REST SUMMARY

Transcript of REST SUMMARY

DNV GL © 2013

Ungraded

25 November 2016 SAFER, SMARTER, GREENER1 DNV GL © 2013 AM002

Ungraded

25 November 2016

Reliable Sensor Technologies (REST)

DNV GL © 2013

Ungraded

25 November 20162

Scope of REST Project To examine factors that lead to long-term performance deterioration of sensor

systems.

To assess the reliability of the sensor components vs total system (power, communications, data processor, and inter-connections).

To investigate using modelling analysis (e.g. Bayesian networks) for predicting and evaluating sensor system reliability.

To explore business opportunity for DNV GL in the field of sensor systems reliability.

DNV GL © 2013

Ungraded

25 November 20163

Importance of REST Digitalization– Sensor Technology itself is an important part of Digitalization.– DNV GL relies on reliable sensor data for surveying, inspection, monitoring, digital approval,

risk assessment etc. Business Opportunities– Verification/validation of sensors performance; Prediction of sensor reliability; Assessment of

risk.

DNV GL © 2013

Ungraded

25 November 20164

Definition

A sensor is a device that measures a physical quantity by generating a functionally related output which can be read by an observer or by an electronic instrument.

A working sensor system is a composite of four distinct parts: – Sensing element produces electrical response

when stimulated by external factors;– Signal conditioning element modifies and

processes the electrical signal to be understood properly by the receiver;

– Sensor interface allows the device to acquire, store, and communicate with an external interface;

– Power system provides external power resources or to harvest energy.

DNV GL © 2013

Ungraded

25 November 20165

Sensor System Reliability

The ability of a sensor system to perform its required functions under stated conditions for a specified period of time. For this reason, the reliability of a sensor system will be strongly dependent upon its age, context and application.

A high reliability is especially critical for the following application scenarios:– Complex and smart sensor systems (e.g. Sensor Fusion)– Highly integrated miniature sensor systems (e.g. MEMS

sensors)– Long term monitoring requirements (e.g. Condition

Monitoring) – High Consequence/Mission Critical applications (e.g.

Leak Detection)– Application requires dynamic response (e.g. DPS)– Harsh and extreme working environments (e.g. HTHP).

DNV GL © 2013

Ungraded

25 November 20166

Factors Affecting Sensor Reliability Each component of the sensor system, design, manufacturing, packaging,

installation, maintenance, calibration, and the software used by a sensor system can affect its reliability.

One method for assessing sensor system reliability is Failure Mode, Effects and Criticality Analysis (FMECA), where a risk assessment is made of each failure mode to determine its criticality. Criticality is derived from an assessment of the probability that a particular failure will occur combined with the severity of the failure if it does occur (i.e. the consequence).

DNV GL © 2013

Ungraded

25 November 20167

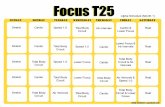

Generic Ranking of a Pressure Sensor To carry out an FMECA for a sensor system, a systematic analysis need to be

performed based on the sensing mechanism, the working environments and the overall redundancy.

Table below shows the criticality of a pressure sensor (generic) used in subsea processing, where the criticalities were divided into five categories of Very Low, Low, Medium, High, and Very High.

Sensor System Components Failure Modes CriticalityVery low Low Medium High Very

HighSensor elements Degradation of Sensing Material

Thermal Induced Signal Processing Components

Degradation of contacts or connections

Thermal Induced Degradation of Signal Processors

Power System

Degradation of contacts or connections

Faulty Electronics Loss of Power

Interface Communicating Components

Degradation of contacts or connections

Faulty Electronics Poor/Insecure Signal

DNV GL © 2013

Ungraded

25 November 20168

Improving Sensor System Reliability

Design/Manufacturing. Choosing the Suitable Sensor Systems. A Strictly Enforced Maintenance and Calibration Plan.

DNV GL © 2013

Ungraded

25 November 20169

Design/Manufacturing

The most effective strategy to improve sensor system reliability is through careful system design and well-controlled manufacturing quality.

A current tendency is to rely on a single vendor who can perform the entire process of sensor design, manufacturing, and testing.

Example: A variable capacitance silicon accelerometer used in implantable devices with no field failures among the four million parts was designed and manufactured using MEMS technology.

DNV GL © 2013

Ungraded

25 November 201610

Choosing the Suitable Sensor Systems

The reliability of a sensor system will be strongly influenced by the working environment into which it is applied.

For mission critical purposes or long term usage such as condition monitoring of infrastructures, certain levels of testing (normally including destructive testing) are necessary before deploying sensors into the field.

There have been attempts to develop computer based models such as “Multi Criteria Decision Making” models for aiding sensor selection.

In practice, the majority of sensor selections is based on manufacturer provided technical data sheets, sensor users’ past experience, or expert knowledge and recommendations.

DNV GL © 2013

Ungraded

25 November 201611

Choosing the Suitable Sensor SystemsClassification Societies Roles: DNV GL’s Recommended Practices on Reliable

Sensor System for Maritime Monitoring. Objective: to lead to more reliable sensor

systems and subsequently improved quality of the data collected for analysis and decision support in condition and performance monitoring of equipment, environmental monitoring and sensing systems Methodology: to ensuring system level reliability through defining the minimum requirements of the lowermost level, i.e. sensor components in a future maritime condition monitoring system.

Component

Failure modes Sensors

OutputComponent Sensor Requirements

(Reliable Sensor Technology

DNV GL © 2013

Ungraded

25 November 201612

A Strictly Enforced Maintenance and Calibration Plan A practical maintenance plan must be determined based on previous experience

and intensive testing in both lab and field to ensure that sensor systems can be used with high reliability, efforts must be taken to eliminate human errors.

After deployment, sensors require occasional testing and replacement of wear-out components. Most sensor manufacturers will provide guidance for the maintenance requirements, but users have to adopt these requirements into their own procedures.

Calibration is essential for establishing the accuracy of a sensor in relation to standards. Some modern “smart” sensing systems have the capability of self-calibration due to integration with an ASIC (Application-Specific Integrated Circuit).

DNV GL © 2013

Ungraded

25 November 201613

Evaluation of Sensor System Reliability Testing can be performed at different levels depends on the application scenarios. Testing is to verify the reliability of a sensor system, but can not improve it. Accelerated Life Testing (ALT) is typically employed to assess the long-term

performance of a sensor in a short period of time. ALT stresses the sensor systems by exposure to purposely harsh environments to

induce field failure at a much faster rate, which should include: 1. Define the scope 2. Collect required information 3. Determine the mechanisms of degradationto establish appropriate types and levels of stresses 4. Conduct the accelerated tests 5. Predict the field life of the sensor system

DNV GL © 2013

Ungraded

25 November 201614

Prediction of Sensor System Reliability Four categories of detection methods can applied to

develop algorithms to detect faulty sensor data as a screening tool prior to passing information on to decision-aid tools: – Rule-based methods define heuristic rules/constraints

that the sensor readings must satisfy.– Estimation methods define “normal” sensor behavior by leveraging spatial correlation in measurements at different sensors.– Time series analysis based methods compare a sensor

measurement against its predicted value based on time series forecasting to determine if it is faulty .

– Learning-based methods infer statistically established models to identify faulty sensor readings using training data.

DNV GL © 2013

Ungraded

25 November 2016

Prediction of Sensor System Reliability There exists the need to estimate the

uncertainty attached to the sensor data being received, useful in the situation where sensor systems can degrade over time in service, and thus the data may need to be corrected or compensated before decisions can be made.

Knowing enough information about a sensor system, including the working mechanism of sensors, its technical specifications, failure modes and working environments, it is feasible to construct a Bayesian network model for filtering and assessing unreliable sensor data.

15

Generic structure of a simplified Bayesian network to predict the reliability of sensor data under the influence of degradation and aging of the sensor components.

DNV GL © 2013

Ungraded

25 November 201616

A Case Study: Digital Downhole Digital downhole refers to the entire instrumented drill string system, the sensor

communication system, and the digital twin model. Sensor systems assessing the conditions downhole and reporting them to the

operations managers. Sensors of significance include pressure, flow, temperature and fluid chemistry

monitoring sensors.

The sensor data flowing back to the operations center provides the inputs needed to construct the real-time digital representation (i.e. the digital twin) of the downhole system, so that operators see an exact picture of the state of health, and can make adjustments to correct any deviations or initiate emergency procedures.

The Digital Downhole instrumented by pressure and flow sensors

DNV GL © 2013

Ungraded

25 November 201617

A Case Study: Digital Downhole System Constraints on Sensor Data Physics engine places constraints upon “normal sensor data” based on type and

position:

Internalizing these constraints allows cross-checking via analytical redundancy relations

Downhole pressure (pd) linked to pump pressure (pp), hydraulic pressure (gravity, Gd) and friction in drillstring (friction factor θd and flow, q)Annular pressure (pa) linked to downhole pressure (pd), and friction across the bore (friction factor θb and flow, q)

DNV GL © 2013

Ungraded

25 November 201618

Fault isolation and detection in digital downhole.

Using Analytical Redundancy Relations to generate digital “fingerprints” for normal operations versus failure modes.

Each failure mode for the downhole system will correspond to a unique pattern of deviation in analytical redundancy relations. These unique patterns can be used as fingerprints that allow fault detection and isolation within the Digital Downhole system.

Data smoothing and p-value hypothesis testing required to discern true constraint-breaking from noise.

A Case Study: Digital Downhole

Sensor issues Process issues

DNV GL © 2013

Ungraded

25 November 201619

A Case Study: Digital Downhole

Combined survival probability models with fingerprinting and the Digital Twins technology for sensor reliability assessment.

As the Digital Downhole system collects

data and reports on sensor performance through the use of analytical redundancy relations, the sensor reliability models can be updated.

Conversely, the updatable sensor reliability models can be used to assess the likelihood of a sensor failure. (i.e. to distinguish a true constraint-breaking event from the background noise.) Sensors reliability model constructed through

lab-based testing, but are then updated in real-time by data coming in through “fingerprint” analysis performed by the Digital Twin

DNV GL © 2013

Ungraded

25 November 201620

A Potential Business Case• With digital communication:

-Either there is communication or not. There is no accuracy reduction along the signal chain.- Only degradation is inside the sensor.

• Pressure Sensor: +/- 0.35 Bar when “out of the box” +/- 9.1 Bar after 25 years• Temperature Sensor: +/- 0.6 C “out of the box” +/- 5.6 C after 25 years

WEPS-100 Series Subsea Sensors Pressure and Temperature by SIEMENS

• The mechanism leads to the huge drift is unclear but may be related to operation temperature etc.

• An unplanned maintenance of each module could cost Akers millions $ per day.

DNV GL © 2013

Ungraded

25 November 201621

A Potential Business CaseDNV GL can help through: Consulting with sensor manufacturer on product details and test results. Consulting with end-users on operation condition and field test results. Creating a Bayesian networks model integrating all factors resulting in sensor drift. Predicting the effect of sensor drift in field operation, i.e. what is the “real” reading. Testing to validate and improve the models.

Year

DNV GL © 2013

Ungraded

25 November 201622

Potential Business Models: Verification and Classification Control/Mitigate Risk for Customer:

- Accurate interpretation of the sensor data (considering the sensor reliability); - Better selection of sensors (predicting the sensor reliability in the field); - Modify the sensor life curve by considering the sensor degradation mechanism and

operation conditions etc.- Create models from top down, i.e. from inputs to results.

Verify/ Qualify Sensors for certain applications: – Using customer provided sensor data as input to an BN model for validation.– Output from the model: * Whether sensor accuracy is within range of actual value and its

frequency. * Whether the signal is a false positive and its frequency, and *Whether the signal quality or accuracy degrades with time.

Explore methods for sensor system reliability assessment as a base for future certification services. – Type approval of sensors for condition monitoring purpose, where sensor data transferred

to class is part of a (semi)real-time survey scheme: CMC.– Outline Class notation on newbuilds and retrofits

DNV GL © 2013

Ungraded

25 November 201623

SAFER, SMARTER, GREENER

www.dnvgl.com

Shan Guan, [email protected]