Renfrew CFDC Renewable Energy Final Report · Renfrew County CFDC Renewable Energy Report May 2011...

Transcript of Renfrew CFDC Renewable Energy Final Report · Renfrew County CFDC Renewable Energy Report May 2011...

Final Report May 11, 2011

EXECUTIVESUMMARY.........................................................................................................................................1

1.ACKNOWLEDGEMENTS...................................................................................................................................2

2.OVERVIEWANDPROJECTSCOPE.................................................................................................................3PROJECTSCOPE.......................................................................................................................................................................4

3.PROCESS...............................................................................................................................................................5PROJECTTEAM........................................................................................................................................................................5FINANCIALMODELS................................................................................................................................................................6SITEVISIT‐RENFREW...........................................................................................................................................................7SITEVISIT‐SHARBOTLAKE.................................................................................................................................................7SECONDSITEVISIT–RENFREW...........................................................................................................................................8NyleneCanadaInc...................................................................................................................................................................8BenHokum&SonLtd............................................................................................................................................................9HerbShaw&SonsLtd........................................................................................................................................................10

4.LITERATUREREVIEW...................................................................................................................................12ONTARIOFEED‐INTARIFF(FIT).......................................................................................................................................16BIOMASSTECHNOLOGIES....................................................................................................................................................21CANADIANENERGYPRODUCTIONFROMBIOMASS.........................................................................................................27CapacityFactors....................................................................................................................................................................28

UBCBIOENERGYRESEARCHANDDEMONSTRATIONPROJECT.......................................................................................30FORESTBIOMASSVOLUME..................................................................................................................................................32MILLRESIDUE.......................................................................................................................................................................32FORESTRESIDUESUPPLYCHAINS.....................................................................................................................................33CASESTUDY:BIOMASSPOWERCOSTANDOPTIMUMPLANTSIZEINWESTERNCANADA.............................................34REVIEWCONCLUSION...........................................................................................................................................................35

5.ASSUMPTIONS,ANALYSISANDDISCUSSION........................................................................................36ASSUMPTIONS........................................................................................................................................................................36ANALYSIS................................................................................................................................................................................38PaybackPeriodDifference...............................................................................................................................................42FuelCostDifference.............................................................................................................................................................42

6.RECOMMENDATIONS....................................................................................................................................43

APPENDIX1:ONTARIOBIOMASSENERGYALLIANCE...........................................................................46

APPENDIX2:INTERVIEWQUESTIONS........................................................................................................47

APPENDIX3:HOWBIOMASSENERGYWORKS.........................................................................................51

APPENDIX4:SPREADSHEETCALCULATIONSOFFITRATESCENARIOS............................................0

APPENDIX5:HYDROONECONNECTIONIMPACTASSESSMENTFEES................................................0

GLOSSARY.................................................................................................................................................................3

Renfrew County CFDC Renewable Energy Report May 2011 Page 1 of 70

Executive Summary

The Ontario government's 20-year energy plan, Building Our Clean Energy Future, recommended creating a balanced mix of clean power sources and increasing Ontario's power supply from renewable sources such as wind, solar and bio-energy to 13 per cent by 2018, up from the current level of 3 per cent.

The Monieson Centre was approached to conduct a preliminary feasibility study on energy generation from biomass under the Ontario Feed-In Tariff (FIT) program by Renfrew County Community Futures Development Corporation (RCCFDC). RCCFDC is a community-based non-profit organization that is dedicated to creating opportunities for entrepreneurship and the pursuit of economic growth in Renfrew County. The research plan was submitted to ethical review by both the General Research Ethics Board at Queen’s University and the Research Ethics Board at St. Lawrence College and received the necessary approvals before commencing the project. Following a literature review, several site visits and extensive financial modeling, a revised FIT rate in the range of $0.273 to $0.450/kWh would seem to be more accurate in attracting interest, helping meet Ontario’s energy demands, restoring jobs and strengthening the Renfrew County economy. The major revisions to the assumed OPA FIT rate calculations include a more realistic fuel cost based on current prices being paid for biomass in Renfrew County and a reduced payback period to be more in line with current industry standards. Recommendations include the following:

1. Promote Biomass through a revised FIT rate: Provide jobs and much-needed energy production while strengthening Ontario’s forestry economy by using biomass for the production of electricity.

2. Remove Barriers: Stimulate the use of biomass for the production of electricity and reflect the true costs of this production by increasing the FIT rate to the range of $0.273 to $0.450/kWh.

3. Remove Barriers: Follow the lead of Europe and British Columbia and update operating engineers (steam engineers) regulations such as Ontario Regulation 219/01.

4. Remove Barriers: Eliminate or reduce to a cost recovery basis all connection assessments and connection fees.

Renfrew County CFDC Renewable Energy Report May 2011 Page 2 of 70

1. Acknowledgements

Leo Hall, Owner/Operator, Opeongo Forestry Service 199 Opeongo Road, Renfrew, ON K7V 2T2 Tel: 613-432-5209 [email protected] A considerable amount of background information was gleaned from Mr. Hall’s research, both here and in Europe, into the use of biomass in electricity and steam generation, and he provided invaluable assistance in reviewing and refining the report drafts. David Stewart, Chair, Renfrew County Community Futures Development Corporation 2 International Drive, Pembroke, ON K8A 6W5 Tel: 613-735-3951 [email protected] Sincere thanks to Mr. Stewart who opened many doors, made many introductions, and clarified many concepts to greatly improve the data collection for this report. Alastair Baird 9 International Drive, Pembroke, ON K8A 6W5 Tel: 613-735-0091, ext. 466 [email protected] Mr. Baird helped coordinate site interviews and introduced the research team to many valuable contacts in Renfrew County. Martin Lensink, P. Eng., Principal-In-Charge, CEM Engineering 26 Hiscott Street, Suite 201, St. Catharines, ON L2R 1C6 Tel: 905-935-5815 [email protected] www.cemeng.ca We acknowledge and thank Martin Lensink of CEM Engineering for his substantial assistance. CEM has extensive experience in converting biomass resources to thermal and electrical energy via a number of cogeneration technologies. They prepared the initial financial model using the assumptions provided by the OPA in May 2009. Christopher Amey, PE, Director, Project Development, Rentech, Inc. 1331 17th Street, Suite 720, Denver CO 80202 Tel: 720-274-3116 [email protected] www.rentechinc.com

Renfrew County CFDC Renewable Energy Report May 2011 Page 3 of 70

Mr. Amey acted as a very knowledgeable "sounding board" for ideas and conclusions relevant to the project and consistently delivered excellent suggestions.

2. Overview and Project Scope

On November 23, 2010, following passage of the Green Energy and Green Economy Act, 2009,1 the Ontario government announced an updated Long-Term Energy Plan that set the course for a clean energy revolution to create thousands of good new jobs in Ontario, and clean up the air we breathe. The government's 20-year energy plan, Building Our Clean Energy Future,2 recommended creating a balanced mix of clean power sources and increasing Ontario's power supply from renewable sources such as wind, solar and bio-energy to 13 per cent by 2018, up from the current level of 3 per cent.

Over the next 20 years, about 80 percent of Ontario’s existing electricity supply capacity will need to be replaced with a combination of conservation and new supply facilities. This outlook reflects some clear realities: projected population and economic growth; the decisions required for Ontario’s nuclear-power generating facilities, which today account for about one-half of total supply; and the need to eliminate environmentally harmful coal-fired generation, which today accounts for about 20 percent of supply.3

Encouraged by this positive synergy between job creation and renewable energy production, the Renfrew County Community Futures Development Corporation (RCCFDC) approached The Monieson Centre to conduct a preliminary feasibility study on energy generation from biomass under the Ontario Feed-In Tariff (FIT) program. RCCFDC is a community-based non-profit organization that is dedicated to creating opportunities for entrepreneurship and the pursuit of economic growth in Renfrew County.

Biomass energy – the conversion of organic waste matter into a combustible fuel for electricity generation – is a cost-effective energy source that can reduce dependence on non-renewable fuels without harming the environment and as an adjunct to other agricultural operations. Ontario has plentiful sources of biomass than can be tapped for electricity generation, especially residual material from forestry and

1 Government of Ontario, Legislative Assembly of Ontario, http://www.ontla.on.ca/web/bills/bills_detail.do?locale=en&BillID=2145.(accessed Mar 29, 2011) 2 Government of Ontario, “Ontario’s Long Term Energy Plan, Building Our Clean Energy Future”, http://www.mei.gov.on.ca/en/energy/html/LTEP_en.html. (accessed March 16, 2011) 3 Government of Ontario, “Ontario’s Renewable Energy Standard Offer Program”, June 2008

Renfrew County CFDC Renewable Energy Report May 2011 Page 4 of 70

agricultural production, as well as millions of tonnes of organic municipal waste.4

The Monieson Centre works with organizations and researchers to provide leading-edge solutions to business, industry and community challenges. Findings are then translated into effective, practical recommendations. The Monieson Centre offers real-world solutions that are evidence-based and comprehensive, so working with RCCFDC on this project was a good fit. Currently, the revenue for electricity fed into the Ontario Power Authority (OPA) grid system is set by the FIT rate. The current FIT rate for biomass power is set at $0.13/kWh, while solar and wind rates are set much higher, up to $0.80/kWh. Potential operators of biomass plants in Renfrew County have estimated a break even price of $0.19-$0.20/kWh to meet the costs of wood supply and plant construction and operation. The OPA will review and modify (if justified) its FIT rates in the fall of 2011 with analysis beginning in spring 2011. To support the justification of an increased rate for biomass energy, RCCFDC sought research on biomass co-generation (power/heat) costs versus revenue. This report opens a dialogue between proponents of low-carbon socioeconomic development in Eastern Ontario and members of the business, economic development, and academic communities in the region. The aim is to support sustainable business development by attracting the required financial and human capital.

Project Scope The scope of the project includes a literature review and an analysis of input costs for a biomass energy supply system including the following:

Biomass value paid to landowner or mill owner in the case of sawmill residue Harvesting costs Transportation costs Processing costs at the energy production site Energy site costs (i.e., construction-capital investment return, operating costs,

labour, utilities, administration and marketing). Based on these costs, recommendations will include an appropriate FIT rate in compliance with the Green Energy and Green Economy Act to encourage the production of electricity in Renfrew County from biomass.

4 Ibid, p. 5

Renfrew County CFDC Renewable Energy Report May 2011 Page 5 of 70

3. Process

Project Team The Monieson Centre established a project team of Queen's faculty and graduate students and experts from other universities to oversee the project, execute the research protocol, and provide recommendations. The research plan underwent ethical review by both the General Research Ethics Board at Queen’s University and the Research Ethics Board at St. Lawrence College and received the necessary approvals before commencing. The project team included the following: The Monieson Centre Dr. Yolande Chan, Director & Jeff Dixon, Assistant Director By drawing together leading researchers, The Monieson Centre at Queen’s School of Business helps organizations and communities discover how to harness and enhance their knowledge capital in the knowledge economy. Teams conduct applied research for client organizations, focusing on complex organizational and knowledge management issues. The Centre then translates these research findings into practice-based recommendations. Moore Partners Steven Moore, Partner & Susan Moore, Partner Moore Partners has implemented and assessed sustainability projects for over 25 years. Current clients include Queen’s University, Bader International Study Centre, Quinte Economic Development Commission, Lennox & Addington Economic Development, St. Lawrence College, Loyalist College, Toronto Region Conservation, Lower Trent Conservation, Ganaraska Region Conservation Authority, Public Works and Government Services Canada, Lennox & Addington Stewardship Council, and Hastings Stewardship Council. Laurentian University’s Bachelor of Business Administration degree program at St. Lawrence College Vincent Durant, Professor Laurentian University offers its Bachelor of Business Administration (BBA) at St. Lawrence College in Kingston. The program is focused on providing an honours degree that combines the practical strengths of a college with the theoretical underpinnings of a university. The focus of this program is to provide access to education in a seamless manner, which gives credit for prior academic and experiential learning.

Renfrew County CFDC Renewable Energy Report May 2011 Page 6 of 70

Queen’s School of Business Centre for Responsible Leadership Dr. Tina Dacin, Director The Queen’s School of Business Centre for Responsible Leadership was founded in 2004 to educate a generation of globally responsible leaders. It fosters high-quality research to build knowledge on topics related to the successful formation and implementation of Responsible Leadership practice strategies. It supports the non-profit community and is a global advocate for Responsible Leadership. Queen’s University Institute for Energy and Environmental Policy Dr. Warren Mabee, Director The Queen's Institute for Energy and Environmental Policy arises from the conviction that trans-disciplinary research increases the scope and influence of work that is already being done. The Institute promotes the meeting of unlike minds; it offers a crossroads where the best academic research intersects with the challenges of policy makers and industry. Sustainable Bioeconomy Centre at Queen’s University Dr. Andrew Pollard, Director The Sustainable Bioeconomy Centre (SBC) is creating a collaborative community to advance the environmental, economic and ethical use of biological resources within the Great Lakes Region. The SBC community serves as the forum for biological, financial and academic engagement in the process of advancing the bioeconomy. Also contributing were Tom Elmer, Industry Liaison, St. Lawrence College; Kevin Majkut, MSc Candidate, Queen’s School of Business; Kanishka Panchal, MSc Candidate, Queen’s School of Business; and Jacqueline Corbett, PhD Candidate, Queen’s School of Business. Data collection included industry analysis, local site analysis, in-depth interviews, and information from other jurisdictions. Data analysis included financial modeling of several different sizes of electricity generating facilities.

Financial Models A web-based search was initiated by the research team to discover what financial models were available for an analysis of the costs of burning biomass to produce electricity. Several models were considered, including one dealing with the food industry, the best being the RetScreen International Model developed by the government of Canada.5 The team also investigated a model developed and used by CEM Engineering in their earlier study on turning biomass to steam that involved Renfrew County and an industrial manufacturer. After discussions with a member of the research team, Martin

5 Natural Resources Canada, “RETScreen Software Biomass Heating Model”, http://www.retscreen.net/ang/g_biomas.php. (accessed November 5, 2010)

Renfrew County CFDC Renewable Energy Report May 2011 Page 7 of 70

Lensink of CEM Engineering generously supplied the research team with the financial model used in that study. The research team discussed the two models (RetScreen and CEM's model) with Prof. Warren Mabee, who was familiar with RetScreen. It was agreed that the CEM model was the better one for our purposes, in part because Martin Lensink and his colleagues had been able to infer, from discussions/meetings with OPA, certain assumptions being made by OPA for their determination of FIT rates. Concurrent with these decisions, data gathering and verification were being carried out by the research team including preliminary contacts with forestry companies and sawmill operators in Renfrew County and the management at Nylene Canada.

Site Visit - Renfrew A Member of the research team attended a meeting of the Ontario Biomass Energy Alliance (OBEA) on November 23, 2010 in Renfrew chaired by Alastair Baird, Manager of Business and Economic Development at the County of Renfrew. The objective of the meeting was to begin promoting investment in biomass projects and finding interested parties willing to invest. (For more information on the Ontario Biomass Energy Alliance, please see Appendix 1.) Issues addressed included the following: Reduced forestry activity in Renfrew County is badly hurting the local economy Practices in Sweden, Finland, and Germany might be helpful in our region Most incentives have been used for power and not for heat In Ontario, we have ample forests but reduced sawmill production and reduced

sawmill residue The Forest Products Association of Canada may have useful models Limited grid capacity may hinder biomass projects Unfortunately, OPA will not assess capacity until an application is submitted.

Site Visit - Sharbot Lake On December 9, 2010, members of the research team met with David Stewart, Chair of RCCFDC, and Barry Verch of M. W. Miller Logging, based in Eganville, for a tour of one of Barry’s red pine harvest operations on crown land. They viewed a harvesting machine that cut the trees down, stripped the branches and cut the logs into lengths and the loading operation of pine logs to a logging truck, as Barry explained the machinery and the process.

Renfrew County CFDC Renewable Energy Report May 2011 Page 8 of 70

Most wood contains 60-75 per cent moisture when cut. If left to dry for several months, it will decrease to 30-40 per cent. A certain level of residue should be left on the ground to replenish nutrients for future growth, but much of the nutrient requirement is supplied by dropped needles from previous years. The local situation was described in detail by David and Barry, including the closure of pulp mills and panel operations, and the local loss of jobs. Without the income from the sale of forest residue and low-end products, the normal logging operations are not profitable enough to continue. There was a good discussion of costs, transportation, uses for the wood products, government restrictions, and possible scenarios for FIT programs.

Second Site Visit – Renfrew Prior to the Renfrew research interviews, the research team identified three interview candidates and sent them each a questionnaire in advance (see Appendix 2). During a second visit to Renfrew County on February 3rd and 4th, 2011, interviews were held with representatives of Nylene Canada Inc. in Arnprior, Herb Shaw & Sons Ltd. in Pembroke and Ben Hokum & Son Ltd. in Killaloe to gather data for use in developing a financial model/case to determine the most appropriate FIT rate for biomass electricity production. Meetings were also held with David Stewart, Chair of RCCFDC; Diane McKinnon, Executive Director of RCCFDC; and Leo Hall, owner/operator of Opeongo Forestry Services, Renfrew. David Stewart and Leo Hall offered invaluable assistance during this visit to Renfrew County by taking time from their busy schedules to discuss the Renfrew biomass project and to view nearby logging operations.

Nylene Canada Inc. The Nylene Canada Inc. Arnprior Site has been in operation since 1966. It is a diverse manufacturing plant for nylon 6 polymers and continuous filament carpet yarns in North America. The processes of polymerization, depolymerization, compounding, fiber extrusion, cabletwist and heatsetting are contained on this site. Nylene has developed an integrated closed loop system producing polymers and yarns with varying levels of recycled content. The use of steam in their manufacturing process and a large industrial load makes them a possible candidate for a cogeneration program. David Steeds, Director of Manufacturing Services at Nylene Canada,6 pointed out in person and in subsequent correspondence the need for Operating Engineers for any

6 http://www.nylene.com/nylene_canada_inc.html (accessed March 22, 2011)

Renfrew County CFDC Renewable Energy Report May 2011 Page 9 of 70

biomass plant under consideration. He made reference to Ontario Regulation 219/017 that lays out the need for operators of boilers in Ontario. He indicated that this requirement may be a regulatory and financial challenge to the ability to operate biomass electrical generation facilities and mentioned other jurisdictions, such as British Columbia and Norway, where this may not be required because of differences in regulations regarding the construction and operation of steam generation and prime movers. Renfrew Sawmills Stockpiling of Residue Cost is a major reason that the mills cannot stockpile a large amount of residue. Other considerations include environmental issues, such as sawdust blowing into the air and water, risk of fire, etc. If the market dries up, the mills can only stockpile for the short term. Revenues The mills receive average net rates of $18 to $35 per green tonne, net to the mill, depending on the species of biomass. They do not calculate the “cost” of their residual biomass. Rather, any net revenue from selling it is applied against the costs of their overall sawmill operations. Cogeneration For some mill operations, there may be an opportunity to operate a “package boiler” on site. This would involve chipping the residuals by putting them through a hammermill, then using torrefaction to render the material to a coke-like consistency, making it easier to store than either raw biomass or pellets. Following this, the torrified material is fed into a cogeneration package boiler that would provide electricity to the grid under the FIT program and heat that could be used to kiln-dry lumber on site.

Ben Hokum & Son Ltd. Ben Hokum & Son Limited,8 a family-operated company in business since 1956, is situated near Killaloe. Their operation utilizes a large log mill using a carriage for its primary breakdown and an optimized, automated high production small log mill. They have grown to be the largest mill in Renfrew County. North American Sawmills Machinery is part of Ben Hokum & Son, and specializes in the fabrication of sawmill machinery, and parts and steel distribution. Their large volume of lumber production makes them a possible candidate for a biomass generation facility. Dean Felhaber, President of Ben Hokum & Son, indicated that they have room for a biomass cogeneration (electricity and heat) operation at their site in Killaloe, and provided the following details on their operation:

7 Ontario Regulation 219/01, Operating Engineers, Queen’s Printer for Ontario, 2001. 8 http://benhokum.com/ (accessed March 22, 2011)

Renfrew County CFDC Renewable Energy Report May 2011 Page 10 of 70

Their sawmill produces approximately 100,000 green tonnes of bark, sawdust, chips

and roundwood pulp per year. Their sawmill operation produces 55 per cent usable lumber and 45 per cent residue. They currently ship the vast majority of their biomass to Quebec. Bark is sent to southern Ontario. 90 per cent goes for mulch; 10 per cent goes to

other locations for hog fuel (wood chips or shavings, residue from sawmills, etc., used for fuel, landfill, and animal feed, and for surfacing paths and running tracks). (Mulch is bark that is used for landscaping, paths/tracks, and soil amendment applications. Hog fuel is bark that is used for fuel purposes.)

They have a 44 kilovolt (kV) line to their site that might be capable of transmitting to the grid.

Herb Shaw & Sons Ltd. Established in 1847, Herb Shaw & Sons Limited, situated near Pembroke, is a family owned company producing pine lumber and utility poles with timber procured from managed forests. The company produces 45,000 poles and the sawmill produces 14 million board feet of rough lumber annually. Their operation includes a sawmill, poleyard and wood-drying facilities. They are a possible candidate for a biomass generation facility because they have the required space and a high volume of tree-length wood. John Shaw, President, and his cousin Dana Shaw, Vice-president, are the principals of Herb Shaw & Sons Ltd.9 Details of their operation are as follows: Currently, 95 per cent of their sawmill residue (biomass) goes to pulp mills in

Quebec. Bark goes for landscaping to an agent in Ontario for mulch. Their yearly production of residue includes:

o 9,000 ODT (oven-dried tonnes) of pine chips o 5,000 ODT of sawdust o 250 loads of white pine bark o 300 loads of red pine peeling (from poles) o 10,000 GT (green tonnes) with 60 per cent moisture content of hardwood

pulp (roundwood) o 20,000 GT of poplar pulp (roundwood) o 10,000 GT of softwood pulp (roundwood).

Note: A load of green wood is a tractor-trailer load with a moisture content of 60 per cent and is equivalent to 14 to 15 oven-dried tonnes. A load of oven-dried wood is a tractor-trailer load with a moisture content of close to zero per cent and is 36 tonnes.

9 http://www.shawlumber.ca/operations (accessed March 22, 2011)

Renfrew County CFDC Renewable Energy Report May 2011 Page 11 of 70

The moisture content makes a significant difference in transportation costs and the load limit on the highways is 36 to 38 tonnes per load. Information gained from this second Renfrew trip was circulated to the research team and adjustments were made to the CEM model to include five scenarios: a 1.5-year payback, a 3-year payback, a 5.2-year payback, a 6.4-year payback, and the current FIT rate (11.8-year payback). These scenarios are reported in the Assumptions, Analysis and Discussion section of this report.

Renfrew County CFDC Renewable Energy Report May 2011 Page 12 of 70

4. Literature Review

The Case for Biomass Ontario Electricity Needs According to the Ontario government’s Long Term Energy Plan10 (released in September, 2010) Ontario's population is expected to rise about 28 per cent — a gain of almost 3.7 million people by the year 2030. The Ontario Power Authority forecasts that this will require more than 15,000 MW (megawatts) of electrical capacity to be renewed, replaced or added. To meet these needs Ontario will need a diverse supply mix and both small and large generators.

Ontario is also planning for energy generation that will involve efficient, localized generation from smaller, cleaner sources of electricity rather than relying exclusively on large, centralized power plants transmitting electricity over long distances. This strategy is known as "distributed generation." Distributed generation opens up opportunities for smaller power producers, allowing individuals, Aboriginal communities and small co-operatives or

partnerships to become generators. Ontario will continue to develop its renewable energy potential over the next decade. Based on the medium growth electricity demand outlook, 10,700 MW of renewable capacity (wind, solar and bioenergy) as part of the supply mix by 2018 is anticipated. This forecast is based on planned transmission expansion, overall demand for electricity and the ability to integrate renewables into the system. This target will be equivalent to meeting the annual electricity requirements of two million homes. The province's renewable energy capacity target will be met with the development of renewable energy projects from wind, solar, biogas, landfill gas and biomass projects across Ontario.11

10 Ontario Ministry of Energy, Long Term Energy Plan, Queen’s Printer for Ontario, 2010, http://www.mei.gov.on.ca/en/energy/, p. 8.Queen’s Printer for Ontario, 2010 11 Ibid., p. 31

Renewable energy—wind, solar, hydro and bioenergy — is an important part of the supply mix.1o

Renewable energy makes it possible to generate electricity in urban and rural areas where it was not feasible before.11

Renfrew County CFDC Renewable Energy Report May 2011 Page 13 of 70

According to the Canadian federal government’s Invest in Canada, a bureau of the Department of Foreign Affairs and International Trade, Canada has the world’s third-largest forest areas; some 44 per cent of the land area is forested and 92 per cent of Canadian fibre (trees) is publicly owned. As could be expected, Canada has a large, well-developed forest sector and is one of the world’s largest exporters. For example, the forest industry exported $41.9 billion in paper, pulp, lumber, board, and other forest products in 2005. The production of woody biomass, which could be used as fuel for electricity generation, is commensurate with this production of forest goods.12 Ontario Biomass With over 68 million acres of forested land and a long-established forestry industry, Ontario offers great opportunities for biomass cogeneration. It is estimated that Ontario’s forest biomass has the potential to supply about 7 per cent of the province’s electrical energy.13 Ontario’s Ministry of Natural Resources is exploring the potential for electricity generation from forest biomass, promoting innovative technologies and developing a policy framework that encourages companies and communities to engage in business ventures in this sector. Renfrew County Renfrew County has a wide diversity of forests, topography, lakes and wetlands. The Canadian Shield that dominates a large portion of the county is marked by red and white pine, aspen, red oak and red maple. Tolerant hardwoods such as sugar maple, beech and basswood prefer scattered pockets of better soil. Sandy flats support jack pine, while the west end of the county is more boreal with aspen, birch, spruce and fir. Finally, the eastern region of the county has agricultural clay soils and supports mixed woods with elm, green ash and bur oak.14 Forestry is a vital part of Renfrew County. Approximately 265,100 hectares (655,100 acres) of the forest is private land, covering 53 per cent of the county, and over 100 forest product companies depend on these forests.15 However, this vitality is diminishing. Ontario's Annual Allowable Cut, that is, the volume of wood that can be harvested from public lands each year, is roughly 32 million cubic metres (m3)/annum.16 But, for many reasons, the Ontario forestry industry is shrinking. 12 Invest in Canada: Biomass Cogeneration, Invest in Canada Bureau, Foreign Affairs and International Trade, Her Majesty the Queen in Right in Canada, 2009, http://investincanada.gc.ca/eng/publications/biomass.aspx, p. 1 13 Ibid., p. 31 14 The Renfrew Chapter of the Ontario Woodlot Association, http://www.ont-woodlot-assoc.org/chapt_Renfrew.html. (accessed Feb. 20, 2010) 15 Ibid. 16 Warren E. Mabee, K. Calvert, N. Manion, J. Mirck, J. Stephen, T. Wood, “Biomass�derived fuels for transportation” (paper presented at the FCRC�NRC Fifth Annual Colloquium on Fuel Cell and Hydrogen Technologies, Kingston, ON, CanadaDecember 14, 2010).

Renfrew County CFDC Renewable Energy Report May 2011 Page 14 of 70

As Dr. Luc Duchesne, the President and CEO of Forest BioProducts Inc., a firm conducting project development in bioproducts, says, “At the best of times, when the forest industry was thriving and the mills were humming day and night, we harvested 25 M m3/annum. Now we are harvesting about 14 M m3/annum. At the best of times, we have a resource at 18 M m3/annum that is used neither as fibre or biofibre. In practice, this means we are not supporting jobs with this wood. It means we aren't taking advantage of our resources.”17 There is considerable disagreement that Ontario's Annual Allowable Cut is, in fact, sustainable, but there does appear to be unused capacity within the limits of sustainability. Products from forestry operations could be used as biomass fuel in Renfrew County to help meet Ontario’s future power needs. Direct Combustion power plants burn the biomass fuel directly in boilers that supply steam for the same kind of steam-electric generators used to burn fossil fuels. The heat generated can be used to dry the feedstock before it is burned and to heat nearby buildings, while any excess steam can also be used to drive any number of industrial processes.

17 Dr. Luc Duchesne, “If a tree falls in the woods where is the value?” Northern Ontario Business, March 1, 2009, http://www.thefreelibrary.com/If+a+tree+falls+in+the+woods+where+is+the+value%3f-a0195856791 (accessed March 26, 2011)

Renfrew County CFDC Renewable Energy Report May 2011 Page 15 of 70

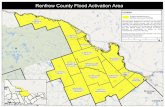

Figure 1: Renfrew County Forests18

A complete description of the conversion of biomass to electrical energy from the Union of Concerned Scientists can be found in Appendix 3: How Biomass Energy Works. Biomass conversion projects can take many forms, from steam production only to electricity production only, with various combinations in between. Key project drivers tend to be:

Proximity to fuel supply by-products and surplus materials from the forestry and paper sector

Proximity to transmission and distribution systems Governmental policies encouraging green technologies Existing and future land uses and zoning approval Market rate for energy produced.

18 County of Renfrew Forestry Map, http://www.countyofrenfrew.on.ca/departments/development-and-property/forestry/forestry-map/. (accessed Feb. 5, 2010)

Renfrew County CFDC Renewable Energy Report May 2011 Page 16 of 70

With these drivers in mind, the Invest in Canada bureau provides a representative profile as follows that is a good general description of the requirements of a 50 MW biomass project: 19

General description of operations Biomass cogenerating (heat and electricity) facility that uses bark, wood chips, wood pellets and sludge, with 50 MW electrical capacity Capital costs for machinery and equipment CDN $ 65,000,000 Estimated costs for financial modeling Labour Production operatives: 40 Supervisor/engineers: 10 Maintenance and technicians: 10 Management and administration: 3 Property Land: 4 acres Building: 49,000 sq. ft. Utilities Monthly power consumption: 500,000 kWh

Ontario Feed-In Tariff (FIT) The key to developing the renewable resources of Renfrew County is Ontario's Feed-In Tariff or FIT Program, North America's first comprehensive guaranteed pricing structure for renewable electricity production.20 The FIT Program offers stable prices under long-term contracts for energy generated from renewable sources, including biomass, biogas, landfill gas, on-shore and off-shore wind, solar photovoltaic (PV) and waterpower. The FIT Program was enabled by the Green Energy and Green Economy Act, 2009, which was passed into law on May 14, 2009. The Ontario Power Authority is responsible for implementing the program.

19 Invest in Canada: Biomass Cogeneration, op.cit., p. 5 20 Ontario Power Authority, Renewable Energy Feed-In Tariff Program, http://fit.powerauthority.on.ca/Page.asp?PageID=1115&SiteNodeID=1052. (accessed Feb. 20, 2011)

Renfrew County CFDC Renewable Energy Report May 2011 Page 17 of 70

Figure 2: Ontario Power Authority, Renewable Energy Feed-In Tariff Program21

Source Price Contract Term

Time Differentiated Price

Biomass less than 10 MW

13.8 ¢/kWh

20 years

1.35 for all peak hours 0.90 for all off-peak hours

Biomass more than 10 MW

13.0 ¢/kWh

20 years

1.35 for all peak hours 0.90 for all off-peak hours

On-shore wind any size

13.5 ¢/kWh

20 years

n/a

Solar photovoltaic rooftop less than 10 kW

80.2 ¢/kWh

20 years

n/a

Solar photovoltaic rooftop 10 kW to 250 kW

71.3 ¢/kWh

20 years

n/a

Solar photovoltaic rooftop 250 kW to 500 kW

63.5 ¢/kWh

20 years

n/a

Solar photovoltaic rooftop more than 500 kW

53.9 ¢/kWh

20 years

n/a

Solar photovoltaic ground-mounted 10 kW to 10 MW

44.3 ¢/kWh

20 years

n/a

Waterpower less than 10 MW

13.1 ¢/kWh

40 years

1.35 for all peak hours 0.90 for all off-peak hours

Waterpower 10 MW to 50 MW

12.2 ¢/kWh

40 years

1.35 for all peak hours 0.90 for all off-peak hours

21 Ibid, http://fit.powerauthority.on.ca/Page.asp?PageID=1115&SiteNodeID=1052. (accessed Feb. 20, 2011)

Renfrew County CFDC Renewable Energy Report May 2011 Page 18 of 70

Figure 3 below provides the current contract details for bioenergy projects: 22

22 Ontario Power Authority Quick Facts Table, http://fit.powerauthority.on.ca/Page.asp?PageID=122&ContentID=10196&SiteNodeID=1097&BL_ExpandID=259 (accessed Feb 10, 2010)

Renfrew County CFDC Renewable Energy Report May 2011 Page 19 of 70

To date, there have been relatively few applications for biomass generation facilities under the FIT Program as shown in Figure 4 below. 23 Biomass applications only account for 19 of 4,567 applications (0.42 per cent) and only 191 of 16,448 MW (1.16 per cent). With a rich supply of potential biomass from forestry operations in Ontario, this raises the question of why the number of biomass applications is so low. One common explanation is that the tariff is inadequate to make biomass projects economically attractive to business and communities. Figure 4. MicroFIT report February 18, 2011

23 Ontario Power Authority, Bi-weekly FIT and microFIT Program reports, Feb 18, 2011, http://fit.powerauthority.on.ca/Page.asp?PageID=1115&SiteNodeID=1052. (accessed Feb 20, 2011)

Renfrew County CFDC Renewable Energy Report May 2011 Page 20 of 70

Another key factor that has been identified is the inability of projects to confirm wood supply from the Crown.24 Accordingly, Ontario has begun to streamline the process to gain access to an estimated 22 million cubic metres of biomass, including harvest tops and branches, unused allowable harvest, and unmerchantable timber. Other major barriers to the conversion of biomass to energy have been antiquated legacy legislation by the Ministry of the Environment; conflicting air quality permits; onerous permitting processes; and poor definitions that lump woody biomass together with municipal waste. It is hoped that the Green Energy Act will eventually streamline approvals for renewable energy projects.

24 Douglas Bradley, Canada Report on Bioenergy 2010, http://www.climatechangesolutions.net. (accessed Jan 15, 2011)

Renfrew County CFDC Renewable Energy Report May 2011 Page 21 of 70

Biomass Technologies Biomass produces renewable energy on demand, and can produce renewable heat, power, fuels and bio-chemicals. At present, most biomass power plants burn lumber, agricultural, or construction/demolition wood wastes. Direct combustion power plants burn the biomass fuel directly in boilers that supply steam for the same kind of steam-electric generators used to burn fossil fuels. The biomass fuel may be in the form of logging residue or wood pellets made from residue. Another process is biomass gasification, where biomass is converted into methane that can be used to fuel steam generators, combustion turbines, combined cycle technologies or fuel cells. The primary benefit of biomass gasification, compared to direct combustion, is that extracted gasses can be used in a variety of power plant configurations. Because biomass technologies use combustion processes to produce electricity, they can generate electricity at any time, unlike wind and most solar technologies that only produce when the wind is blowing or the sun is shining. Whether combusting directly or engaged in gasification, biomass electricity generation does result in air emissions. These emissions vary depending upon the precise fuel and technology used. If wood is the primary biomass resource, very little sulfur dioxide (SO2) comes out of the stack. NOx (nitric oxide and nitrogen dioxide) emissions vary significantly among combustion facilities depending on their design and controls. Some biomass power plants show a relatively high NOx emission rate per kilowatt hour generated if compared to other combustion technologies.25 Carbon monoxide (CO) is also emitted - sometimes at levels higher than those for coal plants. Biomass plants also release carbon dioxide (CO2), the primary greenhouse gas. However, the cycle of growing, processing and burning biomass recycles CO2 from the atmosphere. If this cycle is sustained, there is little or no net change in atmospheric CO2. The collection of biomass fuels can have significant environmental impacts. Harvesting timber and growing agricultural products for fuel require large volumes to be collected, transported, processed and stored. However, biomass fuels may be obtained from supplies of clean, uncontaminated wood that otherwise would be landfilled, or from sustainable harvests. Therefore, in both of these fuel collection examples, the net environmental benefits of biomass are significant when compared to fossil fuel collection alternatives. On the other hand, the collection, processing and combustion of biomass fuels may cause environmental problems if, for example, the fuel source contains toxic

25 Natural Resources Defense Council, Rating the Environmental Impact of Electricity Products, http://www.powerscorecard.org/tech_detail.cfm?resource_id=1 . (accessed Feb 21, 2011)

Renfrew County CFDC Renewable Energy Report May 2011 Page 22 of 70

contaminants or burning biomass deprives local ecosystems of nutrients that forest waste may otherwise provide.26 Soil carbon (C) and nitrogen (N) are often considered master variables determining both soil fertility and the role of soils as a source or sink for C on a global scale. The effects of forest management on soil C and N depend on many variables: the soil type and structure, the tree species, and the range of availability of nutrients, to name just three. A literature review of forest management effects on soil C and N showed that forest harvesting, on average, had little or no effect on soil C and N.27 Significant effects of harvest type and species were noted, with sawlog harvesting causing increases (+18 per cent) in soil C and N and whole-tree harvesting causing decreases (−6 per cent). The positive effect of sawlog harvesting appeared to be restricted to coniferous species. As fuel for electricity generation, biomass has several advantages: Farmers and foresters already produce a great deal of residue. While much of it is

needed to protect habitat, soil and nutrient cycles, tens of millions of tons could be safely collected, and even more could be collected in the future with the right management practices.

Unlike coal, biomass produces no harmful sulfur or mercury emissions and has

significantly less nitrogen -- which means less acid rain, smog and other toxic air pollutants.

Over time, if the deliberate growth of biomass is sustainably managed, burning

biomass can result in zero net carbon dioxide emissions, meaning that the carbon .dioxide released in the burning can be absorbed right back from the atmosphere by growing more biomass.

Switchgrass, a promising source of biofuel, if planted in such a way that it does not

replace native habitat, is a native, perennial prairie grass that is easier to grow responsibly than most row crops. It can help reduce erosion and nitrogen runoff, and it increases soil carbon faster when mowed than when standing.

All these benefits can be gained regardless of the specific biomass conversion technology used. These technologies can include combustion (including pelletization), gasification, pyrolysis, fermentation, transesterification, and anaerobic digestion.28

26 Ibid 27 Dale W. Johnson and Peter S. Curtis, “Effects of forest management on soil C and N storage: meta analysis,” Forest Ecology and Management, Volume 140, Issues 2-3 (2001): 227-238. 28 Natural Resources Canada, Bioenergy Systems, http://canmetenergy-canmetenergie.nrcan-rncan.gc.ca/eng/bioenergy/publications/200843.html. (accessed February 19, 2011)

Renfrew County CFDC Renewable Energy Report May 2011 Page 23 of 70

Combustion The most common conversion of biomass is through combustion. It produces electric power, steam and heat. It is commercially available and regarded as proven technology. However, improvements to further the technology are being developed to help increase efficiencies, reduce emission levels, and reduce costs. Pelletizing Lignocellulosic biomass (biomass from plants), in its original form, usually has a low bulk density of 30 kg/m3 and a moisture content ranging from 10 to 70 per cent. Pelleting increases the density of biomass to more than 1,000 kg/m3. 29 Pelleted biomass is low in moisture content and can be handled and stored cheaply and safely using well-developed handling systems for grains. Forest and sawmill residues, agricultural crop residues and energy crops can be densified into pellets. Pellets are cylindrical, 6 to 8 mm in diameter and 10 to 12 mm long. In North America in 2005, more than 1.2 million tonnes of fuel pellets are produced annually.30 Most of the U.S. pellets are bagged and marketed for domestic pellet stoves. In Canada, most pellets produced from sawdust and wood shavings are exported to Sweden and Denmark. Canada’s 30 wood pellet plants now produce about 1.5 million tonnes/year, with about 90 per cent exported. The vast majority go to European power companies, which co-fire pellets with coal to reduce greenhouse gas (GHG) emissions.31 The European Experience Leo Hall of Opeongo Forestry Service in Renfrew, Ontario visited sites in Italy, Germany and Austria in 2009 that are converting renewable biomass resources into pellets, heat and electricity. The objective was to collect information on energy product markets, costs and processes in place currently in Europe.

29 S. Mani, S. Sokhansanj, X. Bi, A. Turhollow, Economics Of Producing Fuel Pellets From Biomass, Applied Engineering in Agriculture, Vol. 22(3): 421-426, 2006 American Society of Agricultural and Biological Engineers 30 Melin, S. Personal Communications. [email protected]. Delta, BC, Delta Research Center, 2005. 31 Gordon Murray, Pellet Power, Canadian Biomass Magazine, Wood Pellet Association of Canada, http://www.canadianbiomassmagazine.ca/content/view/1787/63/ . (accessed February 21, 2011)

Renfrew County CFDC Renewable Energy Report May 2011 Page 24 of 70

The major findings from the visit included the following: 32

The markets for wood pellets are large, growing rapidly (10 per cent or more annually), and apparently still quite young and variable in most of Europe.

Wood pellets produced in Ontario are not going to be shipped at an adequate profit into the simplest electrical coal plant co-firing market in Europe, under current cost and market price realities.

To be profitable from Ontario, a marketing strategy enabling access to higher value residential and small commercial heat market segments will be necessary.

The technology for converting wood biomass directly into renewable district heat and electrical energy is understood, developed and proven in the European context. Such activity in Ontario is not economical at this time because of less expensive fossil fuel alternatives such as natural gas.

A European type market is needed in Ontario for pellets, district heat and electricity to take advantage of our rich and available biomass resources.

Gasification Gasification produces a synthesis gas (syngas) in an oxygen-starved environment at high temperatures. This syngas can be used either as fuel gas for production of heat, electricity and process steam or the syngas can be cleaned to remove contaminants and used for production of synthetic natural gas, high value chemicals.33 Pyrolysis This is a process that involves rapidly heating biomass at high temperatures in the absence of oxygen, producing vapours from the decomposition. Upon cooling, the vapour condenses to form a liquid fuel. This process is known as pyrolysis of biomass. Bio-oils are produced from the pyrolysis of various biomass feedstocks such as hardwoods and softwoods, grasses and agricultural residues, for example.

32 Leo Hall, Owner/Operator, Opeongo Forestry Service, 199 Opeongo Road, Renfrew, ON K7V 2T2 33 Natural Resources Canada, Bioenergy Systems, op.cit.

Renfrew County CFDC Renewable Energy Report May 2011 Page 25 of 70

Torrefaction

Torrefaction is a pre-treatment of biomass at a temperature between 200 and 300 °C, and can be considered a mild form of pyrolysis. During torrefaction the biomass properties are changed to obtain a much better fuel quality for combustion and gasification applications. Torrefaction by the Torrefaction and Pelletization Process (TOP) can lead to a very energy dense fuel pellet of 15-18.5 GJ/m3 (gigajoules per cubic metre).

Typically, the process has a thermal efficiency of 96 per cent and the total production costs amount to 40 to 50 €/tonne of TOP pellets. The logistical costs are 50 to 66 per cent of the costs of wood pellets.34 In combination with pelletization, torrefaction also reduces the logistical issues that exist for untreated biomass. Torrefaction of biomass is also an effective method to improve the grindability of biomass to enable more efficient co-firing in existing power stations or entrained-flow gasification for the production of chemicals and transportation fuels.

The torrefied biomass has the following properties: 35

Hydrophobic nature: the material does not regain humidity in storage. Unlike wood and charcoal, it is stable with a well-defined composition.

Lower moisture content and higher calorific values compared to biomass Formation of less smoke when burned Higher density and similar mechanical strength compared to the initial biomass Suitable for various applications as a fuel - in the steel industry, combustion and

gasification. Fermentation In simple terms, fermentation is a specialized method of decomposition. A key product of one particular fermentation process is ethanol. It is produced mainly by the traditional fermentation/distillation process of using sugars from sugar crops or derived from the starch in cereal grain and corn. Increased environmental awareness and the commitment to reduce greenhouse gases have heightened the need for increased 34 Patrick .C.A. Bergman and Jacob H.A. Kiel, Torrefaction For Biomass Upgrading, Energy Research Centre of the Netherlands (ECN), Unit ECN Biomass, Published at 14th European Biomass Conference & Exhibition, Paris,2005 35 M. Pach, R. Zanzi, and E. Björnbom, Torrefied Biomass a Substitute for Wood and Charcoal, Department of Chemical Engineering and Technology, Universidad PolitÈcnica de Catalunya, EUETIT 6 th Asia-Pacific International Symposium on Combustion and Energy Utilization, 2002

Renfrew County CFDC Renewable Energy Report May 2011 Page 26 of 70

production of ethanol in Canada. At present, about 200 million litres of fuel ethanol are produced in Canada each year from cereal grain and corn. On a full life cycle basis, ethanol made from corn or grain reduces greenhouse gases by 30 to 40 per cent compared to gasoline, while that made from the cellulosic part of biomass reduces greenhouse gases by 60 to 80 per cent.36 Transesterfication In this process, specific kinds of biomass such as vegetable or animal fats are treated with sodium hydroxide and methanol to yield glycerine and fatty acid methyl esters. These esters are referred to as biodiesel.37 Anaerobic Digestion (AD) AD is a naturally occurring process whereby biomass is broken down or ‘digested’ by bacteria in an air free environment. AD takes place in landfills and is used to treat certain fractions of municipal wastewater and other industrial wastewaters. More recently, AD has been introduced to the Canadian farming community to treat manure, animal processing wastes and other agricultural residues. The anaerobic bacteria produce methane rich biogas that can be converted to heat, electricity and/or ethanol.38

36 Natural Resources Canada, Bioenergy Systems, op.cit. 37 Ibid., Natural Resources Canada, Bioenergy Systems 38 Ibid., Natural Resources Canada, Bioenergy Systems

Renfrew County CFDC Renewable Energy Report May 2011 Page 27 of 70

Canadian Energy Production from Biomass Capacity is typically expressed as power output, the amount of energy a technology can deliver when fully engaged. It is measured in watts or multiples of that value (kW, MW, GW, etc.). Figure 5 below indicates that total renewable energy capacity in Canada, including electricity generation, thermal generation and liquid fuel production, was approximately 81 GW (gigawatts) in 2008. Renewable energy capacity includes electric capacity (95.1 per cent of renewable energy in Canada), thermal capacity (4.5 per cent), and liquid fuel capacity (0.3 per cent). Figure 5. Renewable Energy Capacity in Canada, 2008

The 77.5 GW of installed renewable electric represents approximately 62.4 per cent of total Canadian electrical capacity.39 Not including large hydro, installed renewable electrical capacity represents 5.3 per cent of total Canadian electrical capacity.40

39 Statistics Canada (2009). Energy Statistics Handbook: Third Quarter 2009. Statistics Canada: Ottawa, Ontario. Catalogue No. 57-601-XIE. 40 John Nyboer, Steven Groves, A Review of Renewable Energy in Canada, 2008, Prepared for Natural Resources Canada and Environment Canada, Canadian Industrial Energy End-use Data and Analysis Centre, Simon Fraser University, Burnaby, BC, March, 2010, http://www2.cieedac.sfu.ca/publications.

Renfrew County CFDC Renewable Energy Report May 2011 Page 28 of 70

Another way to look at this data is in Figure 6 below. Figure 6. Total Renewable Energy Capacity by Resource Type, Including and Excluding Large Hydro 41

Capacity Factors Energy facilities don’t run at full capacity 100 per cent of the time. Reduced production from facilities generating electricity from non-renewable sources typically includes planned down time for maintenance, mechanical failure, and a lack of demand during non-peak hours. Barriers to obtaining a 100 per cent capacity factor from renewable sources could include these situations plus an inconsistent supply of fuel (biomass), sunlight (solar), or water (hydro). The Canadian Industrial Energy End-use Data and Analysis Centre (CIEEDAC) used the capacities and annual generation data provided for a sample of facilities to calculate an average capacity factor for each resource type. The capacity factor, listed in Figure 7 below, is the amount of energy that a facility produces over a certain period of time, one year in this case, divided by the amount of energy that it could have produced at nominal power over that same period. The authors note that these estimates are a weighted average of current facilities and do not represent the typical capacity factor of state-of-the-art facilities.42 The confidence that CIEEDAC has in the estimated capacity factor for each type of 41 Nyboer, op. cit., p. 9 42 Ibid., p. 11

Renfrew County CFDC Renewable Energy Report May 2011 Page 29 of 70

renewable energy is high when they had information for over 20 facilities and when the standard deviation in the capacity factor of these facilities did not exceed 15 per cent. A smaller sample size and higher standard deviation lowered their confidence in the estimate. Figure 7. Capacity Factors For Renewable Energy Generation In this analysis, biomass showed the highest capacity factor, along with biogas, indicating that it can be a stable source of renewable energy.

Renfrew County CFDC Renewable Energy Report May 2011 Page 30 of 70

UBC Bioenergy Research and Demonstration Project 43 Using biomass to produce energy is becoming increasingly common. An example of the production of energy through biomass gasification is the University of British Columbia (UBC) Bioenergy Research and Demonstration Project, which produces renewable biomass-based heat and power for its campus. The project is a collaboration among Nexterra Systems Corp., GE Jenbacher (General Electric’s gas engine division), FPInnovations and the University of British Columbia. The UBC bioenergy project has two main operating modes. The first mode – commercial thermal (heat) mode – will utilize commercial Nexterra gasification technology to convert waste wood into “syngas” that will replace some of the natural gas currently used for campus heating. The second mode – the demonstration (heat and power) mode – will use Nexterra proprietary syngas conditioning technology with a high-efficiency GE Jenbacher gas engine to convert syngas into electrical power. Currently, the campus heat requirements are fulfilled by burning fossil fuels that produce greenhouse gases. The project will provide 12 per cent of UBC’s average heat and up to 4.5 per cent of peak power demand in cogeneration mode and 25 per cent of UBC’s average heat in thermal mode. In the demonstration or cogeneration mode, the system will produce steam heat as well as up to two megawatts of electricity – equal to the energy required for approximately 1,500 homes. By reducing the use of fossil fuel, the UBC bioenergy project will eliminate up to 9,000 tonnes of greenhouse gas emissions each year. This is the equivalent of taking more than 2,200 cars off the road. UBC research collaborators include the Institute for Resources, Environment and Sustainability, the Clean Energy Research Centre, the Centre for Interactive Research on Sustainability, the faculty of Applied Science, and the Sauder School of Business. The project will be designed to support research activities – including laboratory space, process access, and sampling ports – within the facility.

43 Nexterra UBC Bioenergy Research and Demonstration Project, http://www.nexterra.ca/news/100215_backgrounder.html. (accessed November 10, 2010)

Renfrew County CFDC Renewable Energy Report May 2011 Page 31 of 70

Figure 8. Strengths and Weaknesses of Direct Combustion and Gasification 44

44 David Peterson and Scott Haase, Market Assessment of Biomass Gasification and Combustion Technology for Small- and Medium-Scale Applications, National Renewable Energy Laboratory, U.S. Department of Energy, NREL/TP-7A2-46190 July 2009. http://www.cleanenergystates.org/Publications/NREL_Biomass_Gasification_Mkt_Assessment_46190.pdf

Renfrew County CFDC Renewable Energy Report May 2011 Page 32 of 70

Forest Biomass Volume Most analyses separate forest biomass into two categories: mill residue (bark, sawdust and shavings primarily from pulp mill and sawmill operations) and forest residue (tops, branches and leaves from harvest and thinning operations that are left in the forest or at the roadside after delimbing).45 Mill residue bears a lower cost as it is already at a mill site and is partially pulverized. Biomass projects tend to use the lowest cost feedstock, usually 100 per cent mill residue. Where mill residues are scarce or dispersed, an energy plant will try to find the lowest cost mix encompassing mill residue and some forest residue.

Mill Residue A 2005 mill residue survey 46 of Canadian pulp mills and sawmills indicated an annual production of bark, sawdust and shavings of 21.2 million oven-dried tonnes (ODT). Much of this biomass is committed to produce onsite energy, or sold to independent power producers, board and pellet manufacturers, farmers for animal bedding, and landscapers for garden beds. Ontario showed a surplus of 100,000 ODT. A January 2007 survey 47 of Eastern Ontario showed that while virtually all mill residues were consumed, only 20 per cent went to energy while 50 per cent was sold or given away to landscapers. Prices ranged from $0 to $22.50/ODT, but much was sold for under $12/ODT. A sizable amount of this biomass could be recovered for energy at reasonable cost. Estimated biomass recovery from landscaping to energy is 415,000 ODT in Ontario. Heritage Bark Piles In Ontario, mills pile excess residue at the mill site, and a broad estimate for availability is 6.6 million ODT.48 Only recently have mills been looking to this bark as fuel source. In some cases this bark is contaminated with rocks or soil, or is too wet to be economically usable. However, many of these piles are excellent sources of biomass.

45 Douglas Bradley, Canada- Sustainable Forest Biomass Supply Chains, Climate Change Solutions, 2007, p.6, http://www.canbio.ca/documents/publications/sustainableforestsupplychainsoct192007.pdf. (accessed Dec 18, 2010) 46 Estimated Production, Consumption and Surplus Mill Wood Residues in Canada-2004, A National Report- NRCan & FPAC; Prepared by BW McCloy and Associates and Climate Change Solutions,

http://catalogue.nrcan.gc.ca/opac/extras/unapi?format=htmlholdings-full;id=tag:open-ils.org,2011:biblio-record_entry/8068091/CFS-SCF-SAULTSTEMARIE. (accessed December 15, 2010) 47 Douglas Bradley, op.cit., p. 7 48 Ibid., p. 7

Renfrew County CFDC Renewable Energy Report May 2011 Page 33 of 70

Forest Residue With much of the mill residues consumed, forestry and energy companies and provincial governments are looking to harvest residues as the next fuel source. In Ontario, the harvest method is primarily full-tree to roadside, which results in 1.5 million ODT of slash (tops and branches) left at the roadside that is relatively accessible.

Forest Residue Supply Chains There are four main sources of forest biomass: 49 1. Slash left after stand harvesting 2. Slash and small trees from thinnings and cleanings 3. Unmerchantable wood 4. Wood impacted by fire or insect infestation. The lowest cost source of forest biomass is usually harvest slash since it is already at the roadside and plentiful, usually 10 per cent of tree volume. Slash from thinnings is also available, but it is more costly to acquire since there is a lower volume per hectare than after harvest, and it is at the stump. There are numerous slash supply chain options that might be categorized as follows: 50 1. Terrain chipping - Slash is chipped using a mobile chipper where harvesting has taken place. Chips are collected in a small container and brought to the roadside where they are transferred to a truck. 2. Roadside chipping - Either trees are felled and forwarded to roadside for delimbing (full tree harvesting, most common in Canada), or trees are delimbed in the field and slash is forwarded to roadside. Slash is chipped at roadside using either a mobile chipper or a truck mounted chipper and transferred to a truck. 3. Terminal chipping - Raw slash is transported a short distance to a terminal where it is pulverized and loaded onto large bulk trucks. 4. Bundling - Raw slash is compressed either in the field or at roadside into composite residue logs using a mobile bundler, and transported in standard logging trucks to the end user, where pulverizing takes place. In addition, there are numerous loading and trucking options to handle and carry chips from the pulverizing point to the end user. Some are just standard trucks that carry and

49 Ibid., p. 9 50 Ibid., p. 10

Renfrew County CFDC Renewable Energy Report May 2011 Page 34 of 70

dump chips, some are purpose-built to load and compress chips to reduce costs, and some include the capability to tip at the end-user to further reduce handling costs. Transportation In all these supply chains, the cost of moving feedstock or products is a key component of the overall cost of recovering energy from biomass. Two cost components are critical in analyzing transportation cost: distance variable costs (DVC), the component that is directly dependent on the distance traveled, and distance fixed costs (DFC), which are independent of the distance traveled. DVC depends on the transportation mode and the specific location; an example is the “per ton kilometre” cost of trucking or rail shipment. DFC depends on the type of biomass being transported and the equipment and contractual arrangements involved, and both are case specific; examples include the cost of loading and unloading biomass from a truck, railcar or ship. Hence, DFC will vary based on the specific form of biomass to a far greater extent than DVC, and the impact of DFC on overall transportation cost diminishes with increasing distance.51 Biomass has a relatively low energy density, defined as the amount of energy contained in a volume of material, and the energy produced from biomass is lower than the energy in the biomass as a result of conversion losses. The energy density can have a significant impact on the final cost of generating electricity. For example, at 500 km, the cost of transporting biomass by truck is more than $4/GJ (gigajoule), a significant cost considering that, throughout 2010, wholesale monthly Canadian natural gas prices (intra-Alberta) fluctuated between $3.19 CDN/GJ and $5.23 CDN/GJ. 52

Case Study: Biomass power cost and optimum plant size in western Canada 53 While the actual amount of the costs might vary, this case study by Kumar et al., describes the kinds of costs that were calculated to determine the power cost and optimum plant size for power plants using three biomass fuels in western Canada. The three fuels are biomass from agricultural residues (grain straw), whole boreal forest, and forest harvest residues from existing lumber and pulp operations (limbs and tops). This study provides a reasonable starting template to determine the costs that should be considered in determining an economic FIT for biomass in Ontario. 51 Erin Searcy, Peter Flynn, Emad Ghafoori, Amit Kumar, “The Relative Cost Of Biomass Energy Transport”, Applied Biochemistry and Biotechnology, Volume 137-140, Numbers 1-12, 639-652, http://www.springerlink.com/content/h73770482r5p8418/ 52 Natural Resources Canada, North American Natural Gas - Heating Season and Winter Update, http://nrcan.gc.ca/eneene/sources/natnat/shocou-eng.php. (accessed Feb 21, 2011) 53 Amit Kumar, Jay B. Cameron, Peter C. Flynn, “Biomass power cost and optimum plant size in western Canada”, Biomass and Bioenergy 24 (2003), 445 – 464. http://www.citeulike.org/user/nathanparker/article/1629524

Renfrew County CFDC Renewable Energy Report May 2011 Page 35 of 70

Whole forest harvest cost Felling Skidding Chip loading, unloading and transport Road construction and infrastructure Silviculture Nutrient spreading Chipping cost for whole tree Premium above cost of fuel that is paid to owner as an incentive to collect and sell the fuel Forest residues Chipping cost Forwarding and piling Chip loading, unloading and transport Power plant characteristics and costs Plant capital cost Plant life (in years) Plant operating factor (percentage of capacity) Operating staffing, excluding maintenance Power generation capital cost Average annual labour cost including benefits Ash disposal and hauling Transmission charges Capital cost of hook-up Operating cost

Review Conclusion In addition to job creation at the local level, the regional economic benefits of the generation of electricity and/or steam from biomass could be considerable in areas that already produce a supply of biomass such as Renfrew County. The outlook is encouraging in light of research conducted in the context of Geraldton, a small municipality in northern Ontario, where calculations based on 80 per cent capacity utilization produced rates of return of approximately 12 per cent for sawmill residues and about 2 per cent for chipped forest biomass respectively. 54 The task that remains is to determine the FIT rate required to encourage this development.

54 Naomi Beke, Glenn Fox, and Dan Mckenney, “A Financial Analysis Of Using Sawmill Residues For Cogeneration In Northern Ontario” Energy Studies Review, http://digitalcommons.mcmaster.ca/esr/vol8/iss1/2

Renfrew County CFDC Renewable Energy Report May 2011 Page 36 of 70

5. Assumptions, Analysis and Discussion

The literature review, interviews and financial models all provided input into the findings and analysis.

Assumptions System Capacity Factor of 85 per cent This is in keeping with a conservative estimate of biomass plants and the industry standard errs on the conservative side. Systems never produce at their “stated” capacity. Chris Amey commented, “This is a reasonable number. We plan on lower capacity factors during the start-up year and first full year of operation. Thereafter, we typically plan on two scheduled shut downs of two weeks per year, as well as unscheduled shut downs totaling an additional two weeks per year for a total capacity factor of 88.5 per cent during the second full year of operation.” Elimination of CoGen Income Markets for any heat/steam from a biomass-burning plant are extremely limited and greatly reduce the number of potential sites. In most cases, siting a plant close to a steam market increases the biomass transportation costs to the plant to such an extent that it is counter-productive. However any excess heat/steam would certainly not be wasted as it could be used for drying green fuel and/or used in sawmill drying kilns. Fuel Costs A price of $49.50/GT is in line with reports from local sawmills on the current price they are paid to deliver biomass to mills/plants in Quebec. The estimate is on the conservative side, since the market for biomass is currently depressed due to economic conditions, but will likely rise due to improvements in demand along with increases in transportation costs related to the price of oil. Chris Amey and Martin Lensink concur with this estimate. Chris Amey comments, “Based on the information that we have gathered to date, which includes a detailed canvas of the Eastern Ontario fibre market, and a commissioned third party wood fibre feedstock study, the expected delivered price of virgin marketable roundwood fibre should be in the range of $45 to $50 per green tonne.” Discount Rate for net present value (NPV) is 10 per cent This was based on normal equity structure (60 per cent debt, 40 per cent equity), and is consistent with normal business practice. The expected return is influenced by the amount of interest that must be paid on debt, and the required return to provide acceptable levels of return to equity investors. A weighted average of these two (called WACC for Weighted Average Cost of Capital) forms a benchmark for evaluating new

Renfrew County CFDC Renewable Energy Report May 2011 Page 37 of 70

projects. Because of this, and also because of the higher return required in order to offset the risk involved with this type of venture, a higher discount rate is required compared to safer investments such as GIC’s. Chris Amey commented, “Yes, this is a reasonable assumption. Equity investors typically evaluate project NPV with a 10 per cent to 15 per cent discount rate for this type of project.” Martin Lensink agreed with the 10 per cent used here, but acknowledged that it might be one or two points high, so he recommended the use of the 10 per cent for early stages of project development. Portion of Project Eligible for Class 43.2 Depreciation This is an estimate based on the eligibility of similar projects. Class 43.1 allows taxpayers an accelerated write-off of the capital cost of certain equipment that is designed to produce energy in a more efficient way or to produce energy from alternative renewable sources. Class 43.1 allows taxpayers to deduct the cost of eligible equipment from taxable income at up to 30 per cent per year, on a declining balance basis. Class 43.2 has been created to provide additional incentive for those systems in Class 43.1 that use fossil fuels more efficiently (efficiency = 72 per cent), for specified-waste-fuelled electrical generation systems, and for renewable energy systems (small-scale hydro-electric, wind, photovoltaic, geothermal, fuel cell and active solar).55 Corporate Income Tax Rate The rate of 32 per cent is a reasonable estimate based on current rates. Escalation Rate on Power Sold This is based on the Renewable Energy Standard Offer Program (RESOP), as of October 1, 2009, replaced by the Feed-In Tariff Program (FIT Program) and assumes a reasonable consumer price index (CPI) increase of 3 per cent. Escalation Rate (Inflation) on Operating & Maintenance (O&M) is 3 per cent per year This is a conservative estimate of CPI for future years. This is higher than used by Martin Lensink, but consistent with recommendations from Chris Amey: “A reasonable escalator would be 3 per cent for O&M (wood, labor, fuel surcharges). Another way to break this up is by Capacity Payment and Energy Payment.” There is little effect on the payback, since O&M is a relatively small percentage of overall cost.

55 Industry Canada, Funding Technologies for the Environment, Accelerated Capital Cost Allowance, http://www.ic.gc.ca/eic/site/fte-fte.nsf/eng/00004.html (accessed March 29, 2011)

Renfrew County CFDC Renewable Energy Report May 2011 Page 38 of 70

Analysis The first thing to understand is that the capital expenditures for generating electricity from biomass are orders of magnitude higher than either wind or solar. With a capital cost of $50-60 million, biomass is not a venture for homeowners, as is the MicroFIT program with a capital cost of less than $100,000. This means that businesses are the only feasible owners and operators of biomass plants. This restriction to businesses must be the starting point for an analysis to determine a FIT rate that would truly encourage business investment. Time before payback drives most of the capital investments by business, and maximum payback times are typically shorter. Some capital improvements or energy efficiencies must have a payback time of less than a year to be justifiable. The industry hurdle for biomass is likely less than five years. Indeed, David Steeds, Director of Manufacturing Services at Nylene Canada, stated that in today’s investment environment, Nylene would not consider a capital improvement unless the payback is two years or less. A short payback period does make sense. Although OPA signs 20-year deals, it is apparent that political pressure can alter this over time, and so there is some uncertainty about the revenue stream. There is also risk that the generation system will become obsolete or cost-ineffective as a newer method for power generation is brought on stream. So, the analysis must use payback periods as a benchmark if a biomass FIT is to encourage business investment, and those payback periods must be shorter rather than longer.

Renfrew County CFDC Renewable Energy Report May 2011 Page 39 of 70

Figure 9 below gathers all of the input and output assumptions together in one table. Figure 9. 15 MW Output Assumptions

Capital cost $ 57,750,000

Normal plant capacity 15,000 kWh

System capacity factor 85%

Gross system heat rate 9,000 BTU/kWh

Fuel costs (fob) site $ 49.50/GT

Escalation rate on power sold 3% per year