Research Article Noncontact Optical Fiber Sensor for...

Transcript of Research Article Noncontact Optical Fiber Sensor for...

Research ArticleNoncontact Optical Fiber Sensor for Measuring the RefractiveIndex of Liquids

R Selvas-Aguilar1 A Castillo-Guzman1 L Cortez-Gonzalez1 D Toral-Acosta1

A Martinez-Rios2 G Anzueto-Sanchez3 V M Duran-Ramirez4 and S Arroyo-Rivera1

1Facultad de Ciencias Fısico Matematicas Universidad Autonoma de Nuevo Leon Avenida Universidad SNCd Universitaria 66455 San Nicolas de los Garza NL Mexico2Centro de Investigaciones en Optica AC Loma del Bosque 115 37150 Leon GTO Mexico3Centro de Investigacion en Ingenieria y Ciencias Aplicadas Universidad Autonoma del Estado de MorelosAvenida Universidad No 1001 Colonia Chamilpa 62209 Cuernavaca MOR Mexico4Centro Universitario de los Lagos Universidad Autonoma de Guadalajara Enrique Diaz de Leon 114447460 Lagos de Moreno JAL Mexico

Correspondence should be addressed to R Selvas-Aguilar rselvasgmailcom

Received 27 November 2015 Accepted 17 February 2016

Academic Editor Xingwei Wang

Copyright copy 2016 R Selvas-Aguilar et al This is an open access article distributed under the Creative Commons AttributionLicense which permits unrestricted use distribution and reproduction in any medium provided the original work is properlycited

A noncontact optical fiber sensor formeasuring the refractive index of transparent liquids is proposed It operates by calculating thepath of a focused laser beam at 635 nm that travels across the boundaries of a liquid sample The optical power Fresnel reflectionsare detected and subsequently the refractive index is determined as the ratio between the traveled beam paths when the liquid isdeposited versus a reference without the liquid sample Additionally a mathematical analysis of the geometrical case is includedThe theoretical data from our sensor are in good agreement with the experimental results The resolution achieved by the sensor isbetter than 10minus3 RIU

1 Introduction

In recent years sensor devices have been widely used forphysical and chemical quantitiesmeasurements in someman-ufacturing processes and gadgets such as small size and highsensitivity sensors [1] These kinds of sensors have gainedgreat interest because of their wide demand for implemen-tation in many industrial processes Such processes requirethe monitoring of certain properties in liquids for examplethese kinds of sensors are used in fields of study such as thechemicals food industry biotechmedicalmeasurement andenvironment assessment or in research laboratories

Some properties of these liquids such as the refractiveindex have been considered as one of the most importantparameters used to be monitored A well-known device typi-cally used for this purpose is the traditional Abbe refractome-ter [2] or in a similar way one can find setups that employthe ray deviation through a glass-liquid interface to measure

the refractive index of transparent liquids [3ndash5]Those worksoffer accurate results but under the point of view of simplicityand compactness they result rather in being bulky Notwith-standing recent advances in optoelectronics have motivatedthe development of novel fiber-optic refractive index (RI)sensors Fiber-optic based sensors have therefore the sameadvantages attributable to other sensors plus the advantagesowing to their waveguide their electromagnetic immunityand their remote sensing capability among others Regardingthese novel devices there are a couple of research groups[6 7] who demonstrated that by using the Fresnel reflectionsexhibited at the liquid-glass interface of fiber probes it ispossible to obtain a ratio between a reference and a test signalto calculate liquids refractive indices More recently anothersetup also based on a Fresnel reflection added only an opticalswitch to obtain the signal ratios resulting in an enhancedaccuracy for the measurement of RI [8] additionally in [9]a time-delayed optical signal through a remote large fiber

Hindawi Publishing CorporationJournal of SensorsVolume 2016 Article ID 3475782 6 pageshttpdxdoiorg10115520163475782

2 Journal of Sensors

Port 1

Port 2

Photodetector

processingData

Port 3

Port 4

Liquid sample

Reflective surface

Lenses

scanningz-axis

cleaved fiberAngle facet

Optical coupler

LD 635nm

3 (dB)

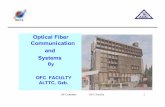

Figure 1 Optical fiber refractometer setup

segment is employed to obtain the same signal ratio in themeasurement A slightly different approach uses a taperedoptical fiber [10 11] where the immersion of a fiber-taperedsection in the liquid sample produces changes in the evanes-cent field which allow calculating the RI Finally in [12] themeasurement process of the RI was based on the shift in theinterference pattern as a result of a fiber inline micronotchcavity The results of the above-cited works are important inmeasurements where the immersion of the fiber probe intothe liquid sample is necessary however it can be a potentialdrawback when a noncontact measurement is required

In this paper a versatile noncontact optical fiber sensorfor measuring the refractive index of a transparent liquid isproposed This setup employs a laser diode at 635 nm andoperates as a function of the launched light into the bound-aries of a liquid sample By means of the back-reflectedoptical intensities in a photodetector the RI is consequentlycalculated as the ratio between the traveled beam paths whenliquid is deposited versus a reference without the liquid sam-ple The system proved to be compact robust repeatableand reliable and unlike liquid-glass fiber-based sensors oursystem operates without the requirement of immersion ofthe fiber probe into the liquid sample Interestingly since theterminal sensor is not required in a degradation process thissensor guarantees a longer lifetime due to its lowmaintenancerequirements Furthermore a mathematical analysis of thegeometrical case for the refractive index principle is shownThe theoretical data calculated from our sensor are in goodagreement with the experimental results Refractive indicesof the tested liquids weremeasured at a wavelength of 635 nmand with a resolution of 10minus3 RIU

2 Optical Fiber Refractometer

Figure 1 shows the experimental setup of the refractometerIt consists of an optical fiber-based setup and a laser lightAttached to amotorized 119911-axismechanism theymake a scan-ning sweep along its vertical 119911-axis to get the correspondingretroreflected optical power for every step along the way

A stabilized laser source at 635 nm (Thorlabs LPS-635-FC) with controlled temperature is fusion-spliced to port 1of a 3 dB optical fiber coupler (2 times 2 wideband fiber opticalcoupler 630 nmThorlabs TW630R5F2) as shown in Figure 1Coupled to fiber end (single mode fiber 600 to 860 nmThorlabs SM600) at port 4 a pair of lenses collimates andfocuses the laser beam this arrangement serves as the fiberprobe for the sensorTheproposed positioning scheme for the119911-axis-scanner mechanism is based on a motorized actuator[16] (Thorlabs Z812B) which is set to allow moving the fiberprobe backward and forward along all the way of the liquidsample under test Every position where the focused lightis set to reach the boundaries of two different planar mediacorresponds to a Fresnel reflection which retroreflects theoptical power back to the fiber probe For this reason a fiber-pigtailed photodetector (Thorlabs FDSP660) is spliced to port2 in order to measure the retroreflected optical power

It is worthmentioning that the fiber in port 3 of the opticalcoupler has an angle facet cleaved to prevent any feedbackof light which in turn could cause a significant error in ourmeasurement

3 Mathematical Analysis for Refractive IndexMeasurement

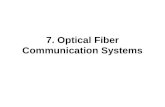

Let us now consider that the sample is illuminated by the fiberprobersquos output laser beam Tracing the incident and refractedrays at the interface of two different media with refractiveindexes 119899

1

and 1198992

and the lengths ℎ1

and ℎ2

in Figure 2 it ispossible to write the following geometrical analysis

Using Snellrsquos law

1198991

sin 1205791

= 1198992

sin 1205792

(1)

Considering the geometry of the angles we can demon-strate that

1198992

= 1198991

(

1

1199031

) 1199032

(2)

Journal of Sensors 3

1205792

12057911205791

1205792

n1

n2

y

h1

h2r21205792

r11205791

Figure 2 Geometrical analysis of refracted light

Equation (2) can be also stated in terms of the incidentangle and the values of ℎ

1

and ℎ2

as follows

1198992

= 1198991

(

cos 1205791

ℎ1

)radic1199102

+ ℎ2

2

(3)

Given the fact that 119910 has the same value for both angleswe can express (3) in terms of the incident angle and thereforeget the resultant equation for the refractive index of thesample which can finally be stated as

1198992

= 1198991

(

cos 1205791

ℎ1

)radic(ℎ2

1

tan2 1205791

) + ℎ2

2

(4)

4 Measurement Process

The operation principle of the refractometer is based on theoptical path length traveled by a ray of light to reach a mirrortarget through a sample and without it For this purpose itis then necessary to know the thickness of the sample Ingeneral this can be obtained given the fact that in every pla-nar interface between the two media a high intensity Fresnelreflection is exhibited each time such interfaces are reachedby the focal point

Given the experimental setup and the analysis of themathematical model applicable to describe the refractometerin Section 3 a method must be provided to find the values ofℎ1

and ℎ2

A better understanding of this can be achieved byconsidering the details of the whole measurement process

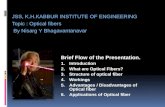

Regarding Figure 3 if we assume that the motorizedmechanism starts moving from the zero-reference positionthe laser focal point will sometime reach a reflective interface(ie air-liquid liquid-metallic mirror or air-metallic mirrorinterface) Subsequently the retroreflected light enters backinto the fiber probe and it is then guided to the opticalfiber coupler where a photodetector will receive the reflectedoptical power and convert it into a voltage signal For each 119911-axis position where the focal point reaches one high reflectivesurface the voltage signal exhibits a local maximum Finallythe voltage signal is computer-monitored and plotted for eachvertical position

Once a scanning sweep is performed it is possible to findthe desired ℎ

1

and ℎ2

values From Figures 2 and 3 it can beconfirmed that

ℎ1

=10038161003816100381610038161198713

minus 1198712

1003816100381610038161003816 (5)

where 1198712

is the distance from the reference position to thesample surface and 119871

3

is the required displacement from thereference to a position such that the focal point of the lighthas completely penetrated the sample and reached the sampleholderrsquos reflective bottom

Additionally we can calculate ℎ2

as

ℎ2

=10038161003816100381610038161198711

minus 1198712

1003816100381610038161003816 (6)

where 1198711

is the distance of the sample holderrsquos bottom withrespect to the reference position

Consequently the measurement process can be done interms of the values 119871

1

1198712

and 1198713

In order to complete theprocess it is necessary to implement only two steps (i) with-out a sample in the sample holder a scanning sweep must becarried out to obtain 119871

1

and (ii) with a layer of sample addedin the sample holder 119871

2

and 1198713

must be obtained

5 Experimental Results

To determine the repeatability and accuracy in the experi-ment a series of measurements were performed On the onehand by choosing randomly two different samples standarddeviation was obtained out of 10 measured valuesThe resultsshowed an agreement better than 10minus3 See Figure 4

On the other hand in order to verify the accuracy ofour device at different sample thickness somemeasurementswere performed using glycerin The obtained error remainedin a value lt 10minus3 See Figure 5 Moreover the sensor exhibitedgood performance evenwhen thickness was reduced down tosim1mm which corresponds to 10 of the focal length of theoptical system

Table 1 shows a comparison between the refractive indexvalues obtained for different substance samples measuredby our refractometer (patent pending) [17] with respect tothe values obtained using a commercial analog Abbe refrac-tometer (model Atago 1T) An additional column shows the

4 Journal of Sensors

Lens

Lens

Lens

Lenss

Lenss

Leens

Disp

lace

men

t

Low HighVoltage

L1

0

(a)

Disp

lace

men

t

Low

Lens

Lens

Lens

HighVoltage

L2

L3

Sample

0

(b)

Figure 3 Obtaining process of the refractive index (a) Measurement implemented with an empty sample holder shows a single reflectivesurface (b) Measurement with a liquid sample on the sample holder gives two reflective surfaces

14601465147014751480

13701375138013851390

Refr

activ

e ind

ex

Glycerin

Refr

activ

e ind

ex

Isopropyl alcohol

Measurement11109876543210

Measurement11109876543210

913E minus 4Error

Error 8859E minus 4

Figure 4 Standard deviation in measurements with glycerin and isopropyl alcohol Straight lines (horizontal) represent reported values

Journal of Sensors 5

Table 1 Comparison of results with reported values

Substance Proposed refractometer (25∘C) Commercial Abbe refractometer (235∘C) Reported in literature[2 13ndash15]

Distilled water 13346 13344 13327 (25∘C)Hydrogen peroxide (40wt) 13579 13625 13598 (25∘C)Glycerin 14757 14685 14739 (20∘C)Isopropyl alcohol 13798 13819 1378 (20∘C)

1 2 3 414601465147014751480

14601465147014751480

14601465147014751480

Refr

activ

e ind

exRe

frac

tive i

ndex

Refr

activ

e ind

ex

Number of experiments

1 2 3 4Number of experiments

1 2 3 4Number of experiments

29mm thickness

36mm thickness

6mm thickness

Figure 5 Measurements with different thicknesses of glycerinsamples showed an error lt 10minus3 Straight lines (horizontal) representthe reported value of glycerin

corresponding refractive index values of the same substancesreported in literature

It is worth mentioning that each measured refractiveindex exhibited small deviationswith respect to reference val-ues reportedThe fact that reported values of refractive indexin literature are given for a sodium D-line (589 nm) must beconsidered while in our system a 635 nm laser wavelengthwas used In fact most measured substances show a decreas-ing refractive index as the wavelength increases On the otherhand the optical power of the laser used for the measure-mentswas 04mWwhichmeans that we can discard any ther-mal issue related to the incident light over the amount of ana-lyzed substance We registered all the measurements in a lab-controlled temperature performing the experiment in about6 seconds We addressed possible shake issues by attachingthe motorized 119911-axis-mechanism to an overweighed plate

6 Conclusions

The mathematical analysis and the obtained experimentalresults demonstrated that the deviation of the principal rayof the laser beam when it emerges from the sample holder byFresnel reflection throughout a transparent liquid sample andwithout it can be determined in terms of the scanning dis-placements that set the focal point of the focused beam at theboundaries of the liquid sample As a result we can determinethe refractive index of the liquid with simple measurementswithout the requirement of physical contact The measuredrefractive index values of liquids such as distilled waterhydrogen peroxide glycerin and isopropyl alcohol closelyagree with the reported values and themeasured values usinga commercial refractometer The optical system exhibited agood accuracy for thicknesses as low as 1mm under thechosen lenses for the fiber probe Smaller thickness resultedin an inaccurate calculation of RI

Competing Interests

The authors declare that they have no competing interests

Acknowledgments

This work was supported in part by the Scientific and Tech-nology Research Support Program (PAICyT) hosted by theUniversidad Autonoma de Nuevo Leon (UANL) ProjectsEstudio y Caracterizacion de Linternas Fotonicas de ModosSelectivos (MSPLs) IT1047-11 CA354 and IT1087-11 bySecretarıa de Educacion Publica by Projects PROFOCIE2015 PRODEP-REDES 10351511043 and by the PROMEPhosted by UANL Project 1035136444 D Toral-Acosta wassupported by theNationalCouncil of Science andTechnology(CONACyT) Grant no 260496 The authors also want tothank to Adriana Linan Montes Daniel Ceballos HerreraHelena de los Reyes and Jaime Reyes for their valuable com-ments on the paper

References

[1] S Yio P B B Ruffin F T S Yu and S Yin Fiber Optic SensorsMarcel Dekker New York NY USA 2008

[2] J Rheims J Koser and T Wriedt ldquoRefractive-index measure-ments in the near-IR using an Abbe refractometerrdquo Measure-ment Science and Technology vol 8 no 6 pp 601ndash605 1997

[3] M Daimon and A Masumura ldquoMeasurement of the refractiveindex of distilled water from the near-infrared region to the

6 Journal of Sensors

ultraviolet regionrdquoApplied Optics vol 46 no 18 pp 3811ndash38202007

[4] S Nemoto ldquoMeasurement of the refractive index of liquid usinglaser beam displacementrdquo Applied Optics vol 31 no 31 pp6690ndash6694 1992

[5] F Docchio S Corini M Perini and R S Gasana ldquoA simpleand reliable system for measuring the refractive index of liq-uids using a position-sensitive detectorrdquo IEEE Transactions onInstrumentation and Measurement vol 44 no 1 pp 68ndash701995

[6] P Nath H K Singh P Datta and K C Sarma ldquoAll-fiber opticsensor for measurement of liquid refractive indexrdquo Sensors andActuators A Physical vol 148 no 1 pp 16ndash18 2008

[7] C-B Kim and C B Su ldquoMeasurement of the refractive indexof liquids at 13 and 15 micron using a fibre optic Fresnel ratiometerrdquo Measurement Science and Technology vol 15 no 9 pp1683ndash1686 2004

[8] W Xu X G Huang and J S Pan ldquoSimple fiber-optic refractiveindex sensor based on fresnel reflection and optical switchrdquoIEEE Sensors Journal vol 13 no 5 pp 1571ndash1574 2013

[9] J Yuan C Zhao M Ye J Kang Z Zhang and S Jin ldquoA Fresnelreflection-based optical fiber sensor system for remote refrac-tive indexmeasurement using an OTDRrdquo Photonic Sensors vol4 no 1 pp 48ndash52 2014

[10] J-F Ding A P Zhang L-Y Shao J-H Yan and S He ldquoFiber-taper seeded long-period grating pair as a highly sensitiverefractive-index sensorrdquo IEEE Photonics Technology Letters vol17 no 6 pp 1247ndash1249 2005

[11] A Iadicicco A Cusano A Cutolo R Bernini and MGiordano ldquoThinned fiber Bragg gratings as high sensitivityrefractive index sensorrdquo IEEE Photonics Technology Letters vol16 no 4 pp 1149ndash1151 2004

[12] T Wei Y Han Y Li H-L Tsai and H Xiao ldquoTemperature-insensitive miniaturized fiber inline Fabry-Perot interferome-ter for highly sensitive refractive index measurementrdquo OpticsExpress vol 16 no 8 pp 5764ndash5769 2008

[13] P R Cooper ldquoRefractive-Index measurements of liquids usedin conjunction with optical fibersrdquo Applied Optics vol 22 no19 pp 3070ndash3072 1983

[14] EMoreels C deGreef andR Finsy ldquoLaser light refractometerrdquoApplied Optics vol 23 no 17 pp 3010ndash3013 1984

[15] httpwwwrefractometerplrefraction-datasheet-basic[16] httpwwwthorlabscomnewgrouppage9cfmobjectgroup id=

1882amppn=Z812B2497[17] R Selvas A Castillo L Cortez and D Toral ldquoSistema Detector

de no contacto de Espesor y Propiedades Opticas en Materialesy Lıquidos Apilados o Crecidos en Multicapasrdquo IMPI Patenteno MXE2014064537 2014

International Journal of

AerospaceEngineeringHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

RoboticsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Active and Passive Electronic Components

Control Scienceand Engineering

Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

RotatingMachinery

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporation httpwwwhindawicom

Journal ofEngineeringVolume 2014

Submit your manuscripts athttpwwwhindawicom

VLSI Design

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Shock and Vibration

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Civil EngineeringAdvances in

Acoustics and VibrationAdvances in

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Electrical and Computer Engineering

Journal of

Advances inOptoElectronics

Hindawi Publishing Corporation httpwwwhindawicom

Volume 2014

The Scientific World JournalHindawi Publishing Corporation httpwwwhindawicom Volume 2014

SensorsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Modelling amp Simulation in EngineeringHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Chemical EngineeringInternational Journal of Antennas and

Propagation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Navigation and Observation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

DistributedSensor Networks

International Journal of

2 Journal of Sensors

Port 1

Port 2

Photodetector

processingData

Port 3

Port 4

Liquid sample

Reflective surface

Lenses

scanningz-axis

cleaved fiberAngle facet

Optical coupler

LD 635nm

3 (dB)

Figure 1 Optical fiber refractometer setup

segment is employed to obtain the same signal ratio in themeasurement A slightly different approach uses a taperedoptical fiber [10 11] where the immersion of a fiber-taperedsection in the liquid sample produces changes in the evanes-cent field which allow calculating the RI Finally in [12] themeasurement process of the RI was based on the shift in theinterference pattern as a result of a fiber inline micronotchcavity The results of the above-cited works are important inmeasurements where the immersion of the fiber probe intothe liquid sample is necessary however it can be a potentialdrawback when a noncontact measurement is required

In this paper a versatile noncontact optical fiber sensorfor measuring the refractive index of a transparent liquid isproposed This setup employs a laser diode at 635 nm andoperates as a function of the launched light into the bound-aries of a liquid sample By means of the back-reflectedoptical intensities in a photodetector the RI is consequentlycalculated as the ratio between the traveled beam paths whenliquid is deposited versus a reference without the liquid sam-ple The system proved to be compact robust repeatableand reliable and unlike liquid-glass fiber-based sensors oursystem operates without the requirement of immersion ofthe fiber probe into the liquid sample Interestingly since theterminal sensor is not required in a degradation process thissensor guarantees a longer lifetime due to its lowmaintenancerequirements Furthermore a mathematical analysis of thegeometrical case for the refractive index principle is shownThe theoretical data calculated from our sensor are in goodagreement with the experimental results Refractive indicesof the tested liquids weremeasured at a wavelength of 635 nmand with a resolution of 10minus3 RIU

2 Optical Fiber Refractometer

Figure 1 shows the experimental setup of the refractometerIt consists of an optical fiber-based setup and a laser lightAttached to amotorized 119911-axismechanism theymake a scan-ning sweep along its vertical 119911-axis to get the correspondingretroreflected optical power for every step along the way

A stabilized laser source at 635 nm (Thorlabs LPS-635-FC) with controlled temperature is fusion-spliced to port 1of a 3 dB optical fiber coupler (2 times 2 wideband fiber opticalcoupler 630 nmThorlabs TW630R5F2) as shown in Figure 1Coupled to fiber end (single mode fiber 600 to 860 nmThorlabs SM600) at port 4 a pair of lenses collimates andfocuses the laser beam this arrangement serves as the fiberprobe for the sensorTheproposed positioning scheme for the119911-axis-scanner mechanism is based on a motorized actuator[16] (Thorlabs Z812B) which is set to allow moving the fiberprobe backward and forward along all the way of the liquidsample under test Every position where the focused lightis set to reach the boundaries of two different planar mediacorresponds to a Fresnel reflection which retroreflects theoptical power back to the fiber probe For this reason a fiber-pigtailed photodetector (Thorlabs FDSP660) is spliced to port2 in order to measure the retroreflected optical power

It is worthmentioning that the fiber in port 3 of the opticalcoupler has an angle facet cleaved to prevent any feedbackof light which in turn could cause a significant error in ourmeasurement

3 Mathematical Analysis for Refractive IndexMeasurement

Let us now consider that the sample is illuminated by the fiberprobersquos output laser beam Tracing the incident and refractedrays at the interface of two different media with refractiveindexes 119899

1

and 1198992

and the lengths ℎ1

and ℎ2

in Figure 2 it ispossible to write the following geometrical analysis

Using Snellrsquos law

1198991

sin 1205791

= 1198992

sin 1205792

(1)

Considering the geometry of the angles we can demon-strate that

1198992

= 1198991

(

1

1199031

) 1199032

(2)

Journal of Sensors 3

1205792

12057911205791

1205792

n1

n2

y

h1

h2r21205792

r11205791

Figure 2 Geometrical analysis of refracted light

Equation (2) can be also stated in terms of the incidentangle and the values of ℎ

1

and ℎ2

as follows

1198992

= 1198991

(

cos 1205791

ℎ1

)radic1199102

+ ℎ2

2

(3)

Given the fact that 119910 has the same value for both angleswe can express (3) in terms of the incident angle and thereforeget the resultant equation for the refractive index of thesample which can finally be stated as

1198992

= 1198991

(

cos 1205791

ℎ1

)radic(ℎ2

1

tan2 1205791

) + ℎ2

2

(4)

4 Measurement Process

The operation principle of the refractometer is based on theoptical path length traveled by a ray of light to reach a mirrortarget through a sample and without it For this purpose itis then necessary to know the thickness of the sample Ingeneral this can be obtained given the fact that in every pla-nar interface between the two media a high intensity Fresnelreflection is exhibited each time such interfaces are reachedby the focal point

Given the experimental setup and the analysis of themathematical model applicable to describe the refractometerin Section 3 a method must be provided to find the values ofℎ1

and ℎ2

A better understanding of this can be achieved byconsidering the details of the whole measurement process

Regarding Figure 3 if we assume that the motorizedmechanism starts moving from the zero-reference positionthe laser focal point will sometime reach a reflective interface(ie air-liquid liquid-metallic mirror or air-metallic mirrorinterface) Subsequently the retroreflected light enters backinto the fiber probe and it is then guided to the opticalfiber coupler where a photodetector will receive the reflectedoptical power and convert it into a voltage signal For each 119911-axis position where the focal point reaches one high reflectivesurface the voltage signal exhibits a local maximum Finallythe voltage signal is computer-monitored and plotted for eachvertical position

Once a scanning sweep is performed it is possible to findthe desired ℎ

1

and ℎ2

values From Figures 2 and 3 it can beconfirmed that

ℎ1

=10038161003816100381610038161198713

minus 1198712

1003816100381610038161003816 (5)

where 1198712

is the distance from the reference position to thesample surface and 119871

3

is the required displacement from thereference to a position such that the focal point of the lighthas completely penetrated the sample and reached the sampleholderrsquos reflective bottom

Additionally we can calculate ℎ2

as

ℎ2

=10038161003816100381610038161198711

minus 1198712

1003816100381610038161003816 (6)

where 1198711

is the distance of the sample holderrsquos bottom withrespect to the reference position

Consequently the measurement process can be done interms of the values 119871

1

1198712

and 1198713

In order to complete theprocess it is necessary to implement only two steps (i) with-out a sample in the sample holder a scanning sweep must becarried out to obtain 119871

1

and (ii) with a layer of sample addedin the sample holder 119871

2

and 1198713

must be obtained

5 Experimental Results

To determine the repeatability and accuracy in the experi-ment a series of measurements were performed On the onehand by choosing randomly two different samples standarddeviation was obtained out of 10 measured valuesThe resultsshowed an agreement better than 10minus3 See Figure 4

On the other hand in order to verify the accuracy ofour device at different sample thickness somemeasurementswere performed using glycerin The obtained error remainedin a value lt 10minus3 See Figure 5 Moreover the sensor exhibitedgood performance evenwhen thickness was reduced down tosim1mm which corresponds to 10 of the focal length of theoptical system

Table 1 shows a comparison between the refractive indexvalues obtained for different substance samples measuredby our refractometer (patent pending) [17] with respect tothe values obtained using a commercial analog Abbe refrac-tometer (model Atago 1T) An additional column shows the

4 Journal of Sensors

Lens

Lens

Lens

Lenss

Lenss

Leens

Disp

lace

men

t

Low HighVoltage

L1

0

(a)

Disp

lace

men

t

Low

Lens

Lens

Lens

HighVoltage

L2

L3

Sample

0

(b)

Figure 3 Obtaining process of the refractive index (a) Measurement implemented with an empty sample holder shows a single reflectivesurface (b) Measurement with a liquid sample on the sample holder gives two reflective surfaces

14601465147014751480

13701375138013851390

Refr

activ

e ind

ex

Glycerin

Refr

activ

e ind

ex

Isopropyl alcohol

Measurement11109876543210

Measurement11109876543210

913E minus 4Error

Error 8859E minus 4

Figure 4 Standard deviation in measurements with glycerin and isopropyl alcohol Straight lines (horizontal) represent reported values

Journal of Sensors 5

Table 1 Comparison of results with reported values

Substance Proposed refractometer (25∘C) Commercial Abbe refractometer (235∘C) Reported in literature[2 13ndash15]

Distilled water 13346 13344 13327 (25∘C)Hydrogen peroxide (40wt) 13579 13625 13598 (25∘C)Glycerin 14757 14685 14739 (20∘C)Isopropyl alcohol 13798 13819 1378 (20∘C)

1 2 3 414601465147014751480

14601465147014751480

14601465147014751480

Refr

activ

e ind

exRe

frac

tive i

ndex

Refr

activ

e ind

ex

Number of experiments

1 2 3 4Number of experiments

1 2 3 4Number of experiments

29mm thickness

36mm thickness

6mm thickness

Figure 5 Measurements with different thicknesses of glycerinsamples showed an error lt 10minus3 Straight lines (horizontal) representthe reported value of glycerin

corresponding refractive index values of the same substancesreported in literature

It is worth mentioning that each measured refractiveindex exhibited small deviationswith respect to reference val-ues reportedThe fact that reported values of refractive indexin literature are given for a sodium D-line (589 nm) must beconsidered while in our system a 635 nm laser wavelengthwas used In fact most measured substances show a decreas-ing refractive index as the wavelength increases On the otherhand the optical power of the laser used for the measure-mentswas 04mWwhichmeans that we can discard any ther-mal issue related to the incident light over the amount of ana-lyzed substance We registered all the measurements in a lab-controlled temperature performing the experiment in about6 seconds We addressed possible shake issues by attachingthe motorized 119911-axis-mechanism to an overweighed plate

6 Conclusions

The mathematical analysis and the obtained experimentalresults demonstrated that the deviation of the principal rayof the laser beam when it emerges from the sample holder byFresnel reflection throughout a transparent liquid sample andwithout it can be determined in terms of the scanning dis-placements that set the focal point of the focused beam at theboundaries of the liquid sample As a result we can determinethe refractive index of the liquid with simple measurementswithout the requirement of physical contact The measuredrefractive index values of liquids such as distilled waterhydrogen peroxide glycerin and isopropyl alcohol closelyagree with the reported values and themeasured values usinga commercial refractometer The optical system exhibited agood accuracy for thicknesses as low as 1mm under thechosen lenses for the fiber probe Smaller thickness resultedin an inaccurate calculation of RI

Competing Interests

The authors declare that they have no competing interests

Acknowledgments

This work was supported in part by the Scientific and Tech-nology Research Support Program (PAICyT) hosted by theUniversidad Autonoma de Nuevo Leon (UANL) ProjectsEstudio y Caracterizacion de Linternas Fotonicas de ModosSelectivos (MSPLs) IT1047-11 CA354 and IT1087-11 bySecretarıa de Educacion Publica by Projects PROFOCIE2015 PRODEP-REDES 10351511043 and by the PROMEPhosted by UANL Project 1035136444 D Toral-Acosta wassupported by theNationalCouncil of Science andTechnology(CONACyT) Grant no 260496 The authors also want tothank to Adriana Linan Montes Daniel Ceballos HerreraHelena de los Reyes and Jaime Reyes for their valuable com-ments on the paper

References

[1] S Yio P B B Ruffin F T S Yu and S Yin Fiber Optic SensorsMarcel Dekker New York NY USA 2008

[2] J Rheims J Koser and T Wriedt ldquoRefractive-index measure-ments in the near-IR using an Abbe refractometerrdquo Measure-ment Science and Technology vol 8 no 6 pp 601ndash605 1997

[3] M Daimon and A Masumura ldquoMeasurement of the refractiveindex of distilled water from the near-infrared region to the

6 Journal of Sensors

ultraviolet regionrdquoApplied Optics vol 46 no 18 pp 3811ndash38202007

[4] S Nemoto ldquoMeasurement of the refractive index of liquid usinglaser beam displacementrdquo Applied Optics vol 31 no 31 pp6690ndash6694 1992

[5] F Docchio S Corini M Perini and R S Gasana ldquoA simpleand reliable system for measuring the refractive index of liq-uids using a position-sensitive detectorrdquo IEEE Transactions onInstrumentation and Measurement vol 44 no 1 pp 68ndash701995

[6] P Nath H K Singh P Datta and K C Sarma ldquoAll-fiber opticsensor for measurement of liquid refractive indexrdquo Sensors andActuators A Physical vol 148 no 1 pp 16ndash18 2008

[7] C-B Kim and C B Su ldquoMeasurement of the refractive indexof liquids at 13 and 15 micron using a fibre optic Fresnel ratiometerrdquo Measurement Science and Technology vol 15 no 9 pp1683ndash1686 2004

[8] W Xu X G Huang and J S Pan ldquoSimple fiber-optic refractiveindex sensor based on fresnel reflection and optical switchrdquoIEEE Sensors Journal vol 13 no 5 pp 1571ndash1574 2013

[9] J Yuan C Zhao M Ye J Kang Z Zhang and S Jin ldquoA Fresnelreflection-based optical fiber sensor system for remote refrac-tive indexmeasurement using an OTDRrdquo Photonic Sensors vol4 no 1 pp 48ndash52 2014

[10] J-F Ding A P Zhang L-Y Shao J-H Yan and S He ldquoFiber-taper seeded long-period grating pair as a highly sensitiverefractive-index sensorrdquo IEEE Photonics Technology Letters vol17 no 6 pp 1247ndash1249 2005

[11] A Iadicicco A Cusano A Cutolo R Bernini and MGiordano ldquoThinned fiber Bragg gratings as high sensitivityrefractive index sensorrdquo IEEE Photonics Technology Letters vol16 no 4 pp 1149ndash1151 2004

[12] T Wei Y Han Y Li H-L Tsai and H Xiao ldquoTemperature-insensitive miniaturized fiber inline Fabry-Perot interferome-ter for highly sensitive refractive index measurementrdquo OpticsExpress vol 16 no 8 pp 5764ndash5769 2008

[13] P R Cooper ldquoRefractive-Index measurements of liquids usedin conjunction with optical fibersrdquo Applied Optics vol 22 no19 pp 3070ndash3072 1983

[14] EMoreels C deGreef andR Finsy ldquoLaser light refractometerrdquoApplied Optics vol 23 no 17 pp 3010ndash3013 1984

[15] httpwwwrefractometerplrefraction-datasheet-basic[16] httpwwwthorlabscomnewgrouppage9cfmobjectgroup id=

1882amppn=Z812B2497[17] R Selvas A Castillo L Cortez and D Toral ldquoSistema Detector

de no contacto de Espesor y Propiedades Opticas en Materialesy Lıquidos Apilados o Crecidos en Multicapasrdquo IMPI Patenteno MXE2014064537 2014

International Journal of

AerospaceEngineeringHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

RoboticsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Active and Passive Electronic Components

Control Scienceand Engineering

Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

RotatingMachinery

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporation httpwwwhindawicom

Journal ofEngineeringVolume 2014

Submit your manuscripts athttpwwwhindawicom

VLSI Design

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Shock and Vibration

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Civil EngineeringAdvances in

Acoustics and VibrationAdvances in

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Electrical and Computer Engineering

Journal of

Advances inOptoElectronics

Hindawi Publishing Corporation httpwwwhindawicom

Volume 2014

The Scientific World JournalHindawi Publishing Corporation httpwwwhindawicom Volume 2014

SensorsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Modelling amp Simulation in EngineeringHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Chemical EngineeringInternational Journal of Antennas and

Propagation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Navigation and Observation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

DistributedSensor Networks

International Journal of

Journal of Sensors 3

1205792

12057911205791

1205792

n1

n2

y

h1

h2r21205792

r11205791

Figure 2 Geometrical analysis of refracted light

Equation (2) can be also stated in terms of the incidentangle and the values of ℎ

1

and ℎ2

as follows

1198992

= 1198991

(

cos 1205791

ℎ1

)radic1199102

+ ℎ2

2

(3)

Given the fact that 119910 has the same value for both angleswe can express (3) in terms of the incident angle and thereforeget the resultant equation for the refractive index of thesample which can finally be stated as

1198992

= 1198991

(

cos 1205791

ℎ1

)radic(ℎ2

1

tan2 1205791

) + ℎ2

2

(4)

4 Measurement Process

The operation principle of the refractometer is based on theoptical path length traveled by a ray of light to reach a mirrortarget through a sample and without it For this purpose itis then necessary to know the thickness of the sample Ingeneral this can be obtained given the fact that in every pla-nar interface between the two media a high intensity Fresnelreflection is exhibited each time such interfaces are reachedby the focal point

Given the experimental setup and the analysis of themathematical model applicable to describe the refractometerin Section 3 a method must be provided to find the values ofℎ1

and ℎ2

A better understanding of this can be achieved byconsidering the details of the whole measurement process

Regarding Figure 3 if we assume that the motorizedmechanism starts moving from the zero-reference positionthe laser focal point will sometime reach a reflective interface(ie air-liquid liquid-metallic mirror or air-metallic mirrorinterface) Subsequently the retroreflected light enters backinto the fiber probe and it is then guided to the opticalfiber coupler where a photodetector will receive the reflectedoptical power and convert it into a voltage signal For each 119911-axis position where the focal point reaches one high reflectivesurface the voltage signal exhibits a local maximum Finallythe voltage signal is computer-monitored and plotted for eachvertical position

Once a scanning sweep is performed it is possible to findthe desired ℎ

1

and ℎ2

values From Figures 2 and 3 it can beconfirmed that

ℎ1

=10038161003816100381610038161198713

minus 1198712

1003816100381610038161003816 (5)

where 1198712

is the distance from the reference position to thesample surface and 119871

3

is the required displacement from thereference to a position such that the focal point of the lighthas completely penetrated the sample and reached the sampleholderrsquos reflective bottom

Additionally we can calculate ℎ2

as

ℎ2

=10038161003816100381610038161198711

minus 1198712

1003816100381610038161003816 (6)

where 1198711

is the distance of the sample holderrsquos bottom withrespect to the reference position

Consequently the measurement process can be done interms of the values 119871

1

1198712

and 1198713

In order to complete theprocess it is necessary to implement only two steps (i) with-out a sample in the sample holder a scanning sweep must becarried out to obtain 119871

1

and (ii) with a layer of sample addedin the sample holder 119871

2

and 1198713

must be obtained

5 Experimental Results

To determine the repeatability and accuracy in the experi-ment a series of measurements were performed On the onehand by choosing randomly two different samples standarddeviation was obtained out of 10 measured valuesThe resultsshowed an agreement better than 10minus3 See Figure 4

On the other hand in order to verify the accuracy ofour device at different sample thickness somemeasurementswere performed using glycerin The obtained error remainedin a value lt 10minus3 See Figure 5 Moreover the sensor exhibitedgood performance evenwhen thickness was reduced down tosim1mm which corresponds to 10 of the focal length of theoptical system

Table 1 shows a comparison between the refractive indexvalues obtained for different substance samples measuredby our refractometer (patent pending) [17] with respect tothe values obtained using a commercial analog Abbe refrac-tometer (model Atago 1T) An additional column shows the

4 Journal of Sensors

Lens

Lens

Lens

Lenss

Lenss

Leens

Disp

lace

men

t

Low HighVoltage

L1

0

(a)

Disp

lace

men

t

Low

Lens

Lens

Lens

HighVoltage

L2

L3

Sample

0

(b)

Figure 3 Obtaining process of the refractive index (a) Measurement implemented with an empty sample holder shows a single reflectivesurface (b) Measurement with a liquid sample on the sample holder gives two reflective surfaces

14601465147014751480

13701375138013851390

Refr

activ

e ind

ex

Glycerin

Refr

activ

e ind

ex

Isopropyl alcohol

Measurement11109876543210

Measurement11109876543210

913E minus 4Error

Error 8859E minus 4

Figure 4 Standard deviation in measurements with glycerin and isopropyl alcohol Straight lines (horizontal) represent reported values

Journal of Sensors 5

Table 1 Comparison of results with reported values

Substance Proposed refractometer (25∘C) Commercial Abbe refractometer (235∘C) Reported in literature[2 13ndash15]

Distilled water 13346 13344 13327 (25∘C)Hydrogen peroxide (40wt) 13579 13625 13598 (25∘C)Glycerin 14757 14685 14739 (20∘C)Isopropyl alcohol 13798 13819 1378 (20∘C)

1 2 3 414601465147014751480

14601465147014751480

14601465147014751480

Refr

activ

e ind

exRe

frac

tive i

ndex

Refr

activ

e ind

ex

Number of experiments

1 2 3 4Number of experiments

1 2 3 4Number of experiments

29mm thickness

36mm thickness

6mm thickness

Figure 5 Measurements with different thicknesses of glycerinsamples showed an error lt 10minus3 Straight lines (horizontal) representthe reported value of glycerin

corresponding refractive index values of the same substancesreported in literature

It is worth mentioning that each measured refractiveindex exhibited small deviationswith respect to reference val-ues reportedThe fact that reported values of refractive indexin literature are given for a sodium D-line (589 nm) must beconsidered while in our system a 635 nm laser wavelengthwas used In fact most measured substances show a decreas-ing refractive index as the wavelength increases On the otherhand the optical power of the laser used for the measure-mentswas 04mWwhichmeans that we can discard any ther-mal issue related to the incident light over the amount of ana-lyzed substance We registered all the measurements in a lab-controlled temperature performing the experiment in about6 seconds We addressed possible shake issues by attachingthe motorized 119911-axis-mechanism to an overweighed plate

6 Conclusions

The mathematical analysis and the obtained experimentalresults demonstrated that the deviation of the principal rayof the laser beam when it emerges from the sample holder byFresnel reflection throughout a transparent liquid sample andwithout it can be determined in terms of the scanning dis-placements that set the focal point of the focused beam at theboundaries of the liquid sample As a result we can determinethe refractive index of the liquid with simple measurementswithout the requirement of physical contact The measuredrefractive index values of liquids such as distilled waterhydrogen peroxide glycerin and isopropyl alcohol closelyagree with the reported values and themeasured values usinga commercial refractometer The optical system exhibited agood accuracy for thicknesses as low as 1mm under thechosen lenses for the fiber probe Smaller thickness resultedin an inaccurate calculation of RI

Competing Interests

The authors declare that they have no competing interests

Acknowledgments

This work was supported in part by the Scientific and Tech-nology Research Support Program (PAICyT) hosted by theUniversidad Autonoma de Nuevo Leon (UANL) ProjectsEstudio y Caracterizacion de Linternas Fotonicas de ModosSelectivos (MSPLs) IT1047-11 CA354 and IT1087-11 bySecretarıa de Educacion Publica by Projects PROFOCIE2015 PRODEP-REDES 10351511043 and by the PROMEPhosted by UANL Project 1035136444 D Toral-Acosta wassupported by theNationalCouncil of Science andTechnology(CONACyT) Grant no 260496 The authors also want tothank to Adriana Linan Montes Daniel Ceballos HerreraHelena de los Reyes and Jaime Reyes for their valuable com-ments on the paper

References

[1] S Yio P B B Ruffin F T S Yu and S Yin Fiber Optic SensorsMarcel Dekker New York NY USA 2008

[2] J Rheims J Koser and T Wriedt ldquoRefractive-index measure-ments in the near-IR using an Abbe refractometerrdquo Measure-ment Science and Technology vol 8 no 6 pp 601ndash605 1997

[3] M Daimon and A Masumura ldquoMeasurement of the refractiveindex of distilled water from the near-infrared region to the

6 Journal of Sensors

ultraviolet regionrdquoApplied Optics vol 46 no 18 pp 3811ndash38202007

[4] S Nemoto ldquoMeasurement of the refractive index of liquid usinglaser beam displacementrdquo Applied Optics vol 31 no 31 pp6690ndash6694 1992

[5] F Docchio S Corini M Perini and R S Gasana ldquoA simpleand reliable system for measuring the refractive index of liq-uids using a position-sensitive detectorrdquo IEEE Transactions onInstrumentation and Measurement vol 44 no 1 pp 68ndash701995

[6] P Nath H K Singh P Datta and K C Sarma ldquoAll-fiber opticsensor for measurement of liquid refractive indexrdquo Sensors andActuators A Physical vol 148 no 1 pp 16ndash18 2008

[7] C-B Kim and C B Su ldquoMeasurement of the refractive indexof liquids at 13 and 15 micron using a fibre optic Fresnel ratiometerrdquo Measurement Science and Technology vol 15 no 9 pp1683ndash1686 2004

[8] W Xu X G Huang and J S Pan ldquoSimple fiber-optic refractiveindex sensor based on fresnel reflection and optical switchrdquoIEEE Sensors Journal vol 13 no 5 pp 1571ndash1574 2013

[9] J Yuan C Zhao M Ye J Kang Z Zhang and S Jin ldquoA Fresnelreflection-based optical fiber sensor system for remote refrac-tive indexmeasurement using an OTDRrdquo Photonic Sensors vol4 no 1 pp 48ndash52 2014

[10] J-F Ding A P Zhang L-Y Shao J-H Yan and S He ldquoFiber-taper seeded long-period grating pair as a highly sensitiverefractive-index sensorrdquo IEEE Photonics Technology Letters vol17 no 6 pp 1247ndash1249 2005

[11] A Iadicicco A Cusano A Cutolo R Bernini and MGiordano ldquoThinned fiber Bragg gratings as high sensitivityrefractive index sensorrdquo IEEE Photonics Technology Letters vol16 no 4 pp 1149ndash1151 2004

[12] T Wei Y Han Y Li H-L Tsai and H Xiao ldquoTemperature-insensitive miniaturized fiber inline Fabry-Perot interferome-ter for highly sensitive refractive index measurementrdquo OpticsExpress vol 16 no 8 pp 5764ndash5769 2008

[13] P R Cooper ldquoRefractive-Index measurements of liquids usedin conjunction with optical fibersrdquo Applied Optics vol 22 no19 pp 3070ndash3072 1983

[14] EMoreels C deGreef andR Finsy ldquoLaser light refractometerrdquoApplied Optics vol 23 no 17 pp 3010ndash3013 1984

[15] httpwwwrefractometerplrefraction-datasheet-basic[16] httpwwwthorlabscomnewgrouppage9cfmobjectgroup id=

1882amppn=Z812B2497[17] R Selvas A Castillo L Cortez and D Toral ldquoSistema Detector

de no contacto de Espesor y Propiedades Opticas en Materialesy Lıquidos Apilados o Crecidos en Multicapasrdquo IMPI Patenteno MXE2014064537 2014

International Journal of

AerospaceEngineeringHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

RoboticsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Active and Passive Electronic Components

Control Scienceand Engineering

Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

RotatingMachinery

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporation httpwwwhindawicom

Journal ofEngineeringVolume 2014

Submit your manuscripts athttpwwwhindawicom

VLSI Design

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Shock and Vibration

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Civil EngineeringAdvances in

Acoustics and VibrationAdvances in

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Electrical and Computer Engineering

Journal of

Advances inOptoElectronics

Hindawi Publishing Corporation httpwwwhindawicom

Volume 2014

The Scientific World JournalHindawi Publishing Corporation httpwwwhindawicom Volume 2014

SensorsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Modelling amp Simulation in EngineeringHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Chemical EngineeringInternational Journal of Antennas and

Propagation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Navigation and Observation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

DistributedSensor Networks

International Journal of

4 Journal of Sensors

Lens

Lens

Lens

Lenss

Lenss

Leens

Disp

lace

men

t

Low HighVoltage

L1

0

(a)

Disp

lace

men

t

Low

Lens

Lens

Lens

HighVoltage

L2

L3

Sample

0

(b)

Figure 3 Obtaining process of the refractive index (a) Measurement implemented with an empty sample holder shows a single reflectivesurface (b) Measurement with a liquid sample on the sample holder gives two reflective surfaces

14601465147014751480

13701375138013851390

Refr

activ

e ind

ex

Glycerin

Refr

activ

e ind

ex

Isopropyl alcohol

Measurement11109876543210

Measurement11109876543210

913E minus 4Error

Error 8859E minus 4

Figure 4 Standard deviation in measurements with glycerin and isopropyl alcohol Straight lines (horizontal) represent reported values

Journal of Sensors 5

Table 1 Comparison of results with reported values

Substance Proposed refractometer (25∘C) Commercial Abbe refractometer (235∘C) Reported in literature[2 13ndash15]

Distilled water 13346 13344 13327 (25∘C)Hydrogen peroxide (40wt) 13579 13625 13598 (25∘C)Glycerin 14757 14685 14739 (20∘C)Isopropyl alcohol 13798 13819 1378 (20∘C)

1 2 3 414601465147014751480

14601465147014751480

14601465147014751480

Refr

activ

e ind

exRe

frac

tive i

ndex

Refr

activ

e ind

ex

Number of experiments

1 2 3 4Number of experiments

1 2 3 4Number of experiments

29mm thickness

36mm thickness

6mm thickness

Figure 5 Measurements with different thicknesses of glycerinsamples showed an error lt 10minus3 Straight lines (horizontal) representthe reported value of glycerin

corresponding refractive index values of the same substancesreported in literature

It is worth mentioning that each measured refractiveindex exhibited small deviationswith respect to reference val-ues reportedThe fact that reported values of refractive indexin literature are given for a sodium D-line (589 nm) must beconsidered while in our system a 635 nm laser wavelengthwas used In fact most measured substances show a decreas-ing refractive index as the wavelength increases On the otherhand the optical power of the laser used for the measure-mentswas 04mWwhichmeans that we can discard any ther-mal issue related to the incident light over the amount of ana-lyzed substance We registered all the measurements in a lab-controlled temperature performing the experiment in about6 seconds We addressed possible shake issues by attachingthe motorized 119911-axis-mechanism to an overweighed plate

6 Conclusions

The mathematical analysis and the obtained experimentalresults demonstrated that the deviation of the principal rayof the laser beam when it emerges from the sample holder byFresnel reflection throughout a transparent liquid sample andwithout it can be determined in terms of the scanning dis-placements that set the focal point of the focused beam at theboundaries of the liquid sample As a result we can determinethe refractive index of the liquid with simple measurementswithout the requirement of physical contact The measuredrefractive index values of liquids such as distilled waterhydrogen peroxide glycerin and isopropyl alcohol closelyagree with the reported values and themeasured values usinga commercial refractometer The optical system exhibited agood accuracy for thicknesses as low as 1mm under thechosen lenses for the fiber probe Smaller thickness resultedin an inaccurate calculation of RI

Competing Interests

The authors declare that they have no competing interests

Acknowledgments

This work was supported in part by the Scientific and Tech-nology Research Support Program (PAICyT) hosted by theUniversidad Autonoma de Nuevo Leon (UANL) ProjectsEstudio y Caracterizacion de Linternas Fotonicas de ModosSelectivos (MSPLs) IT1047-11 CA354 and IT1087-11 bySecretarıa de Educacion Publica by Projects PROFOCIE2015 PRODEP-REDES 10351511043 and by the PROMEPhosted by UANL Project 1035136444 D Toral-Acosta wassupported by theNationalCouncil of Science andTechnology(CONACyT) Grant no 260496 The authors also want tothank to Adriana Linan Montes Daniel Ceballos HerreraHelena de los Reyes and Jaime Reyes for their valuable com-ments on the paper

References

[1] S Yio P B B Ruffin F T S Yu and S Yin Fiber Optic SensorsMarcel Dekker New York NY USA 2008

[2] J Rheims J Koser and T Wriedt ldquoRefractive-index measure-ments in the near-IR using an Abbe refractometerrdquo Measure-ment Science and Technology vol 8 no 6 pp 601ndash605 1997

[3] M Daimon and A Masumura ldquoMeasurement of the refractiveindex of distilled water from the near-infrared region to the

6 Journal of Sensors

ultraviolet regionrdquoApplied Optics vol 46 no 18 pp 3811ndash38202007

[4] S Nemoto ldquoMeasurement of the refractive index of liquid usinglaser beam displacementrdquo Applied Optics vol 31 no 31 pp6690ndash6694 1992

[5] F Docchio S Corini M Perini and R S Gasana ldquoA simpleand reliable system for measuring the refractive index of liq-uids using a position-sensitive detectorrdquo IEEE Transactions onInstrumentation and Measurement vol 44 no 1 pp 68ndash701995

[6] P Nath H K Singh P Datta and K C Sarma ldquoAll-fiber opticsensor for measurement of liquid refractive indexrdquo Sensors andActuators A Physical vol 148 no 1 pp 16ndash18 2008

[7] C-B Kim and C B Su ldquoMeasurement of the refractive indexof liquids at 13 and 15 micron using a fibre optic Fresnel ratiometerrdquo Measurement Science and Technology vol 15 no 9 pp1683ndash1686 2004

[8] W Xu X G Huang and J S Pan ldquoSimple fiber-optic refractiveindex sensor based on fresnel reflection and optical switchrdquoIEEE Sensors Journal vol 13 no 5 pp 1571ndash1574 2013

[9] J Yuan C Zhao M Ye J Kang Z Zhang and S Jin ldquoA Fresnelreflection-based optical fiber sensor system for remote refrac-tive indexmeasurement using an OTDRrdquo Photonic Sensors vol4 no 1 pp 48ndash52 2014

[10] J-F Ding A P Zhang L-Y Shao J-H Yan and S He ldquoFiber-taper seeded long-period grating pair as a highly sensitiverefractive-index sensorrdquo IEEE Photonics Technology Letters vol17 no 6 pp 1247ndash1249 2005

[11] A Iadicicco A Cusano A Cutolo R Bernini and MGiordano ldquoThinned fiber Bragg gratings as high sensitivityrefractive index sensorrdquo IEEE Photonics Technology Letters vol16 no 4 pp 1149ndash1151 2004

[12] T Wei Y Han Y Li H-L Tsai and H Xiao ldquoTemperature-insensitive miniaturized fiber inline Fabry-Perot interferome-ter for highly sensitive refractive index measurementrdquo OpticsExpress vol 16 no 8 pp 5764ndash5769 2008

[13] P R Cooper ldquoRefractive-Index measurements of liquids usedin conjunction with optical fibersrdquo Applied Optics vol 22 no19 pp 3070ndash3072 1983

[14] EMoreels C deGreef andR Finsy ldquoLaser light refractometerrdquoApplied Optics vol 23 no 17 pp 3010ndash3013 1984

[15] httpwwwrefractometerplrefraction-datasheet-basic[16] httpwwwthorlabscomnewgrouppage9cfmobjectgroup id=

1882amppn=Z812B2497[17] R Selvas A Castillo L Cortez and D Toral ldquoSistema Detector

de no contacto de Espesor y Propiedades Opticas en Materialesy Lıquidos Apilados o Crecidos en Multicapasrdquo IMPI Patenteno MXE2014064537 2014

International Journal of

AerospaceEngineeringHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

RoboticsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Active and Passive Electronic Components

Control Scienceand Engineering

Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

RotatingMachinery

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporation httpwwwhindawicom

Journal ofEngineeringVolume 2014

Submit your manuscripts athttpwwwhindawicom

VLSI Design

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Shock and Vibration

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Civil EngineeringAdvances in

Acoustics and VibrationAdvances in

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Electrical and Computer Engineering

Journal of

Advances inOptoElectronics

Hindawi Publishing Corporation httpwwwhindawicom

Volume 2014

The Scientific World JournalHindawi Publishing Corporation httpwwwhindawicom Volume 2014

SensorsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Modelling amp Simulation in EngineeringHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Chemical EngineeringInternational Journal of Antennas and

Propagation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Navigation and Observation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

DistributedSensor Networks

International Journal of

Journal of Sensors 5

Table 1 Comparison of results with reported values

Substance Proposed refractometer (25∘C) Commercial Abbe refractometer (235∘C) Reported in literature[2 13ndash15]

Distilled water 13346 13344 13327 (25∘C)Hydrogen peroxide (40wt) 13579 13625 13598 (25∘C)Glycerin 14757 14685 14739 (20∘C)Isopropyl alcohol 13798 13819 1378 (20∘C)

1 2 3 414601465147014751480

14601465147014751480

14601465147014751480

Refr

activ

e ind

exRe

frac

tive i

ndex

Refr

activ

e ind

ex

Number of experiments

1 2 3 4Number of experiments

1 2 3 4Number of experiments

29mm thickness

36mm thickness

6mm thickness

Figure 5 Measurements with different thicknesses of glycerinsamples showed an error lt 10minus3 Straight lines (horizontal) representthe reported value of glycerin

corresponding refractive index values of the same substancesreported in literature

It is worth mentioning that each measured refractiveindex exhibited small deviationswith respect to reference val-ues reportedThe fact that reported values of refractive indexin literature are given for a sodium D-line (589 nm) must beconsidered while in our system a 635 nm laser wavelengthwas used In fact most measured substances show a decreas-ing refractive index as the wavelength increases On the otherhand the optical power of the laser used for the measure-mentswas 04mWwhichmeans that we can discard any ther-mal issue related to the incident light over the amount of ana-lyzed substance We registered all the measurements in a lab-controlled temperature performing the experiment in about6 seconds We addressed possible shake issues by attachingthe motorized 119911-axis-mechanism to an overweighed plate

6 Conclusions

The mathematical analysis and the obtained experimentalresults demonstrated that the deviation of the principal rayof the laser beam when it emerges from the sample holder byFresnel reflection throughout a transparent liquid sample andwithout it can be determined in terms of the scanning dis-placements that set the focal point of the focused beam at theboundaries of the liquid sample As a result we can determinethe refractive index of the liquid with simple measurementswithout the requirement of physical contact The measuredrefractive index values of liquids such as distilled waterhydrogen peroxide glycerin and isopropyl alcohol closelyagree with the reported values and themeasured values usinga commercial refractometer The optical system exhibited agood accuracy for thicknesses as low as 1mm under thechosen lenses for the fiber probe Smaller thickness resultedin an inaccurate calculation of RI

Competing Interests

The authors declare that they have no competing interests

Acknowledgments

This work was supported in part by the Scientific and Tech-nology Research Support Program (PAICyT) hosted by theUniversidad Autonoma de Nuevo Leon (UANL) ProjectsEstudio y Caracterizacion de Linternas Fotonicas de ModosSelectivos (MSPLs) IT1047-11 CA354 and IT1087-11 bySecretarıa de Educacion Publica by Projects PROFOCIE2015 PRODEP-REDES 10351511043 and by the PROMEPhosted by UANL Project 1035136444 D Toral-Acosta wassupported by theNationalCouncil of Science andTechnology(CONACyT) Grant no 260496 The authors also want tothank to Adriana Linan Montes Daniel Ceballos HerreraHelena de los Reyes and Jaime Reyes for their valuable com-ments on the paper

References

[1] S Yio P B B Ruffin F T S Yu and S Yin Fiber Optic SensorsMarcel Dekker New York NY USA 2008

[2] J Rheims J Koser and T Wriedt ldquoRefractive-index measure-ments in the near-IR using an Abbe refractometerrdquo Measure-ment Science and Technology vol 8 no 6 pp 601ndash605 1997

[3] M Daimon and A Masumura ldquoMeasurement of the refractiveindex of distilled water from the near-infrared region to the

6 Journal of Sensors

ultraviolet regionrdquoApplied Optics vol 46 no 18 pp 3811ndash38202007

[4] S Nemoto ldquoMeasurement of the refractive index of liquid usinglaser beam displacementrdquo Applied Optics vol 31 no 31 pp6690ndash6694 1992

[5] F Docchio S Corini M Perini and R S Gasana ldquoA simpleand reliable system for measuring the refractive index of liq-uids using a position-sensitive detectorrdquo IEEE Transactions onInstrumentation and Measurement vol 44 no 1 pp 68ndash701995

[6] P Nath H K Singh P Datta and K C Sarma ldquoAll-fiber opticsensor for measurement of liquid refractive indexrdquo Sensors andActuators A Physical vol 148 no 1 pp 16ndash18 2008

[7] C-B Kim and C B Su ldquoMeasurement of the refractive indexof liquids at 13 and 15 micron using a fibre optic Fresnel ratiometerrdquo Measurement Science and Technology vol 15 no 9 pp1683ndash1686 2004

[8] W Xu X G Huang and J S Pan ldquoSimple fiber-optic refractiveindex sensor based on fresnel reflection and optical switchrdquoIEEE Sensors Journal vol 13 no 5 pp 1571ndash1574 2013

[9] J Yuan C Zhao M Ye J Kang Z Zhang and S Jin ldquoA Fresnelreflection-based optical fiber sensor system for remote refrac-tive indexmeasurement using an OTDRrdquo Photonic Sensors vol4 no 1 pp 48ndash52 2014

[10] J-F Ding A P Zhang L-Y Shao J-H Yan and S He ldquoFiber-taper seeded long-period grating pair as a highly sensitiverefractive-index sensorrdquo IEEE Photonics Technology Letters vol17 no 6 pp 1247ndash1249 2005

[11] A Iadicicco A Cusano A Cutolo R Bernini and MGiordano ldquoThinned fiber Bragg gratings as high sensitivityrefractive index sensorrdquo IEEE Photonics Technology Letters vol16 no 4 pp 1149ndash1151 2004

[12] T Wei Y Han Y Li H-L Tsai and H Xiao ldquoTemperature-insensitive miniaturized fiber inline Fabry-Perot interferome-ter for highly sensitive refractive index measurementrdquo OpticsExpress vol 16 no 8 pp 5764ndash5769 2008

[13] P R Cooper ldquoRefractive-Index measurements of liquids usedin conjunction with optical fibersrdquo Applied Optics vol 22 no19 pp 3070ndash3072 1983

[14] EMoreels C deGreef andR Finsy ldquoLaser light refractometerrdquoApplied Optics vol 23 no 17 pp 3010ndash3013 1984

[15] httpwwwrefractometerplrefraction-datasheet-basic[16] httpwwwthorlabscomnewgrouppage9cfmobjectgroup id=

1882amppn=Z812B2497[17] R Selvas A Castillo L Cortez and D Toral ldquoSistema Detector

de no contacto de Espesor y Propiedades Opticas en Materialesy Lıquidos Apilados o Crecidos en Multicapasrdquo IMPI Patenteno MXE2014064537 2014

International Journal of

AerospaceEngineeringHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

RoboticsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Active and Passive Electronic Components

Control Scienceand Engineering

Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

RotatingMachinery

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporation httpwwwhindawicom

Journal ofEngineeringVolume 2014

Submit your manuscripts athttpwwwhindawicom

VLSI Design

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Shock and Vibration

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Civil EngineeringAdvances in

Acoustics and VibrationAdvances in

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Electrical and Computer Engineering

Journal of

Advances inOptoElectronics

Hindawi Publishing Corporation httpwwwhindawicom

Volume 2014

The Scientific World JournalHindawi Publishing Corporation httpwwwhindawicom Volume 2014

SensorsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Modelling amp Simulation in EngineeringHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Chemical EngineeringInternational Journal of Antennas and

Propagation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Navigation and Observation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

DistributedSensor Networks

International Journal of

6 Journal of Sensors

ultraviolet regionrdquoApplied Optics vol 46 no 18 pp 3811ndash38202007

[4] S Nemoto ldquoMeasurement of the refractive index of liquid usinglaser beam displacementrdquo Applied Optics vol 31 no 31 pp6690ndash6694 1992

[5] F Docchio S Corini M Perini and R S Gasana ldquoA simpleand reliable system for measuring the refractive index of liq-uids using a position-sensitive detectorrdquo IEEE Transactions onInstrumentation and Measurement vol 44 no 1 pp 68ndash701995

[6] P Nath H K Singh P Datta and K C Sarma ldquoAll-fiber opticsensor for measurement of liquid refractive indexrdquo Sensors andActuators A Physical vol 148 no 1 pp 16ndash18 2008

[7] C-B Kim and C B Su ldquoMeasurement of the refractive indexof liquids at 13 and 15 micron using a fibre optic Fresnel ratiometerrdquo Measurement Science and Technology vol 15 no 9 pp1683ndash1686 2004

[8] W Xu X G Huang and J S Pan ldquoSimple fiber-optic refractiveindex sensor based on fresnel reflection and optical switchrdquoIEEE Sensors Journal vol 13 no 5 pp 1571ndash1574 2013

[9] J Yuan C Zhao M Ye J Kang Z Zhang and S Jin ldquoA Fresnelreflection-based optical fiber sensor system for remote refrac-tive indexmeasurement using an OTDRrdquo Photonic Sensors vol4 no 1 pp 48ndash52 2014

[10] J-F Ding A P Zhang L-Y Shao J-H Yan and S He ldquoFiber-taper seeded long-period grating pair as a highly sensitiverefractive-index sensorrdquo IEEE Photonics Technology Letters vol17 no 6 pp 1247ndash1249 2005

[11] A Iadicicco A Cusano A Cutolo R Bernini and MGiordano ldquoThinned fiber Bragg gratings as high sensitivityrefractive index sensorrdquo IEEE Photonics Technology Letters vol16 no 4 pp 1149ndash1151 2004

[12] T Wei Y Han Y Li H-L Tsai and H Xiao ldquoTemperature-insensitive miniaturized fiber inline Fabry-Perot interferome-ter for highly sensitive refractive index measurementrdquo OpticsExpress vol 16 no 8 pp 5764ndash5769 2008

[13] P R Cooper ldquoRefractive-Index measurements of liquids usedin conjunction with optical fibersrdquo Applied Optics vol 22 no19 pp 3070ndash3072 1983

[14] EMoreels C deGreef andR Finsy ldquoLaser light refractometerrdquoApplied Optics vol 23 no 17 pp 3010ndash3013 1984

[15] httpwwwrefractometerplrefraction-datasheet-basic[16] httpwwwthorlabscomnewgrouppage9cfmobjectgroup id=

1882amppn=Z812B2497[17] R Selvas A Castillo L Cortez and D Toral ldquoSistema Detector

de no contacto de Espesor y Propiedades Opticas en Materialesy Lıquidos Apilados o Crecidos en Multicapasrdquo IMPI Patenteno MXE2014064537 2014

International Journal of

AerospaceEngineeringHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

RoboticsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Active and Passive Electronic Components

Control Scienceand Engineering

Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

RotatingMachinery

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporation httpwwwhindawicom

Journal ofEngineeringVolume 2014

Submit your manuscripts athttpwwwhindawicom

VLSI Design

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Shock and Vibration

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Civil EngineeringAdvances in

Acoustics and VibrationAdvances in

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Electrical and Computer Engineering

Journal of

Advances inOptoElectronics

Hindawi Publishing Corporation httpwwwhindawicom

Volume 2014

The Scientific World JournalHindawi Publishing Corporation httpwwwhindawicom Volume 2014

SensorsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Modelling amp Simulation in EngineeringHindawi Publishing Corporation httpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Chemical EngineeringInternational Journal of Antennas and

Propagation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Navigation and Observation

International Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

DistributedSensor Networks

International Journal of

International Journal of

AerospaceEngineeringHindawi Publishing Corporationhttpwwwhindawicom Volume 2014

RoboticsJournal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Active and Passive Electronic Components

Control Scienceand Engineering

Journal of

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

International Journal of

RotatingMachinery

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporation httpwwwhindawicom

Journal ofEngineeringVolume 2014

Submit your manuscripts athttpwwwhindawicom

VLSI Design

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Shock and Vibration

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Civil EngineeringAdvances in

Acoustics and VibrationAdvances in

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014

Hindawi Publishing Corporationhttpwwwhindawicom Volume 2014