Centrifugal Compressor Wet Seals Seal Oil De-gassing and Control

Reducing Emissions from Compressor Seals

-

Upload

hadley-emerson -

Category

Documents

-

view

43 -

download

1

description

Transcript of Reducing Emissions from Compressor Seals

Reducing Emissions from Reducing Emissions from Compressor SealsCompressor Seals

Lessons LearnedLessons Learnedfrom Natural Gas STARfrom Natural Gas STAR

Transmission Technology Transfer WorkshopTransmission Technology Transfer Workshop

Duke Energy Gas TransmissionDuke Energy Gas Transmission

Interstate Natural Gas Association of America (INGAA) andInterstate Natural Gas Association of America (INGAA) and

EPA’s Natural Gas STAR ProgramEPA’s Natural Gas STAR Program

September 22, 2004September 22, 2004

Page 2Reducing Emissions, Increasing Efficiency, Maximizing Profits

Compressor Seals: AgendaCompressor Seals: Agenda

Methane LossesMethane Losses

Methane RecoveryMethane Recovery

Is Recovery Profitable?Is Recovery Profitable?

Industry ExperienceIndustry Experience

Discussion QuestionsDiscussion Questions

Page 3Reducing Emissions, Increasing Efficiency, Maximizing Profits

Methane Losses from Transmission Methane Losses from Transmission and Storageand Storage

Transmission and storage sector responsible for 96 Transmission and storage sector responsible for 96 billion cubic feet (Bcf) in methane emissionsbillion cubic feet (Bcf) in methane emissions

EmissionsEmissionsReductionsReductions

Trans & Storage Trans & Storage 96 Bcf 96 Bcf

Production Production 149 Bcf149 Bcf

Processing Processing 36 Bcf 36 Bcf

Distribution Distribution 77 Bcf77 Bcf

26 Bcf26 Bcf

5 Bcf5 Bcf

20 Bcf20 Bcf

1 Bcf1 BcfOil Downstream Oil Downstream 2 Bcf 2 Bcf

Inventory of U.S. Inventory of U.S. Greenhouse Gas Greenhouse Gas Emissions and Emissions and Sinks 1990 - 2002Sinks 1990 - 2002

Page 4Reducing Emissions, Increasing Efficiency, Maximizing Profits

Methane Losses from Methane Losses from Compressor SealsCompressor Seals

Compressor seals contribute 50% of transmission Compressor seals contribute 50% of transmission and storage emissionsand storage emissions 40 Bcf from reciprocating compressors40 Bcf from reciprocating compressors 8 Bcf from centrifugal compressors8 Bcf from centrifugal compressors

Pneumatic DevicesPneumatic Devices11 Bcf11 Bcf

Centrifugal CompressorsCentrifugal Compressors8 Bcf8 Bcf

Pipeline LeaksPipeline Leaks7 Bcf 7 Bcf

Gas Engine ExhaustGas Engine Exhaust11 Bcf11 Bcf

ReciprocatingReciprocatingCompressors Compressors 40 Bcf40 Bcf

Station VentingStation Venting7 Bcf7 Bcf

Other Sources Other Sources 5 Bcf5 Bcf

Station FugitivesStation Fugitives7 Bcf7 Bcf

Inventory of U.S. Inventory of U.S. Greenhouse Gas Greenhouse Gas Emissions and Emissions and Sinks 1990 - 2002Sinks 1990 - 2002

Page 5Reducing Emissions, Increasing Efficiency, Maximizing Profits

Compressor SealsCompressor SealsWhat is the problem?What is the problem?

Compressor seals account for 13% of natural gas Compressor seals account for 13% of natural gas industry emissionsindustry emissions Over 45,000 compressors in the natural gas industryOver 45,000 compressors in the natural gas industry Over 8,500 compressors in gas transmission sectorOver 8,500 compressors in gas transmission sector

CompressorStation

CompressorStation

Production

32,000 Compressors

Processing

5,000 Compressors

Transmission & Storage

8,500 Compressors

Distribution

0 Compressors

CompressorStation

Page 6Reducing Emissions, Increasing Efficiency, Maximizing Profits

Methane Losses from Methane Losses from Reciprocating CompressorsReciprocating Compressors

Reciprocating compressor rod packing leaks Reciprocating compressor rod packing leaks some gas by designsome gas by design Newly installed packing may leak 60 cubic feet per Newly installed packing may leak 60 cubic feet per

hour (cf/h)hour (cf/h) Worn packing has been reported to leak up to 900 Worn packing has been reported to leak up to 900

cf/hcf/h

Distance PieceDistance Piece

Piston RodPiston Rod

(Side View, Cut in Half)(Side View, Cut in Half)

OILOIL

CylinderCylinder

SuctionSuction

DischargeDischarge

PistonPiston

Rod Packing CaseRod Packing Case

Page 7Reducing Emissions, Increasing Efficiency, Maximizing Profits

Reciprocating Compressor Reciprocating Compressor Rod PackingRod Packing

A series of flexible rings fit around the shaft A series of flexible rings fit around the shaft to prevent leakageto prevent leakage

Leakage still occurs through nose gasket, Leakage still occurs through nose gasket, between packing cups, around the rings and between packing cups, around the rings and between rings and shaftbetween rings and shaft

LubricationLubrication

FlangeFlange

GasGasLeakageLeakage

(Side View, Cut in Half)(Side View, Cut in Half)

Cylinder WallCylinder Wall

High Pressure High Pressure

Gas Inside Gas Inside

CylinderCylinder

Two RingsTwo Rings(In Three Segments)(In Three Segments)

SpringsSprings

Packing CupPacking Cup

Piston RodPiston Rod

Page 8Reducing Emissions, Increasing Efficiency, Maximizing Profits

Gas STAR Partners Reduce Emission with Gas STAR Partners Reduce Emission with Economic Rod Packing ReplacementEconomic Rod Packing Replacement

Compare current leak rate to initial leak rateCompare current leak rate to initial leak rateto determine leak reduction expectedto determine leak reduction expected

Monitor and record baseline packing Monitor and record baseline packing leakage and piston rod wearleakage and piston rod wear

Assess costs of replacementsAssess costs of replacements

Determine economic replacement thresholdDetermine economic replacement threshold

Replace packing and rods where cost-effectiveReplace packing and rods where cost-effective

Decision ProcessDecision Process

Page 9Reducing Emissions, Increasing Efficiency, Maximizing Profits

Methane Recovery Through Economic Methane Recovery Through Economic Rod Packing ReplacementRod Packing Replacement

Step 1: Monitor and record baseline leakage and rod Step 1: Monitor and record baseline leakage and rod wearwear Establishing baseline leak rates and monitoring rod wear Establishing baseline leak rates and monitoring rod wear

can help to track leakage and evaluate economicscan help to track leakage and evaluate economics

Step 2: Compare current leak rate to initial leak rate to Step 2: Compare current leak rate to initial leak rate to determine leak reduction expecteddetermine leak reduction expected Leak Reduction Expected (LRE) = Current Leak Rate (CL) Leak Reduction Expected (LRE) = Current Leak Rate (CL)

– Initial Leak Rate (IL)– Initial Leak Rate (IL) Example: The current leak rate is measured as 100 cf/h, Example: The current leak rate is measured as 100 cf/h,

the same component leaked 11.5 cf/h when first installedthe same component leaked 11.5 cf/h when first installed

LRE = 100 cf/h – 11.5 cf/hLRE = 100 cf/h – 11.5 cf/hLRE = 88.5 cf/hLRE = 88.5 cf/h

Page 10Reducing Emissions, Increasing Efficiency, Maximizing Profits

Methane Recovery Through Economic Methane Recovery Through Economic Rod Packing ReplacementRod Packing Replacement

Step 3: Assess costs of replacementsStep 3: Assess costs of replacements A set of rings:A set of rings: $ 500$ 500 to to $ 800$ 800

(with cups and case)(with cups and case) $1500$1500 to to $2500$2500

Rods:Rods: $1800$1800 to to $3500$3500 Step 4: Determine economic replacement Step 4: Determine economic replacement

thresholdthreshold Partners can determine economic threshold Partners can determine economic threshold

for all replacementsfor all replacements

@ interest i

Page 11Reducing Emissions, Increasing Efficiency, Maximizing Profits

Is Recovery Profitable?Is Recovery Profitable?

Step 5: Replace packing and rods when Step 5: Replace packing and rods when cost-effectivecost-effective Example:Example: Rod and RingsRod and Rings

Rings:Rings: $1,200$1,200Rod:Rod: $7,000$7,000Gas:Gas: $3/Mcf$3/McfOperating:Operating: 8,000 hrs/yr8,000 hrs/yr

Rings OnlyRings OnlyRings:Rings: $1,200$1,200Rod:Rod: $0$0Gas:Gas: $3/Mcf$3/McfOperating:Operating: 8,000 hrs/yr8,000 hrs/yr

Based on 10% interest rateMcf = thousand cubic feet, scfh = standard cubic feet per hour

Page 12Reducing Emissions, Increasing Efficiency, Maximizing Profits

Industry ExperienceIndustry Experience

One partner reported replacing worn rod One partner reported replacing worn rod packing rings on 15 compressor unitspacking rings on 15 compressor units

Estimated gas savings of 7,000 Mcf or $21,000 Estimated gas savings of 7,000 Mcf or $21,000 @ $3/Mcf@ $3/Mcf

Cost including materials and labor of $17,000Cost including materials and labor of $17,000

Payback period of less than one yearPayback period of less than one year

Page 13Reducing Emissions, Increasing Efficiency, Maximizing Profits

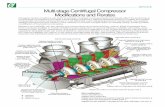

Methane Losses from Methane Losses from Centrifugal CompressorsCentrifugal Compressors

Centrifugal compressor wet seals leak little gas at Centrifugal compressor wet seals leak little gas at the seal facethe seal face Seal oil degassing may vent 40 to 200 cubic feet per Seal oil degassing may vent 40 to 200 cubic feet per

minute (cf/m) to the atmosphereminute (cf/m) to the atmosphere A Natural Gas STAR partner reported wet seal A Natural Gas STAR partner reported wet seal

emissions of 75 Mcf/day (52 cf/m)emissions of 75 Mcf/day (52 cf/m)

ShaftSeal

Page 14Reducing Emissions, Increasing Efficiency, Maximizing Profits

Centrifugal Compressor Wet SealsCentrifugal Compressor Wet Seals

High pressure seal oil is circulates between rings High pressure seal oil is circulates between rings around the compressor shaft around the compressor shaft

Gas absorbs in the oil on the inboard side Gas absorbs in the oil on the inboard side Little gas leaks through the oil sealLittle gas leaks through the oil seal Seal oil degassingSeal oil degassing

vents methane to vents methane to the atmospherethe atmosphere

Page 15Reducing Emissions, Increasing Efficiency, Maximizing Profits

Gas STAR Partners Reduce Emissions Gas STAR Partners Reduce Emissions with Dry Sealswith Dry Seals

Dry seal springs press the stationary ring in the seal Dry seal springs press the stationary ring in the seal housing against the rotating ring when the housing against the rotating ring when the compressor is not rotatingcompressor is not rotating

At high rotation speed, gas is pumped between the At high rotation speed, gas is pumped between the seal rings creating a high pressure barrier to leakageseal rings creating a high pressure barrier to leakage

Only a very smallOnly a very smallamount of gas amount of gas escapes through escapes through the gap the gap

2 seals are often 2 seals are often used in tandemused in tandem

Page 16Reducing Emissions, Increasing Efficiency, Maximizing Profits

Methane Recovery with Dry SealsMethane Recovery with Dry Seals

Dry seals typically leak at a rate of only Dry seals typically leak at a rate of only 0.5 to 3 cf/m0.5 to 3 cf/m Significantly less than the 40 to 200 cf/m Significantly less than the 40 to 200 cf/m

emissions from wet sealsemissions from wet seals These savings translate to approximately These savings translate to approximately

$48,960 to $48,960 to $279,360 $279,360 in annual gas in annual gas valuevalue

Page 17Reducing Emissions, Increasing Efficiency, Maximizing Profits

Other Benefits with Dry SealsOther Benefits with Dry Seals

Aside from gas savings and reduced emissions, dry Aside from gas savings and reduced emissions, dry seals also:seals also: Lower operating costLower operating cost

Dry seals do not require seal oil make-upDry seals do not require seal oil make-up Reduced power consumptionReduced power consumption

Wet seals require 50 to 100 kiloWatt hours (kW/hr) for Wet seals require 50 to 100 kiloWatt hours (kW/hr) for ancillary equipment while dry seals need only 5 kW/hrancillary equipment while dry seals need only 5 kW/hr

Improve reliabilityImprove reliability More compressor downtime is due to wet sealsMore compressor downtime is due to wet seals

Eliminate seal oil leakage into the pipelinesEliminate seal oil leakage into the pipelines Dry seals lower drag in pipelines (and horsepower to Dry seals lower drag in pipelines (and horsepower to

overcome)overcome)

Page 18Reducing Emissions, Increasing Efficiency, Maximizing Profits

Gas STAR Partners Reduce Emissions Gas STAR Partners Reduce Emissions with Dry Seal Replacementwith Dry Seal Replacement

Estimate savings of dry seal retrofitEstimate savings of dry seal retrofit

Identify candidates for wet seal replacementIdentify candidates for wet seal replacement

Determine costs for conversion to dry sealsDetermine costs for conversion to dry seals

Compare costs to savingsCompare costs to savings

Decision ProcessDecision Process

Page 19Reducing Emissions, Increasing Efficiency, Maximizing Profits

Decision Process to Replace SealsDecision Process to Replace Seals

Step 1: Identify candidates for replacementStep 1: Identify candidates for replacement Dry seals are routinely used for compressors Dry seals are routinely used for compressors

operating up to 1,500 pounds per square inch operating up to 1,500 pounds per square inch (psi), up to 400º Fahrenheit(psi), up to 400º Fahrenheit

Step 2: Estimate savings from a dry sealStep 2: Estimate savings from a dry seal Gas savings between 34 to 196 cf/mGas savings between 34 to 196 cf/m Other dry seal benefits ≈ $63,000/yrOther dry seal benefits ≈ $63,000/yr

Page 20Reducing Emissions, Increasing Efficiency, Maximizing Profits

Decision Process to Replace SealsDecision Process to Replace Seals

Step 3: Determine dry seal conversion costsStep 3: Determine dry seal conversion costs Dry seals cost $5,000 to $6,000 per inch of Dry seals cost $5,000 to $6,000 per inch of

shaft diameter or $8,000 to $10,000 for shaft diameter or $8,000 to $10,000 for tandem sealstandem seals

Beam compressors require two seals, one at Beam compressors require two seals, one at each endeach end

Overhung compressors require one seal at Overhung compressors require one seal at the inboard endthe inboard end

Page 21Reducing Emissions, Increasing Efficiency, Maximizing Profits

Decision Process to Replace SealsDecision Process to Replace Seals

Step 4: Compare costs and savings for a Step 4: Compare costs and savings for a 6-inch shaft beam compressor6-inch shaft beam compressor

Flowserve CorporationFlowserve Corporation

Page 22Reducing Emissions, Increasing Efficiency, Maximizing Profits

Is Recovery Profitable?Is Recovery Profitable?

Replacing wet seals in a 6 inch shaft beam Replacing wet seals in a 6 inch shaft beam compressor operating 8,000 hr/yrcompressor operating 8,000 hr/yr Net Present Value = $531,940Net Present Value = $531,940

Assuming a 10% discount over 5 yearsAssuming a 10% discount over 5 years Internal Rate of Return = 86%Internal Rate of Return = 86% Payback Period = 14 monthsPayback Period = 14 months

Ranges from 8 to 24 months based on wet seal Ranges from 8 to 24 months based on wet seal leakage rateleakage rate

Economics are better for new installationsEconomics are better for new installations Vendors report that 90% of compressors sold Vendors report that 90% of compressors sold

to the natural gas industry are centrifugal with to the natural gas industry are centrifugal with dry sealsdry seals

Page 23Reducing Emissions, Increasing Efficiency, Maximizing Profits

Industry ExperienceIndustry Experience

One Gas STAR partner replaced a wet seal One Gas STAR partner replaced a wet seal with a dry seal and reduced emissions by with a dry seal and reduced emissions by 97%97%

Dry seal leaked 2 Mcf/d versus wet seal Dry seal leaked 2 Mcf/d versus wet seal emissions of 75 Mcf/demissions of 75 Mcf/d

Page 24Reducing Emissions, Increasing Efficiency, Maximizing Profits

Discussion QuestionsDiscussion Questions

To what extent have you replaced rod To what extent have you replaced rod packing or seals in your reciprocating and packing or seals in your reciprocating and centrifugal compressors?centrifugal compressors?

How can the Lessons Learned study be How can the Lessons Learned study be improved upon or altered for use in your improved upon or altered for use in your operation(s)?operation(s)?

What are the barriers (technological, What are the barriers (technological, economic, lack of information, regulatory, economic, lack of information, regulatory, etc.) that are preventing you from etc.) that are preventing you from implementing this technology?implementing this technology?