Responses to Questionnaire on Environmental Issues in FP7 NMP ...

Transcript of Responses to Questionnaire on Environmental Issues in FP7 NMP ...

Responses to Questionnaire on

Environmental Issues

in FP7 NMP Projects

on Materials

Research and Innovation

EUROPEAN COMMISSION

Directorate-General for Research and Innovation

Directorate G – Industrial Technologies

Unit G3 – Materials

E-mail: [email protected]

EUROPEAN COMMISSION

REPORT ON

Responses to Questionnaire on

Environmental Issues in FP7 NMP

Projects on Materials

Edited by

Dr. Johan Veiga Benesch

© beholdereye Fotolia.com

Directorate-General for Research and Innovation

2012 Industrial Technologies Material Unit EUR 12366 EN

LEGAL NOTICE

Neither the European Commission nor any person acting on behalf of the Commission is

responsible for the use which might be made of the following information.

The views expressed in this publication are the sole responsibility of the author and do not

necessarily reflect the views of the European Commission.

More information on the European Union is available on the Internet (http://europa.eu).

Cataloguing data can be found at the end of this publication.

Luxembourg: Publications Office of the European Union, 2012

ISBN 978-92-79-25640-0

doi 10.2777/79870

© European Union, 2012

Reproduction is authorised provided the source is acknowledged.

Printed in Belgium

EUROPE DIRECT is a service to help you find answers

to your questions about the European Union

Freephone number (*):

00 800 6 7 8 9 10 11 (*) Certain mobile telephone operators do not allow access to 00 800 numbers

or these calls may be billed

3

Executive Summary

Environmental issues require more and

more attention at EU policy level. This

can for example be seen in the Raw

Materials Initiative by DG Enterprise and

Resource Efficient Europe by DG

Environment which goes back to the

theme of a sustainable economy as

expressed by the Europe 2020 growth

strategy. DG Research and Innovation

supports related research activities, and

the Nanotechnology, Materials &

Production (NMP) Theme in the FP7

Cooperation scheme has taken stock of

this. This would include aspects such as

substitution, life cycle assessment,

improved resource efficiency and better

performance materials in the NMP calls

for proposals.

Materials and their use can have a large

environmental impact in many aspects,

from sourcing, extraction, processing,

auxiliary materials and processes, use up

to end of life. The choice or design of

material solutions can thus have a great

impact on the technologies in which they

are used. This implies that a material

could be an integral part of the solution

to a problem created by the use of a

specific technology. Such solutions could

require entirely new materials either to

replace a material or be part of a new

technology based on materials that

perform better.

With this enquiry the Materials unit of

the Directorate for Industrial

Technologies of the DG of Research and

Innovation aimed to understand better

how project consortia view

environmental issues. This would refer to

how they could be included and handled

in FP7 NMP projects on Materials. A brief

questionnaire was therefore devised,

comprising 6 questions covering the level

of importance of environmental issues

with focus on RTD projects, how they are

incorporated and affect the outcome of

the project as well as including

recommendations on how to best handle

environmental issues in RTD projects.

Environmental issues for the purpose of

this questionnaire include, but are not

restricted to, resource efficiency,

recycling, precautionary and substitution

principles, eco-toxicity, bioaccumulation,

life cycle assessment, end of life use,

sustainable use, green production, and

European environmental policies.

61 out of the contacted 103 FP7 NMP

projects on materials responded of which

74% claimed to include environmental

issues. Of those that stated that they do

not handle environmental issues most

claimed they were of too fundamental a

character to include any such issues.

Some of those also stated that their

outputs have the potential to lead to

improved environmental impact by

4 Questionnaire on Environmental Issues in FP7 NMP Projects on Materials

development of better performing

material's solutions. The responses to

the open-ended questions were grouped

thematically in an attempt to get a

better appreciation of the relative

importance of the comments from the

consortia. This grouping could also aid in

devising questionnaires for potential

future studies on environmental issues in

projects.

Two main advantages to include

environmental issues were identified by

the respondents, namely; to develop less

harmful materials and/or processes (by

substitution or optimisation), and to

make the output from projects more

attractive to industry. An improved

environmental impact could then be

demonstrated, such as environmental

protection for a secure and healthy life

by avoiding harm to people and

environment. About half of the

respondents use recognised

environmental protocols, such as Life

Cycle Assessment according to ISO

14040 and/or ILCD handbook,

environmental management systems or

activities to comply with REACH. It is

generally expected that newly developed

materials would be correlated to

environmental friendliness, which can be

increased by using the feedback from life

cycle assessment support during its

development. Some noted the

importance of handling environmental,

health and safety (EHS) in conjunction.

Almost two thirds say that inclusion of

environmental concerns help to steer the

output from the projects, such as helping

in selecting optimal materials or

processes. Approximately one third said

environmental issues are the basis for

the projects. Overall, consideration of

environmental issues helps to create a

technological culture that avoids future

human and environmental damage,

which is costly in human and economic

terms. It was also perceived to increase

the need to develop new

(environmentally friendly) materials and

substitute materials. This would

encourage industry towards innovation

and exploitation resulting in

technological leadership of European

industries. For many of the respondents

a big justification for the project was to

develop new environmentally friendly

materials solutions, e.g. sustainable

sources materials for products based on

eco-design and/or with entire life cycle in

mind. Better environmental behaviour is

expected to improve the competitiveness

of new materials and their market value.

Tackling environmental and eco-toxicity

issues upstream in the innovation value

chain is by the respondents overall seen

as advantageous, as it allows avoid

investing in research in technologies

which finally would not into industrial

production, and to pave the way to

accelerate industrial take-up of

promising material solutions.

5

The respondents' highlighted the value

also of on non-monetary support from

the European Commission such as

networking between projects and

between projects and other stakeholders.

It was suggested to explore the

possibilities for cross-project activities

including data and tools sharing and

horizon mapping. The setting up of a

tight network among projects related to

the various environmental issues was

seen as desirable. Further suggestions

entailed training (e.g. LCA, REACH, EU

regulations, work place safety etc.),

environmental guidelines (for proposers

and running projects) and EU database

(single entry point) on environmental

issues (e.g. guidelines and regulations).

The most common recommendation from

respondents for projects on materials

was to include environmental issues as

soon as possible to get an early view of

the required research efforts and

regulatory requirements so as to be able

to adapt the projects accordingly, while

at the same time, not losing valuable

time on less sound material options.

Among the suggestions was noted the

need to define environmental

requirements, risks and specifications at

the beginning of the project, and to

analyse the most recent status of

environmental regulation. The

respondents also recommended to

include pertinent expertise, use

recognised protocols and to look at the

entire life cycle of the studied materials.

Identification of the required specialised

fields of expertise needed is essential

and, as a consequence, the inclusion of

personnel already qualified or ready to

undergo specific trainings on handling

the relevant environmental issues.

Assessment of environmental issues in a

life cycle perspective, in combination

with comprehensive safety

considerations and risk assessment of

processes, is considered as crucial in

order to optimise the environmental

performance and commercialisation of

the material technologies under

development. Some suggested

reinforcing the importance of

environmental issues in EU calls for

proposals and subsequent evaluations.

7

Table of Contents

Executive Summary......................................................................................... 3

Table of Contents............................................................................................. 7

Methodology..................................................................................................... 8

Replies .............................................................................................................. 9

Q1. Does the work in your FP7 NMP materials project cover

environmental issues (Yes/No)? .................................................. 9

Q2. What are the advantages of including environmental issues in

your materials project? .............................................................. 10

Q3. Does your project follow any recognised procedures in

handling environmental issues, e.g. REACH, LCA (ILCD or ISO

14040) or OECD guidelines for testing of chemicals etc?............ 17

Q4. How do the environmental issues influence the outcome of

your materials project? .............................................................. 20

Q5. What kind of non-monetary support from European

Commission could be of use?...................................................... 23

Q6. Which are your recommendations on handling environmental

issues in materials projects? ...................................................... 27

Annex 1 List of pertinent websites.............................................................. 34

Annex 2 Examples of horizontal projects on environmental issues ........ 35

Annex 3 List of respondents, in alphabetical order of project acronym.. 36

8 Questionnaire on Environmental Issues in FP7 NMP Projects on Materials

Methodology A brief questionnaire was devised,

comprising 6 questions covering the level

of importance of environmental issues

with focus on RTD projects, as follows:

1. Does the work in your FP7 NMP

materials project cover environmental

issues (Yes/No)?

2. What are the advantages of including

environmental issues in your materials

project?

3. Does your project follow any

recognised procedures in handling

environmental issues, e.g. REACH, LCA

(ILCD or ISO 14040) or OECD guidelines

for testing of chemicals etc?

4. How do the environmental issues

influence the outcome of your materials

project?

5. What kind of non-monetary support

from European Commission could be of

use?

6. Which are your recommendations on

handling environmental issues in

materials projects?

The questionnaire was sent to the

coordinators asking them to confer with

their project partners. The focus was on

FP7 NMP projects with RTD activities

related to materials (i.e. handled by the

unit G3 Materials) albeit some CSAs

were also contacted. It was noted to be

important to as well invite coordinators

for projects in which the calls for

proposal did not necessarily specify any

environmental concerns. The

questionnaire was sent in the first

quarter of 2012 to projects starting

latest 1 February 2012. The coordinators

were also asked to keep their reply

concise, not more than 2 pages. It was

also highlighted that the questionnaire is

not an evaluation of their FP7 NMP

project. In some cases the replies came

separately from the partners, these were

collated to make one reply per project

(See Annex 3).

The choice of using open-ended

questions was made to allow for a wide

range of replies. In an attempt to

structure the replies for questions 2 to 6

they were grouped in themes based on

their commonalities. The occurrences

were then counted to get an appreciation

of the relative importance of the

identified themes. For each question

these are put into figures followed by a

summary of the responses for each

theme. These summaries were made as

collages of the received replies.

9

Replies

103 projects were contacted of which 61

replied. See the response rates in Figure

1.1. Note that questions 5 and 6 were

asking for recommendations, hence "no"

was not an answer. As seen in the

replies to second, third and fourth

questions the level of involvement in

environmental issues varies to a fairly

large extent for those that said yes. The

majority had constructive comments and

suggestions on how to handle

environmental issues in projects and

ideas for non-monetary support to

running projects, also from consortia

which saw no environmental issues in

their current FP7 NMP projects on

materials.

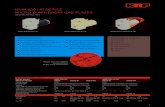

Figure 1. Response rate including distinction Yes/No, where appropriate.

Q1. Does the work in your FP7 NMP materials project cover environmental issues (Yes/No)? 74% of the respondents claim that their

projects include environmental issues,

and 26% said they have none. This is

not a surprisingly high number since

many calls for proposals at least hint at

environmental issues, without

necessarily demanding them to be

included in the proposals.

Response rates

0%10%20%30%40%50%60%70%80%90%

100%

Q1 Q2 Q3 Q4 Q5 Q6

No replyNoYes

10 Questionnaire on Environmental Issues in FP7 NMP Projects on Materials

Q2. What are the advantages of including environmental issues in your materials project? Circa 80% of all the respondents saw

one or more advantages of including

environmental issues in materials

projects. Overall 60% noted multiple

advantages (ca 80% of the positive

replies to the 1st question (Q1.yes)).

Only 20% saw no advantage or did not

respond. All Q1.yes gave at least one

example of an advantage. Given the

open ended nature of this question the

answers have been loosely grouped into

9 themes as follows in the below sub-

headings, with an overview in Figure 2.1.

The two most commonly stated

advantages were development of less

harmful materials or processes (48%)

and making the RTD output more

attractive to industry (40%). A third of

the respondents stated improved

resource efficiency, and a quarter of

them stated early incorporation of

environmental assessment and/or

important driver for RTD on new

materials. Below follows a collage of the

comments from the respondents.

Advantages of including environmental issues in NMP projects on materials?

0 10 20 30 40 50

No response

None

Compliance with regulation

Improve the work environment

Stakeholders' awareness and/or acceptance

End-of-life

Driver for RTD on new materials

Early incorporation of environmental assessment

Improved resource efficiency

Making RTD output attractive to industry

Development of less harmful materials/processes

% responses Figure 2. Percentage of the respondents that gave replies as per the identified themes of

advantages of including environmental issues in materials projects

Development of less harmful materials or processes

Almost half the respondents claimed that

their material projects aim to develop

less harmful materials, procedures

around the materials and/or materials

for processes with improved

environmental impact. In some projects

environmental, health and safety aspects

(EHS) are taken into account in

conjunction. For new materials it often

the case of finding substitutes but also to

improve their use (see also "improved

resource efficiency") that may lead to

environmental protection for a secure

and healthy life by avoiding harm to

people and environment. Additionally,

the use of eco-friendly reagents and

11

chemicals could also make the new

materials more suitable for applications

in the biomedical sector. The comments

can be summed up as aiming to:

• decrease of CO2 emissions

• lower emission/leaching of (potentially) toxic substances to the environment (e.g. air, water, soil)

• lower the eco-toxicity

• substitute a material (e.g. silver, rare earth metals, fossil oil-based chemicals, biocides etc) for another

• eliminate hazardous toxic and difficult to handle chemical reagents (see also "regulation compliance")

• benchmark against current materials/technology

• use green chemistry (eco-friendly chemicals/polymers and sustainable sources raw materials) as a precautionary measure for both process chemicals and final product.

• develop processing routes that are more environmentally friendly

• move to technology that uses less harmful materials (see also "regulation compliance") e.g. self-cleaning surfaces rather than frequent maintenance, magnetic probes rather than radioisotopes etc

Making the RTD output more attractive to industry

40% of the respondents thought that

handling environmental issues would

make the output more attractive to

industry. The real value of including

environmental issues in material project

is the link between environmental

criteria throughout the life cycle, the

strategies of the partners and planning

to achieve sustainable business benefits.

All these parameters can provide

valuable information about efficiency of

resource use of a production system and

waste management. It also can help

companies gain competitive advantages

through cost savings, increase profits

and improve the image (of the company

or of a particular product). This can help

to strengthen the market position or to

increase the market share.

The advantage is to have the possibility

to know the environmental friendliness

of the materials developed and compare

these properties with actual used

commercial materials. This offers the

possibility to develop competitive

materials with a good performance being

at the same time sustainable and

environmental friendly, which is a high

added value for the developed products.

One may also benchmark the

environmental performance against

competing technologies and add to the

overall evaluation of our technique. It

was suggested that industrialists are

sensitive to this impact, and one has to

take into account it during the

elaboration of materials as well as

implementation of these new

technologies, especially, if this fits with

their corporate policy based on

sustainable growth. It might even be

that the industrial partners reminded the

others to take care of the environmental

issue and if necessary reoriented the

work toward this issue.

12 Questionnaire on Environmental Issues in FP7 NMP Projects on Materials

R&D projects are the main interfaces

where innovative companies are

confronted with critical decisions about

implementing new types of advanced

materials in their product portfolios. One

goal is to make use of any possibility to

evaluate and to apply protective

measures already at the project level.

This is done in order to guarantee the

ecological sustainability of a company.

Notably since improved environmental

may provide additional selling points.

Improved resource efficiency

Over a third of the respondents identified

issues related to improved use of

resources. See also "end-of-life". The

advantages are economic and social

since the materials developed within

materials project could allow:

• lower input of material during production, e.g. additive rather than subtractive manufacturing

• decrease in consumption of materials, e.g. longer lasting materials, reusable products and easier recycling

• less use of energy during production, usage and end-of-life

• less use of energy since smaller amount of material to achieve same level of functionality, e.g. smart design of materials and components for photovoltaics.

One may also increase the resource

efficiency by using and wasting less

scarce or non-renewable materials in

combination with improved recycling

processes. For example by:

• working at lower scale (microfluidics) thus lowering the amount of liquids.

• using polymeric based conductors, the amount of metal employed is expected to decrease.

• adaptable progress by tailoring a surface to the requirements of the part. This simplifies the manufacturing process by saving raw material as well as effort in manpower.

• Developing multifunctional materials that each could lead to improved efficiency such as, thermal storage (reduction of energy consumption for heating), self-cleaning capacity (reduction in use of hazardous products) and IR high reflection (reduction of energy consumption for cooling) are included.

• sorting materials out of components at the end of life

Early incorporation of environmental assessment

Almost 30% claimed advantages of

including and integrating environmental

issues at the beginning of materials

projects. One can then identify and take

action if any materials have toxic or

other adverse impacts on the

environment or human health. Materials

and technologies thusly developed are

expected to be widely used in the future,

prepare and preserve the future as they

already take into account environmental

concerns. Otherwise a situation may

occur where the material and

corresponding technologies are being

13

developed quite far and afterward one

finds out that the environmental and

health risks that the material possess

does not allow its successful

implementation into the products.

This is can also be reflected in the choice

of criteria to aid in selecting the best

performing materials. Such as having

clear guidelines for the materials search;

e.g. they must consist of elements that

are non-toxic and environmental benign

(in addition to cheap and abundant). The

sustainability criterion can also be used

to assess the project progress and be

used as an efficient project management

tool. The Life Cycle Assessment (LCA)

tool also offers the possibility of

comparing the environmental impacts of

different materials/systems used for the

same purpose, in order to determine the

economic and environmental optimum.

By including attention to environmental

issues, one can better understand the

advantages using a material, allowing

the identification of potential

environmental impacts of the new

materials jointly with the development of

control measures for them. The LCA

provides relevant knowledge about the

stage of the life cycle of a

product/process that is susceptible to

changes or improvements to increase

the sustainability of the overall process,

also when looking at cradle to gate

production systems. Including the

impacts throughout the product life cycle,

LCA provides a more accurate picture of

the true environmental trade-offs in

product and process selection.

It is also an advantage to have the

possibility to know the environmental

friendliness of the developed materials

and compare these properties with

currently used commercial materials.

This offers the possibility to develop

competitive materials with a good

performance being at the same time

sustainable and environmental friendly.

This in turn can be viewed as a high

added value for the developed products.

The assessment of technologies/products

developed in the project provides

information about the potential

environmental benefits that can be

obtained.

Important driver for RTD on new materials

Circa a quarter of the respondents

pointed out this issue. A project

focussing on the development of new

materials should be aware of the

importance of the environmental issues

as potential risks of new technologies

and products/materials are becoming an

ever increasing factor of sustainable

success of these technologies and

products. It is an obvious advantage to

work in a very competitive area because

Environmental Material Science and

Engineering constitutes one of the

14 Questionnaire on Environmental Issues in FP7 NMP Projects on Materials

currently most potential and rapidly

developing fields.

Environmental issues are gaining more

and more importance during the last few

years. Current materials solutions have

technological, cost or environmental

limitations. Indeed in the past most of

the research and developments in

materials were axed around cost

reduction and new functionality. Today

there is a need for materials at

equivalent costs and performances but

with better environmental aspect. In this

respect it can be viewed more as a

necessity, since materials and processes

that would not also take environmental

issues into account would probably be

less likely to be used in practice.

End-of-life (recycling, waste management etc)

Around a quarter of the respondents

pointed out at least one issue related to

the whole value chain starting from

sourcing of raw materials, to material

optimisation up to the production of

individual components. Some related

issues can be seen under "improved

resource efficiency". Part of the

European materials industry to a large

extent relies on external sources.

Improving waste management and

recycling at end-of-life could alleviate

this; also improve the environmental

impacts of the waste handling. This is

also true for internally sourced materials.

Extension of the lifecycle endurance is

expected by use of the new materials.

This in turn could lead to an increased

sustainability, reducing environmental

pressure on its disposal, making it also

more cost effective. To find

environmentally friendly ways of

producing the final product helps to

avoid expensive ways of disposal of

waste materials (e.g. by producing less

waste) and helps in marketing new

products.

Increasing stakeholders' awareness and/or acceptance

A fifth of the respondents noted that by

taking environmental issues into account

one can improve the image of the

project in relation to its external

stakeholders. Environmental issues

influence the long term impact of our

society on its surrounding and as such

they should indeed be evaluated

carefully. It provokes a continued

awareness of the relevance of devices in

future environmental research that could

lead to increased acceptance of the novel

technologies by both the industrial and

the societal sector, and strengthen the

worldwide recognition of research in the

EU. The advantage of including

environmental issues in materials project

is also to provide the society the

response to a legitimate question. In

general, complying with recognised

15

environmental precautions strengthens

possible end users’ faith in the project

and its output.

For example, it was considered that it is

advantageous to include environmental

topics in the discussions so that the

community is aware of the broader

impacts of nanomaterials in formulations,

i.e. by putting the new material solutions

into a wider context. Deeper

investigation of the interactions of the

developed materials with biota could

facilitate their further acceptance by

industries and consumers (more

generally by society). Environmental

management offers increased

competitive advantage when customers

are involved in the production or service

process. It might be easier to

disseminate project activities to the

public, since the public is highly

interested in the environmental issues.

The public would also realise how tax-

payers’ money has been spent for

research activities. This is an advantage

not only for materials project but also

other projects.

This increase in awareness could also

happen within the consortia, e.g.

researchers specialised in materials are

trained to use LCA and thanks to the

continuous assessment of the

environmental impact all along the

project, partners that were initially not

used to sustainability assessment to give

project orientations have integrated this

“way of doing things”. There is a good

chance that the partners, specialised in

material development, keep the use of

LCA in their other projects even if it is

not explicitly requested. Inclusion of

environmental obligations in the projects

was perceived to help to increase the

awareness of environmental issues

(including working conditions).

Improve the work environment

1 out of 5 respondents claim to include

research and/or measures to improve

the quality of the work environment

either in laboratory or for production

lines. Such as setting up protocols and

procedures to safely handle reactants

and solvents. These range from control

in laboratory security to protocols for

chemical waste management. The use of

less harmful reagents/materials can in

itself ease the access to laboratories and

other third party facilities (e.g. service

measurements) thanks to reduced

material safety concerns, also, by

avoiding transports of “dangerous goods”.

Projects can contribute to the

development of guidance on risk

management and best available

techniques to minimise and control any

health risks to manufacturers,

downstream users and the environment.

In addition such issues are a natural part

of the research work itself and is

becoming more and more important, to

16 Questionnaire on Environmental Issues in FP7 NMP Projects on Materials

protect the employees and the

environment, and to contribute to a

positive working environment.

Compliance with regulation

Reasonably few, just below 15% of the

respondents, made the connection to

regulatory compliance. It was noted that

one should be vigilant in order to

minimise the risk of developing materials

systems which are not compliant with

environmental regulation. There can be

regulatory pressure to develop new

materials for which a phase out is

foreseen, e.g. related to bans or limits of

specific materials on the European

market. Similar issues could also be

found in workers' health and work place

security related regulations. Chemical

companies are aware that this can be

achieved firmly by following

internationally acknowledged standards

which also cover the R&D projects. For

example, to already at an early stage

include environmental and health

certification of developed materials. It is

also important that all materials are

handled strictly following applicable

European guidelines and regulations

during the development stages. Materials

with less regulatory restrictions are also

more easily accepted and handled by

producers, intermediaries and end-users.

Very few identified advantages

The projects described themselves as

either too theoretical or basic science, or

simply did not include any environmental

aspects at the proposal stage. Some

stated that, albeit out of the scope of the

project, the outputs might eventually

indirectly lead to improved

environmental impact by enhanced

performance of the studied materials or

processes based on fundamental

research.

17

Q3. Does your project follow any recognised procedures in handling environmental issues, e.g. REACH, LCA (ILCD or ISO 14040) or OECD guidelines for testing of chemicals etc? Almost half of the respondents relied on

some kind of externally defined

guidelines in handling environmental

issues. A third mentioned included

multiple guidelines, 40% relied on

standards and 30% on regulations. 28%

included LCA according to ILCD or ISO

14040, and 22% mentioned compliance

with REACH regulation. A collage of the

feedback follows below.

Inclusion of recognised procedures

0 10 20 30 40 50

Standards

LCA

Legislation (excl REACH)

REACH

External guidelines

In-house guidelines

No

No response

% of respondents

Figure 3. Percentage of the respondents that said they include identified recognised

procedures in their project.

Standards (e.g. ISO/CEN, excluding LCA)

Almost all mentioned related

environmental standards were ISO

standards, ranging from technical testing

of materials, health and safety practises

for work environment to environmental

management certification, both ISO

14001 and EMAS. Very few also

mentioned that projects partners are

active members in CEN or ISO technical

committees.

Life Cycle Assessment (ISO 14040 and/or ILCD handbook)

The included Life Cycle Assessments

(LCA) relied on either the ISO 14040

family or the ILCD handbook. LCA is a

standardised technique to assess the

environmental aspects and potential

impacts associated with a product,

process or service, following four

phases: goal definition and scoping,

inventory analysis, impact assessment

and interpretation. It is generally

expected that newly developed materials

would be correlated to environmental

friendliness, which can be increased by

using the feedback from life cycle

assessment support during its

development. For the chosen

environmental categories the method

recommended in ILCD were often

followed. An assessment of

environmental and socio-economic

18 Questionnaire on Environmental Issues in FP7 NMP Projects on Materials

impacts will be developed about the

following phases: 1. production of raw

materials needed; 2. industrial process;

3. using the product; 4. disposal of

waste. Some also mentioned the use of

sub-contractors for the external review

required for some levels of LCA.

Legislation (excluding REACH)

Some noted that it is useful to be aware

of regulations and development thereof.

Those that mentioned specific

regulations often related to national

legislation on waste management and

work environment. It was also stated

that more and more new technologies

are precisely supervised with regulations

sometimes in perceived contradiction

with their future use.

REACH

REACH legislation (Registration,

Evaluation, Authorisation and Restriction

of Chemical substances, EC 1907/2006)

was mentioned at various levels, such

as:

• partners have set in place procedures to handle REACH compliance

• only use chemicals that have REACH compliant MSDS

• assessing the need for REACH compliance of the materials developed in the project

• do the evaluation according to REACH (and OECD guidelines)

A few projects have tasks or work

packages entirely devoted to REACH

compliance. Also, some mentioned the

importance to recognise the EU directive

on the precautionary principle, advice on

life cycle approaches, REACH regulations,

specific food and cosmetic regulations,

and to use a hazard/exposure score

matrix approach to determine the health

risks of all chemicals employed. REACH

is always an issue when chemists look

for new ways to manipulate biomass-

based products. Also, projects' newly

developed testing protocols could

provide means to support REACH or

similar regulatory requirements for

testing of chemicals.

External guidelines (OECD, WHO, UNEP etc)

Reference was given to guidelines

provided by a good number of

organisations both international and

non-governmental such as UNEP

(SAICM), WHO, OECD, ICCA (GPS), and

some related to USA bodies and

regulations, e.g. DOE and ChAMP.

Typically these were seen as part of the

landscape of environmental issues to

take into account depending on the

scope of the project. However, care must

be taken with handling of these products

and therefore the existing guidelines

should be taken into consideration

19

whenever relevant. Again, some looked

at the wider scope of HSE issues and/or

the product chain.

In-house guidelines

These refer to in-house guidelines on

work environment and standard

operating procedures. These could aim

to handle laboratory testing to handling

of waste, but also to build solid

laboratory culture with the aim to take

on board environmental management

systems and good practises.

None or no response

These projects consider themselves too

fundamental to include any

environmental concerns, or simply that

they were not defined to be within the

scope of the project. Albeit some noted

that environmental issues may need to

be taken into account when aiming to

push the foreground beyond the scope of

the project.

20 Questionnaire on Environmental Issues in FP7 NMP Projects on Materials

Q4. How do the environmental issues influence the outcome of your materials project? Almost 70% of the respondents stated

that environmental issues have an

impact on their projects by steering the

project (63%) and/or being the basis for

it (33%), and almost half said both.

Those that claimed no or little influence

mostly did so because their projects

were perceived to be too fundamental or

that environmental issues were not

defined to be part of the project from the

start. A collage of the feedback follows

below.

Influence on project outcomes

0 10 20 30 40 50 60 70

Steers the project

Basis for the design of the project

Does not or only little

No response

% of respondents Figure 4. The percentages of the respondents that identify an influence of environmental

issues on the outcomes of their project.

Steer the project

Most of these comments noted that the

(LCA) analysis of environmental (and

occupational) impacts has influenced the

selection of the best materials and/or

sustainable production options. This

includes materials, equipment, controls

and management measures. Best in this

context often meant optimisation of both

environmental and economic aspects,

and in some cases also included health

and safety issues, in relation to the

expected applications and existing

technologies. This has also raised the

level of awareness of environmentally-

constrained design, production and

waste disposal issues in the research,

the development, scale-up and

commercialisation of the material. This

helps to create a technological culture

that better avoids future human and

environmental damage, which is costly in

human and economic terms. It can

increase pressure for the development of

new (environmental-friendly) materials

and substitute materials thus provides

an incentive for industry to aim towards

innovation and exploitation resulting in

technological leadership of European

industries.

Not all projects looked at the entire

value chain, so focus might have been

solely on sourcing of materials,

production, usage and end-of-life, or a

combination thereof. This also influenced

the level at which environmental issues

were taken into account. Some saw

environmental issues as the first

priorities in steering the project which

then was related to whether the

21

environmental issues was seen as the

basis for the project, or not. For example,

some noted that environmental issues

are critical because they can decide the

future of the field.

The timing of the assessment can also

influence the project. For example, since

each substitution must be justified on

the ground that it brings a sufficient

benefit. In many cases, it is not bringing

a benefit and the project must consider

these results in order to improve their

strategy. It can create bottlenecks when

basic research topics are performed in

order to understand basic dependencies

and material behaviour. For example, if

included in projects of more fundamental

nature.

Environmental aspects can also provide

added value to the projects being

researched if placed in a real world

context and drive the main objective

(environmentally-friendly materials and

processes). In other cases they are

issues that need to be taken into account

in the same way as costs. It may lead to

safety regulations in production, use and

end of life stages. It may also influence

the choice and extent of recycling

techniques.

Inclusion of environmental issues may

also influence materials project and its

partners in different ways such as

helping to establish collaborations with

groups of academic excellence within

and outside Europe, and production of

scientific work publishable in high impact

journals

Basis for the design of the project

For these respondents a big justification

for the project was to develop new

environmentally friendly materials

solutions, e.g. sustainable sourced

materials for products based on eco-

design and/or with the entire life cycle in

mind. Also better environmental

behaviour is expected to improve the

competitiveness of the new material and

its market value. Often the reason is to

find substitutions to harmful and/or non-

renewable materials, e.g. the materials

search was restricted in order to have

products that could enter the market

providing non-toxic and environmentally

benign component materials. Some

aimed to use environmentally friendly

raw materials for the development of

materials, such as recycled materials and

also the recycling and life cycle analysis

of the products developed are considered.

At the same time many also aimed to

develop materials that are expected to

give higher performance in specific

applications such as catalysis,

22 Questionnaire on Environmental Issues in FP7 NMP Projects on Materials

photovoltaics, magnets, light-weight

materials etc. Some aimed at green

product design (design for the

environment) since it can lead to less

waste, less use of harmful materials,

greater productivity, and greater

innovation. Also noting that continuous

effort to develop more environmental

friendly materials will lead to sustainable

and cost efficient products and

production processes and hence to better

marketable products and enhanced

competitiveness. Inclusion of

environmental issues at the R&D project

level was perceived to provide valuable

know-how and the daily practice of

environmental thinking, which facilitate

the future commercialisation of the

project outputs.

23

Q5. What kind of non-monetary support from European Commission could be of use? Almost 70% had ideas for non-monetary

support to projects. The most frequent

comments were related to networking

activities (33%) closely followed by

guidelines and EU database (single entry

point) (30%). A collage of the

suggestions follows below.

Suggestions of non-monetary support from the European Commission

0 10 20 30 40

Networking

Guidelines

EU database

Training

LCA support

Regulations/Standards

Other

No reply

% of respondents

Figure 5. Percentages of the respondents giving suggestions for non-monetary support.

Networking

The most common suggestion was to

support networking options with between

projects either on similar topics or more

horizontal issues such as LCA, toxicity

and risk analysis. Some ideas aimed to

improved exchange of information and

achieve a better overview of the running

projects on related topics. This could also

help to achieve consistency, e.g. in

handling horizontal issues. It was

suggested to explore the possibilities for

cross-project activities including data

and tools sharing and horizon mapping.

Also, the realisation of a tight network

among projects related to the various

environmental issues.

Almost every aspect of materials usage,

from production, through product design

and disposal, should be now subject to

environmental considerations. Therefore,

a suggestion was that the EC could

organise events and meetings in order to

foster cross-sector and inter-disciplinary

collaboration in physics, chemistry, and

materials science and to bridge the gap

between the scientists and industrial

sector.

Guidelines

The suggestions for guidelines aimed at

various stages of project life cycle and

somewhere more general including hints

on which regulations may be pertinent.

Readily accessible common guidelines

are always helpful especially if they are

24 Questionnaire on Environmental Issues in FP7 NMP Projects on Materials

easy to access. As a general rule, then,

it would be helpful to have access to

concise material (e.g. database)

encouraging partners in the project to

re-think procedures to make them more

environmentally friendly. Here follow

some examples:

• Creation of a sort of “good environmental practice” list, naming all products which are made or can be made following these environmental issues. This should create a sort of simple “Eco”-label.

• Guidelines for handling of the (nano)materials at working place. There are many on-going and past projects funded by the EC which deal with the risks of using nanomaterials. The results from these projects could be used to elaborate guidelines

and/or protocols of handling and safety and to promote the development of standards.

• Establish guidelines to all materials projects indicating which elements of the periodic table should at best not be part of future generations of consumer products, produced in small, medium or large scales for a global market.

• Publication and communication about a handbook of best practises in designing eco-efficient materials followed up with workshops and trainings

• A guide (or online tool) listing the points which should be checked or acted upon in proposal-, negotiation- and project- stage for protecting the environment.

EU database on environmental data and regulations etc

Overall guidance on regulatory issues

was suggested, especially if provided by

a single entry point at the European

Commission, for example, by creating a

dedicated unit or website or database

covering environmental data and

regulations; current, discussed and

future. This would also be a tool to

provide condensed updates of the status

of environmental regulations in Europe.

Especially if combined with regulatory

support that provides clear and brief the

information about new regulations and

more information according to possible

interpretation of these regulations. Some

examples:

• Access to databases or other relevant sources of information related to environmental effects of new materials and especially nanomaterials, and how to handle

them in laboratory, production and disposal.

• Better information on how to handle dangerous wastes, programmes for a more responsible use of hazardous materials.

• It would be helpful to establish different degrees of requirements and regulations on material projects divided in Research / Development / Prototyping including exception rules.

• Checklist of environmental issues in the context of materials, e.g. a search engine to get a list of related environmental issues related to my proposal or project

• Support for SMEs to implement eco-friendly practises.

25

Training

A large range of topics related to

environmental issues were suggested to

be the focus of trainings or consultancy

services that could be provided by the

European Commission and its Services to

running projects and other stakeholders,

such as:

• Dissemination activities by European agencies such as EEA and EU-OSHA

• Expertise and consultancy in HSE issues

• Introduction to new EU regulations and dissemination of information pertaining to the issues, trends and innovations in materials development from the environmental issues stand point. This might bring all partners to the same fundamental level of knowledge needed to reach successful the project goals.

• Training courses in laboratory security, protocols, and chemical waste management with emphasis on increased awareness of recognised procedures for handling environmental issues. This could also include training on recognised international standards and guidelines

• Communication and seminars on the new under-development regulation on energy consumption of machinery could be of great support

• Training programs in the field of political environment, the area of cultural heritage

• Dissemination activities like workshops, training, trying to have audience from industry, research centres and academics

• Introduction of environmental aspects for materials projects to potential applicants through seminars/webinars

• Dissemination of projects funded by EC to the public.

• Provide consultancy service of expert advisors (for instance from ECHA) helping each group involved in the project in applying REACH guidelines

• Be trained/educated to recognise the multifaceted aspects of it, would be an effective (not only intellectual) improvement. Where specialist will emphasise the importance at the EU level of such issues that might be strongly overlooked during projects

LCA support

These comments where similar to those

mentioned under "Training" and

"Networking" albeit aimed specifically at

Life Cycle Assessments. It would be

interesting to promote the importance of

LCA and how all the partners in the value

chain are important to provide data for

the LCA. Seminars involving all the

partners in a project (as are already

done in the case of the exploitation of

results) could be a possible way to

promote the active participation (even if

only for providing data) in the LCA of the

materials in the projects. Also with the

intent to ensure that the research and

technology related interests of RTD

projects are well matching the interest of

environmental safety and sustainability

and follow the principles of "LCA

Thinking Approach". Life cycle analysis

can be an extremely effective way of

linking many different aspects of the

environmental impacts of materials

usage. Sometime, researchers only think

about environmental impact of the

chemicals used in the laboratory. But, it

26 Questionnaire on Environmental Issues in FP7 NMP Projects on Materials

could be that the finished product by

itself could have a much more important

environmental aspect. Additionally,

workshops on LCA could strengthen the

relations between industry and academia,

and improve their cooperation in

resolving environmental issues in

material science. Some examples of

suggested training and consultancy

activities:

• Education and Training on Life Cycle Analysis to consider the entire environmental impact, energy and resource usage of a material or product, and also to legislative aspects. Inputs for the priorities of future activities in the area LCA/risk

• Seminars and workshops for the partners who are carrying out the LCA

• External audits of the LCA and related consultancy

• Support for life cycle assessment seminars, both on materials and processes could be useful for SMEs.

• Workshops and short trainings regarding especially LCA and ISO 14040

• Putting efforts into establishing a more encompassing database of Life Cycle data

• Workshops about the importance of LCA for materials as an indispensable tool to put products in the market from the point of view of EC

• Access to database or other relevant sources of information related to environmental effects of new materials and especially nanomaterials

Environmental regulations

These suggestions overall have much

wider scope than giving support to

research projects. The non-monetary

support from European Commission

could be the proposal of new regulations

about the use and exploitation of

materials presenting some human risks

as well as the environmental impact

derived from any process/materials (e.g.

LCA), particularly when end-life is

concerned. In general environmental

issues were suggested to be supported

by a legislative apparatus that push both

producers and end user to select

environmental friendly technologies and

solutions. Some examples:

• Transparent EU regulations and updates for the industry available to project partners

• European agreement on ecologically approved environmental standards and regulations.

• Legislative increase of collection obligation (e.g. EU/66/2006) and control of country implementation

• Legislative measures for increased use of “green” materials such as green taxes for effective internalisation of environmental costs of products, improving the competitiveness of “green” materials

• Make LCA mandatory by regulation

• More standardisation towards nanotechnology related EHS aspects, for example in the measurement of dust and in the identification of relevant impact categories for nanomaterials in LCA is needed in the coming years to ensure a consistent approach among the different studies in this field

27

Q6. Which are your recommendations on handling environmental issues in materials projects? Over 90% of the respondents had

recommendations, thus including some

of those that did not identify any

environmental issues in their projects.

The by far most common was to identify

the environmental issues early in the

project life cycle (67%), followed by

taking into account the life cycle of the

material or process (40%), and to use

recognised protocols to handle these

issues (32%) as can be seen in Figure 6.

A collage of the recommendations

follows below.

Recommendations for materials projects

0 10 20 30 40 50 60 70

Identify them early

Look at the life cycle

Use recognised protocols

Adapt to the scope of the project

Include environmental expertise

Reinforce evaluation of proposals

Other recommendations

No reply

% of respondents Figure 6. Percentages of the respondents giving recommendations on handling

environmental issues in projects on materials.

Identify and include them early on

Among the suggestions was noted to

define environmental requirements, risks

and specifications at the beginning of the

project, and analyse recent status of

environmental regulation. Also, it was

suggested that the project/program

should be in its draft formulation stages

when dealing with environmental issues,

later it will be very difficult and less

efficient. Furthermore, develop a

decision tree to help to estimate the

relevance of environmental issues in

materials projects and subsequently and

the need for the implementation of

environmental issues.

Aim for substitution (of harmful

materials) and improved resource

efficiency whenever it is possible. One

needs a better understanding of the

value of environmental performance in

general and resource efficiency in

particular. One should always maintain

an environmental perspective in the

development of materials, especially,

with regards to one’s choice of the

materials to exploit in any given

technological development. One must

always have an eye to the ultimate

influence on our environment once the

28 Questionnaire on Environmental Issues in FP7 NMP Projects on Materials

new materials/processes have been

developed and implemented on a larger

scale in industrial production.

Sensitise the partners about

environmental issues at the beginning of

the project in order to make them

integrate environmental concerns from

the beginning of research. At every

project start-up, a workshop should be

done between material designers,

construction designers and producers, in

which it is explained how to handle and

take into consideration environmental

issues for the studied materials and

processes. That would bring all partners

to a common level of understanding.

Projects developing new materials should

always include environmental issues

(jointly with occupational issues) as a

transversal activity, analysing potential

impacts of them, and proposing

measures to minimise and control those

impacts. For that purpose it is useful to

perform HSE and/or LCA Analysis in

combination with risk-oriented tools.

Some of examples of suggested

pertinent issues:

• Focus on how dangerous wastes are, or could be

• Emphasise the use of less harmful and more environmentally friendly chemicals and reagents.

• Protocols for safe disposal of chemicals, reagents and by-products.

• Innovation for developing sustainable and eco-friendly materials.

• Emphasis on the research and innovation for developing materials from waste products.

• Use of renewable resources or not should be mentioned in order to identify the environmental impact, not only upon LCA analyses, but also the renewable carbon-derived content.

• Address the use of environmentally sound process technologies

• Address end-life of the resulting materials to gain insights into how the materials will be handled at end-life.

• Pollution of atmosphere and environment by:

o application of new materials, o production of new materials, o waste treatment of new materials.

• A combined LCA and an assessment of recycling and exploration efforts will support the definition of the best production strategy

• How to optimise recycling processes whilst addressing the trade-off between the natural capital we decrease in mining and the capital we create by production?

• The format of LCA as set out in ISO 14040/44 is well known, however it is often not put into context in terms of economic benefit. Much effort has been made to increase and account for the environmental benefits of European projects, but the end product is often only appreciated if it can be commercialised. LCA in many respects should be combined with cost benefit analysis (CBA) to maximise the understanding and potential of the developed process or product.

29

Look at the entire value chain / life cycle

Assessment of environmental issues in a

life cycle perspective, in combination

with comprehensive safety

considerations and risk assessment of

processes, is crucial in order to optimise

the environmental performance and

commercialisation of the material

technologies being developed. Use

(mixtures of) materials which are

downwards compatible in industrial

recovery routes.

The use Life Cycle Assessment studies

should be encouraged to measure

environmental impacts. However the

value of LCA can only be guaranteed if

high quality data are collected and if the

relevant impact categories are

considered. To consider environmental

issues from the beginning of the project

(selection of raw materials, procedures,

etc.) and try to find the most real data to

develop the LCA of all the steps involved

on the development of the materials.

Whole life environmental impacts should

be considered. This means that the "LCA

Thinking Approach" is here to stay and

that the integration of the risk

considerations with and along the life

cycle is a challenge in the years to come.

Besides what is said above, some also

noted the importance to take into

account:

• the fate of materials in water, e.g. plastic waste in oceans

• aspects beyond purely chemical or biological hazards, like acoustic or light contamination and hazards related with the use of nanoparticles and other nanotechnologies

• life cycle analysis (including cost and CO2 emission)

• market perspectives, what will customers want in the next 5-10 years?

It is important to realise that the

development of a new materials typically

takes years in term of simulation,

fabrication and characterisation. Only

after this long process, this material can

eventually be ready for applications. The

subsequent introduction of such a

material in a Hazardous Substances

Directive would stop this process and put

to waste all the time and money spent

for its development. It is therefore very

important to be aware about possible

restrictions but also to support more

studies that properly establish risks and

potential toxicity.

Use recognised protocols

Environmental issues have to be

managed by using standard and

validated procedures such as LCA (e.g.

ISO 1040 or ILCD) in order to have

30 Questionnaire on Environmental Issues in FP7 NMP Projects on Materials

reliable data concerning the entire life

cycle of a specific product or

technologies. In fact the risk is that the

minimisation of the environmental load

in a single part of the global life cycle is

not corresponding to an effective

reduction of the environmental load. As

the entire life cycle is taken into account

it is necessary to have the commitment

of all the partners involved in the value

chain to provide accurate data to

perform the analysis. From a purely

operational perspective existing

regulations should be used as the

guiding principle – i.e. follow all

applicable environmental legislation so

as to minimise environmental

contamination.

Inclusion of recognised protocols such as

LCA or environmental makes it is easier

to:

• Have a clear understanding of the nature and the magnitude of the environmental issues

• Have a clear idea on how to handle any environmental issue occurring during the course of the project

• Involve participants at project partners having knowledge of EHS, LCA etc.

• Ensure clear communication and exchange among all consortium partners on the encountered issues and the way they were mitigated

Adapt to the scope of the project

It was suggested that project proposers

should be aware of the importance of

these issues and, when relevant this

should be addressed in the project,

noting that its extent depends on the

particular case. The respondents noted

two levels of distinctions to determine

when it is important to incorporate

environmental issues into research

projects: fundamental vs. applied

research, and the level of technical

maturity.

Care must be taken not to overwhelm

fundamental research with aspects that

become relevant at the application stage

because that might hinder innovative

research. For example, a quantum

mechanical study on the structure of

novel materials should not require from

the scientists to "think outside the box"

and elucidate environmental applications.

Nevertheless, environmental aspects

should be considered in projects oriented

to applications at a medium and large

scale projects.

If the project deals with a new product

or new formulations based on already

existing or adapted materials, existing

databases and literature resources are a

valuable support to find if these issues

are relevant. If yes, they must be

covered in the frame of the project. For

projects generating new materials in

large quantities or with polluting

techniques, an evaluation of risks and

benefits should accompany the project

proposal. In small projects, a precise

analysis of the intrinsic properties of

31

chemical substances might be sufficient.

Projects which are not directly involved

in environmental research but deal with

development of new materials might find

a good (or even sufficient) support from

interacting with some semi-permanent

environmental-oriented “panel”, which

could be represented by a long-term

coordinated action or similar.

Environmental issues should be

addressed in any kind of material

project; however it should be

differentiated whether an existing

material is being implemented in a new

process or product or a totally new

material is being produced. However,

such issues should not be so strict to

avoid the development of new materials

that could be optimised, with attention

to monetary and energetic costs and

eco-compatibility of synthesis and

precursors, in the last part of the

projects.

Include environmental expertise

Developing more environmentally

friendly materials and applications

requires higher standards in dealing with

environmental issues in accordance with

local and European chemical regulations

(REACH). Working with partners who

have established environmental

management systems, the R&D projects

have better chances to conduct the

generated know-how to the market.

Therefore, the generated know-how has

better chances to be in use of the society.

Because most of the know-how about

environmental issues of new materials is

gained at the project level, the pro-

active way of environmental thinking

should be implemented in the daily

routine of R&D projects. It is practically

impossible to educate all the responsible

consortium partners about the

environmental issues during the project

periods. It has also additional costs to

introduce regulatory partners for

environmental issues in the consortia

and through this way the know-how may

not be inherited in the institutions’ daily

routine after the project period. However,

it may be a realistic option to implement

competent project partners in the

consortia, who have experience with

environmental issues. To sustain the

environmental-responsible consideration

among the EU project consortia,

European Commission may consider

encouraging partners already in the

proposal status to find partners with

environmental management systems to

build an effective auto-control

mechanism in the future. In addition, it

would also be beneficial to encourage the

project partners who want to implement

environmental management systems,

and that financial resources can be

allocated for such activities.

The identification of the specialised fields

of expertise needed is essential and,

thus, the inclusion of personnel either

32 Questionnaire on Environmental Issues in FP7 NMP Projects on Materials

qualified or ready to receive specific

training on handling the relevant

environmental issues. Include industrial

partners in project because they are

aware of these issues. The

environmental overview must be

undertaken using a broad mix of

specialists and others. Mapping of

competences, capacities and project

activities can play a decisive role in order

to ensure focussing of efforts, filling the

gaps and avoiding multiplication of

efforts. Joint partnerships between

Experimental, Theory and

Simulation/Modelling groups are a pre-

requisite for a proper shaping/tailoring of

a material for environmental engineering

applications. This also helps the

participants of the projects to be aware

and/or informed of the possibilities to

improve environments issues.

Furthermore, it was suggested that EC

should encourage the participation of

industrial and academia experts on

external advisory boards to draw the

attention of the public and policy makers

to environmental issues.

Reinforce during evaluation of proposals

Organisations are increasingly under

pressure from environmental regulation,

decreasing margins and shortages of

certain resources. Combined with the

growing sustainability awareness of

customers these are important drivers

for companies to reduce the

environmental impacts of their

operations. As a result the importance of

environmental management has

significantly increased, and the inclusion

of these environmental topics highlights

the need for successful R&D projects on

materials. Thus, some of the

respondents suggested reinforcing

environmental aspects in both the calls

for proposals and the subsequent

evaluations, even during negotiation and

project follow-up. A few also noted that

this is to some extent already is done

well, at least up to the evaluation stage.

Here follows a collage of the

suggestions:

• To set a criterion or sub-criterion focussed on environmental issues for the evaluation of the proposals; covering issues such as design for successful recycling, waste minimisation, energy efficiency and increased lifetime

• If environmental issues become an essential part of projects funded by EU we would recommend that this topic is addressed by a special category (beside of RTD, Dem, Management) which is funded with 100%, perhaps as an additional budget.

• To require in every material project the presence in the consortium of an environmentally/ecologically informed partner or consultant.

• The environmental issues are of great importance especially for projects dealing with the development of novel materials. Therefore, special motivation should be given to the applicants in order to include and analyse issues related to health, safety and environmental impact.

33

• If awareness of environmental issue are linked to proposal success and evaluations in an obvious and fair way, then scientists will take them very seriously

• Need to be part of the call and the project description submitted.

• Have some environmental objectives conditional to grant (e.g. undertaking life cycle analysis)

• Include a section on environmental issues in the proposal template.

Some suggestions were also given for negotiation and project follow-up:

• It is important that the issue is discussed on a case to case basis, with the possibility of the proposers to explain their position towards this issue

• Discussions during project progress meetings together with EU officer, e.g. during workshops organised by the EU.

• Make sure that any starting EC project that handles chemicals, drugs, and new materials be aware at a minimal level of the existing rules/commonly agreed procedures in the field

34 Questionnaire on Environmental Issues in FP7 NMP Projects on Materials

Annex 1 List of pertinent websites European Commission Services

DG Research and Innovation http://ec.europa.eu/research DG Research and Innovation: Industrial Technologies http://ec.europa.eu/research/industrial_technologies/index_en.cfm Horizon 2020 http://ec.europa.eu/research/horizon2020/index_en.cfm NMP Materials blog http://ec.europa.eu/research/industrial_technologies/materials-blog_en.html CORDIS http://cordis.europa.eu/home_en.html Participant Portal http://ec.europa.eu/research/participants/portal/page/home Joint Research Centre IES: Life Cycle website, LCA & ILCD/ELCD http://lct.jrc.ec.europa.eu DG Environment: Policies http://ec.europa.eu/environment/policies_en.htm European Chemicals Agency: CLP & REACH http://echa.europa.eu European Environment Agency http://www.eea.europa.eu EIONET: European Environment Information and Observation Network http://www.eionet.europa.eu/

International organisations and initiatives

Inclusion does not imply endorsement by the European Commission OECD Environment Directorate: Chemical Safety and Biosafety http://www.oecd.org/env/ UNEP Strategic Approach to International Chemicals Management http://www.saicm.org/ WHO Environmental Health http://www.who.int/topics/environmental_health/en/ UNECE Globally Harmonized System of Classification and Labelling of Chemicals http://www.unece.org/trans/danger/publi/ghs/ghs_welcome_e.html Substitution Support Portal http://www.subsport.eu/ ChemSec SIN list http://www.chemsec.org/list/

35