetis oriented such that front-to-back corresponds tothe East-West direction. The front of the cabinethas doors which enclose the 3/16 inch thick steelinstrument panels, one vertical and the otherdiagonal, tilted at 30 degrees up from thehorizontal. Instruments and switches are mountedon both panels (see Figure 1). Steel separationbarriers are welded to the back of the panelsto isolate various instruments. The rear of thecabinet has doors which provide service access towiring and instrumentation.

A vertical ll gauge sheet metal barrierrunning the full height and depth of the cabinetlaterally separates the interior of the cabinet.This barrier is also shown in Figure l.

The cabinet is mounted on four steel 4 inchchannels which are welded to a box comprised of 10inch I-beams. This box, in turn, is bolted tosteel plates embedded in the concrete floor.

VerticalInstrument

PanelSteel

Barrier

Gauges 8

Switches( ypical)

U40 in

78 in

30'A

~ go

Door

InstrumentPanel

70 inOblique Front View

Including Cut-Out

4 inChannel Base

F loor atElevation 100 ft

North

Figure IHot Shutdown Remote Control Cabinet

Overall Configuration

I

Cl i p4 inchChannel

3/16 in. oubl eFillet Weld

(Typica 1 ) 2x2xl/4 i .

Angle ClipStiffener

Plate 5/8 in.Welded

Studj (Typical)

Pq

Bolt

Cl i p

I-Beam

Figure 2

Hot Shutdown Remote Control Cabinet Support

3.1.1

After field verifying the dimensions of thehot shutdown remote control cabinet and itssupporting structure, the IDVP developed amathematical model to simulate the equipment's massand stiffness characteristics. Overall cabinetstiffnesses in the horizontal direction werecalculated for bending and shear (Reference 10).

These stiffnesses were calculated for areduced cross-section of the cabinet structure.Instead of considering the full 36 inch depth ofthe cabinet in the front-to-back direction,stiffnesses were calculated for the 20 inchsection of cabinet equivalent to the section ofupper cabinet above the diagonal panel (see Figure 1).In addition, the model neglected shear stiffnesscontribution of the interior steel barrierand any stiffness contribution in this directionfrom the doors.

The stiffnesses were used to develop a singledegree of freedom lump mass model to representoverall cabinet dynamic characteristics. Thecomplete cabinet mass was lumped at the center ofgravity. This model is more flexible than theactual case, and hence, is conservative because itwould yield lower natural frequencies anda larger response. This model was used todetermine the front-to-back horizontal naturalfrequencies.

The IDVP examined the cabinet's configurationand determined that the model of the cabinet in thefront-to-back direction represented the mostflexible direction. Because the natural frequencyin this direction was found to be greater than 33

'ertz,the IDVP concluded that overall cabinet wasrigid.

Hosgri response spectra for 4% damping andnatural frequency results were used to determineseismic accelerations (Reference 6). Torsionalaccelerations of the auxiliary building wereincluded. The value of damping used, however, isirrelevant because the cabinet was rigid (> 33hertz) and zero period accelerations were used. Thespectra considered in the verification analysis arelisted in Appendix C. 'The following eismicaccelerations were used:

.76 g Horizontal East-Nest

.97 g Horizontal North-South

.60 g VerticalThese accelerations were used to calculate the

loads and forces at key areas (see Table 1). Usingthese forces and loads, stresses at key areas werecalculated and then compared to allowable stresses.

To analyze the cabinet in greater detail, theIDVP created a finite element computer model toexamine the local dynamic characteristics of thecabinet's two instrument panels. Using plateelements, a STARDYNE finite element model wasdeveloped for the two instrument panels. The modeltook into consideration instrument cutouts, majorinstrument weights, and the welded separationbarriers. The configuration of the model is shownin Figure 3. The weights of the instruments werelumped at the node points corresponding to theinstrument locations. The total weight ofinstrumentation included in the model wasapproximately 167 pounds.

0'

VerticalInstrument

Panel

Diagonal.Instrument

Panel

30'EGEND

0 Grid Points

Cutout areas withno plate elements

Note: Barriers onttte reverse sideare omitted forclarity.

Figure 3

STARDYNE Model of Instrument Panels inHot Shutdown Remote Control. Cabinet

10

The 3/16 inch steel instrument panel isintermittently fillet welded to 3 x 2 x 1/4 inchand 2 x 2 x 1/4 inch angles along the perimeter andis tack welded to the 11 gauge interior barrieralong the length of the barrier. The verification,analysis accounted for these attachment configurationsby using two separate computer models to bound theanalysis. The first model assumed the local paneledges to be simply supported, i.e., no momentresistance at the edges. 'he second model assumedthe edges to have a fixed boundary condition, i.e.,the edge support does have moment resistancecapability.

Instrument panel frequencies were calculatedfrom the finite element model, and a computerresponse spectrum analysis was performed todetermine the accelerations, loads and stresses.Hosgri response spectra for 4S damping, wereapplied at the edges in the model representing thepanel attachment to the cabinet. Although Hosgriresponse spectra apply to floor mounted equipment,they also apply to these panels because the cabinetto which they are attached is rigid, (> 33 hertz)in all directions.

Calculated stresses were then compared to theallowables.

The IDVP computed stresses at the followingkey areas and compared them to the allowablestresses (see Table 1). Both the stresses for thecabinet and those stresses due to local dynamiccharacteristics of the instrument panel arepresented.

Cabinet base angle to basechannel bolt stress

Tension*Shear

Cabinet base angle stress

1,113 psi 20,000 psi457 psi 10,000 psi

12,288 psi 22,000 psiBase channel to I-beam weld stress* 1,088 psi 21,000 psiAngle clip at I-beam tensile stress

AxialBending*Combined

Clip to I-beam bolt stressTensionShear

427 psi (only combined9,984 psi stress compared)

10,411 psi 22,000 psi

2,591 psi 20,000 psi687 psi 10,000 psi

I-beam anchor bolt stressTension*Shear

10,792 psi687 psi

20,000 psi10,000 psi

Cabinet sheet metal stress

Side panel buckling load

10,800 psi 22,000 psi

1,260 lb. lli737 lb.

Maximum combined panel stress 2,546 psi 22,000 psi

*Note: Those stresses marked with an asteriskshow those key areas which are also explicitlyevaluated in the design analysis.

Table 1Comparison of Computed and Allowable Loads and Stresses

in the Hot Shutdown Remote Control Cabinet

12

A comparison of the computed stresses for the keyareas to the allowable stresses shows that the hotshutdown remote control cabinet meets the allowablecriteria.

The natural frequency results from the boundinglocal panel analyses showed the model with simplysupported edges has a first natural frequency in theflexible range, and the model with fixed edges nas afirst natural frequency in the rigid range. Thesefrequencies are given below:

Simply supported edges

Fixed edges

26.5 hertz

42.7 hertz

The local panel was judged to be rigid becausethe actual panel edge boundary conditions arebetween fixed and simply supported edges, and theintermittently fillet welded edges are more similarto the fixed edge boundary condition.

13

3.1.3

The design analysis examined the front to backvibrational frequencies using a lump mass modelwith nine dynamic degrees of freedom (as shown inFigure 4) . The side-to-side and vertical naturalfrequencies were determined by inspection to begreater than those for the front-to-back direction,based on the fact that the doors are closed duringnormal plant operation (Reference 11).

The design analysis calculated loads andstresses using a one mode response spectrumanalysis. Key areas were examined for shear andoverturning moment loadings. Three key areastresses were reported for the hot shutdown remotecontrol cabinet (shown in Section 3.1.5).

Both the verification and design analyses ofthe overall cabinet structure considered thecabinet's front-to-back direction to be the mostflexible direction. However, the methodologiesused to represent the front-to-back charateristicsdiffered: while the verification analysis used asingle degree of freedom model based on a reducedcross-section of the cabinet, the design analysisused a lump mass and beam element model with ninelumped masses.

Both the verification and design analysesfound the lowest natural frequency to be in therigid range. Based on this result, botn analysesconcluded that the cabinet natural frequencies inside-to-side and vertical directions were rigid.

The verification analysis also examined thelocal instrument panel.

Degree of FreedomCorresponding toFront-to-Back Motion

Beam Element

Fixed PointLumpMasses

Stiffnesses

Figure 4

Design Analysis Dynamic Model ForHot Shutdown Remote Control Cabinet

15

3.1.5

The IDVP compared the results of theirindependent analysis listed in Section 3.1.2 withthe results of the design analysis as follows:

Cabinet base angle tochannel bolt tensilestress

Verificationhnalz~

1,113 psi

DesignEn',~440 psi

Angle clip at I-beambending stress

9,984 psi 8,000 psi

I-Beam anchor bolttensile stress

2,482 lbs. 520 lbs.

Table 2

Comparison of Verification and Design Analysis Stressesfor the Hot Shutdown Remote Control Cabinet

Both the verification and design analysisstress results are lower than the allowable stresses.Although different methods and assumptions wereused, both analyses produced similar results.

The verification analysis used a single degreeof freedom model using a stiffness calculated froma reduced cross section. The total mass of thecabinet was lumped at the center of gravity. Thedesign analysis used a more refined model with ninedistributed lump masses.

3.1.6

The IDVP issued one EOI report specificallyfor the hot shutdown remote control cabinet. TableA-1 shows the EOI file number, revision, date, andstatus.

EOI 1087 reports differences of greater than150 between the independent analysis results andthe design analysis results. This EOI was sub-sequently closed because the IDVP showed allstresses to be below the allowable stresses.

The IDVP issued three other EOI's not dealingspecifically with the hot shutdown cabinet, but asa result of the RLCA Preliminary Report, "SeismicReverification Program," dated 'November 12, 1981(Reference 4) .

EOI 1004 was issued because insufficientdocumentation was available to veriiy the transmittal ofseismic information across the PGandE and the NSSS(Nuclear Steam Supply System) supplier. The IDVPhas verified this interface through a review ofcorrespondence and an audit of the NSSS supplier.This work is reported in IDVP Interim TechnicalReport ¹ll, Revision 0 (Reference 12). EOI 1004was resolved as a closed item.

EOI 1006 was issued because insufficientdocumentation was available to verify the interfacebetween PGandE and the groups performing electricalequipment analysis. EOI 1006 was subsequentlyclosed because the IDVP sample analyses verify thetechnical adequacy of the electrical equipmentanalyses without examination of the originalinterface.

EOI 1007 was issued because available records didnot adequately document the transfer of seismicinformation betweeh PGandE and their service-relatedcontractors. EOI 1007 was subsequently closed becausethe IDVP sample analyses verify the technicaladequacy of the electrical equipment analyseswithout examination of the original interface.

3 ~ 2

The main annunciator cabinet is an integratedassembly comprised of nine separate cabinets housingvarious electrical components of the main annunciatorsystem (see Figure 5). The cabinet is located onelevation 127 feet in the auxiliary building below thecontrol, room in the cable spreading area. The mainannunciator system is used to sound alarms and lightindicator lamps in the main control room to signal theplant operator.

Each of the nine structurally identical cabinets isconstructed of 12 gauge formed members and sheet metal.They have doors in the front and rear which open to allowaccess to the components mounted within. These doors runthe full length and width of each cabinet and closeout-of-plane from the cabinet structure (as opposed toflush with the structure). The components are mounted oninternal racks. Figure 5 shows the general configurationof the cabinet assembly.

The base of the cabinet assembly is welded to steelplates embedded in the floor slab, and has a truss-typebrace tying the top of the cabinet assembly to anadjacent concrete wall. The brace is attached to the topof each cabinet through two steel channels which runthe full length of the cabinet assembly. Details of thisbrace are shown in Figure 6.

18

0

190 in

ODO DOOOOGOO O

CO

I

CQ

000

ODO

Floor slab atelevation 127 ft-4 i n

Figure 5

Main Annunciator Cabinet AssemblyElevation View Looking West

(shown without doors)

19

5 inchChannels

Connections are1/8 inch doublefillet welded

(typical)Truss

Bracing

Weldedgussetplate

g4 I 3 II

8'-5"

LTop ofCabinetAssembly

7 I 4/II 25 in

West

3x3x3/16 AngleNorth

5/8" diameterconcrete anchors

7 II

Detail A-A

Figure 6

Truss BracingPlan View and Cross Section

20

3.2 '

The IDVP developed a mathematical model of the mainannunciator cabinet assembly after field verifying theconfiguration and selected dimensions of the cabinet andtruss bracing (Reference 13). A single typical cabinetfrom the nine cabinet assembly was examined to determineits individual structural characteristics. The structureof this single cabinet was idealized as solely composedof the four internal 12 gauge formed steel memberslocated at the corners of the cabinet. This simple modelwas deemed to be an adequate representation because thefront and back doors do not close in plane with tnecabinet structure and hence do not contribute to theshear capabilities in that plane.

Figure 7 shows the verification analysis model forthe main annunciator cabinet.

The stiffness of each of the four 12 gaugeinterior members was determined in the side-to-sidedirection. On the basis of these calculated stiffnesses,the stiffness of the complete cabinet assembly was thendetermined. The North-South (side-to-side) model wasdeveloped by first calculating the stiffness contributionof the truss bracing in the North-South direction. Thisstiffness was then included in the model with the cabinetstiffness.

The base of the cabinet assembly, which is welded tosteel plates embedded in the floor, was assumed to berigidly attached to the floor slab for all models.

The mass of each cabinet was assumed to be uniformlydistributed along the height of the cabinet. This is aconservative assumption because the actual cabinets havethe heavier components located towards the bottom.

The East-Nest (front-to-back) and vertical directionswere not examined.

0

0,

Spring representingN-S stiffness ofbracing

Wallconnect'eamwith

uniformlydistributedmass

~.N-S Model

Figure 7

Verification Analysis Model

for Main Annunciator Cabinet

22

The natural frequency of the cabinet assemblyin the North-South directions was calculated as 7.6hertz.

Seismic accelerations were chosen from Hosgriresponse spectra at 4% damping to correspond to the IDVPnatural frequencies. Since there are no response spectraavailable for elevation 127 feet, acceleration valueswere linearly interpolated between spectra values forelevations 115 feet and 140 feet. The interpolationalso considered the height of the truss bracingattachment point. The spectra used in the verificationanalysis are listed in Appendix C.

An equivalent static method was used to determinethe loads and forces from the 6.38g North-South seismicaccelerations. These loads and forces were then used tocalculate stresses at key areas (see Table 3) . Thecalculated stresses were then compared to the allowables.

3.2.2

The verification analysis computed loads andstresses at the following key areas and comparedthem to the allowables. The results show that thebracing concrete expansion anchor loads and the interiorcabinet member loads for North-South loading exceedallowables (EOI 949).

Truss bracing expansionanchor

2.04 * 1.0

Interior member bending 58.2 ksi 28.0 ksi

* Combined shear/tension interaction

Table 3

Comparison of Computed and AllowableLoads and Stresses in the Hain Annunciator

Cabinet Assembly

23

3 ~ 2.3

The design analysis of the main annunciator cabinetassembly modeled the dynamic characteristics using a lumpmass and beam element computer model (Reference 14). Themodel, shown in Figure 8, only accounted for thefront-to-back (East-West) motion of the cabinet assembly.The design analysis concluded that the cabinet assemblyis rigid in the side-to-side direction because the doorswere assumed to provide a substantial stiffnesscontribution in that direction when they were closed.

The model lumped the structural properties of thecolumns of adjacent cabinets together into a series ofindividual beam elements. A total of 30 lump masses arecontained in the computer model. The mass of eachcabinet was equally distributed to three lump masseslocated on each of the series of beams (see Figure 8 forthe design analysis model representation). These lumpmasses are located at the center line of the horizontal.reinforcing members. The model was set up such thatdegrees of freedom for the lump masses allowed forfront-to-back motion only.

For boundary conditions, the design analysis assumedthat the bottom of the cabinet assembly is fixed to thefloor slab. At the top of the cabinet assembly, the modelwas laterally restrained at the brace attachment points.

Natural frequencies in the rigid range werecalculated from this lump mass model. Seismic loadingsfor the assembly location at elevation 127 feet wereobtained by interpolating between elevation 115 feet and140 feet spectra. The seismic inputs used in the designanalysis were compared to the Hosgri spectra. EOI 1008was issued to note that the design analysis seismicinputs were taken from preliminary spectra. Theseseismic loadings were used to calculate stresses at fourkey locations. These stresses were then compared to theallowable stresses.

24

(I

I

Lateralsupport

provided byhorizontal

steel bracke

I

I

I

Typical:interiorcolumn

I

I

Y

Typical beam

Typicalend column

Typi caldynamic

degree offreedom

I

r

Outline ofcabinet assembly

Typicalinter-cabinet

coupling member

Figure 8

Design Analysis Computer Model

3.2.4

The difference between the design analysis and theverification analysis is that the design analysis assumedthat the cabinet assembly was rigid in the side-to-side(North-South) direction. Thus, the design analysis didnot account for the effects of the amplified structuralresponse in the side-to-side (North-South) direction.

The design analysis did not report loads andstresses in the upper truss bracing. The verificationanalysis of the connection between the truss bracing andthe wall showed that when the structural response in theside-to-side (North-South) direction was accounted for,the expansion anchor bolt loads exceeded the allowable(EOI 949).

26

0

3. 2.5

The IDVP issued two EOI reports for the mainannunciator cabinet assembly. Appendix A shows the EOIfile number, revision, date and status.

EOI 949 was issued because the loads (determined bythe IDVP) on the concrete expansion anchors securing thetruss bracing to the wall exceeded the allowable. Inaddition, the design analysis assumed that the cabinetwas rigid in the side-to-side direction. The concreteexpansion anchor loads exceeded allowables because thedesign analysis did not examine the side-to-side motionbased on this rigidity assumption. The IDVP found theside-to-side natural frequency of the structure to be inthe flexible range..

PGandE is modifying the main annunciator cabinetassembly to make the cabinet assembly rigid in the side-to-side direction. EOI 949 is described as an ErrorClass A or B pending IDVP verification of themodification.

EOI 1008 was issued because the PGandE qualifyinganalysis for the main annunciator cabinet assemblyreferenced preliminary Hosgri response spectra (dated4/4/77). Results of the verification analysis indicatethat the use of preliminary spectra did not causeallowables to be exceeded. -EOI 1008 was classified as aClass C Error.

27

4.0 EVALUATION OF ELECTRICAL EQUIPHENT ANALYSISINITIALSAfjPLE

4.1

The IDVP performed analyses for two initialsamples= of electrical equipment qualiried byanalysis: the hot shutdown cabinet and the mainannunciator cabinet assembly. The verificationanalysis found that the allowable criteria were metfor the hot shutdown remote control cabinet but wereevceeded in the main annunciator cabinet assembly.

Three EOIs were issued as a result of thecomparison between the verification and design analysesmethods and results (EOIs 949, 1087, and 1008). Twoconcerns were noted:

o The assumption in the design analysisthat the main annunciator cabinet isrigid in the North-South direction wasshown to be incorrect. This leads to aconcern with rigidity assumptions(EOI 949).

o Spectra not contained in the Hosgrireport were used in the analysis (EOI 1008).

4.2

The following recommendations address theconcerns described in the interpretation section:

o Review the adequacy of all assumptions usedin the frequency calculations for allelectrical equipment qualified by analysis.These include instrument AC panel,instrument panels PIA, B and C, and localinstrument panels. This additionalverification is also described in ITR Cl,Pevision 1 (Reference 1).

o Review all seismic inputs as already setfortn in the. DCP Corrective Action Program.

28

5.0 ADDITIONAL VERIFICATION OF ELECTRICAL EQUIPHENT

5.1

The IDVP reviewed the design analysis for the localinstrument panels and instrument AC panels selected foradditional verification. The recommendation foradditional verification called for review of the designanalyses for the assumptions used in the n'aturalfrequency calculations for all electrical equipmentqualified by analysis (see Section 4.2, firstrecommendation).

The recommendation in Section 4.2 regarding seismicinputs is included in the DCP program of additionalactivities. This work will be verified by the IDVP andreported in a subsequent interim technical reportdescribing control and application of Hosgri spectra.

5.2

The IDVP reviewed the frequency calculations in thedesign analyses for the local instrument panels and theinstrument AC panels. An error noted that unconservativestatic deflections were used in calculating the naturalfrequency. As a result, natural frequencies wereoverestimated. However, the natural frequencycalculated by the IDVP using the correct formulationshows the panels to meet the frequency criteria, i.e.,to be greater than 33 hertz.5.3

The IDVP issued one EOI report for the additionalverification of electrical equipment qualified byanalysis. Appendix A shows the EOI file number,revision, data and status.

EOI 1117 was issued because the design analysisused an unconservative static deflection in thecalculation of the instrument AC panel naturalfrequency. As a result, the natural frequency wasoverestimated. However, an IDVP calculation using thecorrect formulation determined that the panel had anatural frequency greater than 33 hertz and thus met thenatural frequency criteria. Therefore, EOI 1117 wasresolved as a Class C error.

29

6 ' CONCLUSION

The verification analysis for the initial sample ofelectrical equipment qualified by analysis found thatthe hot shutdown remote control cabinet meets theallowable criteria. However, a comparison of the designand verification analyses for the main annunciatorcabinet indicates that tne design analysis used anunrealistic assumption for the cabinet rigidity.Results of the verification analysis show that, as aresult of postulated'Hosgri seismic loading, allowablecriteria have been exceeded for the main annunciatorcabinet assembly (EOI 949). Additional verification ofnatural frequency assumptions was recommended.

The additional verification was performed toaddress the concern identified in the initial sample.One error has been noted arising from the additionalverification (see Section 5.2). However, the IDVP foundthat the frequency criteria have been met for the localinstrument panels and the instrument AC panels selectedfor additional verification.

30

7.0 REFERENCES

Interim Technical Report, Inde-pendent Design Verification Program,Additional Verification and AdditionalSampling, Revision l.

P105-4-839-001

DCNPP Independent Design Verifi-cation Program, Programllanagement Plan, Phase I, Re-vision 1, July 6, 1982.

Interim Technical Report,Independent Design VerificationProgram, Shake Table Testing,Revision 0.

RLCA Preliminary Report — SeismicReverification Program, November 12/1981.

PGandE Final Safety Analysis Report,USAEC Docket Nos. 50-275 and 50-273.

PGandE Report: "Seismic Evaluationfor Postulated 7.5N Hosgri Earth-quake," USNRC Docket Nos. 50-275and 50-323.

P105-4-810-023

P105-4-839-004

P105-4-200-005

P105-4-200-001

10

AISC, "llanual of Steel Construction,"7th Edition, 1973.

PGandE Engineering Standard, DrawingNo. 054162, Revision 3, "ConcreteExpansion Anchors for Seismic andStatic Loading."

DCNPP Independent and Design Veri-fication Program, Program Procedure,Phase I, Engineering Program Plan,Revision 0, l1arch 31, 1982.

RLCA Verification Analysis of theHot Shutdown Remote Control Panel,Revision 2.

P105-4-455-054

P105-4-570-004

31

PGandE Seismic Qualification ofHot Shutdown Panel, El. 100,Auxiliary Building, Diablo CanyonNuclear Power Plant.

IDVP Interim Technical Report,Pacific Gas & Electric - LlestinghouseSeismic Interface Review, ITR Oll,November 2, 1982.

RLCA Verification Analysis — HainAnnunciator Cabinet, Revision 3.

Dynamic Seismic Analysis of t4ainAnnunciator Cabinet Structure,Auxiliary Building, Diablo CanyonPower Plant, June, 1977.

IDVP Interim Technical Report,Additional Verification and Addi-tional Sampling, ITR Ol, Revision 1.

IDVP, Program Procedure, Preparationof Open Item Reports, Error Reports,Program Resolution Reports, and IDVPCompletion Reports, DCNPP-IDVP-PP-003,Revision l.RLCA Review, Electrical Panels—Additional Verification, Revision 0.

P105-4-437-004

P105-4-570-001

P105-4-447-010

P105-4-506-012

32

Robert L. Cloud and Associates, Inc

Appendix A

EOI Status - Electrical Equipment Analysis

(2 pages)

tW

Appends A

Error and Open Item Reports

EOIFile Ho.

949

1004

Subject

Hain Annunciator Cabinet-Stresses Exceed Allowables

Documentation of FormalTransmittals of spectra toWestinghouse (issued as aresult of the RLCA Pre-liminary Report, 11/12/82)

Rev. Date

1/20/824/21/829/3/82

2/6/823/22/824/17/825/24/82

6/9/826/22/826/22/82

By

RLCARLCA

TESTES

RLCATESTES

Type

OIRPER/AorB

OIR

OIRPPRR/DEV

PRR/OIP.OIR

PPRR/CIPRR/CI

ActionRequired

RLCATES

PGandERLCA

TESTES

None

Physicalt'iod.

Yes

1006

1007

1008

Docunentation for Elec-trical Equipaent Analysis(issued as a result ofthe PreliIainary Report,11/12/82)

Documentation for. Elec-trical EquipIrent Analysis(issued as a result ofthe PreliIllinary Purport,ll/12/82)

Yiain Annunciator Cabinet-Preliminary Spectra

'012

2/6/823/9/82

4/21/82

2/6/823/9/82

4/21/82

'2/9/823/18/826/8/82

10/18/82

RLCARLCA

YES

RLCARLCA

TESTES

OIRPPRR/CI

OIRPPRR/CI

CR

OIRPER/C

ER/C

RLCATES

None

RLCATES

PGandENone

STATUS: Status is indicated by the type of classif1cation of latest report received by PGandE:

OIR - Open Item Report ER - Error Report A - Class A ErrorPPRR - Potential Program Resolution Report CR - Complet1on Report B - Class 0 ErrorPRR - Program Resolut1on Report Cl - Closed Item C - Class C ErrorPER - Potential Error Report OEV - Deviation O - Class O ErrorOIP - Open Item with future action by PGandE

PHYSICAL ROD: Physical modification required to resolve the issue. Blank entry indicates thatmodification has not been determined.

appendix A

Error and Open Item Reports

EOIFile No. Subject Rev. Date By Type

ActionRequired

PhysicalPod.

1087 Hot Shutdown Rerrote Con-trol Panel 15% Difference

5/14/82 RIZA5/26/82 RLCA5/28/82 RLCA6/23/82 TES6/23/82 TES

OIRPPRR/CIPPRR/CI

PRR/CICR

RLCATj".S

TESTES

None

1117 Instr. Power AC Panels,unconservative stiffnesscalculated

3/16/83 RLCA3/16/83 RLCA3/26/83 TES4/19/83 TES

OIRPER/C

ER/CCR

RLCATES

PGandENone

STATUS: Status is indicated by the type of classification of latest report received by PGandE:

OIR - Open Item Report ER - Error Report A - Class A ErrorPPRR - Potential Program Resolution Report CR - Completion Report B - Class B ErrorPRR - Program Resolution Report CI » Closed Item C - Class C ErrorPER - Potential Error Report 'EV - Deviation 0 - Class 0 Error

OIP - Open Item with future. action by PGandE

PBYSICAL NOD: Physical modification required to resolve the issue. Blank entry indicates thatmodification has not been determined.

Robert L. Cloud and Assoc/ates, Inc,

Appendix B

Key Term Definitions

(6 pages)

KEY TERf1S AND DEFINITIONS USED INTHE ELECTRICAL EQUIPI1ENT ANALYSIS REPORT

(The definitions in tnis glossary establish the meaningsof words in the context of their use in this document.These meanings in no way replace the specific legal andlicensing definitions.)

Acceptance Criteria— The comparison between the design analysis and

the independent analysis where the results mustagree within 15% and be below allowable. Fail-ure to meet this acceptance criteria results inthe issuance of an Open Item.

Allowable Criteria— Naximum stress or load provided by the licensing

criteria.Closed Item

— A form of program resolution of an Open Itemwhich indicates that the reported aspect isneither an Error nor a Deviation. No furtherIDVP action is required (from Reference 16).

Completion Report— Used to indicate that the IDVP effort related

to the Open Item identified by the File Numberis complete. It references either a ProgramResolution Report which recategorized the itemas a Closed Item or a PGandE document whichstates that no physical modification is to beapplied in the case of a Deviation or a ClassD Error (from Reference 16).

DCNPP-l

— Diablo Canyon Nuclear Power Plant Unit lDesign Codes

— Accepted industry standards for design (ex. AISC,AISIg ANSI'Sl'1Eg AW'JAN IEEE) .

EOI

— Error and Open Item Report

Error Report

— An Error is a form of program resolution of anOpen Item indicating an incorrect result that hasbeen verified as such. It may be due to a matn-ematical mistake, use of wrong analyticalmethod, omission of data or use of inapplicabledata.

Each Error shall be classified as one of thefollowing:

o Class A: An Error is considered Class A if designcriteria or operating limits of safety relatedequipment are exceeded and, as a result, physicalmodifications or changes in operating procedures

, are required. Any PGandE corrective action issubject to verification by the IDVP.

o Class B: An Error is considered Class B if designcriteria or operating limits of safety relatedequipment are exceeded, but are resolvable bymeans of more realistic calculations or retesting.Any PGandE corrective action is subject to veri-fication by the IDVP.

8-2

J

o Class C: An Error is considered Class C ifincorrect engineering or installation ofsafety related equipment is found, but nodesign criteria or operating limits are exceeded.No physical modifications are required, but ifany are applied they are subject to verificationby the IDVP.

o Class D: An Error is considered Class D ifsafety related equipment is not affected.No physical modifications are required, butif any are applied, they are subject toverification by the IDVP (from Reference 16).

FSAR

- PGandE's Final Safety Analysis Report

Hosgri Criteria— Licensing criteria referring specifically to

the postulated 7.5H Hosgri earthquake.

Hosgri Report— A report issued by PGandE that summarizes their

evaluation of the DCNPP-1 for the postulatedHosgri 7.5H earthquake. Includes seismiclicensing criteria.

Hosgri 7.5N Earthquake— llaximum earthquake for which the plant is

designed to remain functional. Same as SafeShutdown Earthquake (SSE).

Interim Technical Report

Interim technical reports are prepared when aprogram participant has completed an aspect oftheir assigned effort in order to provide thecompleted analysis and conclusions. These maybe in support of an Error, Open Item or Program

Interim Technical Report (cont)

Resolution Report or in support of a portionof the work which verifies acceptability.Since such a report is a conclusion of theprogram, it is subject to the review of theProgram l1anager. The report will be trans-mitted simultaneously to PGandE and to the k1RC(from Reference 2).

Licensing Criteria— Contained in PGandE Licensing Documents,

includes allowable criteria (See HosgriReport definition).

NRC

— Nuclear Regulatory Commission.

NRC Order Suspending License CLI-81-30

— The order dated November 19, 1981 that sus-pended the license to load fuel and operateDCNPP-1 at power levels up to 5S of full powerand specified the programs that must be completedprior to lifting of the suspension.

Open Item

— A concern that has not been verified, fullyunderstood and its significance assessed. Theforms of program resolution of an Open Item arerecategorized as an Error, Deviation, or a ClosedItem. (From Reference 16) .

PGandE

— Pacific Gas and Electric Company.

Phase I Program

— Review performed by RLCA, RFR, and TES restrictedto veriiying work performed prior to June 1978related to the Hosgri re-evaluation designactivities of PGandE and their seismic service-relatedcontractors.'-4

Potential Program Resolution Reportand Potential Error Report

— Forms used for communication within IDVP.

Program Resolution Report— Used to indicate that the specific item is no

longer active in the IDVP. It indicates whetherthe resolution is a Closed Item, a Deviation, orthat responsibility for an Open Item has beentransferred to the PGandE Technical Program.Further IDVP action is required upon completionof the associated PGandE Technical Program Taskif the IDVP transfers an Open Item to PGandE orif physical modifications are applied with respectto a deviation (Reference 16).

Response

— The motion resulting from an excitation of adevice or system under specified conditions.

Response Spectra— Graph showing relationship between acceleration

and frequency. Used in seismic analysis.RLCA

— Robert L. Cloud and Associates, Inc.

Sample

Initial Sample stipulated in Phase I Programof equipment, components, and buildings to bedesign verified by independent analysis.

B-5

Sampling Approach

— Hethod used by the IDVP to determine the initialsample (buildings, piping, equipment and compon-ents) for analysis and to provide for sampleexpansion when required.

SSE

- Safe Shutdown Earthquake: Haximum earthquakefor which the plant is designed to remainfunctional (Hosgri 7.5H).

Seismic

— Refers to earthquake data.

Single Deg'ree of Freedom Hodel

— Simplified mathematical representation of astructure.

TES

— Teledyne Engineering Services.

Verification Program

— Undertaken by the IDVP to evaluate DiabloCanyon Nuclear Power Plant for compliancewith the licensing criteria.

B-6

' L

Robert L. C1oud and Associates, Inc

Appendix C

Hosgri Response Spectra Considered

in IDVP Electrical Equipment Analysis

(1 page)

4

APPENDIX C

HOSGRI RESPONSE SPECTRA CONSIDERED IN THEIDVP ELECTRICAL EQUIPIIENT ANALYSIS

Horizontal: Figures *

Vertical: Figures *

4 114' 119' 123~ 4 1274-13 2, 4-137, 4-141, 4-145

4-150

Horizontal: Figures * 4 112' ll3g 4 117' 118/4-121, 4-122, 4-125'-126/

*Figure numbers correspond to those from the HosgriReport (Reference 6) .

I

e

Robert L. Cloud and Associates, Inc.

Appendix D

Program Manager ' Assessment

(1 page)

~ ~ a

~ ~ ~ ~ A TELEDYNEENGINEERtNG SERVlCES

APPENDIX D

PROGRAM MANAGERS ASSESSMENT

As IDVP Program Manager, TELEDYNE ENGINEERING SERVICES (TES) has

established a Review and Evaluation Team, headed by a qualified team

leader, as described in Section 7.4 (C) of the Phase I ProgramManagement Plan (Rev. 1). The assigned team leader for the area,Electrical Equipment, included in the Interim Technical Report, has

personally discussed the procedures, approach, field trip files,analyses, calculations, etc. with RLCA personnel. In addition, the TES

Team Leader has reviewed the Open Item Files pertaining to this area ofresponsibility and, in particular, those fields for which RLCA has

issued Potential Program Resolution Reports or Potential Error Reports,and on the basis of this evaluation, has recommended appropriateresolution to the IDVP Program Manager. Similar review procedures as

described above for the initial sample were followed in the review ofthe RLCA additional verification.

Based on this review and evaluation process to date, the Team

Leader, along with the TES Program Management Team, has studied and has

concur'red with the Interpretation and Recommendations outlined inSections 4.1 and 4.2 of this report as well as the Conclusions stated inSection 6.0.

~ ~ L +4

wj

r.

![IELTS [Diablo]](https://static.fdocuments.in/doc/165x107/5536222c5503462c748b4913/ielts-diablo.jpg)