Reservoir Simulation.doc

Transcript of Reservoir Simulation.doc

-

7/27/2019 Reservoir Simulation.doc

1/7

Reservoir Simulation

To run a reservoir simulation model, you must:

(a) Gather and input the fluid and rock (reservoir description)

data; the model incorporates data on the reservoir fluids (PVT)and the reservoir description (porosities, permeabilities etc.) and

their distribution in space.

(b) Choose certain numerical features of the grid (number of grid

blocks, time step sizes etc);

(c) Set up the correct field well controls (injection rates, bottom

hole pressure constraints etc.); it is these which drive the model;

(d) Choose which output (from a vast range of possibilities) you

would like to have printed to file which you can then plot later or -

in some cases - while the simulation is still running.

The output can include the following (non-exhaustive) list of

quantities:

The average field pressure as a function of time

The total field cumulative oil, water and gas production profileswith time

The total field daily (weekly, monthly, annual) production rates

of each phase: oil, water and gas

The individual well pressures (bottom hole or, through lift

curves, wellhead) over time

The individual well cumulative and daily flowrates of oil, water

and gas with time

Either full field or individual well watercuts, GORs, O/W ratios

with time

-

7/27/2019 Reservoir Simulation.doc

2/7

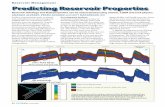

The spatial distribution of oil, water and gas saturations

throughout the reservoir as functions of time i.e. So(x,y,z;t),

Sw(x,y,z;t) and Sg(x,y,z;t)

The central objective of reservoir simulation is to produce futurepredictions (the output quantities listed above) that will allow us

to optimise reservoir performance. At the grander scale, what is

meant by optimise reservoir performance is to develop the

reservoir in the manner that brings the maximum economic

benefit to the company

Appraisal stage: at this stage, reservoir simulation will be a tool

that can be used to design the overall field development plan in

terms of the following issues:

The nature of the reservoir recovery plan e.g. natural depletion,

waterflooding, gas injection etc.

The nature of the facility required to develop the field e.g. a

platform, a subsea development tied back to an existing platform

or a Floating Production System (for an offshore fileld).

The nature and capacities of plant sub-facilities such as

compressors for injection, oil/water/gas separation capability.

The number, locations and types of well (vertical, slanted or

horizontal) to be drilled in the field.

The sequencing of the well drilling program and the topside

facilites.

It is during the initial appraisal stage that many of the biggest -

i.e. most expensive- investment decisions are made e.g. the type

of platform and facilities etc. Therefore, it is the most helpful time

to have accurate forward predictions of the reservoir

-

7/27/2019 Reservoir Simulation.doc

3/7

performance. But, it is at this time when we have the least

amount of data and, of course, very little or no field performance

history (there may be some extended production well tests).

In such cases, we may still be able to build a range of possiblereservoir models, or reservoir scenarios, that incorporate the

major uncertainties in terms of reservoir size (STOIIP), main fault

blocks, strength of aquifer, reservoir connectivity, etc. By running

forward predictions on this range of cases, we can generate a

spread of predicted future field performance cases

For example, scenarios for various cases may involve:

Different assumptions about the original oil in place (STOIIP;

Stock Tank Oil Originally In Place).

Different values of the reservoir parameters such as

permeability, porosity, net-to-gross ratio, the effect of an aquifer,

etc..

Major changes in the structural geology or sedimentology of the

reservoir e.g. sealing vs. leaky faults in the system, the

presence/absence of major fluvial channels, the distribution of

shales in the reservoir etc..

Mature field development: has been in production for some

time

(2 - 20+ years) but there is still a reasonably long lifespan ahead

for the field, say; 3 - 10+years. At this stage, reservoir simulation

is a tool for reservoir management which allows the reservoirengineer to plan and evaluate future development options for the

reservoir. This is a process that can be done on a continually

updated basis. The main difference between this stage and

appraisal is that the engineer now has some field production

history, such as pressures, cumulative oil, watercuts and GORs

-

7/27/2019 Reservoir Simulation.doc

4/7

(both field-wide and for individual wells), in addition to having

some idea of which wells are in communication and possibly some

production logs. The initial reservoir simulation model for the field

has probably been found to be wrong, in that it fails in some

aspects of its predictions of reservoir performance e.g. it failed topredict water breakthough in our waterflood (usually, although

not always, injected water arrives at oil producers before it is

expected).

At this development stage, typical reservoir simulation activities

are as follows:

Carrying out a history match of the (now available) field

production history in order to obtain a better tuned reservoirmodel to use for future field performance prediction

Using the history match to re-visit the field development

strategy in terms of changing the development plan e.g. infill

drilling, adding extra injection water capability, changing to gas

injection or some other IOR scheme etc.

Deciding between smaller project options such as drilling an

attic horizontal well vs. working over 2 or 3 existingvertical/slanted wells

It may be necessary to review the equity stake of various

partner companies in the field after some period of production

although this typically involves a complete review of the

engineering, geological and petrophysical data prior to a new

simulation study

The reservoir recovery mechanisms can be reviewed using acarefully history matched simulation model e.g. if we find that, to

match the history, we must reduce the vertical flows (by lowering

the vertical transmissibility), we may wish to determine the

importance of gravity in the reservoir recovery mechanism:

educational value of simulation models and it is a part of good

-

7/27/2019 Reservoir Simulation.doc

5/7

reservoir management that the engineer has a good grasp of the

important reservoir physics of their asset.

Late field development: we define this stage of fielddevelopment as the closing few years of field production before

abandonment. A question arises here as to whether the field is of

sufficient economic importance to merit a simulation study at this

stage. However, there are two reasons why we may want to

launch a simulation study late in a fields lifetime. Firstly, we may

think that, although it is in far decline, we can develop a new

development strategy that will give the field a new lease of life

and keep it going economically for a few more years. Forexample, we may apply a novel cheap drilling technology, or a

program of successful well stimulation (to remove production

impairment such as mineral scale) or we may wish to try an

economic Improved Oil Recovery (IOR) technique. Secondly, the

cost of field abandonment may be so high - e.g. we may have to

remove an offshore structure - that almost anything we do to

extend field life and avoid this expense will be economic. This

may justify a late life simulation study. However, there are nogeneral rules here since it depends on the local technical and

economic factors which course of action a company will follow. In

some countries there may be legislation (or regulations) that

require that an oil company produces reservoir simulation

calculations as part of their ongoing reservoir management.

(A 5-spot is a particular example of a pattern flood

which is appropriate mainly for onshore reservoirs where

many wells can be drilled with relatively close spacing)

The structure of the simulation study work flow: Accurate

reservoir description

- Develop the simulation model (perform the history

match - see below - use model for future predictions -

-

7/27/2019 Reservoir Simulation.doc

6/7

evaluate alternative operating plans). A history match is

when we adjust the parameters in the simulation model to

make the simulated production history agree with the

actual field performance

Pressure transient work - again gives important ancillary

information on the reservoir; determine whether there

was (i) directional permeability effects, directional

fracturing or channelling; (ii) the degree of stratification

in the reservoir; (iii) evaluation of the pay continuity

between the injectors and producers

A list of possible sources of uncertainty is as follows:

Lack of knowledge or wide inaccuracies in the size of the

reservoir; its areal extent, thickness and net-to-gross ratios

Lack of knowledge about the reservoir architecture i.e. its

geological structure in terms of sandbodies, shales, faults, etc.

Uncertainties in the actual numerical values of the porosities ()

and permeabilities (k) in the inter-well regions (which make upthe vast majority of the reservoir volume)

Inaccuracy in the fluid properties such as viscosity of the oil

(o), formation volume factors (Bo, Bw, Bg), phase behaviour etc.,

or doubts about the representativity of these properties

Lack of data - or very uncertain data- on the multiphase

fluid/rock properties, particularly relative permeability and

capillary pressure, and on knowledge as to how these curves varyfrom rock type within the reservoir volume away from the wells

Because the representational reservoir simulations model may

be poor, e.g. the numerical errors due to the coarse grid block

-

7/27/2019 Reservoir Simulation.doc

7/7

model may significantly affect the answer in either an optimistic

or pessimistic manner.

The above list of uncertainties for a given reservoir, especially at

the appraisal stage, is really quite realistic