Research Article UV-Heat Treatments for the Control of ...

Transcript of Research Article UV-Heat Treatments for the Control of ...

Research ArticleUV-Heat Treatments for the Control of FoodborneMicrobial Pathogens in Chicken Broth

M Gouma1 E Gayaacuten2 J Raso1 S Condoacuten1 and I Aacutelvarez1

1Tecnologıa de los Alimentos Facultad de Veterinaria Universidad de Zaragoza 50013 Zaragoza Spain2Department of Microbial and Molecular Systems (M2S) Laboratory of Food Microbiology KU Leuven 3001 Leuven Belgium

Correspondence should be addressed to I Alvarez ialvalanunizares

Received 10 December 2014 Accepted 1 March 2015

Academic Editor Avelino Alvarez-Ordonez

Copyright copy 2015 M Gouma et al This is an open access article distributed under the Creative Commons Attribution Licensewhich permits unrestricted use distribution and reproduction in any medium provided the original work is properly cited

This investigation established the process criteria for using UV-C light and mild heat (UV-H treatment) to inactivate 5-Log10

cycles (performance criterion) of common foodborne pathogen populations Escherichia coli Salmonella Typhimurium Listeriamonocytogenes and Staphylococcus aureus when inoculated in chicken broth To define the target microorganism and the properUV-H treatment conditions (including UV dose treatment time and temperature) that would achieve the stated performancecriterion mathematical equations based on Geeraerdrsquos model were developed for eachmicroorganism For the sake of comparisoninactivation equations for heat treatments were also performed on the same chicken broth and for the same microorganismsL monocytogenes was the most UV-H resistant microorganism at all temperatures requiring a UV dose between 610 JmL(56min) and 226 JmL (209min) to achieve 5-Log

10reductions In comparison with UV treatments at room temperatures the

combination of UV and mild heat allowed both the UV dose and treatment time to be reduced by 30 and 63 at 55∘C and 60∘Crespectively Compared to heat treatments the UV-H process reduced the heating time for 5-Log

10reductions of all the investigated

microorganisms in chicken broth from 20-fold to 2-fold when the operating temperature varied from 53 to 60∘C

1 Introduction

Despite the fact that conventional heat treatments still prevailin the food industry several nonthermal food processingtechnologies have emerged recently Compelled by the strongpreference of consumers for fresh and minimally processedfood research into food processing has focused on the inves-tigation of alternatives to pasteurization which has long beenpopular for its ability to ensuremicrobial inactivation at lowertemperatures whileminimizing losses of the organoleptic andnutritional properties of food One of these technologies isshort wave ultraviolet radiation (UV-C) which has numerousadvantages including the ability to inactivate a wide rangeof pathogenic and spoilage microorganisms in juices [1 2]therebyminimizing the loss of nutritional and sensorial qual-ity [3] Moreover UV-C does not generate chemical residuesor toxic compounds [4] and requires very little energy con-sumption compared with other nonthermal pasteurizationprocesses [5]The germicidal properties of UV-C light rely on

DNArsquos absorption of the UV light which induces structuraldistortions in the DNA molecule inhibiting transcriptionand replication and eventually leading to cell death

Although previous studies have shown that UV-C radia-tion can be an effective method to inactivate microorganismsin liquid food practical applications of this technology arelimited due to its low penetration capacity in liquids withhigh absorption coefficient and turbidity It is well known thatthe optical properties of the treatmentmedium strongly influ-ence the lethal effect of UV light [6] due to absorption reflec-tion scattering and refraction phenomena caused by thepresence of color compounds and soluble or suspended par-ticles In order to overcome these limitations combinationsof UV radiation with other nonthermal technologies such aspulsed electric fields have been designed based on hurdlestechnology approach For instance it has been demonstratedthat UV light followed by pulsed electric fields (PEF) treat-ments has an additive effect [7]

Hindawi Publishing CorporationBioMed Research InternationalVolume 2015 Article ID 436030 12 pageshttpdxdoiorg1011552015436030

2 BioMed Research International

Recently we have demonstrated that the simultaneousapplication of UV radiation and heat at sublethal tempera-tures (UV-H treatment) remarkably enhances the formerrsquosmicrobial inactivation capacity Specifically studies on theinactivation of various bacterial species both in buffersand fruit juices (orange and apple) have shown that UV-H treatments result in a synergistic lethal effect with thetemperature of maximum synergism being different for eachbacterial species [8ndash10] However so far our studies havefocused on low pH media where acidity can reduce the heatresistance of bacteria and consequently enhance the effec-tiveness of UV-H treatments Additionally data on food withmore neutral pH are scarce but do include some studies oneggwhite [11ndash13]Therefore the question of whether a similarsynergistic lethal effect could also occur in other liquid foodswith different pH chemical composition and absorptioncoefficients was raised

To challenge the inactivation effect of UV-H treatmentson complex food matrices chicken broth was chosen as amulti-ingredient liquid food with higher pH and a morecomplex chemical composition that provides a favorableenvironment for bacteria The goal of this study was toinvestigate whether the UV-H combined process can beapplied to liquid food that has a high absorption coefficientturbidity and low acidity such as chicken broth resulting in asynergistic lethal effect comparablewithsimilar to thatwhichhas been obtained in the case of fruit juices For this study wehave used the most UV resistant strains of differentpathogenic bacteria as reference microorganisms such asEscherichia coli Salmonella Typhimurium Listeria monocy-togenes and Staphylococcus aureus

2 Materials and Methods

21 Bacterial Culture and Media The strains of E coli STCC4201 Salmonella Typhimurium STCC 878 L monocytogenesSTCC 5672 and S aureus STCC 4465 were obtained from theSpanish Type Culture Collection (STCC) The bacterial cul-tures were maintained frozen at ndash80∘C in cryovials A brothsubculture was prepared by inoculating 10mL of tryptone soybroth (Biolife Milan Italy) supplemented with 06 (wv)yeast extract (Biolife) (TSBYE) with a loopful of growth fromtryptone soy agar (Biolife) supplemented with 06 (wv)yeast extract (TSAYE) The subculture was incubated at 35∘Cfor 6ndash12 h in a shaking incubator (150 rpm Heidolph Instru-ments Vibramax 100 Schwabach Germany) With thesesubcultures 250mL flasks containing 50mL of TSBYE wereinoculated to reach a concentration of 104 CFUmL and thenincubated for 24 h under the same conditions until thestationary growth phase was reached (2 times 109 CFUmL)

22 UV Equipment and Treatments UV treatments werecarried out in a unit with 8 individual annular thin film flow-through reactors connected in a series and equipped with afeed tank and a peristaltic pump (ISM 10785 Ismatec Glat-tbrugg Switzerland) as described previously by Gayan et al[8] Each reactor included a low-pressure mercury vaporlamp (8Wof input power model TUV 8WT5 Philips USA)

which converted 30 of the input power as UV-C radiation(Philips Electronics 2012) emitting 85 of UV-C energy at254 nm The lamp was attached to the axis of an outer glasstube (25mm of inner diameter) and was enclosed using aquartz tube (20mm of outer diameter) to prevent direct con-tact of the lamp with the treatment medium In the annulargap (25mm) a stainless steel coil spring was installed toimprove the flowrsquos turbulence The outside and inside coildiameters of the spring were 23mm and 25mm respectivelyand its length and pitch were 270mm and 10mm respec-tively A manual sampling valve was located in the outlet ofeach reactor The entire unit was submerged in a 90 L waterbath (250ndash600∘C) heated by the circulating water of aperipheral thermostatic bath (Kattebad K12 Huber Offen-burg Germany) The equipment also included a heatingcooling coil exchanger at the inlet of the first reactor Ther-mocouples (ZA 020-FS Almeco Bernburg Germany) fittedto the inlet and outlet of the first and last reactor respectivelyallowed for treatment temperature control

Chicken broth (absorption coefficient = 196 cmminus1 tur-bidity = 4460NTU pH = 52) for use as treatment mediumwas purchased from a local market (Interal SA Spain)Brothrsquos absorption coefficient was measured spectrophoto-metrically (254 nm UV500 Unicam Limited CambridgeUK) Samples were diluted and evaluated using quartzcuvettes (Hellma Mullheim Germany) with path lengths of1mm 2mm and 10mm The absorption coefficient of thediluted samples was determined from the slope of the absorb-ance versus the path length and corrected by the dilutionfactor Turbidity was measured with a nephelometer (HI83749 Hanna Instrument Szeged Hungary) pH was mea-sured using a pH-meter Basic 20 (Crison InstrumentBarcelona Spain) The chicken broth was inoculated withthe bacterial suspension to achieve 105ndash107 CFUmL andpumped (85 Lh) through the heat exchanger to the reactorsWhen the treatment conditions were stabilized samples werewithdrawn through the sampling valves and 01mL or 1mLwas immediately pour-plated into the recovery medium

23 Heat Treatments Heat treatments were carried outin specially designed thermoresistometer TR-SC [14] Thisinstrument consisted of a 400mL vessel with an electri-cal heater for thermostation an agitation device used toensure inoculum distribution and temperature homogeneitya pressurization system and ports for injecting the microbialsuspension and for extraction of samples Once the presettemperature had attained stability (119879 plusmn 005∘C) 02mL of anadequately diluted microbial cell suspension was inoculatedinto the vessel which contained the 350mL of chicken brothAfter inoculation 02mL samples were collected at differentheating times and were immediately pour-plated

24 Incubation of Treated Samples and Survival CountingTSAYE was used as a recovery medium and the plates wereincubated at 35∘C for 24 h for E coli Salmonella Typhim-urium and S aureus and for 48 h for L monocytogenes Afterincubation colony forming units (CFU) were counted usingan improved Image Analyzer Automatic Colony Counter

BioMed Research International 3

(Protos Synoptics Cambridge UK) as described elsewhere[15]

25 Curve Fitting and Dose Calculation Survival curves wereobtained by plotting the logarithm of the survival fractionversusUV dose (119889) expressed in joules per milliliter and time(119905) expressed in minutes for UV and heat treatments respec-tively To compareUV-H treatmentswith thermal treatmentsUV-H survival curves were also expressed in treatmenttime The UV dose delivered to the treatment mediumwas estimated with a chemical dosimeter To this end theiodide-iodate actinometer (quantum yield = 073 plusmn 002)was used following the indications of Rahn et al [16] Theactinometer buffer was pumped through the installation at85 Lh and the increase in absorbance (352 nm) was deter-mined at the outlet of each reactor [8] From this data thephoton flux (254 nm) as received per second by each volumefraction of the treatment medium was estimated accordingto Montalti et al [17] Thus considering the energy of aphoton at 254 nm the UV dose delivered to each reactor was049 JmL

To fit the survival curves obtained at each temperatureand to calculate resistance parameters the GInaFiT inacti-vation model-fitting tool was used [18] Specifically the log-linear regression plus shoulder model from Geeraerd et al[19] was chosen (1) sincemost of the survival curves exhibitedshoulders This model describes the survival curves throughtwo parameters the shoulder length (Sl) defined as doseor time before the exponential inactivation begins and theinactivation rate (119870max) defined as the slope of the expo-nential part of the survival curve 119873

0and 119873

119905represent the

initial numbers of the microbial population and the numberof microorganisms that survive at the end of the treatmenttime (119905) respectively Consider the following equation

119873119905= 1198730119890minus119870maxSl(

119890119870maxSl

1 + (119890119870maxSl minus 1) 119890119870max 119905

) (1)

To describe the relationship between treatment temperature(119879) and Sl and 119870max parameters mathematical equationsbased on the Weibull distribution were chosen For Sl theequation introduced by Albert and Mafart [20] (2) was usedas a secondary model whereas the thermodependence of119870max was described using the mirror image of theMafart [21]model (3)

Sl119879= (Sl0minus Slres) 10

minus(119905120575)119901

+ Slres (2)

119870max119879 = lfloor119870max 010minus(119905120575)

119901

rfloor (3)

where Sl119879and119870max119879 are the shoulder length and the inactiva-

tion rate of UV-H treatments at temperature 119879 respectivelySl0and 119870max 0 are the shoulder length and the inactiva-

tion rate of the survival curves of UV treatments at roomtemperature respectively and Slres is the residual shoul-der when the treatment temperature was increased 120575 and119901 are respectively the scale and shape parameters The 120575value represents the temperature increase necessary toachieve the first decimal reduction of Sl or 119870max (from Sl

0

and 119870max 0 to Sl010 and 119870max 010) The 119901 parameter (119901 gt 1)

accounts for the profile of the downward concavity of curves[20 21]

For the heat survival curves which showed an initialshoulder phase the Geeraerd model was also used as aprimary model In order to study the relationship betweenthe inactivationmodel parameters and the treatment temper-ature Albert and Mafartrsquos equation [20] was used for Sl asdescribed above and simple log-linear equations were usedfor 119870max while the slope and the intercept of the regressionline were considered model parameters The coefficient ofdetermination (1198772) the root mean square error (RMSE) thebias (119861

119891) and accuracy (119860

119891) factors were used to determine

the goodness of fits of both the primary and the secondarymodels as well as the accuracy of the final equations [22]The bias factor indicates systematic over-(119861

119891gt 1) or under-

(119861119891lt 1) prediction of the observed data On the other hand

the accuracy factor indicates the extent to which the predic-tions differ from the observed data

26 Statistical Analyses Statistical analyses a 119905-test and anANOVA test were carried out using the GraphPad PRISM50 software (GraphPad Inc SanDiego CA USA) and differ-ences were considered significant for 119875 le 005 All microbialresistance determinations as well as analytical assays wereperformed at least three times on different workings daysThe error bars in the figures correspond to themean standarddeviation

3 Results and Discussion

This study investigated the thermodependence of the UVinactivation of pathogenic bacteria in chicken broth Theintention was to establish the UV-H treatment conditions(process criteria) necessary for obtaining a certain level ofinactivation of the pathogenic microorganisms of referenceFor this purpose the effect of temperature on theUV lethalityof UV tolerant strains of E coli (STCC 4201) SalmonellaTyphimurium (STCC 878) L monocytogenes (STCC 5672)and S aureus (STCC 4465) was assessed The strains usedin this investigation were the most UV resistant among fivedifferent strains of each investigated microorganism accord-ing to previous studies [8 23ndash25] carried out under the samemethodology In particular the selected strains of E coliSalmonella Typhimurium L monocytogenes and S aureuswere 156 151 158 and 27 more resistant than the secondmost resistant strain of each microorganism

To describe this influence and to define the processcriteria mathematical equations including UV dose timeand temperature have been developed In order to compareresults the heat resistance of the indicated microorganismswas also investigated and modeled

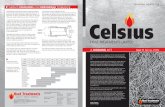

31 Microbial Inactivation by UV-H Treatments in ChickenBroth The survival curves of E coli Salmonella Typhim-urium L monocytogenes and S aureus to UV treatments atroom temperature and at 500 525 550 575 and 600∘C(UV-H) are presented in Figure 1 An initial lag phase

4 BioMed Research International

Dose (JmL)

00 05 10 15 20 25 30 35 40

00 06 11 16 22 44383327

Limit of detection

Time (min)

0

minus1

minus2

minus3

minus4

minus5

minus6

minus7

25∘C

Log 1

0(N

tN0)

Dose (JmL)

00 05 10 15 20 25 30 35 40

Time (min)

0

minus1

minus2

minus3

minus4

minus5

minus6

minus7 Limit of detection

00 06 11 16 22 44383327

50∘C

Log 1

0(N

tN0)

00 05 10 15 20 25 30 35 40

Limit of detection

Time (min)

525∘C

0

minus1

minus2

minus3

minus4

minus5

minus6

minus7

Dose (JmL)00 06 11 16 22 44383327

Log 1

0(N

tN0)

Dose (JmL)

00 05 10 15 20 25 30 35 40

Limit of detection

00 06 11 16 22 44383327

Time (min)

0

minus1

minus2

minus3

minus4

minus5

minus6

minus7

55∘CLo

g 10(N

tN0)

00 05 10 15 20 25 30 35 40

Limit of detection

Time (min)

Dose (JmL)00 05 11 16 22 44373327

0

minus1

minus2

minus3

minus4

minus5

minus6

minus7

575∘C

Log 1

0(N

tN0)

00 4437332722161105

Dose (JmL)

00 05 10 15 20 25 30 35 40

Limit of detection

Time (min)

0

minus1

minus2

minus3

minus4

minus5

minus6

minus7

60∘C

Log 1

0(N

tN0)

Figure 1 Survival curves of E coli (STCC 4201) (◼) Salmonella Typhimurium (STCC 878) (998771) L monocytogenes (STCC 5672) (e) and Saureus (STCC 4465) (X) to UV treatment at room temperature (25∘C) and to combined UV-H treatments at 500∘C 525∘C 550∘C 575∘Cand 600∘C in chicken broth

BioMed Research International 5

(shoulder) was observed formost of the survival curves Afterthis the microbial death followed a logarithmic order butno tailing took place UV-H inactivation curves displayedshoulder phases which are often observed in survival curvesfor UV-C light [26 27] According to the ldquomultihit targettheoryrdquo shoulders are related to the DNA damage and repairphenomena [28] DNA repair systems can repair damageup to certain UV doses resulting in shoulders Once themaximum DNA repair capability is surpassed additionalUV exposure is lethal for microorganisms and survivorsexponentially decline [29]

When the maximum UV dose possible in one passthrough the equipment (392 JmL) was applied UV treat-ments at room temperature (25∘C) decreased the microbialpopulation of the investigated bacteria from 5-Log

10cycles

for E coli and S aureus to 3-Log10

cycles for SalmonellaTyphimurium and L monocytogenes which showed thehighest UV resistance (Figure 1) This level of inactivationfor the same bacteria was higher than that observed in otherproducts like fruit juices that have lower turbidity but higherabsorption coefficient Thus Gouma et al [30] observedhardly 1-Log

10reductions of these microorganisms in apple

juice (turbidity 74 NTU 120572 = 24 cmminus1) after applying the sameUV treatment at 25∘C in the same facility Since pH did notaffect the UV lethality [23] and since the turbidity of thechicken broth (4460 NTU) was higher than that of the applejuice the larger inactivation observed in this investigationcould be due to the slightly lower absorption coefficient ofthe chicken broth (196 cmminus1) compared to that of the applejuice This lower absorption coefficient would cause less UV-C light to be absorbed by the treatment medium meaningthat the same UV dose would have more bactericidal effectin the chicken broth than in the apple juice [8] Alsoany component of the chicken broth could interact on themicrobial UV resistance thereby increasing the UV lethality

Although 3-Log10

cycles of inactivation were achievedafter the maximum applied UV dose at 25∘C for all the inves-tigated pathogenic microorganisms which were selected inprevious studies due to their being the most UV resistant[8 23ndash25] a reduction of 999 of the microbial populationcould not be sufficient to ensure the safety of chicken brothfor example at least 5-Log

10reductions of the pathogen of

reference are necessary for the pasteurization of fruit juices[31] Therefore it would be necessary to increase the lethalityof UV treatments

The application of UV at moderate temperatures hasresulted in a synergistic increase of UV lethality [11 13] Inthis investigation when the treatment temperaturewas raisedbetween 500∘C and 600∘C (Figure 1) the UV inactivationof all investigated microorganisms improved considerablyFor instance the UV inactivation of the most resistantmicroorganism L monocytogenes with a dose of 245 JmL(223min) increased from 134-Log

10cycles at 25∘C to 187

196 248 366 and 535-Log10

cycles at 500∘C 525∘C550∘C 575∘C and 600∘C respectively These results indi-cated that combining UV light with mild heat increased theUV inactivation of microorganisms in chicken broth whichparalleled the observation of a higher effect of UV and heatin other food products This fact suggests the possibility of

designing a feasible UV-H hygienization process for this kindof product (ie broth) which is apparently difficult to treatwith this technology due to its high turbidity and absorptioncoefficient

Although an increment of the UV lethality has beenobserved when augmenting the temperature the differentbehavior of E coli Salmonella Typhimurium L monocy-togenes and S aureus in response to UV-H treatments inrelation to the treatment temperature makes it difficult tocompare data Moreover the obtained survival curvesshowed shoulders at lower temperatures that disappearedwhen the temperature was increased which limited the appli-cation of simpler first order inactivation kineticsTherefore itwas necessary to develop mathematical models that enabledan evaluation of the effect of temperature on UV lethality inchicken broth for each investigated microorganism

To describe UV-H inactivation kinetics the log-linearregression plus the shoulder model of Geeraerd et al [19](1) (primary model) was used because it allowed the lengthof the shoulders and the log-linear rate of inactivation to beaccurately and independently described Table 1 includes theaverages and the standard deviations of themodel parameters(119870max and Sl) expressed in time terms obtained from thefitting of the UV-H survival curves of all microorganismstested at different temperatures The coefficient of determi-nation (1198772) and the root mean square error (RMSE) valuesare also included to illustrate the goodness of the fits Asobserved the UV lethality improved when the treatmenttemperature was raised and stemmed from the decrease ofthe shoulder phase (Sl) of the UV-H survival curves until itdisappeared In addition the slope of the survival curves(119870max) increased with the rising temperature Furthermorethe UV resistance variability between species wasmaintainedat different temperatures and was reflected in the Sl and119870maxvalues Thus the higher resistance of L monocytogenes wasdue to larger values of Sl and smaller values of 119870max On thecontrary S aureus was the most sensitive microorganismshowing smaller Sl values and higher 119870max ones Finally theGram negative bacteria E coli and Salmonella Typhimuriumshowed a similar behavior and Sl and119870max values In generalit is believed that Gram positive bacteria are more UVresistant than Gram negative which can be attributed to thethicker peptidoglycan cell wall of the former [32 33] In thisstudy the UV resistance of S aureus at 25∘C was similarto that of E coli and slightly lower than that of SalmonellaTyphimurium which demonstrates that this statementshould not be considered a general rule In fact other authorshave reported a higher susceptibility of S aureus to UVtechnologies compared with coliforms [34 35] At highertemperatures that statement cannot bemaintained since heatinterferes on the microbial UV resistance For example thehighest UV-H lethality for S aureus would be due to thehigher heat sensitivity of this microorganism compared withthe other investigated bacteria as it will presented later on

To describe the effect of the changes in temperature on thekinetic parameters obtained after fitting the primary modelto the UV-H inactivation data of E coli Salmonella Typhim-urium S aureus and L monocytogenes in chicken broth(shown in Table 1) the corresponding secondary models for

6 BioMed Research International

Table 1 Resistance parameters (Sl and 119870max) obtained from the fit of UV-H survival curves of E coli Salmonella Typhimurium S aureusand L monocytogenes at different temperatures in chicken broth to Geeraerdrsquos model (1) Estimated standard deviations (SD) of the meansare in parentheses Letters a b c and d indicate statistically significant differences (119875 le 005) among Sl and 119870max values of UV-H survivalcurves of different microorganisms at the same treatment temperature

Microorganism Temperature (∘C) Sl (min) 119870max (minminus1) RMSE R2

Escherichia coli

250 067 (009)a 366 (034)a 0152 0994500 068 (015)a 431 (022)a 0185 0993525 055 (016)a 459 (020)a 0228 0990550 033 (011)a 506 (034)a 0229 0991575 010 (006)a 600 (043)a 0329 0985600 000 (000)a 733 (062)a 0153 0996

Salmonella Typhimurium

250 068 (004)a 252 (001)b 0098 0995500 065 (010)a 358 (027)b 0144 0994525 045 (002)a 378 (004)b 0140 0996550 030 (010)a 491 (005)a 0219 0992575 009 (005)a 591 (027)a 0261 0991600 000 (000)a 1047 (074)b 0256 0993

Listeria monocytogenes

250 108 (013)b 255 (002)c 0077 0996500 100 (002)a 270 (002)c 0068 0997525 089 (004)b 324 (032)c 0212 0988550 073 (013)b 368 (032)b 0212 0988575 020 (005)b 420 (003)b 0308 0977600 000 (000)a 560 (042)c 0253 0989

Staphylococcus aureus

250 059 (017)a 337 (035)d 0204 0987500 041 (009)a 541 (015)d 0222 0995525 038 (001)a 650 (010)d 0279 0991550 025 (002)c 771 (055)c 0213 0995575 010 (000)a 1193 (024)c 03521 0988

each microorganism were developed Figure 2 depicts therelationship between temperature and the Sl and119870max valuesfor all the investigated microorganisms Mathematical equa-tions (secondarymodels) based on theWeibull distributionmdashAlbert and Mafartrsquos equation (2) for Sl and Mafartrsquos equation(3) for 119870maxmdashwere used to describe the thermodependenceof both parameters Table 2 compiles the obtained parameters(120575 119901 Sl

0 Slres and 119870max 0) from the secondary models of Sl

and 119870max for each microorganism including the 1198772 andRMSE values from the fits The relationship between the Sl(Figure 2(a)) and the temperature displayed a sigmoid pro-file for all microorganisms first showing a lag phase andthen dropping off to zero L monocytogenes showed highershoulder length values of the UV-H survival curves thanall the other species at all treatment temperatures testedespecially at temperatures ranging from 25∘C to 550∘CAbove this value differences were reduced until the shoul-der length became zero When 119870max values were plottedagainst treatment temperature concave upward curves wereobserved (Figure 2(b)) The inactivation rate of S aureus andSalmonella Typhimurium was more sensitive to temperaturechanges than that of E coli and L monocytogenes Thisbehavior was evidenced in the scale parameter (120575) of 119870maxsecondary models which determined the temperature incre-ment that reduced the 119870max 10-fold (Table 2) 120575 values for

S aureus and Salmonella Typhimurium were smaller thanthose obtained for L monocytogenes and E coli

To describe compare and predict the microbial inactiva-tion byUV-H treatments of E coli SalmonellaTyphimuriumL monocytogenes and S aureus in chicken broth finalequations were developed These equations were obtained byintroducing the secondary models for Sl and 119870max values (2)and (3) into Geeraerdrsquos primarymodel (1) To show the good-ness of the fits of the final equations Figure 3 presents theplots of the observed versus predicted data by the finalequations for each microorganism The difference between apoint on the graph and the line of equivalence is a measure ofthe accuracy of the corresponding estimationThe1198772 RMSEaccuracy (119860

119891) and bias (119861

119891) factors from each prediction

were also indicated in the figures The calculated valuesdemonstrated that in general the final equations accuratelypredicted the UV-H inactivation of all microorganismswithout observing over or under predictions Therefore thedeveloped final equations would be adequate to comparethe UV-H resistance of the different microorganisms and todefine the processing conditions (process criteria) to achievea certain level of pathogenic microbial inactivation (perfor-mance criteria) as will be discussed later on

It has been demonstrated that the improvement of UV-Hinactivation was due to the occurrence of a synergistic lethal

BioMed Research International 7

Table 2 Parameters of the secondary models resulting after fitting Albert and Mafartrsquos (2) and Mafartrsquos models (3) to the data representingthe relationship between the Sl and 119870max from UV-H survival curves of E coli Salmonella Typhimurium L monocytogenes and S aureusfrom Table 1 against the treatment respectively Values in parentheses represent the standard errors of the means Letters a b and c indicatestatistically significant differences (119875 le 005)

(a) Shoulder length secondary model

Microorganism 120575 119901 Sl0

Slres 1198772 RMSE

Escherichia coli 5681 (028)a 2146 (299)a 070 (002)a 000 (002)a 0996 0027Salmonella Typhimurium 5669 (042)a 1652 (276)b 070 (003)a 000 (002)a 0992 0034Listeria monocytogenes 5705 (016)a 2406 (271)a 105 (003)b 000 (002)a 0998 0032Staphylococcus aureus 5745 (070)a 1218 (172)b 057 (002)c 000 (003)a 0993 0025

(b) 119870max secondary model

Microorganism 120575 119901 119870max0 1198772 RMSE

Escherichia coli 6922 (039)a 839 (057)a 370 (007)a 0998 0071Salmonella Typhimurium 6311 (127)b 1095 (344)a 276 (039)bc 0981 0501Listeria monocytogenes 6708 (079)a 944 (168)a 252 (014)b 0989 0151Staphylococcus aureus 6225 (168)b 802 (225)a 349 (053)ac 0985 0546

00

02

04

06

08

10

12

25 35 45 55 65

Sl

Temperature (∘C)

E coliSalmonella

ListeriaS aureus

(a)

0

2

4

6

8

10

12

14

25 35 45 55 65

Km

ax

E coliSalmonella

ListeriaS aureus

Temperature (∘C)

(b)

Figure 2 Relationships between temperature and Sl (a) or 119870max (b) values obtained after the fitting of Geeraerdrsquos model (1) to the UV-Hinactivation data of E coli (e) Salmonella Typhimurium (998779) L monocytogenes (◼) and S aureus () in chicken broth Solid lines representthe fitting curves for Sl and 119870max calculated from Albert and Mafartrsquos (2) and Mafartrsquos equation (3) respectively

effect and that the magnitude of this effect increased whenthe treatment temperature was raised to a threshold value[8 10] Above this temperature thermal lethal effects beganto predominate over UV lethality and UV-H synergism wasreduced to the point of disappearing whereby microbialdeath was then exclusively due to heat Prior studies on thecombined UV-H treatment of apple juice have shown that Ecoli STCC 4201 displayed themaximumUV-H synergism at atreatment temperature of about 55∘C above this temperaturethe synergism decreased until it disappeared at 600∘C whenUV-H and heat survival curves overlapped [10]Therefore totake advantage of the combined UV-H process the treatmenttemperature should be limited to temperatures below theintersection of UV-H and heat lethality This requires knowl-edge of the heat resistance abilities of target microorganismsand their thermodependence Therefore the next step was to

investigate the heat resistance of pathogenic microorganismsin chicken broth

32 Microbial Inactivation by Heat Treatments in ChickenBroth To evaluate the contribution of heat to the lethal effectof the combined UV-H treatment experiments on the heatresistance of all the investigatedmicroorganismswere carriedout also in chicken broth The resulting survival curves didnot follow first order kinetics and presented an initial lagphase (shoulder) E coli was the only exception showing aninactivation curvewith a log-linear behaviorThe inactivationdata were fitted by Geeraerdrsquos model (primary model (1))The resulting values for the heat resistance parameters (Sl and119870max) were included in Table 3 As observed Sl valuesdecreased with temperature becoming zero at the highest

8 BioMed Research International

minus7

minus6

minus5

minus4

minus3

minus2

minus1

0minus7minus6minus5minus4minus3minus2minus10

Log 1

0cy

cles o

f ina

ctiv

atio

n (p

redi

cted

dat

a)

Log10 cycles of inactivation (observed data)

RMSE = 0284

Af = 1392

Bf = 1001

E coli

R2 = 0977

(a)

Salmonella Typhimurium

RMSE = 0305

R2 = 0975

Af = 1272

Bf = 1017

minus7

minus6

minus5

minus4

minus3

minus2

minus1

0minus7minus6minus5minus4minus3minus2minus10

Log 1

0cy

cles o

f ina

ctiv

atio

n (p

redi

cted

dat

a)Log10 cycles of inactivation (observed data)

(b)

L monocytogenes

minus7

minus6

minus5

minus4

minus3

minus2

minus1

0

minus7minus6minus5minus4minus3minus2minus10

Log 1

0cy

cles o

f ina

ctiv

atio

n (p

redi

cted

dat

a)

Log10 cycles of inactivation (observed data)

RMSE = 0291

R2 = 0974

Af = 1459

Bf = 0875

(c)

S aureusminus7

minus6

minus5

minus4

minus3

minus2

minus1

0minus7minus6minus5minus4minus3minus2minus10

Log 1

0cy

cles o

f ina

ctiv

atio

n (p

redi

cted

dat

a)

Log10 cycles of inactivation (observed data)

RMSE = 0305

R2 = 0975

Af = 1272

Bf = 1017

(d)

Figure 3 Correlation between observed and predicted data obtained from the tertiary models for E coli (a) Salmonella Typhimurium (b)L monocytogenes (c) and S aureus (d) when treated by UV-H process 119877

2 RMSE accuracy (119860

119891) and bias (119861

119891) factors from each prediction

are also indicated in the figures

temperatures That is the shoulders disappeared proportion-ate to temperature as was observed in the UV-H treatmentsThe relationship between Sl and temperature also followedthe Weibullian distribution and was described by Albertand Mafartrsquos equation (2) In the case of 119870max valuesthey increased with temperature following an exponential

relationshipThese relationships (secondary models) allowedfor the obtention of the corresponding kinetic parametersshowed inTable 4 As observed the shoulder length (Sl value)was higher for S aureus However it rapidly decreased withtemperature differently to L monocytogenes which was lessinfluenced by the temperature (119875 value) Concerning the

BioMed Research International 9

Table 3 Resistance parameters obtained from the fit of heat inactivation data of E coli Salmonella Typhimurium S aureus and Lmonocytogenes at different temperatures in chicken broth by Geeraerdrsquos model (1) Estimated standard deviations (SD) of the means areshown in parentheses Letters a b c and d indicate statistically significant differences (119875 le 005) among Sl and 119870max values of heat survivalcurves for each microorganism at different temperatures

Microorganism Temperature (∘C) Sl (min) 119870max (minminus1) 1198772 RMSE

Escherichia coli

556 mdash 052 (002)a 0981 0204581 mdash 133 (004)b 0993 0203606 mdash 365 (011)c 0991 0122626 mdash 1749 (102)d 0992 0156

Salmonella Typhimurium

556 041 (071)a 049 (011)a 0994 0024581 019 (012)b 300 (016)b 0993 0196606 000 (000)c 703 (066)c 0995 0188626 000 (000)c 2797 (123)d 0994 0157

Listeria monocytogenes

556 080 (015)a 127 (011)a 0995 0105581 081 (027)a 222 (023)b 0983 0153606 080 (019)a 347 (011)c 0992 0204626 047 (000)b 581 (015)d 0995 0165

Staphylococcus aureus531 130 (004)a 224 (003)a 0996 0082556 012 (009)b 348 (004)b 0983 0204581 000 (000)c 593 (031)c 0995 0163

Table 4 Secondary model parameters calculated after plotting Sl and 119870max values obtained from heat survival curves of E coli SalmonellaTyphimurium L monocytogenes and S aureus against treatment temperature and fitting by Albert and Mafartrsquos equation (2) and log-linearregressions respectively Values in parentheses represent the standard errors of the means

(a) Shoulder length secondary model

Microorganism 120575 (min) 119901 Sl0(min) Slres (min) 119877

2 RMSEEscherichia coli mdash mdash mdash mdash mdash mdashSalmonella Typhimurium 5900 (007)a 6300 (723)a 043 (000)a 000 (002)a 0999 0048Listeria monocytogenes 6380 (011)b 3904 (346)b 087 (001)b 000 (002)a 0998 0099Staphylococcus aureus 5526 (003)c 9667 (866)c 132 (000)c 000 (003)a 0999 0063

(b) 119870max secondary model

Microorganism Slope (minminus1) Intercept (min) 1198772 RMSE

Escherichia coli 0212 (0027)a minus12135 (1602)a 0969 0425Salmonella Typhimurium 0240 (0024)a minus13602 (1405)a 0981 0088Listeria monocytogenes 0093 (0004)b minus5042 (0244)b 0996 0018Staphylococcus aureus 0084 (0021)b minus4138 (0121)b 0999 0009

relationships of the inactivation rate 119870max values of E coliand Salmonella Typhimurium showed a similar thermode-pendence (no significant differences among the slope values)although it was somewhat higher than those of both Grampositive microorganisms whose thermodependence variedin a parallel manner This means that the velocity of death ofL monocytogenes and S aureus was affected to a lesser extentby temperature changes than that of E coli and SalmonellaTyphimurium

To predict the heat inactivation in chicken broth for eachstudied microorganism final equations were developed byincluding the obtained secondary models for Sl and 119870maxin Geeraerdrsquos equation (primary model) When comparingthe observed inactivation data at different times and temper-atures from those predicted by the final equations 1198772 values

ranged from 0932 to 0987 RMSE from 0158 to 0386 119860119891

from 1132 to 1444 and 119861119891from 0830 to 1207 indicating

an adequate goodness of the fits Similar to the UV-Hfinal equations the developed final equations for heat wouldbe adequate to compare the heat resistance of the differentmicroorganisms define the process criteria to achieve a cer-tain performance criteria and compare the microbial lethaleffectiveness of both the heat and UV-H treatment processes

33 Process Criteria for 5-Log10

Reductions of FoodborneMicrobial Pathogens in Chicken Broth Figure 4 shows thelogarithm of the treatment time and UV dose necessary toinactivate 5-Log

10cycles of E coli Salmonella Typhimurium

L monocytogenes and S aureus at temperatures between

10 BioMed Research International

25 30 35 40 45

01

1

10

100

012

12

12

120

45 50 55 60

L monocytogenes

S TyphimuriumE coli

S aureus

Temperature (∘C)

Tim

e for

5-L

og10

redu

ctio

ns (m

in)

Dos

e for

5-L

og10

redu

ctio

ns (J

mL)

Figure 4 Times and UV doses required to achieve 5-Log10

reductions by UV-H (dotted lines) and heat treatments (continuouslines) at different temperatures for E coli (red line) SalmonellaTyphimurium (blue line) L monocytogenes (black line) and Saureus (green line) in chicken broth

25∘C and 600∘C in chicken broth UV doses displayed on thesecondary 119874119884 axis were calculated from the trend line equa-tion that resulted fromplotting the treatment time against thecorresponding UV dose for each reactor In our facility thisrelationship was UV dose = 10837 lowast (time) + 00213 (1198772 =0999) For comparison reasons thermal death time (TDT)curves for each microorganism have also been includedshowing the relationship between the time for 5-Log

10

reductions and the heating temperature In the case of theheat treatments all TDT curves showed a log-linear profilefrom which 119911 values were deduced (temperature increase forreducing the treatment time 10-fold) at 47∘C 42∘C 108∘Cand 118∘C for E coli Salmonella Typhimurium L mono-cytogenes and S aureus respectively These values are inthe range of what other authors have obtained for fruitjuices [30 36ndash38] although slightly higher in the case ofthe Gram positive bacteria Based on these data E coli wasthe most heat resistant bacterium when the temperature wasincreased to about 588∘C the temperature at which theTDT curves of E coli and L monocytogenes intersectedAbove this temperature L monocytogenes became the mostthermotolerant microorganism

Concerning the UV-H treatments at temperatures over50∘C the treatment time for 5-Log

10reductions of allmicroor-

ganisms decreased with temperature and followed a concavedownward profile The 5-Log

10reductions time varied with

the treatment temperature in a way that paralleled that ofthe thermodependence of 119870max of the UV-H survival curves(Figure 2 and Table 1) L monocytogenes was the most UV-H resistant microorganism at all studied temperatures UVdoses of 61 JmL at room temperature would permit the5-Log

10reduction of any of the investigated pathogenic

microorganisms in 56 minutes a level of inactivation that isdifficult to achieve with other technologies at the investigatedtemperatures treatment times and energy costs in productslike brothsTheUVdose and time required to achieve 5-Log

10

reductions in the target pathogen (L monocytogenes) by UV

treatment at room temperature would be reduced by 197 at53∘C A more radical improvement was attained by raisingthe temperature to 550 575 and 600∘C at which the UVdose and time needed to achieve the performance criterionfor L monocytogenes was reduced by 301 448 and 629respectively

When comparing UV-H and heat treatments the appli-cation of UV-C light at moderate temperatures noticeablyreduced the heat treatment time for 5-Log

10reductions of

tested microorganisms in chicken broth This reduction intime was greater the lower the temperature of the UV-Htreatment was applied When UV-H treatments were appliedat 53∘C 45 and 935minutes of theUV-C and heat treatmentswould be required respectively that is a 20-fold timereduction of the heat processing time This time reduction ofthe heat treatments was of 9- 4- and 2-fold when the temper-ature was 550 575 and 600∘C respectively Over 60∘C themicrobial inactivation due to heat would be greater therebyreducing the synergistic lethal contribution of UV light andachieving a temperature over which inactivation would beonly due to heat

34 Conclusions This study has investigated the lethalmicro-bial effects of UV-C heat and UV-H on the differentpathogenic microorganisms of reference (E coli SalmonellaTyphimurium Lmonocytogenes and S aureus) when treatedin chicken broth Mathematical equations were developedthat enabled a comparison between the investigatedmicroor-ganismsrsquo levels of resistance to the different applied tech-nologies This defined the target microorganism and estab-lished the process criteria (UV dose time and temperature)required for 5-Log

10reductions of the four pathogens in

chicken broth With all technologies 5-Log10

reductionswere obtained for all investigated microorganisms Howeverdepending on the technology and the target microorganismsthe required time to achieve that performance criterionnoticeably varied ForUV treatments (at roomor atmoderatetemperatures) L monocytogenes was the most resistantmicroorganism but for heat treatments up to temperaturesof 59∘C E coli was Over this temperature L monocytogeneswas again the most resistant bacteria in chicken broth Onthe other hand UV-C light applied even at room temperatureresulted in a technology to control foodborne pathogens inchicken broth that was very promising However the time oftreatment at this temperature could possibly be too long froma practical point of view The application of UV-H permitteda reduction in this processing time which happened to be 20-to 2-fold lower than the corresponding to heat treatments atthe same temperature and with an extra energetic cost vary-ing from 610 JmL to 226 JmL These results indicated thatcombining UV-C light with mild temperatures permitted acertain performance criterion to be achieved by means oflower UV doses and treatment times than those needed forUV or heat treatments applied to chicken broth alone Thefact that this food product is not considered suitable for beingtreated by UV light due to its high turbidity and absorptioncoefficient enhances the importance of the aforementionedresults

BioMed Research International 11

Conflict of Interests

The authors declare that there is no conflict of interestsregarding the publication of this paper

Acknowledgments

This study has been carried out with financial support fromtheMinisterio de Ciencia e Innovacion de Espana the projectAGL 2012-33522 from Comision Interministerial de Cienciay Tecnologıa (CICYT) EU-FEDER (CIT020000-2009-40)and the Departamento de Ciencia Tecnologıa y Universidaddel Gobierno de Aragon E Gayan gratefully acknowledgesthe financial support for her doctoral studies from theMinisterio de Educacion y Ciencia de Espana This workwas also performed in the framework of the graduate pro-gram partly financed by the Act ldquoGreek State ScholarshipsFoundation (IKY) grants program for the academic year2012-2013 through an individualized academic assessmentrdquofunded by the Operational Program ldquoEducation and LifelongLearningrdquo of the European Social Fund (ESF) and the NSRF(2007ndash2013)

References

[1] A A Gabriel ldquoInactivation of Escherichia coli O157H7 andspoilage yeasts in germicidal UV-C-irradiated and heat-treatedclear apple juicerdquo Food Control vol 25 no 2 pp 425ndash432 2012

[2] AMuller M R Stahl V Graef CM A P Franz andMHuchldquoUV-C treatment of juices to inactivate microorganisms usingDean vortex technologyrdquo Journal of Food Engineering vol 107no 2 pp 268ndash275 2011

[3] I M Caminiti I Palgan A Munoz et al ldquoThe effect of ultra-violet light on microbial inactivation and quality attributes ofapple juicerdquo Food and Bioprocess Technology vol 5 no 2 pp680ndash686 2012

[4] J A Guerrero-Beltran andG V Barbosa-Canovas ldquoAdvantagesand limitations on processing foods by UV lightrdquo Food Scienceand Technology International vol 10 no 3 pp 137ndash147 2004

[5] D J Geveke ldquoUV inactivation of bacteria in apple ciderrdquo Journalof Food Protection vol 68 no 8 pp 1739ndash1742 2005

[6] T Koutchma andB Parisi ldquoBiodosimetry ofEscherichia coliUVinactivation in model juices with regard to dose distribution inannular UV reactorsrdquo Journal of Food Science vol 69 no 1 ppFEP14ndashFEP22 2004

[7] T K Gachovska S Kumar H Thippareddi J Subbiah and FWilliams ldquoUltraviolet and pulsed electric field treatments haveadditive effect on inactivation of E coli in apple juicerdquo Journalof Food Science vol 73 no 9 pp M412ndashM417 2008

[8] E Gayan S Monfort I Alvarez and S Condon ldquoUV-C inac-tivation of Escherichia coli at different temperaturesrdquo InnovativeFood Science and Emerging Technologies vol 12 no 4 pp 531ndash541 2011

[9] E Gayan M J Serrano S Monfort I Alvarez and S CondonldquoCombining ultraviolet light and mild temperatures for theinactivation of Escherichia coli in orange juicerdquo Journal of FoodEngineering vol 113 no 4 pp 598ndash605 2012

[10] E Gayan M J Serrano S Monfort I Alvarez and S CondonldquoPasteurization of apple juice contaminated with Escherichiacoli by a combined UVndashmild temperature treatmentrdquo Food andBioprocess Technology vol 6 no 11 pp 3006ndash3016 2013

[11] D J Geveke ldquoUv inactivation ofE coli in liquid eggwhiterdquo Foodand Bioprocess Technology vol 1 no 2 pp 201ndash206 2008

[12] D J Geveke and D Torres ldquoLiquid egg white pasteurizationusing a centrifugal UV irradiatorrdquo International Journal of FoodMicrobiology vol 162 no 1 pp 43ndash47 2013

[13] P M de Souza and A Fernandez ldquoEffects of UV-C on physic-ochemical quality attributes and Salmonella enteritidis inacti-vation in liquid egg productsrdquo Food Control vol 22 no 8 pp1385ndash1392 2011

[14] S Condon M J Arrizubieta and F J Sala ldquoMicrobial heatresistance determinations by the multipoint system with thethermoresistometer TR-SC Improvement of this methodol-ogyrdquo Journal of Microbiological Methods vol 18 no 4 pp 357ndash366 1993

[15] S Condon A Palop J Raso and F J Sala ldquoInfluence of theincubation temperature after heat treatment upon the estimatedheat resistance values of spores of Bacillus subtilisrdquo Letters inApplied Microbiology vol 22 no 2 pp 149ndash152 1996

[16] R O Rahn M I Stefan J R Bolton E Goren P-S Shaw andK R Lykke ldquoQuantum yield of the iodide-iodate chemical acti-nometer dependence on wavelength and concentrationrdquo Pho-tochemistry and Photobiology vol 78 no 2 pp 146ndash152 2003

[17] M Montalti A Credi L Prodi and M T Gandolfi ldquoChemicalactinometryrdquo inHandbook of Photochemistry pp 601ndash611 CRCPress Boca Raton Fla USA 3rd edition 2006

[18] A H Geeraerd V P Valdramidis and J F Van Impe ldquoGInaFiTa freeware tool to assess non-log-linear microbial survivorcurvesrdquo International Journal of Food Microbiology vol 102 no1 pp 95ndash105 2005

[19] AHGeeraerd CHHerremans and J F van Impe ldquoStructuralmodel requirements to describe microbial inactivation duringa mild heat treatmentrdquo International Journal of Food Microbiol-ogy vol 59 no 3 pp 185ndash209 2000

[20] I Albert and P Mafart ldquoAmodifiedWeibull model for bacterialinactivationrdquo International Journal of Food Microbiology vol100 no 1ndash3 pp 197ndash211 2005

[21] P Mafart O Couvert S Gaillard and I Leguerinel ldquoOn cal-culating sterility in thermal preservation methods applicationof the Weibull frequency distribution modelrdquo InternationalJournal of Food Microbiology vol 72 no 1-2 pp 107ndash113 2002

[22] J Baranyi C Pin and T Ross ldquoValidating and comparingpredictive modelsrdquo International Journal of Food Microbiologyvol 48 no 3 pp 159ndash166 1999

[23] E Gayan M J Serrano J Raso I Alvarez and S CondonldquoInactivation of Salmonella enterica by UV-C light Alone andin combination with mild temperaturesrdquo Applied and Environ-mental Microbiology vol 78 no 23 pp 8353ndash8361 2012

[24] E Gayan M J Serrano R Pagan I Alvarez and S CondonldquoEnvironmental and biological factors influencing the UV-Cresistance of Listeria monocytogenesrdquo Food Microbiology vol46 pp 246ndash253 2015

[25] E Gayan D Garcıa-Gonzalo I Alvarez and S Condon ldquoResis-tance of Staphylococcus aureus toUV-C light and combinedUV-heat treatments at mild temperaturesrdquo International Journal ofFood Microbiology vol 172 pp 30ndash39 2014

[26] A Quintero-Ramos J J Churey P Hartman J Barnard and RW Worobo ldquoModeling of Escherichia coli inactivation by UVirradiation at different pH values in apple ciderrdquo Journal of FoodProtection vol 67 no 6 pp 1153ndash1156 2004

[27] S Unluturk M R Atilgan A H Baysal and M S UnluturkldquoModeling inactivation kinetics of liquid egg white exposed to

12 BioMed Research International

UV-C irradiationrdquo International Journal of Food Microbiologyvol 142 no 3 pp 341ndash347 2010

[28] R Latarjet ldquoIntroduction to research in ultraviolet photobiol-ogy JOHN JAGGERrdquo Photochemistry and Photobiology vol 7no 4 p 413 1968

[29] A Lopez-Malo and E Palou ldquoUltraviolet light and food preser-vationrdquo in Novel Food Processing Technologies G V Barbosa-Canovas G V Tapia and M P Cano Eds pp 464ndash484 CRCPress Madrid Spain 2005

[30] M Gouma I Alvarez S Condon and E Gayan ldquoModellingmicrobial inactivation kinetics of combined UV-H treatmentsin apple juicerdquo Innovative Food ScienceampEmergingTechnologiesvol 27 pp 111ndash120 2015

[31] USFDA Hazard Analysis and Critical Control Point (HACCP)Procedures for the Safe and Sanitary Processing and Importing ofJuice Final Rule US Food and Drug Administration Washing-ton DC USA 2001 21 CFR part 120 66 FR 6137-6202

[32] G Lu C Li and P Liu ldquoUV inactivation of milk-relatedmicroorganisms with a novel electrodeless lamp apparatusrdquoEuropean Food Research and Technology vol 233 no 1 pp 79ndash87 2011

[33] S Beauchamp and M Lacroix ldquoResistance of the genome ofEscherichia coli and Listeria monocytogenes to irradiation eval-uated by the induction of cyclobutane pyrimidine dimers and6-4 photoproducts using gamma and UV-C radiationsrdquo Radia-tion Physics and Chemistry vol 81 no 8 pp 1193ndash1197 2012

[34] J C H Chang S F Ossoff D C Lobe et al ldquoUV inactivationof pathogenic and indicator microorganismsrdquo Applied andEnvironmental Microbiology vol 49 no 6 pp 1361ndash1365 1985

[35] WAMHijnen E F Beerendonk andG JMedema ldquoInactiva-tion credit of UV radiation for viruses bacteria and protozoan(oo)cysts in water a reviewrdquo Water Research vol 40 no 1 pp3ndash22 2006

[36] A Alvarez-Ordonez A Fernandez A Bernardo andM LopezldquoA comparative study of thermal and acid inactivation kineticsin fruit juices of Salmonella enterica serovar typhimurium andSalmonella enterica serovar senftenberg grown at acidic condi-tionsrdquo Foodborne Pathogens and Disease vol 6 no 9 pp 1147ndash1155 2009

[37] M E Doyle and A S Mazzotta ldquoReview of studies on the ther-mal resistance of Salmonellaerdquo Journal of Food Protection vol63 no 6 pp 779ndash795 2000

[38] A S Mazzotta ldquoThermal inactivation of stationary-phase andacid-adapted Escherichia coli O157H7 Salmonella and Listeriamonocytogenes in fruit juicesrdquo Journal of Food Protection vol64 no 3 pp 315ndash320 2001

Submit your manuscripts athttpwwwhindawicom

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Anatomy Research International

PeptidesInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporation httpwwwhindawicom

International Journal of

Volume 2014

Zoology

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Molecular Biology International

GenomicsInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

The Scientific World JournalHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

BioinformaticsAdvances in

Marine BiologyJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Signal TransductionJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

BioMed Research International

Evolutionary BiologyInternational Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Biochemistry Research International

ArchaeaHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Genetics Research International

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Advances in

Virolog y

Hindawi Publishing Corporationhttpwwwhindawicom

Nucleic AcidsJournal of

Volume 2014

Stem CellsInternational

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Enzyme Research

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

Microbiology

2 BioMed Research International

Recently we have demonstrated that the simultaneousapplication of UV radiation and heat at sublethal tempera-tures (UV-H treatment) remarkably enhances the formerrsquosmicrobial inactivation capacity Specifically studies on theinactivation of various bacterial species both in buffersand fruit juices (orange and apple) have shown that UV-H treatments result in a synergistic lethal effect with thetemperature of maximum synergism being different for eachbacterial species [8ndash10] However so far our studies havefocused on low pH media where acidity can reduce the heatresistance of bacteria and consequently enhance the effec-tiveness of UV-H treatments Additionally data on food withmore neutral pH are scarce but do include some studies oneggwhite [11ndash13]Therefore the question of whether a similarsynergistic lethal effect could also occur in other liquid foodswith different pH chemical composition and absorptioncoefficients was raised

To challenge the inactivation effect of UV-H treatmentson complex food matrices chicken broth was chosen as amulti-ingredient liquid food with higher pH and a morecomplex chemical composition that provides a favorableenvironment for bacteria The goal of this study was toinvestigate whether the UV-H combined process can beapplied to liquid food that has a high absorption coefficientturbidity and low acidity such as chicken broth resulting in asynergistic lethal effect comparablewithsimilar to thatwhichhas been obtained in the case of fruit juices For this study wehave used the most UV resistant strains of differentpathogenic bacteria as reference microorganisms such asEscherichia coli Salmonella Typhimurium Listeria monocy-togenes and Staphylococcus aureus

2 Materials and Methods

21 Bacterial Culture and Media The strains of E coli STCC4201 Salmonella Typhimurium STCC 878 L monocytogenesSTCC 5672 and S aureus STCC 4465 were obtained from theSpanish Type Culture Collection (STCC) The bacterial cul-tures were maintained frozen at ndash80∘C in cryovials A brothsubculture was prepared by inoculating 10mL of tryptone soybroth (Biolife Milan Italy) supplemented with 06 (wv)yeast extract (Biolife) (TSBYE) with a loopful of growth fromtryptone soy agar (Biolife) supplemented with 06 (wv)yeast extract (TSAYE) The subculture was incubated at 35∘Cfor 6ndash12 h in a shaking incubator (150 rpm Heidolph Instru-ments Vibramax 100 Schwabach Germany) With thesesubcultures 250mL flasks containing 50mL of TSBYE wereinoculated to reach a concentration of 104 CFUmL and thenincubated for 24 h under the same conditions until thestationary growth phase was reached (2 times 109 CFUmL)

22 UV Equipment and Treatments UV treatments werecarried out in a unit with 8 individual annular thin film flow-through reactors connected in a series and equipped with afeed tank and a peristaltic pump (ISM 10785 Ismatec Glat-tbrugg Switzerland) as described previously by Gayan et al[8] Each reactor included a low-pressure mercury vaporlamp (8Wof input power model TUV 8WT5 Philips USA)

which converted 30 of the input power as UV-C radiation(Philips Electronics 2012) emitting 85 of UV-C energy at254 nm The lamp was attached to the axis of an outer glasstube (25mm of inner diameter) and was enclosed using aquartz tube (20mm of outer diameter) to prevent direct con-tact of the lamp with the treatment medium In the annulargap (25mm) a stainless steel coil spring was installed toimprove the flowrsquos turbulence The outside and inside coildiameters of the spring were 23mm and 25mm respectivelyand its length and pitch were 270mm and 10mm respec-tively A manual sampling valve was located in the outlet ofeach reactor The entire unit was submerged in a 90 L waterbath (250ndash600∘C) heated by the circulating water of aperipheral thermostatic bath (Kattebad K12 Huber Offen-burg Germany) The equipment also included a heatingcooling coil exchanger at the inlet of the first reactor Ther-mocouples (ZA 020-FS Almeco Bernburg Germany) fittedto the inlet and outlet of the first and last reactor respectivelyallowed for treatment temperature control

Chicken broth (absorption coefficient = 196 cmminus1 tur-bidity = 4460NTU pH = 52) for use as treatment mediumwas purchased from a local market (Interal SA Spain)Brothrsquos absorption coefficient was measured spectrophoto-metrically (254 nm UV500 Unicam Limited CambridgeUK) Samples were diluted and evaluated using quartzcuvettes (Hellma Mullheim Germany) with path lengths of1mm 2mm and 10mm The absorption coefficient of thediluted samples was determined from the slope of the absorb-ance versus the path length and corrected by the dilutionfactor Turbidity was measured with a nephelometer (HI83749 Hanna Instrument Szeged Hungary) pH was mea-sured using a pH-meter Basic 20 (Crison InstrumentBarcelona Spain) The chicken broth was inoculated withthe bacterial suspension to achieve 105ndash107 CFUmL andpumped (85 Lh) through the heat exchanger to the reactorsWhen the treatment conditions were stabilized samples werewithdrawn through the sampling valves and 01mL or 1mLwas immediately pour-plated into the recovery medium

23 Heat Treatments Heat treatments were carried outin specially designed thermoresistometer TR-SC [14] Thisinstrument consisted of a 400mL vessel with an electri-cal heater for thermostation an agitation device used toensure inoculum distribution and temperature homogeneitya pressurization system and ports for injecting the microbialsuspension and for extraction of samples Once the presettemperature had attained stability (119879 plusmn 005∘C) 02mL of anadequately diluted microbial cell suspension was inoculatedinto the vessel which contained the 350mL of chicken brothAfter inoculation 02mL samples were collected at differentheating times and were immediately pour-plated

24 Incubation of Treated Samples and Survival CountingTSAYE was used as a recovery medium and the plates wereincubated at 35∘C for 24 h for E coli Salmonella Typhim-urium and S aureus and for 48 h for L monocytogenes Afterincubation colony forming units (CFU) were counted usingan improved Image Analyzer Automatic Colony Counter

BioMed Research International 3

(Protos Synoptics Cambridge UK) as described elsewhere[15]

25 Curve Fitting and Dose Calculation Survival curves wereobtained by plotting the logarithm of the survival fractionversusUV dose (119889) expressed in joules per milliliter and time(119905) expressed in minutes for UV and heat treatments respec-tively To compareUV-H treatmentswith thermal treatmentsUV-H survival curves were also expressed in treatmenttime The UV dose delivered to the treatment mediumwas estimated with a chemical dosimeter To this end theiodide-iodate actinometer (quantum yield = 073 plusmn 002)was used following the indications of Rahn et al [16] Theactinometer buffer was pumped through the installation at85 Lh and the increase in absorbance (352 nm) was deter-mined at the outlet of each reactor [8] From this data thephoton flux (254 nm) as received per second by each volumefraction of the treatment medium was estimated accordingto Montalti et al [17] Thus considering the energy of aphoton at 254 nm the UV dose delivered to each reactor was049 JmL

To fit the survival curves obtained at each temperatureand to calculate resistance parameters the GInaFiT inacti-vation model-fitting tool was used [18] Specifically the log-linear regression plus shoulder model from Geeraerd et al[19] was chosen (1) sincemost of the survival curves exhibitedshoulders This model describes the survival curves throughtwo parameters the shoulder length (Sl) defined as doseor time before the exponential inactivation begins and theinactivation rate (119870max) defined as the slope of the expo-nential part of the survival curve 119873

0and 119873

119905represent the

initial numbers of the microbial population and the numberof microorganisms that survive at the end of the treatmenttime (119905) respectively Consider the following equation

119873119905= 1198730119890minus119870maxSl(

119890119870maxSl

1 + (119890119870maxSl minus 1) 119890119870max 119905

) (1)

To describe the relationship between treatment temperature(119879) and Sl and 119870max parameters mathematical equationsbased on the Weibull distribution were chosen For Sl theequation introduced by Albert and Mafart [20] (2) was usedas a secondary model whereas the thermodependence of119870max was described using the mirror image of theMafart [21]model (3)

Sl119879= (Sl0minus Slres) 10

minus(119905120575)119901

+ Slres (2)

119870max119879 = lfloor119870max 010minus(119905120575)

119901

rfloor (3)

where Sl119879and119870max119879 are the shoulder length and the inactiva-

tion rate of UV-H treatments at temperature 119879 respectivelySl0and 119870max 0 are the shoulder length and the inactiva-

tion rate of the survival curves of UV treatments at roomtemperature respectively and Slres is the residual shoul-der when the treatment temperature was increased 120575 and119901 are respectively the scale and shape parameters The 120575value represents the temperature increase necessary toachieve the first decimal reduction of Sl or 119870max (from Sl

0

and 119870max 0 to Sl010 and 119870max 010) The 119901 parameter (119901 gt 1)

accounts for the profile of the downward concavity of curves[20 21]

For the heat survival curves which showed an initialshoulder phase the Geeraerd model was also used as aprimary model In order to study the relationship betweenthe inactivationmodel parameters and the treatment temper-ature Albert and Mafartrsquos equation [20] was used for Sl asdescribed above and simple log-linear equations were usedfor 119870max while the slope and the intercept of the regressionline were considered model parameters The coefficient ofdetermination (1198772) the root mean square error (RMSE) thebias (119861

119891) and accuracy (119860

119891) factors were used to determine

the goodness of fits of both the primary and the secondarymodels as well as the accuracy of the final equations [22]The bias factor indicates systematic over-(119861

119891gt 1) or under-

(119861119891lt 1) prediction of the observed data On the other hand

the accuracy factor indicates the extent to which the predic-tions differ from the observed data

26 Statistical Analyses Statistical analyses a 119905-test and anANOVA test were carried out using the GraphPad PRISM50 software (GraphPad Inc SanDiego CA USA) and differ-ences were considered significant for 119875 le 005 All microbialresistance determinations as well as analytical assays wereperformed at least three times on different workings daysThe error bars in the figures correspond to themean standarddeviation

3 Results and Discussion

This study investigated the thermodependence of the UVinactivation of pathogenic bacteria in chicken broth Theintention was to establish the UV-H treatment conditions(process criteria) necessary for obtaining a certain level ofinactivation of the pathogenic microorganisms of referenceFor this purpose the effect of temperature on theUV lethalityof UV tolerant strains of E coli (STCC 4201) SalmonellaTyphimurium (STCC 878) L monocytogenes (STCC 5672)and S aureus (STCC 4465) was assessed The strains usedin this investigation were the most UV resistant among fivedifferent strains of each investigated microorganism accord-ing to previous studies [8 23ndash25] carried out under the samemethodology In particular the selected strains of E coliSalmonella Typhimurium L monocytogenes and S aureuswere 156 151 158 and 27 more resistant than the secondmost resistant strain of each microorganism

To describe this influence and to define the processcriteria mathematical equations including UV dose timeand temperature have been developed In order to compareresults the heat resistance of the indicated microorganismswas also investigated and modeled

31 Microbial Inactivation by UV-H Treatments in ChickenBroth The survival curves of E coli Salmonella Typhim-urium L monocytogenes and S aureus to UV treatments atroom temperature and at 500 525 550 575 and 600∘C(UV-H) are presented in Figure 1 An initial lag phase

4 BioMed Research International

Dose (JmL)

00 05 10 15 20 25 30 35 40

00 06 11 16 22 44383327

Limit of detection

Time (min)

0

minus1

minus2

minus3

minus4

minus5

minus6

minus7

25∘C

Log 1

0(N

tN0)

Dose (JmL)

00 05 10 15 20 25 30 35 40

Time (min)

0

minus1

minus2

minus3

minus4

minus5

minus6

minus7 Limit of detection

00 06 11 16 22 44383327

50∘C

Log 1

0(N

tN0)

00 05 10 15 20 25 30 35 40

Limit of detection

Time (min)

525∘C

0

minus1

minus2

minus3

minus4

minus5

minus6

minus7

Dose (JmL)00 06 11 16 22 44383327

Log 1

0(N

tN0)

Dose (JmL)

00 05 10 15 20 25 30 35 40

Limit of detection

00 06 11 16 22 44383327

Time (min)

0

minus1

minus2

minus3

minus4

minus5

minus6

minus7

55∘CLo

g 10(N

tN0)

00 05 10 15 20 25 30 35 40

Limit of detection

Time (min)

Dose (JmL)00 05 11 16 22 44373327

0

minus1

minus2

minus3

minus4

minus5

minus6

minus7

575∘C

Log 1

0(N

tN0)

00 4437332722161105

Dose (JmL)

00 05 10 15 20 25 30 35 40

Limit of detection

Time (min)

0

minus1

minus2

minus3

minus4

minus5

minus6

minus7

60∘C

Log 1

0(N

tN0)

Figure 1 Survival curves of E coli (STCC 4201) (◼) Salmonella Typhimurium (STCC 878) (998771) L monocytogenes (STCC 5672) (e) and Saureus (STCC 4465) (X) to UV treatment at room temperature (25∘C) and to combined UV-H treatments at 500∘C 525∘C 550∘C 575∘Cand 600∘C in chicken broth

BioMed Research International 5

(shoulder) was observed formost of the survival curves Afterthis the microbial death followed a logarithmic order butno tailing took place UV-H inactivation curves displayedshoulder phases which are often observed in survival curvesfor UV-C light [26 27] According to the ldquomultihit targettheoryrdquo shoulders are related to the DNA damage and repairphenomena [28] DNA repair systems can repair damageup to certain UV doses resulting in shoulders Once themaximum DNA repair capability is surpassed additionalUV exposure is lethal for microorganisms and survivorsexponentially decline [29]

When the maximum UV dose possible in one passthrough the equipment (392 JmL) was applied UV treat-ments at room temperature (25∘C) decreased the microbialpopulation of the investigated bacteria from 5-Log

10cycles

for E coli and S aureus to 3-Log10

cycles for SalmonellaTyphimurium and L monocytogenes which showed thehighest UV resistance (Figure 1) This level of inactivationfor the same bacteria was higher than that observed in otherproducts like fruit juices that have lower turbidity but higherabsorption coefficient Thus Gouma et al [30] observedhardly 1-Log

10reductions of these microorganisms in apple

juice (turbidity 74 NTU 120572 = 24 cmminus1) after applying the sameUV treatment at 25∘C in the same facility Since pH did notaffect the UV lethality [23] and since the turbidity of thechicken broth (4460 NTU) was higher than that of the applejuice the larger inactivation observed in this investigationcould be due to the slightly lower absorption coefficient ofthe chicken broth (196 cmminus1) compared to that of the applejuice This lower absorption coefficient would cause less UV-C light to be absorbed by the treatment medium meaningthat the same UV dose would have more bactericidal effectin the chicken broth than in the apple juice [8] Alsoany component of the chicken broth could interact on themicrobial UV resistance thereby increasing the UV lethality

Although 3-Log10

cycles of inactivation were achievedafter the maximum applied UV dose at 25∘C for all the inves-tigated pathogenic microorganisms which were selected inprevious studies due to their being the most UV resistant[8 23ndash25] a reduction of 999 of the microbial populationcould not be sufficient to ensure the safety of chicken brothfor example at least 5-Log

10reductions of the pathogen of

reference are necessary for the pasteurization of fruit juices[31] Therefore it would be necessary to increase the lethalityof UV treatments

The application of UV at moderate temperatures hasresulted in a synergistic increase of UV lethality [11 13] Inthis investigation when the treatment temperaturewas raisedbetween 500∘C and 600∘C (Figure 1) the UV inactivationof all investigated microorganisms improved considerablyFor instance the UV inactivation of the most resistantmicroorganism L monocytogenes with a dose of 245 JmL(223min) increased from 134-Log

10cycles at 25∘C to 187

196 248 366 and 535-Log10

cycles at 500∘C 525∘C550∘C 575∘C and 600∘C respectively These results indi-cated that combining UV light with mild heat increased theUV inactivation of microorganisms in chicken broth whichparalleled the observation of a higher effect of UV and heatin other food products This fact suggests the possibility of

designing a feasible UV-H hygienization process for this kindof product (ie broth) which is apparently difficult to treatwith this technology due to its high turbidity and absorptioncoefficient

Although an increment of the UV lethality has beenobserved when augmenting the temperature the differentbehavior of E coli Salmonella Typhimurium L monocy-togenes and S aureus in response to UV-H treatments inrelation to the treatment temperature makes it difficult tocompare data Moreover the obtained survival curvesshowed shoulders at lower temperatures that disappearedwhen the temperature was increased which limited the appli-cation of simpler first order inactivation kineticsTherefore itwas necessary to develop mathematical models that enabledan evaluation of the effect of temperature on UV lethality inchicken broth for each investigated microorganism

To describe UV-H inactivation kinetics the log-linearregression plus the shoulder model of Geeraerd et al [19](1) (primary model) was used because it allowed the lengthof the shoulders and the log-linear rate of inactivation to beaccurately and independently described Table 1 includes theaverages and the standard deviations of themodel parameters(119870max and Sl) expressed in time terms obtained from thefitting of the UV-H survival curves of all microorganismstested at different temperatures The coefficient of determi-nation (1198772) and the root mean square error (RMSE) valuesare also included to illustrate the goodness of the fits Asobserved the UV lethality improved when the treatmenttemperature was raised and stemmed from the decrease ofthe shoulder phase (Sl) of the UV-H survival curves until itdisappeared In addition the slope of the survival curves(119870max) increased with the rising temperature Furthermorethe UV resistance variability between species wasmaintainedat different temperatures and was reflected in the Sl and119870maxvalues Thus the higher resistance of L monocytogenes wasdue to larger values of Sl and smaller values of 119870max On thecontrary S aureus was the most sensitive microorganismshowing smaller Sl values and higher 119870max ones Finally theGram negative bacteria E coli and Salmonella Typhimuriumshowed a similar behavior and Sl and119870max values In generalit is believed that Gram positive bacteria are more UVresistant than Gram negative which can be attributed to thethicker peptidoglycan cell wall of the former [32 33] In thisstudy the UV resistance of S aureus at 25∘C was similarto that of E coli and slightly lower than that of SalmonellaTyphimurium which demonstrates that this statementshould not be considered a general rule In fact other authorshave reported a higher susceptibility of S aureus to UVtechnologies compared with coliforms [34 35] At highertemperatures that statement cannot bemaintained since heatinterferes on the microbial UV resistance For example thehighest UV-H lethality for S aureus would be due to thehigher heat sensitivity of this microorganism compared withthe other investigated bacteria as it will presented later on

To describe the effect of the changes in temperature on thekinetic parameters obtained after fitting the primary modelto the UV-H inactivation data of E coli Salmonella Typhim-urium S aureus and L monocytogenes in chicken broth(shown in Table 1) the corresponding secondary models for

6 BioMed Research International

Table 1 Resistance parameters (Sl and 119870max) obtained from the fit of UV-H survival curves of E coli Salmonella Typhimurium S aureusand L monocytogenes at different temperatures in chicken broth to Geeraerdrsquos model (1) Estimated standard deviations (SD) of the meansare in parentheses Letters a b c and d indicate statistically significant differences (119875 le 005) among Sl and 119870max values of UV-H survivalcurves of different microorganisms at the same treatment temperature

Microorganism Temperature (∘C) Sl (min) 119870max (minminus1) RMSE R2

Escherichia coli

250 067 (009)a 366 (034)a 0152 0994500 068 (015)a 431 (022)a 0185 0993525 055 (016)a 459 (020)a 0228 0990550 033 (011)a 506 (034)a 0229 0991575 010 (006)a 600 (043)a 0329 0985600 000 (000)a 733 (062)a 0153 0996

Salmonella Typhimurium