Recycling options for used sandblasting grit into road ... · PDF fileRecycling options for...

-

Upload

doankhuong -

Category

Documents

-

view

215 -

download

0

Transcript of Recycling options for used sandblasting grit into road ... · PDF fileRecycling options for...

Recycling options for used sandblasting grit into

road construction

1DANIELA LAURA BURUIANA,

1MARIAN BORDEI,

2IOANA DIACONESCU,

2AUREL CIUREA

1Faculty of Metallurgy, Materials Science and Environment

2Faculty of Engineering

“Dunarea de Jos” University of Galati

47, Domneasca Street, 800036, Galati,

ROMANIA

e-mail: [email protected], http://www.fmsm.ugal.ro

Abstract: The grit is an abrasive blasting material used for the preparation of the metal surfaces in the ship

building and ship repair processes prior the application of coatings. The waste is a spent grit used for sand

blasting in the cleaning operations of tankers in the dock yard. This paper presents the modified properties (chemical composition, the shape and size of the particle) of the steel grit during the blasting process and the

possibility of recycling the waste as a fine aggregate in the road construction industry. The management of solid waste from abrasive blasting is an issue which will be more frequently encountered in the future. While existing guidelines and regulations are available, a single resource which spans such a wide array of

information does not currently exist. Future work should concentrate on collecting and summarizing best management practices for abrasive blast material (ABM) waste management in a format which could be used

by the many industries which perform abrasive blasting, and the engineering and regulatory community. The recycling of spent sandblasting grit, commonly referred to as spent ABM, into asphalt concrete is investigated by the shipyard as an alternative to disposing the spent ABM in a landfill.

Key-Words: abrasive blasting material, sandblasting grit, road, shipyard, ship building, repair process.

1 Introduction The naval industry is facing at the beginning of

this century major problems. These appear not

to be linked either to an eventual raw material

resources or energetic crisis, or to the metallic

materials competition with other materials, but

they are rather linked to the acute demands of

the environment protection.

The development of the construction and naval

repairing industry is conditioned by the major

problems solving that come out of the industry

nature relationship on the pollution control and

natural and energetic resources protection.

In the ship repairing area, there should be given

up to the waste notion for the grit used for ship

body sanding/blasting, more correctly being

talked about by products.

The preoccupations followed in the

development strategies of the shipyards around

the world go in two directions:

- the development of superior

technologies that substantially reduce

emissions;

- the growth in efficiency of the

regaining and recycling of the by-products close

to 100% values.

The ecological concept applied to industrial

systems engineering imply the development of

these technological production processes with

closed loop in which no resource is eliminated

all the are continuously reused, no waste

material or other product is evacuated in the

environment that in the subject literature is

found as “waste free industry” or “zero waste

industry”.

In the cleaning of the metallic surfaces of the

ships, new or for fixing, there are used mixtures

made of metallic pellets, grit (cast iron or steel)

and natural sand (derived from natural or

artificial rock grinding). After many usage

cycles in the sanding operations, the material

Recent Researches in Energy, Environment and Landscape Architecture

ISBN: 978-1-61804-052-7 172

loses the abrasive properties, entering to the

waste category. The grit fractions from the

waste material can be recycled and used in

constructions field. This is of both economical

and environmental importance because by

recycling them, the grit wastes dump disappears

not polluting the environmental. Before

recycling them, the waste materials came from

the sanding operations; first they have to

undergo some component separation operations,

metallic respectively non-metallic and then each

of them go through studies for properties

determination. These have to be compared to

the technical conditions provided for each usage

domain.

In comparison with practice and the tendencies

manifested globally, the naval industry in Galati

has collecting shipping and depositing

deficiencies for all categories of waste and in

the technologies for valorization by recycling

and/or their reutilization.

The naval industry in Romania reports an

average 130 (grit waste tons) at a sanded

surface of 8800 [m2 sanded/month] (a ship of

8800 surface [m2]), from which more than 90%

from the wastes derived from this process are

not presently valorized [1], comparing to the

naval shipyards from Germany and Sweden that

have a lesser un-valorized quantity. The

technological processes have a negative impact

upon the environment, being a problem for all

the shipyards in the world. The most modern

shipyards, such as those from Germany, Japan

or Norway promoted the environmental

management plan which supervises the

polluting emissions of the technological

processes from the shipyards [1]. The naval

industry generates important waste amounts and

that is why an environment management plan is

needed to assure the valorization on a large

scale of these wastes (the used grit quantity is

about 130 [grit waste tons/month], the

packaging number is about 180 [boxes/month]).

In the monitoring system, for the emission

impact pollution supervision, quantitative and

quality emissions measurements (NO2, NOx),

powder in suspension and sedimentable

powders in different spots on the shipyard’s

platform were made. Spherical grit pellets are

produced from steel wire cold worked with

medium carbon content, or stainless steel,

according to standards DIN 8201 (St D-Z), DIN

50310, DIN 50311, DIN 50315, EN ISO 1124-

1, EM ISO 1125-3. The composition limits, as

well as the hardness of the grit are given in

Table 1.

The study concerning the recycling of used grit

appeared because of the necessity of solving the

great storage problems, to the fines paid for the

uncontrolled storage [5] and the big waste taxes

[7].

Under the circumstances the reduction of the

pollution level in the naval field by raising the

level of valorization of the grit waste and the

controlled storage represents an important

problem in the environment protection policy.

Table 1. Standard characterization of abrasive material, grit

Material Chemical composition [%]

(density 7.4 g/cm3)

Hardness

[HV]

GP C Mn Si P S 450-560

GL 600-700

class

GH 0.75-1.20 0.60-1.10 0.60-1.10 Max. 0.04 Max. 0.04

800-950

Grit GH

Grit GN

Recent Researches in Energy, Environment and Landscape Architecture

ISBN: 978-1-61804-052-7 173

2 Experimental researches For the grit waste usage for the road

construction there must be taken into

consideration first the hydraulic power of the

addition pendant material, which depends on

stability rate α. In chart 3 it can be found the

recipes for the mixtures determined,

considering the rate. The evaluation of α rate

gives the material quantity necessary for the

preparation of the mixture.

For other materials it is recommended an α rate

between 40-60. The material with α < 20 or α

>80 cannot be used. The binding agent can be

quick lime although the experience shows us

that the slaked lime gives complete necessary

reactions. The lime amount/proportion/dose

fluctuates to 1-2% from the total weight of the

base mixture. The quick lime must have small

dimensions, between 0-2 mm and CaO content

>70%. The comparing results of the

experimentations are presented in Chart 3. In

road construction, grit can replace some natural

insertions with the same granulation. Generally

speaking, the road structure consists of four sub

layers made out of different granulation

material mixtures. The thickness of the layers

differs according to the used mixtures, this first

reassuring the necessary resistance.

The research demonstrated that the grit usage in

materials for road construction has a series of

advantages and also technical disadvantages of

the material:

- it is easily feasible;

- presents homogeneity at a high level

of binding agent;

- the possibility of repairing when

there are damages caused by the

heavy traffic;

- the possibility of some damage that

in the future, can reduce the

bituminous thickness, that is

expensive;

- on bad weather the traffic is stopped;

- there is a possibility of scattering

during traffic.

2.1 The determination of physical and

chemical properties of the sandblasting

grit

Although no specific regulations are in place for

used sandblast grit waste, it is a solid waste, and

as with any non-excluded solid waste the

generator of the waste is responsible for

determining if the waste possesses hazardous

characteristics, and is thus a hazardous waste.

This is therefore a necessary step in determining

the disposal and reuse options available.

Environmental regulations require that a

Toxicity Characteristic Leaching Procedure

(TCLP) test be performed to determine if the

material is hazardous. If it is hazardous, the

material must be managed accordingly. If not

determined hazardous, the grit is a solid waste

which must be disposed of properly. There are

many types of abrasive blasting media

available. Sand is one of the most common

blasting materials. Sand is the least expensive

non-reusable media. Alternatives to sand

abrasives include other mineral sands with no

free silica, metal slag, and coal slag. Coal slag

has been used frequently as a blasting material.

The research concerning the capitalization

possibilities of grit waste derived from sanding,

proposed in this paper is an outcome of thermo-

gravimetric analysis (TGA), X-ray diffraction,

granulometric composition and statistics

methods of PCA (Main Components Analysis)

and BET surface area and porosity using

Micrometrics ASAP (Accelerated Surface Area

and Porosimetry Analysis). The structural characteristics were analyzed using electronic

microscopy. In this study we compared the grit

waste composition with the materials of similar

compositions used in cement factories and

construction materials, from the point of view

of specific properties, by controlling different

compositional factors.

Granulometric fractions were separated both at

the unused material, in its initial state and at the

used grit that goes though a capitalization

analysis after granulometry.

Recent Researches in Energy, Environment and Landscape Architecture

ISBN: 978-1-61804-052-7 174

Table 2. The separation of granulometric fractions ABM/waste ABM

Abrasive blasting material

(sandblasting grit)

Abrasive blasting material

(used sandblasting grit)

Initial weighed quantity 100 g

magnet passing 1 = 2.7 g

magnet passing 2 = 2.2 g

magnet passing 3 = 2.1 g

remains = 91.8 g

screening 0.16 = 90.6 g

screening 0.07 = 1.2 g

Initial weighed quantity = 100 g

magnet passing 1 = 9.2 g

magnet passing 2 = 5.0 g

magnet passing 3 = 5.5 g

remains = 80.3 g

Screening through magnet 1 = 9.2 g

screen 0.16 = 5.2 g

screen 0.07 = 2.3 g

screen 0.05 = 1.2 g

dust = 0.5 g

Screening through magnet 3 = 5.5 g

screen 0.16 = 3.3 g

screen 0.07 = 1.2 g

screen 0.05 = 0.5g

dust = 0.5g

Screening through

screens of the remained grit = 80.3g

screen 0.16 = 54 g

screen 0.07 = 13.3 g

screen 0.05 = 3 g

dust = 10 g

The separation of granulometric fractions wad

made by waste screening, for fractions

separations according to granule dimensions,

using screens of different dimensions

(Granulometric analysis table2)[1]. Separate

granulometric fractions have the following

dimensions: 0.16; 0.07; 0.05; 0.01 [mm].

The screen is laid on a white surface, on the

screen remaining only rough fraction. The

sample on the screen is removed and the

quantity gone through the screen is weighed.

The basic technical characteristics for the solid

materials that mostly determine the properties

and their quality are: composition,

granulometry, density, the specific surface and

pore structure.

The cognition of these characteristics make

possible the parameters determination of the

sand blasting with the optimum

efficiency/output. To establish the recycling

channel, the used grit properties were

determined using granulometric analysis.

The authors collaborated with managing

Shipyards of Galati. We chose the PCA method

using AAS technique (Spectroscopy of Atomic

Absorption), because they are preferred by the

cement industry. Shipyard being directly

interested in the final results collaborated with

the author offering her the analysis bulletin for

the research concerning the capitalization of grit

waste.

For the determination of the elements from used

grit composition it was used the atomic

absorption spectroscopy technique AAS (table

3). AAS measures the concentration of an

element from a given sample, by the

determination of the absorption made by the

atoms brought to a very high temperature. A big

advantage of AAS method is the possibility of

organic solvents usage for sample

concentration.

The basis of the analytic chemistry consists in

the chemical analysis methods, methods that

allow the identification of the composition for

the raw material used in technological

processes, for the example the raw materials

used in road asphalting process. The chemical

used composition of the analyzed grit waste was

made with the support of the Shipyard of Galati,

waste producer in the analyzed area.

Recent Researches in Energy, Environment and Landscape Architecture

ISBN: 978-1-61804-052-7 175

Table 3. The chemical composition of the used sandblasting grit Analysis Bulletin

Beneficiary Shipyard of Galati

Name of the

material Elements [%]

Mn SiO2 CaO MgO Cr2O3 Al2O3 Fe2O3 P.C. Used sandblasting

grit 0.39 39.28 6.7 6.57 1.20 7.56 38.28 absent

EDX analysis indicates the particles

composition as well as the elements distribution

in the examined area. Samples 1 - 4 have

similar structures. The samples have similar

microstructures, highlighting the thinnest

diffusion area.

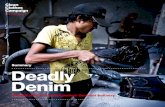

SSaannddbbllaassttiinngg ggrriitt ssaammpplleess ccooaatteedd wwiitthh ccaarrbboonn 9900%%

Fig. 1-4. EDAX analysis of the elements marked using a high energy surface that allows

in-depth view

The study highlights a very important issue for

the used grit recycling and that is the grit

composition doesn’t go through major

deviations from its initial state. The analyzed

waste has as main components Si and iron

oxides. The composition is similar to that which

is formed at hydraulic materials hardening. A

more rugged texture, characteristic to

aggregates, assures bigger adhesion forces

between aggregate granules and the binding

agent, an extremely important thing for road

concretes.

The fully automated ASAP Accelerated Surface

Area and Porosimetry System is designed for

high-performance/high sample throughput to

help today's busy laboratories expand their

workflow while providing highly accurate and

precise surface area and porosimetry

measurements. With six independently operated

analysis ports, a new analysis can begin as soon

as another is finished.

This provides an important advantage over

many multi-port instruments that require all

samples to be prepared or analyzed at the same

time. In addition, a key, standard feature of the

ASAP is a programmable and fully automated

sample preparation module with twelve

independently operated ports. Samples may be

added or removed from degas ports without

disturbing the treatment of other samples

undergoing preparation or analysis.

The term BET was derived from the first initials

of Burnauer, Emmett and Teller, and refers to

the method of measuring the surface area and

porosity of solid materials using the principals

of physical adsorption and de-sorption of gas.

The Micrometric's ASAP 2000 system has the

versatility to characterize samples using a

number of different adsorptive gases as

Nitrogen. In physical gas adsorption, an inert

gas, mostly nitrogen, is adsorbed on the surface

of a solid material.

This occurs on the outer surface and, in case of

porous materials, also on the surface of pores.

Most widely known is the determination of the

BET surface area by gas adsorption. Adsorption

of nitrogen at a temperature of 77 K leads to a

so-called adsorption isotherm, sometimes

referred to as BET isotherm, which is mostly

measured over porous materials

Recent Researches in Energy, Environment and Landscape Architecture

ISBN: 978-1-61804-052-7 176

Fig. 5. Analysis grit BET pore size

The ASAP 2000 measures high-resolution

adsorption isotherms on a wide range of

materials.

The interactive display allows users to zoom in

on the fine details of the isotherm. The

expanded graph shows the precise closure of the

adsorption and desorption isotherms.

The results of sample analysis device

sandblasting grit with ASAP 2000 surface area

and porosity using ASAP 2000 apparatus under

the guidance using Department of

Environmental Engineering and Chemical

Technology, Pannon University Hungary.

3. Recycling options for used sandblasting

grit into road construction

A better knowledge of leaching tests and

results, as well as of material properties, is very

important in the assessment of waste ABM for

use in road construction. The aim of this work

has been to investigate leaching of primary and

secondary road-making materials and study

factors that may have an influence on the

release of trace elements such as chromium,

zinc and manganese, magnesium that are

regarded as pollutants.

The main objective of the study is the

determination of the optimum between the grit composition and its grinding fineness.

The value of the resulted analyses values were

compared to those estimated in the quality

norms of aggregates, value decisively

influenced by factors which can be impurities

content, dimensional characteristics of the

granules and the physic-chemical

characteristics.

The results interpretation of the grit samples

show that the analyzed grit has physical and

chemical properties similar to standard analysis

of the sand used in asphalt composition:

- an angular granulation, unrounded

(considerably influences the concrete

resistance); - a silicon-aluminous composition

(the compounds are similar to those which are

formed at the construction materials hardening,

formed puzzolanic asphalt, mainly from

reactive silicon dioxide and aluminum oxide

which can contain other oxides too – iron

oxide).

The aimed general objective in used grit

capitalization process for asphaltic material

includes the production of a composite with

adequate physic-mechanic properties,

competitive and comparable with traditional

materials used in road asphalting domain:

- reduced connection capacity of the heavy

metals in watery environment;

- less quantities that doesn’t negatively affect

the connection and hardening properties of

heavy metals. Out of the materials used for road construction,

the grit waste can be classified at

hydraulic/puzzolanic binding agents, together

with sand and furnace slag.

Recent Researches in Energy, Environment and Landscape Architecture

ISBN: 978-1-61804-052-7 177

Table 4. Comparative results of the used abrasive blasting material [1, 4, 8, 10]

Bitumen 60/70 [84] Bonded

reinforcement Slow Cure

Composition % weight [1,8,10]

Large aggregate 10/20 30 30 30 - - -

Aggregate average 5/10 25 25 25 40 40 40

Used sandblasting grit [8] - - 13 - 12 12

sand 0/3 13 13 29 12 12 42

Chalk - 4 3 - 8 6

Cement 4 - - 7 - -

Bitumen 5 5 5 6 6 6

Granularity % weight [1]

Screening through ¾” 100 100 100 - - -

Screening through 1/2” 95.8 95.8 95.8 100 100 100

Screening through 3/8” 72.7 72.7 72.7 7.6 7.6 7.6

Screening through ¼” 57 57 57 78.3 78.3 78.3

Screening through mm 5 44.8 44.8 44.8 60.8 60.8 60.8

Characteristics [4]

Density of mix real [kg/dm3] 2.717 2.693 2.711 2.723 2.681 2.701

Specific gravity bitumen [kg/dm3]

1.025 1.025 1.025 1.025 1.025 1.025

Specific gravity conglomerate [kg/dm3]

2.519 2.499 2.514 2.490 2.456 2.477

4 Conclusions The paper presents the research results made for the

purpose of recycling options for used sandblasting grit in composite materials realization used into road

construction. The purpose of this research was to emphasize the possibility of recycling used grit was

an asphalt composition material, presenting the necessary grit granulation as well as the Si and iron oxides concentration necessary for the mixture used

in asphalting (asphaltic mixture) process. Looking for a way/method of using grit waste, the

propounded solution could be the large scale use of stabilized mixture technology (treated granular aggregate with puzzometric binding agents using

used grit), following the example of advanced countries (in our country the roads rehabilitation

problem needs big material, aggregate, binding materials consumption, difficult to be provided from traditional resources).

Conclusions conclude that theoretical and experimental research presented in the paper was

called for by the importance of recycling grit wastes. Proposals for using the material obtained from recycling of grit wastes in stabilized mixtures with

binders used in roads asphalt, the shipyard studied being able to benefit from economic advantages by

reducing costs allocated to the collection, transport and disposal grit wastes.

References:

[1] D. NegoiŃă (Buruiana), Contribution to the reduction of waste generated by shipyards” PhD

thesis, 2007. [2] Al-Sayed M. H., Madany I. M., Use of copper blasting grit waste in asphalt mixes in Bahrain,

Construction and Building Materials, Vol. 6, Issue

2, 1992, pp. 113-116.

[3] Amada S., Hirose T., Senda T., Quantitative evaluation of residual grits under angled blasting, Surface and Coatings Technology, Vol. 111,1999

[4] Gheorghe M., Valorificarea deşeurilor si subproduselor industriale în construcŃii, Ed.

MatrixRom, Bucuresti, 2004. [5] Henley, N, Spash, C., Cost-Benefit Analysis and the environment, UK, Edward Elgar Publishing

Ltd., Gower House Aldershot, 1993.

[6] Mandravel C., Stanescu R., Metode fizico

chimice aplicate la măsurarea noxelor in mediul

profesional, Ed. Academiei Române, Bucureşti,

2033, pp. 139-158.

[7] Mohammad Ismail M., Madany H.,

Raveendran Al-Sayed, Utilization of copper

blasting grit waste as a construction material,

Waste Management, Volume 11, Issues 1-2,

1991, pp. 35-40.

Recent Researches in Energy, Environment and Landscape Architecture

ISBN: 978-1-61804-052-7 178