Request for Quote (RFQ) - hiiraan.com · Respond via e-mail with attached document in MS Word / pdf...

-

Upload

trinhkhanh -

Category

Documents

-

view

214 -

download

0

Transcript of Request for Quote (RFQ) - hiiraan.com · Respond via e-mail with attached document in MS Word / pdf...

RFQ Template v6, January 2016

Request for Quote (RFQ) Commodity/Service Required: Construction of a fish processing warehouse

(equipped with cold storage equipment, blast-freezers, chiller rooms, ice machines, and processing machinery) for Somali Marine Products Company (SMPC) in Mogadishu

Type of Procurement: One-off purchase/construction agreement Type of Contract: “Fixed price” Term of Contract: 90 days Submit Proposal to: [email protected] Date of Issue of RFQ: May 3, 2018 Date Questions from Supplier Due: May 10, 2018 Date Proposal Due: May 17, 2018 Approximate Date Purchase Order Issued to Successful Bidder(s):

May 20, 2018

Method of Submittal: Via email: [email protected] Respond via e-mail with attached document in MS Word / pdf format. The Bidder/Seller agrees to hold the prices in its offer firm for 60 days from the date specified for the receipt of offers, unless another time is specified in the addendum of the RFQ. Solicitation Number: M-2018/51

This RFQ has been issued by International Resources Group (IRG) a wholly-owned subsidiary of Research Triangle Institute (RTI), with its principal place of business at 3040 East Cornwallis Road, Research Triangle Park, NC 27709-2194. Any references in this RFQ to RTI is intentional and shall be deemed to mean both RTI and IRG and that Bidders / Sellers understand this and agree that they will comply. Attachments to RFQ:

1. Attachment “A” – Commodity Specifications

2. Attachment “B” – Instructions to Bidders/Sellers

3. All PO Terms and Conditions are listed on our website at forth at: http://www.rti.org/POterms, http://www.rti.org/files/PO_FAR_Clauses.pdf or for commercial items: http://www.rti.org/files/PO_FAR_Clauses_Commercial_Items.pdf (hereinafter the “Terms”). Supplier’s delivery of products, performance of services, or issuance of invoices in connection with this purchase order establishes Supplier’s agreement to the Terms. The Terms may only be modified in writing signed by both parties.

All bidders/sellers are responsible to carefully review each attachment and follow any instructions

Attachment A RFQ Template v6, January 2016

Attachment A Commodity Specifications or Statement of Work

Statement of Work Indicate a description of the activity/service that is expected from the supplier. Provide product specifications or service expectations (both if applicable). Include deliverables, timelines, and any special terms and conditions

Description of Activity/Service:

Description of activity: The Supplier will build a fish processing warehouse (equipped with cold storage equipment, blast-freezers, chiller rooms, ice machines, and processing machinery) for Somali Marine Products Company (SMPC) in Mogadishu. To do so, it will assist GEEL in determining what is required at the designated Mogadishu location (GPS Coordinates: N2 2' 13'', E45 21' 28''). The Supplier will:

1. Provide • General preliminaries • Sub-structures • Walling and superstructures, including steel pillars • Finishing works • Doors • Roofing • Plumbing and mechanical installation • Power connections and electrical installation

2. Estimate cost and time to purchase materials and build the facility (this will form part of the selection criteria)

3. Recommend measures and actions to ensure the sustainability and proper usage of finished building, especially if GEEL decides to further invest in the operation

4. Ensure SMPC staff know how to maintain the facility

Product or Service Expectations (both if applicable): Product/Service Expectations

• Transport and unload at site of all necessary parts, materials and equipment • Site clearance and demolition wherever needed • Disposal of waste material • Construction of Fish Processing warehouse following on as per the design and BOQ • Site cleanup after construction

Building Specifications:

Attachment A RFQ Template v6, January 2016

Minimum Standards 1.0 General

1.1 Quality of Materials & Technical Specifications The GEEL Engineer and GEEL Technical Specialist shall check and approve the quality of all materials delivered to site. Materials must meet the minimum requirements and will not be recycled, previously used or repaired. Any material that does not meet the minimum standards shall be rejected. Such materials shall be removed from site and replaced at the Contractors expense with materials of the required quality.

1.2 Quantity of Materials The GEEL Site Engineer shall check that the required quantity of materials has been delivered to site and used in the works. The Engineer will not certify payment for any materials specified in the contract but not used in the works, for whatever reason.

1.3 Quality of Workmanship The GEEL Engineer and GEEL Technical Specialist shall be responsible for checking that the quality of workmanship by the contractor is of an acceptable standard according to this Specification. The GEEL Supervisor Engineer will reject any work that has not been executed to the required standard. The Contractor shall redo any rejected works at his own expense and with no time delays to the overall scheme.

2.0 Building and Structures

2.1 Excavations Excavations shall be clean and free of water. All excavations will be inspected by the Site Engineer before work proceeds. The Contractor shall give the GEEL Supervisor Engineer 3 days’ notice of the inspection date. Excavations are dangerous and liable to collapse, particularly in wet weather or waterlogged ground. The Contractor shall take all necessary precautions to ensure that all excavations are properly protected to prevent accidental or unauthorized entry. Excavations deeper than 1.2m deep shall not be entered unless they are shored up with wooden or other temporary bracing.

1. Excavate for all walls, piers and other foundations to the depths, widths and inclinations shown on the drawings or to such other depths as may be direct by the Engineer or his representative and deposit sufficient soil for all refilling of trenches as may be necessary or demanded, removing any surplus.

2. No work shall be backfilled until approval has been obtained from the Engineer or his

representative. The earth shall then be brought back from the place where it was temporarily deposited and the trenches or the excavations shall be filled up to the height of the original surface with earth in layers of not more than 25 cms, in thickness. Each layer shall be well watered and rammed and consolidated as may be required, all to the directions and satisfaction of the Engineer or his representative.

3. Provide all materials and labor for making good all settlement and keeping in repair the

Attachment A RFQ Template v6, January 2016

surface of any road, footway or areas upon the site during the whole period of the Works are in his hand, and for a period six months after the completion of such works, and in case he neglects or refuses to make good and settlements in any trench, or other area whether public or private, Site Engineer may have such works or necessary repairs carried out by other persons and the expenses thereof shall be paid by the Contractor, or deducted from any money that may be due to him or shall be paid by the sureties.

4. Remove all building debris and clear the whole of the site on completion, to the

satisfaction of the Engineer or his representative.

5. No sand or any other materials found or excavated on the site may be used in the work unless written permission has been obtained from the GEEL Infrastructure Engineer if it is agreed to make use of any such materials for back filling around foundation, the material must be clear of rock and rubbish. The total price to be paid shall be agreed upon and the value deducted from sums due to the Contractor.

6. A. The filling under floors, where shown in the drawings shall be clean desert or drift sand, deposited in layer not exceeding 15 cms. In depth, each layer being well rammed and watered. B. Hard Core Filling: Hard core is to be formed or clean, hard broken stone that will pass in all directions through a 100-mm. dia. ring. Only sufficient stand is to be mixed with the hard core as will completely fill the interstices and aid in the work of consolidation. Hard core is to be well packed, rammed and, where possible rolled with a heavy roller.

2.2 Backfilling Backfilling shall be made in max 20 cm layers by using proper compactor. The soil shall be watered to provide moisture to get higher compaction rate. Desirable compaction is 95%. The backfill material should be well graded with fine and aggregate. The max size of the aggregate /stone should be less than 50 mm. The Site Supervisor Engineer shall check and approve the compaction before the commencement of the works.

2.3 Sand Sand shall be clean and free from contaminants such as oil, silt, soil, wood, metal or vegetable matter (preferable clean river sand). Very fine or smooth sand shall not be used. The GEEL Infrastructure Engineer and the Site Engineer shall check and approve the quality before the commencement of the works. Coarse Sand (used for concrete) shall have a maximum size of 5mm. Medium Sand (used for masonry mortar and plaster) shall have a maximum size of 2mm. Shall be natural sand or crushed gravel or stone clean sharp, coarse grift, pit or river sand free from silt, dust, clay, salt or any other matter, shall pass a 3/16'' (4.7 mm) squire mesh and shall be the best reasonably obtainable for the work. All sand shall be washed and sieved as often as is required to make it conform to this specification

2.4 Aggregate Shall be natural gravel, stone or other approved materials hard strong and durable, non-porous free from adherent coating or other harmful matter and shall pass or be crushed to pass the meshes specified in the concrete mixes and be well graded by sieving and combination where necessary.

Attachment A RFQ Template v6, January 2016

Aggregate used for concrete shall be angular crushed rock varying in size from 5mm to 20mm for Grade 1 Concrete and 5mm to 60mm for Grade 2 Concrete. It shall be clean and free from contaminants such as oil, silt, soil, wood, metal or vegetable matter.

2.5 Cement Mortar Cement shall be delivered in sealed bags to the site. It shall be kept clean and dry until usage. Partially used bags of cement shall be stored in a dry place until required. Any partially used bags that have become damp shall be rejected. Cement mortar for blockwork, masonry, rendering, tiling, screening, pitching and jointing shall consist of Ordinary Portland Cement and natural sand mixed by hand or an approved mechanical mixer in the proportions by volume of one-part cement to four parts sand. The cement and sand shall first be mixed dry until the cement color can no longer be distinguished from the sand in any part of the mass and the whole shall then be uniformly wetted by approved means while undergoing further mixing. The water content shall just be sufficient to ensure a dense mortar of still consistency and adequate workability to permit troweling or floating into place. Mortar shall be prepared and used in such quantities that no more than 20 minutes shall elapse between first wetting and its completed use. Under no circumstance shall any mortar that has stiffened by commencing to set be used. Fresh mortar shall not be mixed with mortar prepared earlier and all batches shall be used entirely separately. Sand for cement mortar to be used for external renderings and internal plastering with lime and Portland cement shall comply with BS 119. Sand for cement mortar for all other purposes (plain and reinforced brickwork, block-walling, masonry etc.) shall comply with BS 1200. It should be well graded siliceous sand of good, sharp, hard quality. It shall be free from lumps of stone, earth, loam, dust, slat, organic matter and any other deleterious substance.

2.6 Water Water used for mixing concrete, mortar, plaster and other construction materials shall be potable, clean and free from organic material, humus, acid, chemicals, salts or other matter that may be harmful to the concrete. If none is available on site, the contractor shall transport suitable water to site.

2.7 Concrete Mixes The below classes of concrete shall be used unless otherwise indicated on the drawings. Class 20 Concrete shall always be used for the structural concrete. Class 15 shall be used for blinding works. Concrete shall be mixed in the following proportions by volume: Class 30(structural) Concrete: 1: 1: 2 cement: coarse sand: aggregate Class 25(structural) Concrete: 1: 1,5: 3 cement: coarse sand: aggregate Class 20 (structural) Concrete: 1: 2: 4 cement: coarse sand: aggregate Class 15 (Mass) Concrete: 1: 3: 6 cement: coarse sand: aggregate Class 10 (Mass) Concrete: 1: 4: 8 cement: coarse sand: aggregate The water cement ratio shall be approximately 0.55 by weight, thus a mix containing 50 kg of cement will require 27.5 L of water. Too much water improves the workability but reduces the strength. Concrete that has too much water added shall be rejected.

Attachment A RFQ Template v6, January 2016

a. Mix ''A'' Concrete: - For unreinforced concrete: 1 Part Portland cement (but not less than 225 kg. per M3 concrete) 3 Parts sand. 6 Parts coarse aggregate to pass 1 1/2 square mesh (40 mms) b. Mix ''B'' Concrete: - For unreinforced or mass concrete: 1 Part Portland cement (but not less than 330 kgs, M3 concrete) 2 Parts sand 4 Parts coarse aggregate to pase 1 1/2'' square mesh (40 mms) well graded. c. Mix ''C'' Concrete: - For all reinforced concrete as mix ''B'' but the coarse aggregate broken to pass 3/4'' mesh (20 mms) well graded. d. Mix ''D'' Concrete: - For granolithic concrete 1 Part Portland Cement (but not less than 550 kgs/M3 concrete).

2.8 Mixing Concrete Concrete mixed on site shall be machine mixed on a clean dry platform of level boards. Concrete shall not be mixed on the bare ground. Mixing by hand shall be carried out in the following way: First the cement and sand shall be thoroughly mixed. Second, this mixture shall be thoroughly mixed with the aggregate that has been slightly wetted. When the mixture is completely mixed and uniform in color, the correct quantity of water shall be added, and the concrete thoroughly mixed. Hand mixed concrete is not to be used for the structural works. If ready mixed concrete is delivered to site, the contractor shall produce certificates from the mixing plant describing the details of the mix. Ready mixed concrete suppliers shall be approved in advance. Any ready mixed concrete delivered to site shall be rejected if the supplier had not been previously approved by the GEEL Site Engineer.

2.9 Placing Concrete Once mixed, concrete shall be used immediately. Any concrete that has been allowed to achieve its initial setting shall not be placed. Concrete shall be placed in layers with a maximum thickness of 250mm and a maximum length of 1M. Each layer shall be thoroughly compacted with a wooden rammer. When placing on old or set concrete, the surface of the old concrete shall be thoroughly cleaned and wetted with water/cement paste prior to the placing of new concrete. If the surface is smooth it must be chipped to form a good bonding key. If concrete has been in position 30 minutes. The Engineer may require that no more concrete may be placed in contact there with until 24 hours have elapsed. Should the concrete have been laid 24 hours, the set surface shall be scrubbed with a hard steel wire brush dusted and saturated with water and the concrete shall be well rammed in contact when the concrete has been laid more than seventy-two hours in addition to the above, the surface shall be chipped. In both cases, thick slurry of neat cement must be applied first before the new concrete is to be poured allowed to pour concrete.

2.10 Concrete Finishing Concrete shall be finished to a smooth uniform surface and finished using a metal or wooden

Attachment A RFQ Template v6, January 2016

float. The surface texture shall be flat and smooth with no irregularities or air bubbles. When formwork is removed, the face of the concrete shall be flat and smooth. If there are signs of voids, air bubbles or inadequate compaction, the concrete shall be removed, disposed of and re-laid with a fresh mix.

2.11 Plaster and Wall Work Plaster for internal walls and external rendering shall be mixed in the proportion 1 cement: 4 medium clean sand by volume. Sufficient water shall be added to achieve the desired workability. The walls shall be wetted before applying the plaster. The plaster shall be 20mm to 25mm thick and shall have a uniform flat finish free of irregularities and blemishes. When the internal plaster is still damp, the wall shall be sprinkled liberally with semi dry cement powder and floated to a smooth finish with a wet steel float. At corners and between walls and ceilings, the finish shall be clean and precise in a straight line. Untidy or poorly finished plaster shall be rejected. All floor screeds to be done in same level. Roughening and cleaning the concrete slab before putting the floor screed. Cement and water paste shall be applied before the screed to ensure good bonding with the floor slab. Proper curing to be done.

2.12 Formwork Formwork shall be adequately braced and supported to withstand the pressure of the wet concrete before it sets. The faces of the formwork shall be smooth and clean, so that the faces of the fresh concrete are not marked. The joints should be very tight to avoid honey combing. Mould oil may be used to prevent the concrete sticking to the formwork. Side formworks should be struck 3 days after concreting, and underside formworks should be removed after 28days. 2.13 Reinforcement Reinforcement shall be designed and placed as shown on the drawing and bending schedule and in accordance with the following:

A. Rod reinforcement shall be of mild steel conforming to B.S 785. Mesh reinforcement shall comply with B.S.4483. Materials, which at any time show signs of brittleness or cracking shall be rejected and removed from the site. The Contractor shall allow for taking three samples of every thickness of the reinforcement rods, at any stage of work and depositing them with the Engineer. High Tensile (H.T.) steel reinforcement shall be either cold worked steel bars of circular or octagonal section complying with B.S. 1144 or hot rolled high tensile bars having a guaranteed minimum yield stress of 60.000 Ibs. Per sq. inch and other physical properties in accordance with B.S. 1144 the overall size of any bar shall not exceed its nominal size by more than 10 percent. All reinforcements shall be in the ‘'diameter'' range and the substitution of `Square twisted` range shall not be allowed. Test: if required by the Engineer, the Contractor shall submit that his own expense certified test data of the following characteristics:

a. Ultimate tensile stress b. Yield point stress c. Elongation d. Cold bend test

Attachment A RFQ Template v6, January 2016

e. Should such certificates not be submitted by the manufactures, the Contractor shall also have the requisite tests made at his own expense at approved testing laboratories.

B. All reinforcements shall be stored in such a manner as to prevent deterioration. Before being placed in position and before the concrete is poured, it shall be clean and free from loose rust, scale, oil, grease, paint or other matters liable to weaken the bond of the concrete to the steel. Reinforcement shall be cut and bend cold. Hooks cranks overlaps etc, shall be as shown on the bending schedule or details. Hooks shall have an inner diameter of four times the rod diameter and the straight return beyond the bend shall be at least four times the rod diameter. All edges of rods in tension shall be hooked and connected longitudinally shall have an overlap of at least 40 diameters in beams and slabs.

C. Welding will not be permitted unless special approval is obtained.

D. Reinforcement shall be accurately placed and maintained in position with precast concrete blocks while the concrete is poured and rammed.

E. Unless otherwise shown on the drawings, cover to main reinforcement shall be 2.5 cms, in beams and 2 cms, in slabs precast packing blocks should be used for correct cover of reinforcement casted at least 10 days before use with cement and sand mortar mix (1:4).

F. Rods, stirrups, etc, in contact shall be tightly wired with malleable soft iron wire not less

than 16 S.W.C.

G. Mesh reinforcement shall be laid with the long way of the mesh spanning from support and shall have laps equal to 40x the diameter of the bars, and where these are two layers of fabric the laps shall be staggered in both direction all laps shall be securely wired as above to prevent movement.

H. Gang-boards and supports shall be laid over the reinforcement to prevent damage and heading down after it has been placed in position. Special attention should be given to cantilevers.

I. The Contractor shall notify the Site Engineer when concreting is about to commence to each section of the work and no concrete shall be poured until the Site Engineer or his representative has a proved the reinforcement and formwork.

2.14 Painting Colors of Paints: The priming, undercoats and finishing coats shall each be of different tints, the printing and undercoats shall be the correct brands and tints to suit the respective finishing coats, in accordance with the manufacturer’s instructions. All finishing coats shall be of the colors and types specified by GEEL. Preparation prior to painting: The Contractor shall include for the preparation of surfaces, rubbing-down between each coat, stopping, knotting and all other works necessary to obtain a first-class finish. The floors and other fittings shall be covered up with dust sheets when carrying out the painting works. Paint splashes, spots and stains shall be removed from floors, wood work

Attachment A RFQ Template v6, January 2016

etc. and the same left clean and perfect upon completion of the painting works.

2.15 Flooring Work All the ceramic tiles used should be in the first class and of approved quality and brand (40x40cm for floor, 30x20cm for walls and 40x10cm for skirting) the cement mortar of 1:6 to be used and white cement for filling. The contractor shall provide samples for the approval of GEEL Supervisor engineer. Plumbing works The contractor has to supply all the plumbing materials as specified in the BoQs and GEEL Supervisor engineer shall check and inspect the materials for usage. PVR pipes different sizes used for water connections, PVC 4” & 2” used for drainage. All sinks, seats and kitchen sink supplied of a good brand Plumber and Drain Layer Diameters: The Diameter of all pipes is the internal bores. Joints: The threaded ends of the pipes shall be painted with white lead linseed or before jointing joints shall be made by winding a few threads of gasket; yarn around the threaded ends and screwing into the coupling to one half the coupling depth. Before and after jointing the interior shall be free of all burrs and obstructions. Fittings: Shall be malleable iron for use with the piping used. All pipes inside the building are to be bedded in channels inside the walls below plaster or glazed tiles levels unless otherwise ordered by the Engineer and shall be of approved quality and jointed as described. No knuckles bends will be permitted. Fixing Pipes: Piping shall be fixed to walls with spring pipe hooks or clips of size suitable for the various pipes diameters and not exceeding 125 cms between hooks or other supports. Supply pipe shall be laid and fixed to allow air escape naturally at big tap. Rates: The Contractor shall allow for all connection and bends being made by the plumber in the length of the pipe jointing and fixing elbows bends and other readymade fittings and shall include cutting, threading and making joints and connections. Sanitary Fittings: Shall be as shown in the drawing and of a manufacture approved by the Site Engineer. The manufacturer`s reference number and the type of fittings which is proposed to be installed shall be submitted to the Site Engineer and his approval obtained before ordering. Electricity works The process included all the fittings and the network (cables) completed according to the distribution of the fitting in the drawings. All the electrical connections shall be made with quality certified cables of appropriate thickness and in accordance with the best current industry standards. Cables shall be installed in one continuous length from supply to point of termination. Socket Cables shall be 3X2.5 mm² NYM and Lighting Cables 2x1.5 mm² NYM. Cables: (2000 Watt, 220 Volt). The entire electrical network shall be earthed according to the relevant European standards. Plugs and sockets shall be made from plastics or rubber. The panels shall be fixed on its pedestals with steel bolts. No welding to the panels shall be permitted. The cable connections

Attachment A RFQ Template v6, January 2016

shall be sized to fit the outlet connection of the circuit breakers and terminals. The cables shall not be connected without using of cable crimp connectors or lugs. Site Plans/Drawings: See Attachment A.

Deliverables, Timelines, Special Terms and Conditions: Deliverables:

• Construction of a fish processing warehouse, per the above-mentioned specifications, in 90 days.

• Bimonthly (every two weeks) progress report with pictures • Monthly progress report with pictures

Timeline:

Description Quantity Delivery Date Deliver To

Terms of Payment 1 During contract negotiations

Infrastructure Engineer and Deputy Chief of Party

Work Schedule 1 3 days after award Infrastructure Engineer and Deputy Chief of Party

Pre-Construction Site Review

1 Upon award Infrastructure Engineer and Deputy Chief of Party

Payment Request

As per completed works and the terms of payment

Infrastructure Engineer and Deputy Chief of Party

Bi-Monthly Progress Report and photographs

By Sunday every second week of project implementation

Infrastructure Engineer and Deputy Chief of Party

Updates to Work Schedule 1 By Sunday of every second week of project implementation if needed

Infrastructure Engineer and Deputy Chief of Party

Final Report 1 After acceptance Infrastructure Engineer and Deputy Chief of Party

Final Invoice 1 After acceptance Infrastructure Engineer and Deputy

Attachment A RFQ Template v6, January 2016

Chief of Party

Place of Performance: GPS Coordinates: N2 2' 13'', E45 21' 28'' Address: Mogadishu, Somalia Environmental Monitoring Report: In accordance with USAID Environmental Procedures, the GEEL project has generated the appropriate environmental management documentation for the Somalia Marine Products Company. The environmental management approach requires that the construction contractor will implement mitigation measures that are described in the subproject-specific Environmental Mitigation and Monitoring Plan (EMMP) provided below. Costs associated with the implementation of the mitigation measures are the responsibility of the construction contractor and should be included in their cost proposal. During project implementation, the construction contractor will be contractually obligated to fully implement the following environmental mitigation measures listed in the EMMP and the GEEL Infrastructure Engineer will monitor the construction contractor to ensure that the measures are implemented effectively.

Mitigation Action Responsible Party Monitoring / Verification Method

Monitoring Record (date,

result, corrective

actions taken, if any)

General contractor will not extract fill, sand or gravel from waterways or ecologically sensitive areas, nor will it knowingly purchase these materials from vendors who do so

Construction contractor GEEL monitoring

Identify and implement any feasible measures to increase the probability that timber is procured from legal, well-managed sources

Construction contractor GEEL monitoring

Ensure that paint procured is non lead-based and that workers are trained on paint storage and disposal practices

Construction contractor GEEL monitoring

Attachment A RFQ Template v6, January 2016

Institute health and safety practices and train workers on personal protection equipment (PPE) based on an activity analysis

Construction contractor GEEL monitoring

Ensure public safety is maintained through use of signage, cones, caution tape and spotters during ingress/egress of heavy equipment and vehicles from the site

Construction contractor GEEL monitoring

Construction contractor must collect and dispose according to municipal standards all construction debris, sanitary waste and refuse generated by its activities in a timely manner and to the satisfaction of the GEEL Infrastructure Engineer

Construction contractor GEEL monitoring

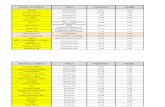

BOQ (Bill of Quantity):

See Attachment B. By signing this attachment, the bidder confirms he has a complete understanding of the specifications and fully intends to deliver items that comply with the above listed specifications.

Signature:

Title:

Date:

Attachment B — Page 1 RFQ Template v6, January 2016

Attachment “B” Instructions to Bidders/Sellers

1. Procurement Narrative Description: The Buyer (IRG) intends to purchase commodities and/or services identified in Attachment A. The Buyer intends to purchase the quantities (for commodities) and/or services (based on deliverables identified in a Statement of Work). The term of the Ordering Agreement shall be from Award Date to the Delivery date of the Offeror unless extended by mutual agreement of the parties. The Buyer intends to award to a single “approved’ supplier based on conformance to the listed specifications, the ability to service this contract, and selling price. We reserve the right to award to more than one bidder. If an Ordering Agreement is established as a result of this RFQ, supplier understands that quantities indicated in the specifications (Attachment A) are an estimate only and IRG does not guarantee the purchase quantity of any item listed.

2. Procuring Activity: This procurement will be made by International Resources Group (IRG), located at

Mogadishu, Somalia

(insert full address of the office)

who has a purchase requirement in support of a project funded by USAID

(insert client’s name) IRG shall award the initial quantities and/or services and any option quantities (if exercised by IRG) to Seller by a properly executed Purchase Order as set forth within the terms of this properly executed agreement.

3. Proposal Requirements. All Sellers will submit a quote/proposal which contains offers for all items and options included in this RFQ. All information presented in the Sellers quote/proposal will be considered during IRG’s evaluation. Failure to submit the information required in this RFQ may result in Seller’s offer being deemed non-responsive. Sellers are responsible for submitting offers, and any modifications, revisions, or withdrawals, so as to reach IRG’s office designated in the RFQ by the time and date specified in the RFQ. Any offer, modification, revision, or withdrawal of an offer received at the IRG office designated in the RFQ after the exact time specified for receipt of offers is “late” and may not be considered at the discretion of the IRG Procurement Officer. The Seller’s proposal shall include the following: (a) The solicitation number: (b) The date and time submitted: (c) The name, address, and telephone number of the seller (bidder) and authorized signature

of same: (d) Validity period of Quote:

Attachment B — Page 2 RFQ Template v6, January 2016

(e) A technical description of the items being offered in sufficient detail to evaluate compliance with the requirements in the solicitation. This may include product literature, or other documents, if necessary.

(f) If IRG informs Seller that the Commodity is intended for export and the Commodity is not classified for export under Export Classification Control Number (ECCN) “EAR99” of the U.S. Department of Commerce Export Administration Regulations (EAR), then Seller must provide IRG the correct ECCN and the name of Seller’s representative responsible for Trade Compliance who can confirm the export classification.

(g) Lead Time Availability of the Commodity/Service.

(h) Terms of warranty describing what and how the warranties will be serviced. (i) Special pricing instructions: Price and any discount terms or special requirements or

terms (special note: pricing must include guaranteed firm fixed prices for items requested.

(j) Payment address or instructions (if different from mailing address)

(k) Acknowledgment of solicitation amendments (if any)

(l) Past performance information, when included as an evaluation factor, to include recent and relevant contracts for the same or similar items and other references (including points of contact with telephone numbers, and other relevant information)

(m) Special Note: The Seller, by his response to this RFQ and accompanying signatures, confirms that the terms and conditions associated with this RFQ document have been agreed to and all of its attachments have been carefully read and understood and all related questions answered.

4. Forms: Sellers (potential bidders or suppliers) must record their pricing utilizing the format found on Attachment “A”. Sellers must sign the single hardcopy submitted and send to address listed on the cover page of this RFQ.

5. Questions Concerning the Procurement. All questions in regard to this RFQ to be directed to

GEEL Procurement Division (insert name of procurement officer)

at this email address: [email protected]

(insert email address of the procurement officer).

The cut-off date for questions is (insert date). May 10, 2018

Attachment B — Page 1 RFQ Template v6, January 2016

6. Notifications and Deliveries: Time is of the essence for this procurement. Seller shall deliver the items or services no later than the dates set forth in the contract that will be agreed by both parties as a result of this RFQ. The Seller shall immediately contact the Buyer’s Procurement Officer if the specifications, availability, or the delivery schedule(s) changes. Exceptional delays will result in financial penalties being imposed of Seller.

7. Documentation: The following documents will be required for payment for each item: (a) A detailed invoice listing Purchase Order Number, Bank information with wiring

instructions (when applicable) (b) Packing List (c) All relevant product/service documentation (manuals, warranty doc, certificate of

analysis, etc.)

8. Payment Terms: Refer to IRG purchase order terms and conditions found in www.rti.org/poterms, http://www.rti.org/POterms, http://www.rti.org/files/PO_FAR_Clauses.pdf, or http://www.rti.org/files/PO_FAR_Clauses_Commercial_Items.pdf. Payment can be made via wire transfer or other acceptable form. Sellers may propose alternative payment terms and they will be considered in the evaluation process.

9. Alternative Proposals: Sellers are permitted to offer “alternatives” should they not be able to meet the listed requirements. Any alternative proposals shall still satisfy the minimum requirements set forth in Attachment A Specifications.

10. Inspection Process: Each item shall be inspected prior to final acceptance of the item. All significant discrepancies, shortages, and/or faults must be satisfactorily corrected and satisfactorily documented prior to delivery and release of payment.

11. Evaluation and Award Process: The IRG Procurement Officer will award an agreement contract resulting from this solicitation to the responsible Seller (bidder) whose offer conforms to the RFQ will be most advantageous to IRG, price and other factors considered. The award will be made to the Seller representing the best value to the project and to IRG. For the purpose of this RFQ, price, delivery, technical and past performance are of equal importance for the purposes of evaluating and selecting the “best value” awardee. IRG intends to evaluate offers and award an Agreement without discussions with Sellers. Therefore, the Seller’s initial offer should contain the Seller’s best terms from a price and technical standpoint. However, IRG reserves the right to conduct discussions if later determined by the IRG Procurement Officer to be necessary.

The evaluation factors will be comprised of the following criteria: (a) PRICE. Lowest evaluated ceiling price (inclusive of option quantities). (b) TIMING. Provides the most advantageous work time schedule. (c) TECHNICAL. Items/Services shall satisfy or exceed the specifications (d) PAST PERFORMANCE - Provider can demonstrate his/her capability (e) EXPERIENCE WORKING IN MODAGISHU

Mandatory Requirements: • Certified and valid copy of registration certificate/license, with Banadir

Regional Administration office in Mogadishu.

Attachment B — Page 2 RFQ Template v6, January 2016

• Completed, filled and signed BOQ • Provide a company profile with list of BODs. • CVs of all key personnel. • Must have a minimum of 3 years of experience with a concrete evidence like

offers and contracts copies.

Schedule Category Max Points

Points awarded

1 Technical 35

Past performance and Reference List 15

# of projects completed through the defect and liability period in the last 5 years 10

Experience with projects of similar value to the solicited project 10

2 Key Personnel 15

Project Manager

Bachelor’s Degree in management

5 years of experience in construction Field 5

Site Engineer

Bachelor’s Degree in civil engineering or relevant area

7 years of experience in construction 5

Foreman

Diploma in Technical School

10 years of experience in construction 5

3 List of Equipment 10

Concrete Mixer 2

Vibrator 2

4x4 Pickup vehicles 2

Scaffolding 2

Attachment B — Page 3 RFQ Template v6, January 2016

Personal Protective Equipment 2

4 Methodology 10

Proposed Work Plan and Schedule of Activities 5

Reporting and Recording systems - including environmental monitoring 5

5 Budget 30

Budget proposal for the project 30

TOTAL 100

12. Award Notice. A written notice of award or acceptance of an offer, mailed or otherwise furnished to the successful supplier within the time acceptance specified in the offer, shall result in a binding contract without further action by either party.

13. Validity of Offer. This RFQ in no way obligates IRG to make an award, nor does it commit IRG to pay any costs incurred by the Seller in the preparation and submission of a proposal or amendments to a proposal. Your proposal shall be considered valid for 90 days after submission.

14. Representations and Certifications. Winning suppliers under a US Federal Contract are required to complete and sign as part of your offer IRG Representations and Certifications for values over $10,000.

15. Anti- Kick Back Act of 1986. Anti-Kickback Act of 1986 as referenced in FAR 52.203-7 is hereby incorporated into this Request for Proposal as a condition of acceptance. If you have reasonable grounds to believe that a violation, as described in Paragraph (b) of FAR 52.203-7 may have occurred, you should report this suspected violation to the IRG’s Ethics Hotline at 1-877-212-7220 or by sending an e-mail to [email protected]. You may report a suspected violation anonymously.

Acceptance:

Seller agrees, as evidenced by signature below, that the seller’s completed and signed solicitation, seller’s proposal including all required submissions and the negotiated terms contained herein, constitute the entire agreement for the services described herein.

Attachment B — Page 2 RFQ Template v6, January 2016

By: (Seller Company Name) Signature: __________________________________________________________ Title: Date:

GSPublisherEngine 0.12.100.100

CLIENTSOMALI MARINE PRODUCT

COMPANY

PROJECTPROPOSED FISH PROCESSING

FACILITY IN MOGADISHU

DRAWINGSPROPOSED ARCHITECTURAL

DRAWINGS

IMPLEMENTED BYGEEL/USAID

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

PROPOSED FISH PROCESSING FACILITYMARCH 2018: DRAWING INDEX

SHEET NO. SHEET CONTENT REVISION NO.0102

PROPOSED SET-OUT PLANPROPOSED SITE PLAN

PROPOSED GROUND FLOOR LAYOUT

PROPOSED GROUND FLOOR LAYOUT - 02

PROPOSED ELEVATIONS 01/02

PROPOSED ELEVATIONS 03/04

PROPOSED SECTION X-X

PROPOSED GENERATOR ROOM LAYOUT

PROPOSED ROOF PLAN LAYOUT

PROPOSED GENERATOR ROOM ROOF DEATILS

PROPOSED GENERATOR ROOM VIEWS

PROPOSED GENERATOR ROOM ELEVATIONS

PROPOSED GENERATOR ROOM SECTION

PROPOSED GUARD HOUSE DEATILSPROPOSED ADDITIONAL DEATILS

PROPOSED GARAGE CUBICLE DETAILS

PROPOSED SEPTIC TANK DETAILS

0304

05

06

07

0809

10

11

1213

14

15

16

1718-21 PROPOSED 3D VIEWS

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

12,800 43,000 14,200

6,80024,000

16,20047,000

45,598 24,402

6,80024,000

16,200

11,800

70,000

47,000

70,000

14,000

14,000

16,000

16,000

11,800

ENTRANCE

Guardhouse

DRIVE WAY WELLCOMPACTED GRAVEL

ROAD LIIDO

ANGLED PARKING AREA

DRIVE WAY WELLCOMPACTED GRAVEL

MAIN GATE

ELEVATEDWATER TANK

16 PAX CONFERENCE HALL

GENERAL MANAGER OFFICE

OPEN WORKSTATIONS

LADIESCHANGING RM

LADIESGENTS

GENTSCHANGING RM

WCWCWCWCWCWC

COMMON PASSAGE

RECEIVING ROOM

ICE ROOM

PACKAGINGAND

DISPATCHINGHALL

plain concrete ramp

FREEZERROOM

FREEZERROOM

FREEZERROOM

BLAST FREEZERROOM

BLAST FREEZERROOM

LOADING AREA

DRIVE WAY W

ELLCOMPACTED GRAVEL

PROCUREMENTOFFICE

LABORATORY

STORAGE ROOM

FISH HOLDINGCHILLER

cabinets

COMMONCIRCULATION AREA

PROCESSINGHALL

gt gt gtgtgtgtIC IC IC IC

SEPTIC TANK

GARBAGECUBICLE

GENERATORROOM

PROPOSEDW

AREHOUSE BUIDLING

PROPOSED SITE SET-OUT PLAN

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

12,800 43,000 14,200

6,80024,000

16,20047,000

45,598 24,402

6,80024,000

16,200

11,800

70,000

47,000

70,000

14,000

14,000

16,000

16,000

11,800

ENTRANCE

Guardhouse

DRIVE WAY WELLCOMPACTED GRAVEL

ROAD LIIDO

ANGLED PARKING AREA

DRIVE WAY WELLCOMPACTED GRAVEL

MAIN GATE

ELEVATEDWATER TANK

16 PAX CONFERENCE HALL

GENERAL MANAGER OFFICE

OPEN WORKSTATIONS

LADIESCHANGING RM

LADIESGENTS

GENTSCHANGING RM

WCWCWCWCWCWC

COMMON PASSAGERECEIVING ROOM

ICE ROOM

PACKAGINGAND

DISPATCHINGHALL

plain concrete ramp

FREEZERROOM

FREEZERROOM

FREEZERROOM

BLAST FREEZERROOM

BLAST FREEZERROOM

LOADING AREA

DRIVE WAY W

ELLCOMPACTED GRAVEL

PROCUREMENTOFFICE

LABORATORY

STORAGE ROOM

FISH HOLDINGCHILLER

cabinets

COMMONCIRCULATION AREA

PROCESSINGHALL

gt gt gtgtgtgtIC IC IC IC

SEPTIC TANK

GARBAGECUBICLE

GENERATORROOM

PROPOSED SITE PLAN LAYOUT

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

BB

CC

DD

EE

FF

GG

HH

II

JJ

KK

01 01

02 02

03 03

04 04

05 05

06 06

AA

43,000

1004,280 4,280 4,280 4,280 4,280 4,280 4,280 4,280 4,280 4,280

100

20012,690

1004,180

1004,180

1004,180

1004,180

1004,180

1004,180

1004,130

200

43,000100

4,280 4,280 4,280 4,280 4,280 4,280 4,280 4,280 4,280 4,280100

2008,410

1008,460

1004,180

1004,180

1004,180

1004,180

1004,180

1004,130

20024,000

1004,780

4,7804,780

4,7804,780

2009,410

1004,680

1002,290

1006,920

200

24,000

1004,780

4,7804,780

4,7804,780

2004,630

1004,680

1004,680

1009,310

200

8,460

14,190

3,2201001,550

2,050

1001,327

1001,321

1001,332

1001,332

1001,321

1001,327

100

3,339

+300+300

+300

+300

+300

+300

ENTRANCE

16 PAX CONFERENCE HALL

GENERAL MANAGER OFFICE

OPEN WORKSTATIONS

LADIESCHANGING RM

LADIESGENTSGENTS

CHANGING RM

WCWCWCWCWCWC

COMMON PASSAGE

RECEIVING ROOM

PROCUREMENT OFFICE

LABORATORY

STORAGE ROOM

ICE ROOM FISH HOLDINGCHILLER

PACKAGING ANDDISPATCHING

HALL

plain concrete ramp

FREEZERROOM

FREEZERROOM

FREEZERROOM

BLAST FREEZER ROOM

BLAST FREEZER ROOM

LOADING AREA

cabinets

cabinets

cabinets

COMMONCIRCULATION AREA

PROCESSINGHALL

300x300mm

cer. tiles f.f

300x300mm

cer. tiles f.f

300x300mm

cer. tiles f.f

300x300mm

cer.tiles f.f

cement sand screed f.f

cement sand screed f.f

cement sand

screed f.f

cement sand

screed f.f

cement sand

screed f.f

300x300mm

cer. tiles f.f

cement sand

screed f.f

COMMONCIRCULATION AREA

cement sand screed f.f

COMMONCIRCULATION AREA

cement sand screed f.f

cement sand screed f.f

300x300mm

cer.tiles f.f

300x300mm

non-slip cer. tiles f.f

300x300mm

non-slip cer. tiles f.f

300x300mm

non-slip cer. tiles f.f

300x300mm

non-slip cer. tiles f.f

300x300mm

non-slip cer.tiles f.f

300x300mm

non-slip cer.tiles f.f

300x300mm cer. tiles f.f

p.v

p.v

p.vp.v

p.vp.v

p.v p.v

p.v p.v

p.v

p.v p.v

p.v

p.v

p.vp.v

p.vp.v

p.vp.v

p.vp.vp.vp.vp.vp.vp.vp.vp.vp.v

p.vp.v

p.vp.v

p.v p.v p.v p.v p.v p.v p.v p.v p.v p.v

p.vp.v

E 01

E 02

E 03

E 04

XX

3,581

PROPOSED GROUND FLOOR PLAN

100mm thick block walling100mm thick insulatedpanels walling

KEY

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

I

J

K

01 02 03 04

4,630100

4,680100

4,680100

8,410

8,410

100mmthickx4000mm highinsulated panels tomanufuctureresspecs'

3750x2400mm hardenedglass folding doors withhardwood timber frames

mechanicalcoolingequipments tomanufacturers'specs'

FREEZERROOM

FREEZERROOM

FREEZERROOM

300x300mm non-slip cer. tiles f.f

300x300mm non-slip cer. tiles f.f

300x300mm non-slip cer. tiles f.f

p.vp.vp.v

p.vp.vp.v

p.v

p.v

Temp -20 deg. Temp -20 deg. Temp -20 deg.

F

G

H

04 05 06

4,280

4,280

100

4,180

100

4,180

100

100

9,310

9,310

1,340

1,500

1,440

270 1,5

002,4

10

4,180

100

4,180

mechanical coolingequipments tomanufacturers'specs'

100mm thickx4000mmhigh insulated panels tomanufuctureres specs'

BLAST FREEZER ROOM

BLAST FREEZER ROOM300x300mm non-slip cer.

tiles f.f

300x300mm non-slip cer.tiles f.f

p.v

p.v

p.v

p.v

Temp -42 deg.

Temp -42 deg.

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

BB

CC

DD

EE

FF

GG

HH

II

JJ

KK

01 01

02 02

03 03

04 04

05 05

06 06

AA

4,280 4,280 4,280 4,280 4,280 4,280 4,280 4,280 4,280 4,280

4,280 4,280 4,280 4,280 4,280 4,280 4,280 4,280 4,280 4,280

4,7804,780

4,7804,780

4,680

4,7804,780

4,7804,780

4,680

FALL

FALL

FALL

FALL

FALL

FALL

FALL

FALL

FALL

FALL

FALL

FALL

FALL

FALL

FALL

FALLPROPOSED ROOF PLAN

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

06 05 04 03 02 01

4,680 4,780 4,780 4,780 4,780

5,300

5,300

4,380300

4,480300

4,480300

4,480300

4,505

4,000

4,000x4,000mmhigh steel roll updoors

150 mm block walling plastered andpainted to approval

300mm wide steel I columnsframe for the main strucutralsupport of the building

300mm widesteel I columns

frame for themain strucutralsupport of the

building

G.LG.L

ELEVATION 01

p.v p.v

p.v

p.v

p.v p.v

A B C D E F G H I J K

4,280 4,280 4,280 4,280 4,280 4,280 4,280 4,280 4,280 4,280

300

5,000

300

5,000

300

5,000

12 deg roof on steel framedstructuresFive box profile G.I sheets Ventilation blocksVentilation blocks

150 mm block wallingplastered and painted to

approval

Plain conctreteaccess ramp

Plain conctreteaccess ramp

300mm widesteel I columnsframe for themain strucutralsupport of thebuilding

300mm widesteel I columns

frame for themain strucutralsupport of the

building

ELEVATION 02

G.LG.L

p.v p.v p.v p.v p.v p.v p.v p.v p.v p.v

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

ABCDEFGHIJK

4,2804,2804,2804,2804,2804,2804,2804,2804,2804,280

300

5,000

300

5,000

300

5,000

12 deg roof on steel framedstructures

Five box profile G.I sheetsVentilation blocks Ventilation blocks

150 mm block wallingplastered and painted toapproval

Plain conctreteaccess ramp

Plain conctreteaccess ramp

300mm wide steel Icolumns frame forthe main strucutral

support of thebuilding

300mm widesteel I columnsframe for themain strucutralsupport of thebuilding

ELEVATION 04

G.L G.L

p.v p.v p.v p.v p.v p.v p.v p.v p.v p.v

01 02 03 04 05 06

4,780 4,780 4,780 4,780 4,680

4,000x4,000mmhigh steel roll updoors

150 mm block walling plastered andpainted to approval

300mm wide steel I columnsframe for the main strucutralsupport of the building

300mm widesteel I columns

frame for themain strucutralsupport of the

building

G.LG.L

ELEVATION 03

p.v p.v p.v p.vp.v

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

01 02 03 04 05 06

4,780 4,780 4,780 4,780 4,6807,3

90

300

5,000

300

5,000

100mm thickinsulation panels to

manufacturers'specs'

Ventilationblocks

1200x2400mmhigh steel door

150 mm blockwalling plasteredand painted toapproval

100 mm blockwalling plasteredand painted toapproval

150 mm block wallingplastered and painted toapproval

900x2400mm high wooden door

12 deg roof on steel framedstructuresFive box profile G.I sheets

300mm wide steel I columnsframe for the main strucutral

support of the building

FOUNDATION SPECIFICATION- 150mm thick slab laid on app.dpm and blinding- b.r.c mesh- 600x200mm deep R.C strip fnd to S.E's details- depth to be determined on site.-hardcore fill consolidated at 300mm level

p.v p.v

p.v p.v p.v p.v

SECTION X-X

LADIESCHANGING RMSTORAGE ROOM LADIES

WC RMPASSAGE TOOFFICE AREA

COMMONPASSAGE

G.L G.L

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

2002,000

2006,000

2008,600

1200

2,00

012

00

200

4,00

020

0

2002,000

2006,000

200

200

4,00

020

0

4,40

0

MAIN ENTRY

CONTROLROOM

RAMP

A

B

GeneratorPlinth 1

GeneratorPlinth 2

GENERATOR ROOM

11 2

Fuelsupply

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

LegendDirection of fall

ROOF PLAN

TRUSS LAYOUT

500 GAUGE POLYTHENE D.P.M.

25mm MURRAM BLINDING

B.R.C. MESH A142

250mmTHK. MIN. WELL

3Y8-02-225 B2

Y10-01-250 B1

50

200200 200

600

SCALE 1:25SECTION A-A

D.P.C.

GRD. LEVEL -450

+450

50mm CONCRETE BLINDING

200

COMPACTED HARDCORE

DET

ERM

INED

ON

SITE

MIN

.120

0

FOUNDATION FOOTING DETAIL

500 GAUGE POLYTHENE D.P.M.

25mm MURRAM BLINDING

250mmTHK. MIN. WELLCOMPACTED HARDCORE

B.R.C. MESH A142

SCALE 1:25SECTION D-D

+450

+0.00

RAMP DETAILS

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

1,178 2,000 1,222

300

1,40

01,

000

SOUTH ELEVATION EAST ELEVATION

4,400

150 1001,876

1001,876

100 150

NORTH ELEVATION WEST ELEVATION

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

450

470

330 68

71,

213

911

2004,025

150

Gauge 28 prepainted iron resincotroofing sheets: IT4 box profile,

nailed on sawn hardwood structure.Roof pitch=22o.

For structure; see S.E. details.

Heavy guage fabric mesh wire

R.C. strip footingand foundation walling,see S.E. details.

RampSlope 10o

Purpose built CHS gatewith heavy duty fabric mesh

200mm hollow block wallingwith plaster and paint

Timber framework

150mm thick R.C. floorslabwith B.R.C. mesh and D.P.M.

cast on well compacted hardcorewith blinding layer; see S.E. details.

RCC plinth.

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

01 02

A

B

3,200200

2,800200

2002,800

200

3,200

2002,800

200200300

1,200300

1,000200

3,600

200

2,000

200

1,000

200

200 55

090

055

0200

1,000

200

3,600

200

2,000

200

1,000

200

+450

GAURD HOUSE

TYPICAL GUARD HOUSE LAYOUTTOTAL FLOOR AREA = 11.5M2

300x300mm cer.tiles f.f

p.v

p.v

E 01

E02

E04

E 03

C C

p.v

B

A

01 02PVC gutters with pvcwater downpipes

FALL

FALL

FALL

FALL

GUARD HOUSE ROOF PLAN

01 02

3,000

1,200

900

1,500 900x2400mm

high steel flushdoor

PVC drainagedownpipes

2 No. concrete stepsT=300mm,R=150mm

p.v

G.L G.L

First Storey3.950m

Slab level0.45m

ELEVATION 01

p.v

A B

3,400

1,200

900

1,500

1200x1500mm highsteel windows

wall plastered andpainted to approval

p.v

G.L

First Storey3.950m

Slab level0.45m

ELEVATION 02

02 01

3,000

wall plastered andpainted to approval

G.L G.L

First Storey3.950m

Slab level0.45m

ELEVATION 03

B A

3,400

G.LG.L

First Storey3.950m

Slab level0.45m

ELEVATION 04

02 01

3,000

900

1,500

1,060

450

3,500

200mm thick concrete hollow blockwalling plastered and painted to approval

200x300mm deep R.Cbeam to S.E details

p.v

FOUNDATION SPECIFICATION- 150mm thick slab laid on app.dpm and blinding- b.r.c mesh- 600x200mm deep R.C strip fnd to S.E's details- depth to be determined on site.- hardcore fill consolidated at 300mm level

- pitch 18.0 deg Five box profile 28 guage roofing- 100x50mm rafters at 600mm c/c 50x50mm- 100x50mm ties and struts- 100x75mm wall plate- fascia board and gutter to S.E's detail- all timber to be cured & painted with 2 coats of timber- 12mm thick chipboard

First Storey3.950m

Slab level0.45m G.L

SECTION C-C

d.p.cd.p.c

p.v

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

300x300x3150mm High R.CBoundary wall with 50mm

thick coping

3000mm high masonry block wallwith 50mm thick coping plastered andpainted to approval

4,000 4,000 4,000 4,000

BOUNDARY WALL - ELEVATION

4,000 4,000

300X300x3150mmR.C columns

200mm thick concretehollow blocks walling

BOUNDARY WALL - FOOTING LAYOUT

A

A

B

B

3000x3000mmhigh steel gate

1000x3000mmhigh steel gate

ACCESS GATE

200

D.O.S

3,000

200

2,800

600x200mm deep R.C stripfoundation to S.E details `

Rubble stone

200mm thick concretehollow block walling with50mm thick coping

G.LG.L

SECTION A-A

200

D.O.S

3,150

200

2,950

600x200mm deep R.C stripfoundation to S.E details `

Rubble stone

200mm thick concretehollow block walling with50mm thick coping

G.LG.L

SECTION B-B

600

D.O.S

5,540

2,600

600

D.O.S

5,540

1,000 1,000

2300 litres plasticwater tank

steel water supportstructure,30X5 flatbar

125x125x30 EN10025-2-S355JRsteel plattform

steel water supportstructure,60X60X5angleRHS

40x40x5 anglehorizontal brace

1200mm highsteel guard rails

1000x1000x600mm25Mpa concrete footing

60x60x5 Rhsbolted to theconcrete footing

G.L

SECTION Y-Y

2,200

2,400

2300 litresplastic watertank

Steel ladder with25mm plates

Y

Y

ELEVATED WATER TANK PLAN

2,200

1,850

1000x100x600mm 25Mpaconcrete footing

ELEVATED WATER TANKFOUNDATION PLAN

D.O.SDETERMINED ON SITE MINIMUM OF 1000MM DEEP

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

01 02

A

B

2,600200

2,200200

200600 1,000 600

200

2,600

2002,200

200

200

2,200

200

2,600

200

2,200

200

2,600

2,000

2,000

2,000

+450

Plain concreteramp

GARBAGE AREACement screed f.f

p.v

GARBAGE CUBICLETOTAL FLOOR AREA = 6.80M2

E02

E04

E 01

E 03

D

D

01 02

A

B

PVC gutters with pvcwater downpipes

GARBAGE AREA ROOF PLAN

B A

2,400

450

2,400

600

50

Plain concreteramp

ELEVATION 02

First Storey3.50m

Slab level0.45mG.L

02 01

2,400

450

3,050

2,100

265

1000X2100mmhigh steel door

400mm highventilation blocks

ELEVATION 01

First Storey3.50m

Slab level0.45mG.L

0201

2,400

450

3,050

ELEVATION 03

G.L

First Storey3.50m

Slab level0.45m

BA

2,400

450

3,050

ELEVATION 04

L

First Storey3.50m

Slab level0.45m

B A

2,400

1000x2100mm high steeldoor to Archs'schedules

200x300mm deep R.Cbeam to S.E details

G.LFOUNDATION SPECIFICATION- 150mm thick slab laid on app.dpm and blinding- b.r.c mesh- 600x200mm deep R.C strip fnd to S.E's details- depth to be determined on site.- hardcore fill consolidated at 300mm level

ROOF SPECIFICATION- pitch 18.0 deg Five box profile 28 guage roofing- 100x50mm rafters at 600mm c/c 50x50mm- 100x50mm ties and struts- 100x75mm wall plate- fascia board and gutter to S.E's detail- all timber to be cured & painted with 2 coats of paint

First Storey3.50m

Slab level0.45m

GARBAGEAREA

d.p.c d.p.c

SECTION D-D

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

PROPOSED VIEW 01

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

PROPOSED VIEW 02

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

PROPOSED VIEW 03

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Reviwed By :

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

ARCHITECTURAL DRAWINGS

SHEET REVISION N0.

SOMALIA MARINEPRODUCTS CO.

of SMPC

CLIENT

Drawing title:

Designed By ENG. Wanja DavidENG. Salah Abdulkadir

GEEL/USAIDIMPLEMENTED BY -

PROPOSED VIEW 04

GSPublisherEngine 0.12.100.100

DRAWINGSPROPOSED STRUCTURAL

DRAWINGS

CLIENTSOMALI MARINE PRODUCT

COMPANY

PROJECTPROPOSED FISH PROCESSING

FACILITY IN MOGADISHU

IMPLEMENTED BYGEEL/USAID

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Designed By:Drawn By:

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

STRUCTURAL DRAWINGS

SHEET REVISION N0.of SMPC

CLIENT

Drawing title:

GEEL/USAIDIMPLEMENTED BY -

SOMALIA MARINEPRODUCTS CO. ENG. Wanja David

ENG. Salah Abdulkadir

PROPOSED FISH PROCESSING FACILITYMARCH 2018: DRAWING INDEX

SHEET NO. SHEET CONTENT REVISION NO.0102 FOUNDATION DETAILS

FOUNDATION LAYOUT

ROOF TRUSSES DETAILS03

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Designed By:Drawn By:

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

STRUCTURAL DRAWINGS

SHEET REVISION N0.of SMPC

CLIENT

Drawing title:

GEEL/USAIDIMPLEMENTED BY -

SOMALIA MARINEPRODUCTS CO. ENG. Wanja David

ENG. Salah Abdulkadir

43,075

43,075

24,125

24,125

43,075

A A

A

A

A

A

A A

A A

A

A

A

A

150mm thick slabA142 BRC mesh onboth top & bottom

150mm thick slabA142 BRC mesh onboth top & bottom

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

C1B1

FOUNDATION LAYOUT

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Designed By:Drawn By:

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

STRUCTURAL DRAWINGS

SHEET REVISION N0.of SMPC

CLIENT

Drawing title:

GEEL/USAIDIMPLEMENTED BY -

SOMALIA MARINEPRODUCTS CO. ENG. Wanja David

ENG. Salah Abdulkadir

150

600

200

DET

ERM

INE

ON

SIT

E

500g POLYTHENE SHEET.50MM THK MURRUM BLINDING.

WELL COMPACTEDHARDCORE TO STRUCTURALENGINEER'S APPROVAL

1000 GUAGE POLYTHENE PAPER DPC

EXTERNAL STRIP FOOTING)

A142 B.R.C. WIRE MESH

MASS CONCRETE CLASS 20/20

50mm Thick Blinding(1:4:8 Mix)

Concrete stripfooting

D-01

300

1,500

D.O

.S5,

000

1,500

1,50

0

300

300

200

200

0505

300X200 COLUMN C1

50mm Thick Blinding(1:4:8 Mix)

SECTION 01 - 01

6Y12-01

Y8-02-200

GROUND FLOOR

01 01

8Y10-05-200B2

8Y10-05-200B1

1500X1500X300 BASE B1

ROOF LEVEL

heavy hex bolt tighteningthe steel column on theconcrete foundation

Concrete columnfoundation

steel I sectioncolumn

DETAIL O1

GSPublisherEngine 0.12.100.100GSPublisherEngine 0.11.100.100

NOTES

All drawings and concepts remain theproperty

All dimensions are in mm unless statedAny discrepancies in the drawings should bereported to the consultants before thecontractor commences work on site.

*

PROJECT: ScaleDate

AS SHOWNMARCH 2018

Designed By:Drawn By:

-- PROPOSED FISH COLD

CHAIN PROCESSINGBUIDLINGS

STRUCTURAL DRAWINGS

SHEET REVISION N0.of SMPC

CLIENT

Drawing title:

GEEL/USAIDIMPLEMENTED BY -

SOMALIA MARINEPRODUCTS CO. ENG. Wanja David

ENG. Salah Abdulkadir

1,2011,201

1,2011,202

1,1941,195

1,1951,195

1,1951,195

1,1951,195

1,1951,195

1,1951,195

1,1701,170

1,1701,172

100mm