Recovery and Sporicidal Resistance of Various B. …lib3.dss.go.th/fulltext/Journal/J.AOAC...

Transcript of Recovery and Sporicidal Resistance of Various B. …lib3.dss.go.th/fulltext/Journal/J.AOAC...

MICROBIOLOGICAL METHODS

Recovery and Sporicidal Resistance of VariousB. subtilisSporePreparations on Porcelain Penicylinders Compared with Resultsfrom AOAC Test Methods

DANIELSON ET AL.: JOURNAL OF AOAC INTERNATIONAL VOL. 83, NO. 1, 2000JAMES W. DANIELSON, KRISTINE E. ZUROSKI, and CHRISTINE TWOHY

U.S. Food and Drug Administration, Central Laboratory for Microbiological Investigations, 240 Hennepin Ave,Minneapolis, MN 55401RICHARD D. THOMPSON

U.S. Food and Drug Administration, Minneapolis District, 240 Hennepin Ave, Minneapolis, MN 55401ELLIS BELL

1

Gustavus Adolphus College, Biochemistry Program, St. Peter, MN 56082FOSTER MCCLURE

U.S. Food and Drug Administration, 200 C St, SW, Washington, DC 20204

Sporicidal test results obtained from carriers inoc-ulated with 4 types of defined Bacillus subtilisspore preparations were compared with the stan-dard AOAC sporicidal test using soil extract nutri-ent broth (SENB) B. subtilis 19659 spores. Recov-eries of spores inoculated on penicylinders fromB. subtilis clean spores (washed and suspended inwater) and B. subtilis 19659 spores inoculatedfrom culture filtrates according to the AOACmethod were compared. Spores were exposed to6 concentrations (0.5–3.0 % w/v) of glutaraldehydein phosphate buffer (pH 7.5) for 10 h. Concentra-tions were established by titrimetry and liquidchromatography. Recoveries of surviving sporeswere determined for 3 types of clean B. subtilisvar. niger preparations, one clean B. subtilis 19659preparation, and the SENB B. subtilis 19659 fil-trates. Spore carriers, inoculated by the standardAOAC protocol, resulted in as much as a 2-lognumber difference in runs 1–12, but not more than0.5 log number for each clean spore preparation.The SENB spores varied most in resistance toglutaraldehyde, with no growth in recovery mediafrom 3 different batches of 1, 1.5, and 2 %glutaraldehyde. Separate batches of SENB prepa-rations of B. subtilis 19659 were resistant and de-stroyed by 1.0 % glutaraldehyde, with 3.98 and6.0 log numbers of spores on penicylinders, re-spectively. Clean spore preparations of B.subtilis 19659 on porcelain penicylinders weremore resistant to glutaraldehyde than were SENBspores. Nutrient agar/Mg/Ca and nutrient agar/Mg

spore preparations of B. subtilis var. niger showedthe most uniform resistance to glutaraldehyde.Spores with calcium added showed increased re-sistance to glutaraldehyde. B. subtilis 19659spores from the Columbia broth spore preparationwere the most resistant and were recovered afterexposure to 3.0 % glutaraldehyde.

AOAC Official Method966.04(1) tests sporicidal ac-tivity of disinfectants, using porcelain penicylindersand silk suture loops as spore carriers. The carriers are

inoculated in 72 h culture filtrates ofBacillus subtilis(19659)andClostridium sporogenes(3584) from soil extract nutrientbroth (SENB) and soil extract egg meat medium, respectively.In the AOAC sporicidal test, loading carriers by submersion inbroth culture can cause variation among carriers from test totest because of different media, degree of sporulation, and ex-tent to which carriers are coated with dried media (2). Soil ex-tract provides minerals that are necessary for culturing resis-tant spores suitable for testing chemical germicides. Our pre-vious work showed that resistance ofB. subtilisspores to HClcan vary depending on different batches of soil extract used inthe SENB. Two samples of soil extract, prepared according tothe AOAC method with soil from separate locations and sentto the National Forensic Chemistry Center, U.S. Food andDrug Administration, Cincinnati, OH, showed more than3 times the calcium in one sample than in the other sample anddifferent quantities of magnesium, sodium, and potassium.Marquis and Shin (3) reported that spore mineralization in-creased bacterial spore resistance to heat and enhanced resis-tance to oxidation by agents such as tertiary butyl hydrogenperoxide and hydrogen peroxide. Bender and Marquis (4) de-termined that the hierarchy of protection of minerals againstmoist heat damage forB. megaterium(ATCC 19213),B.

DANIELSON ET AL.: JOURNAL OF AOAC INTERNATIONAL VOL. 83, NO. 1, 2000 145

Received November 19, 1998. Accepted by AH September 3, 1999.1 Author to whom correspondence should be addressed.

subtilis var. niger, andB. stearothermophilus(ATCC 7953)was Ca > Mn > Mg > K. The AOAC sporicidal test does notspecify the number of spores to be inoculated on the carriers.Danielson et al. (5, 6) reported that the resistance ofB. subtilisvar. niger inoculated from a clean spore suspension to 2.5NHCl was directly proportional to the numbers of spores inocu-lated on porcelain penicylinders and silk suture loops. Ascenziet al. (7) found thatB. subtilisspores inoculated from culturefiltrates according to the AOAC method on porcelainpenicylinders retained only 28% on the carriers.B. subtilisvar.nigerspores inoculated from a clean spore suspension anddried on porcelain penicylinders retained 99% after being sub-merged in a chemical germicide (chlorine dioxide) neutralizedwith sodium bicarbonate for 15 h (8). Clean spores have beenrinsed and suspended in water, whereas AOAC preparedspores are supended in culture filtrates.

This study compared the reproducibility of various prepa-rations ofB. subtilisspores recovered after inoculation on por-celain penicylinders and their resistance to glutaraldehydecompared with that of AOAC-preparedB. subtilisspores.

Experimental

Media and Reagents

(a) Soil extract nutrient broth (SENB).—Prepared as di-rected in AOAC Method966.04(1), 10 mL in 25× 150 mmtubes; Anatone (American Laboratories, Inc., Omaha, NE);beef extract (Difco Laboratories, Detroit, MI); and garden soilextract.

(b) Anatone.—American Laboratories, Inc.(c) Beef extract.—Difco.(d) Garden soil extract.—Prepared as in AOAC Method

966.04.(e) Soil extract egg meat medium.—Prepared as in AOAC

Method966.04.(f) Egg meat medium.—Difco.(g) Nutrient agar (Difco) and garden soil extract.—Pre-

pared as in AOAC Method955.11.(h) Manganese sulfate.—Aldrich Chemical Co., Milwau-

kee, WI.(i) Pour plate agar.—Bacto tryptic soy agar, lot 51449 JE

(Difco).(j ) Phosphate-buffered dilution water.—Weber Scien-

tific, Hamilton, NJ.(k) Sterile water.—For irrigation, USP (Abbott Labs,

North Chicago, IL).(l) Hydrochloric acid.—Baker analyzed, 5N,

Lot 5618-02 F36533 (J.T. Baker, Inc., Phillipsburg, NJ).(m) Acid potassium phthalate 84j.—National Institute of

Standards and Technology, Gaithersburg, MD.(n) Lab-Lemco agar (LL).—Oxoid Unipath Ltd.,

Basingstoke, Hampshire, UK.(o) Fluid thioglycollate.—Lot 44854JE (Difco).(p) Tryptic soy broth.—Lot 46054JB (Difco).(q) Columbia broth.—Difco.(r ) Sodium hydroxide.—Baker analyzed 2.5N, Lot

601528 (J.T. Baker).

(s) Sulfuric acid.—Mallinckrodt, Paris, KY.(t) Carbon dioxide absorbent.—Mallcosorb 20–50 mesh

(Mallinckrodt).(u) Dibasic potassium phosphate (K2HPO4) buffer,

0.025M.—8.71 g ACS grade anhydrous powder (Fisher Sci-entific Co., Fairlawn, NJ) dissolved in 2 L distilled water.

(v) Monobasic potassium phosphate (KH2P04).—HPLCgrade (Fisher Scientific). This salt was used to prepare the liq-uid chromatography (LC) mobile phase.

(w) Phosphoric acid.—HPLC grade, 85% (v/v; FisherScientific).

(x) Hydroxylamine hydrochloride.—AR grade (J.T.Baker).

(y) Glutaraldehyde.—50% (w/w) in water (Aldrich). Thissolution was stored under refrigeration and used to prepare the6 concentration levels.

(z) Glutaraldehyde reference standard.—Grade 1, 50%(w/w) in water (9; Sigma Chemical Co., St. Louis, MO). Thismaterial, obtained in 10 mL quantities, was packed under ni-trogen and stored at –14EC. Purity of this solution (51.41%w/w) was determined by reacting 0.5 g in 100 mL water with25.0 mL 1M hydroxylamine hydrochloride for 30 min and ti-trating potentiometrically with 0.5M NaOH, applying a cor-rection for the reagent blank (9). The purification index(A235nm/A280nm) determined at a concentration of 10 mg/mL inwater was 0.11 (10, 11). The purification index (PI) is definedas the ratio of UV absorbance of an aqueous glutaraldehydesolution having a concentration of 10 mg/mL at wavelengthsof 235 nm (polymeric form) to 280 nm (monomeric form).Low PI values (<0.5) indicate high purity and absence of poly-meric impurities. UV measurements were made with aPerkin-Elmer Lambda 7 spectrophotometer (Norwalk, CT)using 1 cm silica cuvettes and distilled water as the reference.A reference standard solution (A) was prepared in the LC mo-bile phase at a concentration of 0.4 mg glutaraldehyde/mL forquantitation purposes.

(aa) LC mobile phase.—Aqueous 0.05M monobasic po-tassium phosphate–acetonitrile (96 + 4, v/v) adjusted topH 3.00 with 85% phosphoric acid and passed through a47 mm, 0.45µm porosity polysulfone membrane (GelmanSciences, Inc., Ann Arbor, MI) before use.

(bb) Trypticase soy agar.—Lot 44854JE (BBL, BectonDickinson Microbiology Systems, Cockeysville, MD) usedby Presque Isle Cultures (Presque Isle, PA) for aerobic platecounts.

Organisms

(a) Bacillus subtilisvar. niger.—ATCC 9372 (AmericanType Culture Collection, Manassas,VA).

(b) Bacillus subtilis.—ATCC 19659 (Presque Isle Cultures).

Apparatus

(a) Porcelain (steatite ceramic) penicylinders.—8× 10 mm(Fisher Scientific, Eden Prairie, MN).

(b) Sonicator.—Heathsonics Corp., San Ramon, CA.(c) Filter paper.—No. 597, 9 cm (Schleicher & Schuell,

Keene, NH).

146 DANIELSON ET AL.: JOURNAL OF AOAC INTERNATIONAL VOL. 83, NO. 1, 2000

(d) Vortex mixer.—Daigger Vortex Genie 2 (Scientific In-dustries, Inc., Bohemia, NY).

(e) Colony counter.—Darkfield Quebec (American Opti-cal Corp., Buffalo, NY).

(f) Medication tubes.—Borosilicate glass, 25× 150 mm(VWR Scientific, Chicago, IL). Tubes with closures wereautoclaved at 121EC for 1 h before use.

(g) Morton culture tube closures.—25 mm (ScientificProducts, Minneapolis, MN).

(h) Petri dishes.—Glass (Pyrex), 20× 100 mm, and poly-styrene, 15× 100 mm (Fisher).

(i) Hemacytometer.—Spencer Bright-line (Scientific In-strument Division, Buffalo, NY).

(j ) Microscope.—Standard (Leitz, Wetzlar, Germany).(k) Bent glass rods.—1

8 in. od and ca 212 × 4 in.,

autoclaved in pint jars at 121EC for 1 h.(l) Wire hooks.—Chromol A wire (80% nickel, 20% chro-

mium), 18 gauge (Daigger Scientific, Wheeling, IL) coppertubing 1

8 in. od, 116 in. id (Fisher Scientific, Wheeling, IL).

Copper tubing 514 in. long and crimped on both ends, with one

end having 7 in. long wire with316 in. end bent at 90E. Hookends were placed in 12× 75 mm glass tubes in 12 in. sq. panswith lids and sterilized at 180EC dry heat for 4 h.

(m) Beads.—Protect Bacterial Preservers (MFR-TSCLtd., Lancashire, UK). Beads were used for storingB.subtilis19659 culture at –70EC.

(n) Liquid chromatograph.—LC system consisting ofAltex/Beckman Model 100 A pump; Kratos/ABI Model 757UV detector; Rheodyne Model 7125 Valve (50.0µL loop);and Spectra Physics Model 4270 integrator. LC column wasZorbax Rx C18, 5 mm, 25 cm× 4.6 mm id (Mac-Mod Analyti-cal, Inc., Chadds Ford, PA), flow rate, 1.00 mL/min; moni-tored at 285 nm under ambient conditions.

(o) Dry heat oven.—Blue M Company, Blue Island, IL.(p) Refrigerated constant temperature circulator.—Niles

PolyScience, Niles, IL.(q) Filter apparatus with filter cup and vacuum

base.—Millipore Corporation, Bedford, MA. Unit wasautoclaved with 2 L side arm flask in a paper bag for 1 h at121EC.

(r ) Filters.—0.22 µm cellulose filters (Millipore). Filterpacks were autoclaved for 10 min at 121EC.

(s) SterilGard hood.—The Baker Company, Inc., San-ford, Maine.

(t) pH meter.—Orion Research Model 811, Orion Re-search, Inc., Cambridge, MA.

Preparation of Glutaraldehyde Solutions

Accurately weighed quantities of 50% aqueousglutaraldehyde (Aldrich) were transferred to sterile 1 L gradu-ated g.s. cylinders and diluted to volume with 0.025M dibasicpotassium phosphate (filtered through 0.22µm filters) to pro-vide glutaraldehyde concentrations of 0.5, 1.0, 1.5, 2.0, 2.5,and 3.0% (w/v). These solutions, usually prepared at 2 differ-ent concentration levels each day (randomized sequence),were transferred to a 2.0 L screw cap flask and adjusted topH 7.50 with 1M phosphoric acid. About 80 mL was removed

for analyses, with titrimetric assay performed immediately.Solutions were assayed for glutaraldehyde by 2 methods.Titrimetry was used to target concentration, and LC to moni-tor stability, with differences indicating possible degradationvia polymerization. An appropriate aliquot was diluted withLC mobile phase in a 100 mL volumetric flask to a concentra-tion of 0.4–0.5 mg glutaraldehyde/mL and set aside for the LCassay to be performed within 2 h. The remaining 920 mL wasused for sporicidal testing. Glassware was washed and rinsedin an automatic washer and dried in a drying oven. Glasswarewas sterilized by autoclaving at 121EC for 1 h prior to prepara-tion of glutaraldehyde.

Determination of Glutaraldehyde Content

(a) Titrimetry (12).—Duplicate aliquots equivalent to100 mg glutaraldehyde were transferred to separate 250 mLbeakers; 100 mL water was added, and pH of solution was ad-justed to 3.00 with 10% (v/v) HCl. A 15.0 mL portion of 10%(w/v) hydroxylamine hydrochloride was added; the mixturewas allowed to stand for 15 min and was then titrated back topH 3.00 with standardized 0.1N NaOH. The concentrationwas calculated using 1 mL 0.1N NaOH, equivalent to0.05006 g glutaraldehyde. This reaction (formation ofaldoxime) and that related to the Grade 1, 50% glutaraldehydesolution involves uptake of 2 moles hydroxylamine for eachmole of glutaraldehyde present, resulting in release of 2 molesacid neutralized with 0.1N NaOH. All pH adjustments and ti-trations were performed with an Orion Research Model 811pH meter.

(b) Liquid chromatography (13).—The chromatographicsystem was allowed to equilibrate for 2–3 h under the de-scribed conditions. The response obtained for a 50.0µL injec-tion of the reference standard (A) was between 4 and 6 min witha 60–80% full scale deflection. A suitable volume ofglutaraldehyde solution diluted with LC mobile phase waspassed through a 13 mm, 0.45µm porosity Nylon 66 membrane(Gelman), and 50.0µL of the filtrate was injected into thechromatograph. The response obtained (peak height) was com-pared directly with that for 50.0µL of reference standard solu-tion (A) using duplicate injections in a bracketing sequence.

Spore Preparations

(1) Fourteen preparations of SENBB. subtilis 19659spores were made by Presque Isle Cultures, according toAOAC Method 966.04.B. subtilis 19659 was cultured inSENB at 37EC. After 72 h of incubation, culture filtrates wereprepared. Presque Isle Cultures also determined the concen-trations of spores/vegetative cells/mL from 2 tubes from eachbatch of AOAC spore preparation using sterile water for dilu-tions and BBL Trypticase soy agar. These spore preparationswere not heated.

(2) B. subtilis(19659) spores were cultured from 10% Co-lumbia broth (CV; 14). Three beads from the stock supply, in-oculated with B. subtilis (19659) spores, were added to2 Erlenmeyer flasks, each containing 100 mL of 10% Colum-bia broth plus 0.1 mM Mn+2. The flasks were then incubatedon a platform shaker at 160 rpm at 37EC for 72 h. The spores

DANIELSON ET AL.: JOURNAL OF AOAC INTERNATIONAL VOL. 83, NO. 1, 2000 147

were centrifuged and then washed 3 times by resuspending thepellet in sterile water and centrifuging. The CB spores arenearly all contained in the sporangia after 3 days of incuba-tion, whereas the mother cells are mostly disintegrated awayfrom spores that have been incubated$10 days on sporulationagar. The CB spores were suspended in 200 mL sterile waterwithout nutrients for a stock supply (5.8× 107 spores/vegeta-tive cells/mL).

(3) B. subtilisvar. niger (9372) was inoculated on LL inPetri dishes from the stock spore suspension and incubated at37EC for 24 h. The plates were then incubated at room tempera-ture for 4–5 days. Spores were harvested using sterile water anda bent glass rod; they were cleaned by centrifuging 3 times at ca8000×gand resuspended in sterile water (6.4×109 spores/mL).

This preparation was made by Robert Mooney, Department ofMicrobiology, University of New Hampshire.

(4) B. subtilisvar. niger (9372) was cultured on nutrientagar with 15 mg MnSO4·H2O, 0.5 g CaCl2·2H2O, and 2.0 gMgSO4·7H2O/L (NA/Mg/Ca). We modified the sporulationmedium, nutrient agar plus 5 ppm manganese (15), by addingmagnesium and calcium, which were found in abundance insoil extract which was prepared according to the AOACMethod966.04(1) and sent to the National Forensic Centerfor ion analysis. The concentration of the stock supply was6.3× 109 spores/mL.

(5) B. subtilisvar. niger (9372) was cultured on nutrientagar plus 5 ppm manganese (15), which we modified to nutri-ent agar, 2.5 g MgSO4·7H2O and 15 mg MnSO4·H2O/L

148 DANIELSON ET AL.: JOURNAL OF AOAC INTERNATIONAL VOL. 83, NO. 1, 2000

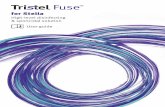

Figure 1. Neutralizer media: Recoveries from duplicate sets of 90 penicylinders with SENB B. subtilis 19659, CB B.subtilis 19659, and nutrient agar/Ca/Mg/Mn B. subtilis var. niger spores; also SENB B. subtilis 19659, Lab-Lemco B.subtilis var. niger , and nutrient agar/Mg/Mn B. subtilis var. niger spores after exposure to 6 concentrations ofglutaraldehyde for 10 h. Average log numbers of spores from 30 check penicylinders are listed.

(NA/Mg). Our unpublished data show that resistance toglutararaldehyde ofB. subtilisvar. niger spores cultured onnutrient agar plus 5 ppm manganese (15) can be increased byadding either magnesium or a combination of magnesium andcalcium.The concentration of the stock supply was5.9× 109 spores/mL.

Each culture was transferred daily 3 times on agar slants(10 mL in 20× 150 mm tubes) incubated at 35EC. The sametype of agar medium (ca 80 mL) in 150×20 mm plates was in-oculated with 0.5 mL inoculum and spread with a bent glassrod. Agar plates were incubated 10–12 days until adequatesporulation occurred. Free spores out of the sporangia of$95% ofB. subtilisvar.niger from spore preparations Nos. 3,4, and 5 were determined from smears of cultures stained withcrystal violet before spores were washed from the agar plates

with sterile water and a bent glass rod. The spores werecleaned by centrifuging at 10 000 rpm and pouring off thesupernatant liquid 3 times. Debris of the lysed cell wallsformed a thin film over the pellet which consists of freespores. This film was rinsed from the pellet and poured off be-fore free spores were resuspended. In the AOAC sporicidalmethod (1), spores are not heated before inoculation of thecarriers. The 3 types (Nos. 3, 4, and 5) ofB. subtilisvar.nigerstock spore suspensions were heated once at 80EC for 20 minto kill vegetative cells, and were then stored in the refrigerator.The SENB and CB 19659 spore preparations were heated onlyfrom the check penicylinders and only on portions of theCB 19659 inocula that were used to determine numbers ofspores/mL. Spores from sporulation agars that we prepared

DANIELSON ET AL.: JOURNAL OF AOAC INTERNATIONAL VOL. 83, NO. 1, 2000 149

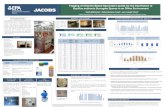

Figure 2. Recovery media: Recoveries from duplicate sets of 90 penicylinders with SENB B. subtilis 19659, CB B.subtilis 19659, and nutrient agar/Ca/Mg/Mn B. subtilis var. niger ; also SENB B. subtilis 19659, Lab-Lemco B. subtilisvar. niger , and nutrient agar/Mg/Mn B. subtilis var. niger spores after exposure to 6 concentrations of glutaraldehydefor 10 h and neutralization. Average log numbers of spores from 30 check penicylinders are listed.

were suspended in sterile water. The stock spore suspensionswere stored in the refrigerator at 2E–4EC.

Two additionalB. subtilis19659 spore preparations werealso made with LL and NA/Mg/Ca sporulation media usingthe above protocol. Concentrations of the stock supplies of LLand NA/Mg/Ca spore preparations ofB. subtilis19659 were3.7× 109 and 6.2× 109 spores/mL, respectively.

Inoculation of Penicylinders

New porcelain (steatite ceramic) penicylinders were usedas spore carriers to test the resistance of all 5 types of sporepreparations. Carriers were prepared according to the AOACsporicidal method, except that they were autoclaved for 1 h at121EC. The AOAC sporesB. subtilis(19659) were inoculatedon penicylinders, from SENB filtrate according to the AOACmethod, by Presque Isle Cultures, and were received by ourlaboratory 4–5 days before testing. The spores were kept un-der vacuum at 24–26 in. Hg in a desiccator with CaCl2. Stockspore preparations from the 4 types of sporulation media(NA/Mg, NA/Mg/Ca, LL, and CB) were warmed to roomtemperature and sonicated for 5–10 s.

Five penicylinders were initially tested for retention ofspores to ensure that the concentration of spores was suitablefor inoculating the carriers. From the CB spore preparation,previously diluted to the appropriate concentration for inocu-lation of ca 5.0× 105–1.0× 106 spores on the carriers, 20 mLwas transferred to a milk dilution bottle. The remaining3 spore preparations were also diluted to 20 mL to achieve thatconcentration. For the diluted spore suspensions, 10 mL wasplaced in 25× 150 mm tubes for inoculating carriers.

Using 5 in. forceps, 10 penicylinders were placed in theinoculum and then mixed on a Vortex mixer for 30 s. After anadditional 30 s, a flamed wire hook was used to transferpenicylinders to a double-matted Petri dish (20× 150 mm).Excess inoculum was drained from each penicylinder bytouching it to the side of the tube during transfer. Dou-ble-matted Petri dishes lined with filter paper were preparedand sterilized according to the AOAC method. The spore car-riers were kept under vacuum at 24–26 in. Hg in a desiccatorwith CaCl2 for 5 days before testing.

Quantitation of Spores on Carriers

Viable spores/mL of inoculum were determined by prepar-ing duplicate pour plates of the 5th and 6th dilutions usingT-soy agar incubated at 35E ± 2EC for 48 h, except for theAOAC inoculum which was prepared by Presque Isle Cul-tures. The TSA plates were incubated at 37EC for 24 h. Thirtycheck penicylinders were tested for numbers of spores fromthe same batch of penicylinders inoculated for sporicidal test-ing. Penicylinders were placed in separate tubes(20× 150 mm) containing 10 mL phosphate-buffered water.Because AOAC and CB spore preparations were not heated,penicylinders with these spores were sonicated 2 min, andthen heated at 80EC in a water bath for 20 min to destroy vege-tative cells. They were then cooled and sonicated for 3 min toremove spores. These spores were sonicated for 2 min beforeheating so that many would be in suspension while beingheated. The 3 stock spore suspensions ofB. subtilisvar.nigerwere previously heated; penicylinders inoculated with thesespores were therefore sonicated continuously for 5 min at thelow setting. The tubes were mixed on a Vortex mixer for 30 s,and 10-fold dilutions were made for pour plates of T-soy agar.Each dilution was mixed on a Vortex mixer for 8–10 s. Pourplates were incubated for 48 h at 35EC. Plates from dilutionswith 30–300 colonies were used to determine aerobic platecounts with a Quebec colony counter (16). Our earlier workshowed that the average number of spores removed from10 porcelain penicylinders on the first sonication (5 min) andmixing on a Vortex mixer (30 s) from 3 sonications/mixingswas: AOACB. subtilis19659, 99%; nutrient agar/Mg/CaB.subtilis19659, 99%; Lab-LemcoB. subtilisvar.niger, 97%;and CBB. subtilis19659, 96% (17). These penicylinders wereall sonicated continuously for 5 min. These data show that onesonication for 5 min and mixing for 30 s was sufficient to de-termine the approximate number of spores on penicylinders.

HCl Resistance

The AOAC sporicidal Method966.04was used to testspore resistance to 2.5N HCl for 2, 5, 10, and 20 min.

150 DANIELSON ET AL.: JOURNAL OF AOAC INTERNATIONAL VOL. 83, NO. 1, 2000

Table 1. Statistical analysis of 6 preparations for each concentration of glutaraldehyde used in 4 sporicidal tests and2 negative controls ( n = 6)

Glutaraldehyde, %a

LC Titrimetry

Mean, % SD CV, % Mean, % SD CV, %

0.50 0.495 0.005 1.106 0.515 0.005 1.064

1.00 0.993 0.015 1.516 1.030 0.000 0.000

1.50 1.502 0.013 0.885 1.548 0.004 0.264

2.00 2.003 0.010 0.516 2.067 0.010 0.500

2.50 2.478 0.019 0.783 2.563 0.043 1.686

3.00 3.003 0.027 0.910 3.093 0.012 0.392

a Each solution was adjusted to pH 7.50.

Sporicidal Test

The study involved 2 spore strains, 5 types of spore prepara-tions, 5 sporulation media, 6 concentrations (0.5–3.0%) ofglutaraldehyde, and 12 runs. Three sets of 30 (90 penicylinders)spore carriers were used for each type of spore preparationagainst 5 levels (0.5–3.0%) of glutaraldehyde. Theglutaraldehyde was pre-cooled to 20EC before spore carrierswere added, as in the AOAC method. Penicylinders were trans-ferred under a laminar flow hood using sterile wire hooks. Fivespore carriers were placed in each tube (25× 150 mm) with

10 mL glutaraldehyde. The exposure time was 10 h at 20EC ina refrigerated, circulating water bath. The penicylinders weretransferred from the glutaraldehyde tubes to the neutralizer(10 mL fluid thioglycollate in 20× 150 mm tubes).Penicylinders with clean spores were transferred to T-soybroth (10 mL in 20× 150 mm tubes) for recovery. The SENBspores on penicylinders were transferred to recovery media(fluid thioglycollate), as in the AOAC method. Carriers inocu-lated with SENB, NA/Mg/Ca, and CB spore preparationswere tested against the same levels of glutaraldehyde on each

DANIELSON ET AL.: JOURNAL OF AOAC INTERNATIONAL VOL. 83, NO. 1, 2000 151

Table 2. Statistical analysis of 30 check penicylinders and controls, 2 sets of AOAC (SENB) spore preparations, and4 sets of different clean spore preparations with corresponding resistance to 2.5N HCl for each run

RunSENBa mean ± SD,

log10

B. subtilis 19659 HClresistance, min Run

SENBa mean ± SD,log10

B. subtilis 19659 HClresistance, min

Control 4.02 ± 0.20

1 4.49 ± 0.17 2 2 4.00 ± 0.26 2

3 3.98 ± 0.20 2 4 5.11 ± 0.22 2

5 4.32 ± 0.24 2 6 4.00 ± 0.29 2

7 5.15 ± 0.27 5 8 5.46 ± 0.11 5

9 6.00 ± 0.13 20 10 6.13 ± 0.09 5

11 5.86 ± 0.17 20 12 5.55 ± 0.35 2

Control 5.20 ± 0.18

Run CBb mean ± SD, log10

B. subtilis 19659 HClresistance, min Run LLc mean ± SD, log10

B. subtilis var. nigerHCl resistance, min

Control 6.02 ± 0.10 Control 5.79 ± 0.14

1 5.93 ± 0.11 5 2 5.63 ± 0.12 10

3 5.92 ± 0.18 5 4 5.11 ± 0.22 10

5 5.83 ± 0.09 5 6 5.43 ± 0.17 10

7 5.92 ± 0.10 2 8 5.76 ± 0.09 10

9 5.74 ± 0.16 10 10 5.85 ± 0.11 10

11 6.00 ± 0.14 10 12 5.77 ± 0.14 10

Control 5.42 ± 0.11 Control 5.73 ± 0.15

RunNA/Mg/Ca/Mnd mean ±

SD, log10

B. subtilis var. nigerHCl resistance, min Run

NA/Mg/Ca/Mnd mean ±SD, log10

B. subtilis var. nigerHCl resistance, min

Control 5.94 ± 0.13 Control 5.81 ± 0.14

1 5.84 ± 0.10 10 2 5.71 ± 0.14 10

3 6.15 ± 0.10 10 4 5.79 ± 0.11 10

5 5.80 ± 0.15 10 6 5.51 ± 0.12 10

7 5.87 ± 0.12 10 8 5.74 ± 0.15 10

9 5.83 ± 0.17 10 10 5.80 ± 0.11 5

11 5.82 ± 0.11 10 12 5.76 ± 0.13 10

Control 5.94 ± 0.17 Control 5.84 ± 0.15

a Soil extract nutrient broth.b Columbia Broth.c Lab-Lemco agar.d Nutrient agar plus minerals.

of 2 different days. SENB, NA/Mg, and LL preparations oncarriers were also tested on separate days.

Run numbers for each concentration tested were 0.5% (1,7); 1.0% (3, 9); 1.5% (5, 11); 2.0% (1, 7); 2.5% (3, 9); 3.0% (5,11); and 0.5% (2, 8); 1.0% (10, 12); 1.5% (4, 6); 2.0% (2, 8);2.5% (10, 12); and 3.0% (4, 6). Neutralizer and recovery me-dia were incubated at 37EC for 21 days. Growth from resistantspores on penicylinders was recorded from neutralizer and re-covery media on the graphs (Figures 1 and 2), with resultsfrom lower-numbered run in column 1 and fromhigher-numbered run in column 2 for each duplicate test.

Controls

A negative control of 90 sterile penicylinders was includedat the beginning and end of the study for each concentration of0.5, 1.0, 1.5, 2.0, 2.5, and 3.0% glutaraldehyde to detect anycontamination caused when carriers were transferred. Usingsterile forceps, 5 penicylinders were placed in each of 6 tubescontaining 10 mL glutaraldehyde. The tubes (20× 150 mm)were placed in a refrigerated water bath at 20EC for 10 h,transferred to the same type of neutralizer and recovery mediaused for each type of spore preparation, and incubated as in thetest. Positive controls were included to ensure that neutralizerand recovery media supported growth from all carriers foreach type of spore preparation. Positive controls were also in-cluded at the beginning and end of the study, with 90 inocu-lated penicylinders used for each type of spore preparation.Buffered water, 0.25M dibasic potassium phosphate withoutglutaraldehyde was used in place of the germicide. Five inocu-lated penicylinders were placed in each of 18 tubes with10 mL buffered water. The tubes were placed in the water bathat 20EC for 10 h and were analyzed as in the test.

Statistical Analysis

The AOAC spore preparations were compared with 4 cleanspore preparations for sporicidal tests of 6 concentrations(0.5–3.0%) of glutaraldehyde. Duplicate tests were performedon each concentration. Using 2 concentrations ofglutaraldyde, a SENB 19659 spore preparation was testedwith the CB 19659 and NA/Mg/Ca spore preparations on eachof 2 different days, using odd-numbered runs, 1–11. OtherSENB 19659 spore preparations were tested withNA/Mg 9372 and LL 9372 spore preparations in the sameway, using even-numbered runs, 2–12. Including 2 controls,there were 14 preparations of SENB 19659 spores in culturefiltrates. One preparation each of CB 19659, NA/Mg/Ca 9372,LL 9372, and NA/Mg 9372 clean spores (washed) were storedin water suspensions for stock supplies. Numbers of sporeswere determined from check penicylinders from each sporepreparation in a run. Plate counts were transformed to logs(base 10). The means, standard deviations (SDs), and coeffi-cients of variation (CV%) were determined for spores ininocula from average log numbers of spores from 30 checkpenicylinders for 2 sets of 7 runs for SENB 19659 spores andone set (n = 8) for each of 4 clean spore preparations (6 runsplus 2 controls). The pairedt-test (P= 0.05) was used to deter-mine if mean recoveries of NA/Mg/Ca 19659 and LL 19659spores exposed to 2% glutaraldehyde on 3 sets (n = 3) of30 penicylinders differed significantly (18). A significancelevelP = 0.05 was used to determine if the pairs of mean val-ues, obtained by LC and titrimetry, for glutaraldehyde prepa-rations for 4 runs and 2 controls (n = 6) for each concentration(0.5–3.0%) differed significantly.

152 DANIELSON ET AL.: JOURNAL OF AOAC INTERNATIONAL VOL. 83, NO. 1, 2000

Table 3. Statistical analysis determined from 30 check penicylinders for 2 sets of 1 spore preparations in soil extractnutrient broth (SENB) made according to the AOAC sporicidal method and 4 sets of various clean spore preparations

Statistic

SENBa B. subtilis 19659 CBb B. subtilis 19659 Na/Mg/Cab B. subtilis var. niger

Inoculumc, log10 PCd, log10 Inoculum, log10 PC, log10 Inoculum, log10 PC, log10

Mean 7.79 4.83 7.59 5.85 7.68 5.90

SD 0.71 0.84 0.29 0.19 0.07 0.11

CV, % 9.11 17.39 3.82 3.25 0.91 1.86

Statistic

SENBa B. subtilis 19659 LLb B. subtilis var. niger Na/Mgb B. subtilis var. niger

Inoculumc, log10 PCd, log10 Inoculum, log10 PC, log10 Inoculum, log10 PC, log10

Mean 7.49 5.07 7.77 5.71 7.95 5.77

SD 0.81 0.80 0.13 0.14 0.13 0.10

CV, % 10.81 15.78 1.67 2.45 1.64 1.73

a SENB (n = 7) with 6 runs plus 1 control.b Clean spore preparations (n = 8) with 6 runs plus 2 controls.c Also contained vegetative cells; all other counts are pure spores.d Contains pure spores.

Results

Glutaraldehyde Stabililty

Comparative assay values obtained by titrimetry and LCfor glutaraldehyde solutions prepared in 0.025M dibasic po-tassium phosphate at pH 7.5 showed excellent correlation (Ta-ble 1). Solutions degraded very little over 10 h. The titrimetricassay targeted the concentration of glutaraldehyde preparedfrom the 50% aqueous commercial preparation. The morespecific LC assay determined the stability of solutions used insporicidal tests. Slight differences in the 2 assays could havebeen due to degradation via polymerization or to impurities.Differences between mean concentrations of the 2 methodswere significant at the 5% level for each of the 6 concentra-tions of glutaraldehyde. Concentrations obtained by titrimetrywere almost always slightly higher than those by LC analyses.The acidic LC mobile phase provided a stable media forglutaraldehyde solutions that allowed LC assays to be per-formed several hours after the initial titration assay.

Loading of Penicylinders from Various SporePreparations

The means and SD for log numbers ofB. subtilis19659spores on 30 check penicylinders from SENB 19659 sporepreparations for 2 sets of 6 runs and 1 control are shown in Ta-ble 2. The average log numbers of spores ranged from 3.98(run 3) to 6.13 (run 10). The spore loads on checkpenicylinders for each run number correspond with batches ofspores tested for resistance to 2.5N HCl and duplicatesporicidal tests on 6 concentrations of glutaraldehyde (Fig-ures 1 and 2).

Table 3 shows average log numbers, SD, and CV% ofspores, using average log numbers of 30 check penicylinders,for 2 sets of SENBB. subtilis19659 preparations (n= 7; 6 runsplus 1 control) and 4 sets of clean spore preparations (n = 8;6 runs plus 2 controls). SENB 19659 spore inocula were theonly preparations not heated to kill vegetative cells for deter-mining numbers of spores/mL. These counts are from bothspores and vegetative cells in the inocula. The SENB 19659penicylinders were heated before spores were counted. Stan-dard deviations for average log numbers of spore/cells ininocula for the 2 sets (n = 7) of SENB spores were 0.71 and0.81. Standard deviations for average log numbers of sporesin inocula for the 4 types of clean spore preparations wereCB 19659, 0.29; LL 9372, 0.13; NA/Mg, 0.13; NA/Mg/Ca,0.07. A high variation in log numbers of spores/vegetativecells in SENB 19659 inocula resulted in a wide range in lognumbers of spores inoculated on penicylinders (Table 2)compared to clean spore preparations. The highest variation(SD) in log numbers of spores on batches of penicylinderswere SENB 19659 (odd runs), 0.84; SENB 19659 (evenruns), 0.80; CB 19659, 0.19; LL 9372, 0.14;NA/Mg/Ca 9372, 0.11; NA/Mg, 0.10. The CV for averagelog numbers of SENB 19659 spores for 2 groups of sporecarriers each with 7 sets (6 runs plus 1 control) of30 penicylinders ranged from 15.78 to 17.39%. The CV for

4 different spore preparations each with 8 sets (6 runs plus2 controls) ranged from 1.73 to 3.25%.

HCl Resistance

Spore resistance to 2.5N HCl of the various preparationsused in 12 runs of sporicidal testing of glutaraldehyde, and thecorresponding mean and SD of log numbers of spores oncheck penicylinders from each run are shown in Table 2. TheSENBB. subtilis19659 spore resistance to HCl ranged from$2 min to$20 min. HCl resistance of the CBB. subtilissporesranged from 2 to 10 min. Spore resistance forB. subtilisvar.nigerpreparations from both LL and NA/Mg/Ca was 10 minfor each of 6 runs.

Glutaraldehyde Resistance

Figures 1 and 2 show recoveries of spores from90 penicylinders in duplicate sporicidal tests on 0.5–3.0%glutaraldehyde for neutralizer and recovery media for SENBand CB 19659 and NA/Mg/Ca 9372 spores. Results are alsoshown for SENB 19659, LL 9372, and NA/Mg/Mn 9372spores. Recoveries of spores washed off penicylinders intoneutralizer media (Figure 1) from SENB 19659 spores werehigher than those from recovery media (Figure 2). For each of4 clean spore preparations, recoveries of spores from neutral-izer media was less than that from recovery media containingpenicylinders. Figure 2 shows variability in resistance ofspores inoculated on penicylinders from SENB spores whereno growth was found in the recovery media in one set of90 penicylinders; growth in 89 of 90 penicylinders corre-sponds to runs 3 and 9 (Table 2), which shows a 2-log numberdifference between 3.98 and 6.00 in the sets of checkpenicylinders. B. subtilis var. niger spores from bothNA/Mg/Ca and NA/Mg preparations showed uniform resis-tance in duplicate sets of penicylinders at 0.5 and 1.0%glutaraldehyde; the latter spore preparation was considerablyless resistant to the 1.0% concentration. Addition of calciumto the medium increased spore resistance to glutaraldehyde at1.0%. The 9372 spores also showed a slight resistance to 1.5%glutaraldehyde from the LL preparation with growth from 2 of90 penicylinders. Concentrations of glutaraldehyde (withoutadditives) corresponding to total destruction of spores on90 penicylinders in recovery media for various spore prepara-tions in duplicate sporicidal tests were SENB 19659 (evenruns), 2%; LL 9372, 2.%; NA/Mg/Ca 9372, 1.5%;NA/Mg 9372, 1.5%; and SENB 19659 (odd runs), 1.5%.CB 19659 spores were resistant to 3% glutaraldehyde. SENBspores had slightly more growth from washoff of spores inneutralizer media than from penicylinders in recovery media.

Sporicidal tests were performed on 1 and 2%glutaraldehyde in phosphate buffer (pH 7.5) withNA/Mg/Ca 19659 and LL 19659 spores. For each concentra-tion, 3 sets of 30 penicylinders were used. Recoveries wereobtained from 100% of spore carriers exposed to 1%glutaraldehyde from both preparations. With 2%glutaraldehyde, recoveries of spores from LL 19659 sporeswere from 22, 15, and 10 spore carriers. Recoveries fromNA/Mg/Ca 19659 spores were from 15,17, and 14 spore carri-

DANIELSON ET AL.: JOURNAL OF AOAC INTERNATIONAL VOL. 83, NO. 1, 2000 153

ers. With 2% glutaraldehyde the means and SDs of recoveriesof spores from 3 sets of 30 penicylinders (n = 3) were 15 ± 1.5from NA/Mg/Ca 19659 spores, and 16 ± 6.0 from LL 19659spores. Average log numbers and SDs of these spores on30 check penicylinders were 5.93 ± 0.17 and 6.07 ± 0.11, re-spectively. NA/Mg/Ca 19659 spores gave the most uniformrecoveries from 3 sets of 30 penicylinders (n= 3). Using a sig-nificance level ofp = 0.05, the 2 different spore preparationsdid not show significantly different values for mean spore re-sistance. When similar levels ofB. subtilisvar. niger 9372spores were tested on penicylinders from the same types ofsporulation media, these spores were destroyed by 2%glutaraldehyde.

At the beginning and end of the study, negative controlsshowed no growth from 90 penicylinders in recovery mediafrom any of the 5 types of spore preparations; positive controlsshowed growth in 90 of 90 penicylinders in the recovery media.

Discussion

The variation in log numbers of spores inoculated onpenicylinders from SENBB. subtilis19659 spore prepara-tions was much greater than for the clean spore preparations(Table 2). The SD of log numbers of spores was also muchhigher between different batches of SENB spore preparationsinoculated on separate days than for 30 penicylinders inocu-lated from a single batch of spores. AOAC sporicidal test re-sults showed thatB. subtilis19659 spores are destroyed by orresistant to 1.0% glutaraldehyde with 4 and 6 log numbers(Figure 2) of spores, respectively, on penicylinders, depend-ing on which batch of SENB spore preparations is used. Resis-tance ofB. subtilisvar.nigerspores from NA/Mg/Ca and LLpreparations was similar to that of SENB 19659 spores, withgrowth in recovery media after exposure to 1%glutaraldehyde and no growth after exposure to 2%glutaraldehyde, except for the AOAC test with the lower aver-age log numbers of spores on the carriers. Resistance of SENBB. subtilis 19659 spores to HCl generally increased whenhigher log numbers of spores were tested on penicylinders.However, exceptions may be caused by different batches ofsporulation media.B. subtilis19659 spores from the CB prep-aration were the most resistant, with recoveries after exposureto 3.0% glutaraldehyde in duplicate tests. It is not clear whyrecoveries of CB 19659 spores in some duplicate runs were in-consistent. Recoveries of these spores, after exposure to 2.0%glutaraldehyde, from neutralizer media (fluid thioglycollate)were from 14 of 90 and 75 of 90 penicylinders, whereas recov-eries in recovery media (T-soy broth) were from 77 of 90 and88 of 90 penicylinders, respectively. After exposure to 2.5%glutaraldehyde in runs 3 and 9, the recoveries (resistance) ofCB 19659 spores from recovery media were from 15 of 90 and53 of 90 penicylinders, which corresponds proportionally tothe HCl resistance of 5 and 10 min, respectively. However, af-ter exposure to 3.0% glutaraldehyde, recoveries of sporesfrom runs 5 and 11 were from 44 of 90 and 6 of90 penicylinders, which is inversely proportional to HCl resis-tance of 5 and 10 min, respectively. The SENB 19659 spores

showed no growth in recovery media after exposure to 2.0%glutaraldehyde; however, there was recovery of these sporesin the neutralizer media from spores washed off thepenicylinders. All 3B. subtilisvar. niger spore preparationswere destroyed at this concentration.

Additional work was performed to test other clean sporepreparations ofB. subtilis19659, because CB 19659 sporeswere more resistant to glutaraldehyde than the AOAC 19659preparation and the 3 clean spore preparations ofB. subtilisvar. niger 9372. The NA/Mg/Ca 19659 and the LL 19659spore preparations were also resistant to 2% glutaraldehyde,with the latter being slightly less resistant. Our previous workshowed that clean spores ofB. subtilis19659 from NA/Mg/Caand CB preparations are destroyed on porcelain penicylindersby a commercial germicide with 2% glutaraldehyde plus addi-tives, whereas concentrations of 4 and 5%, respectively, ofglutaraldehyde in phosphate buffer (pH 7.5) are required todestroy these spores, and T-soy broth is a better recovery me-dia than fluid thioglycollate (17).

Conclusions

The AOAC sporicidal test had a wide range in log numbersof spores on the penicylinders for SENB 19659 spore prepara-tions used in duplicate runs. A much higher variation in num-bers of spores on penicylinders occurs between batches ofSENB spore culture filtrates than with clean spore prepara-tions which are each diluted from a single stock spore suspen-sion. Resistance to HCl is generally relative to numbers ofSENB 19659 spores on penicylinders. However, a particularbatch of these spores can have high numbers of spores on thecarriers and less resistance to HCl. Variable resistance to HClwas obtained with SENB 19659 spore preparations. Uniformresistance of$10 min to HCl and similar resistance toglutaraldehyde was obtained with LL and NA/Mg/Ca prepa-rations of B. subtilis var. niger spores. Resistance ofSENB 19659 spores to HCl was not proportional to resistanceto glutaraldehyde. CB 19659 spores showed variable resis-tance to HCl, with relatively uniform numbers of spores on thepenicylinders, and were resistant to 3.0% glutaraldehyde.B.subtilis19659 spores from LL, NA/Mg/Ca/Mn, and CB prep-arations were more resistant to glutaraldehyde than was theSENB 19659 spore preparation.B. subtilis var. niger cleanspore preparations showed a resistance to glutaraldehyde sim-ilar to that of SENB 19659 spores.B. subtilisvar.nigersporesfrom NA/Mg/Ca/Mn and NA/Mg/Mn spore preparationswere the most uniform in resistance to glutaraldehyde,whereas SENBB. subtilisspores were the most variable. Weconclude that better reproducibility of sporicidal tests resultscan be obtained by using defined sporulation media andquantitated clean spores on penicylinders than withSENB 19659 spores in culture filtrates, which are used in theAOAC sporicidal method.

154 DANIELSON ET AL.: JOURNAL OF AOAC INTERNATIONAL VOL. 83, NO. 1, 2000

Acknowledgment

We thank Karen Wolnik of the National Forensic Chemis-try Center, Cincinnati, OH, for the ion analysis of soil extract.

References

(1) Official Methods of Analysis(1995) 16th Ed., AOAC IN-TERNATIONAL, Arlington, VA, Chapter 6,sec. 6.3.05

(2) Oxborrow, G.S., & Berube, R. (1991) inDisinfection, Steril-ization, and Preservation, 4th Ed., S.S. Block (Ed.), Lea &Febiger, Philadelphia, PA, Chapter 59, pp 1047–1057

(3) Marquis, R.E., & Shin, S.Y. (1994) Federation of EuropeanMicrobiology Societies Microbiology Reviews14, 375

(4) Bender, G.R., & Marquis, R.E. (1985)Appl. Environ.Microbiol. 50, 1414

(5) Danielson, J.W. (1995)Current Lab Activities and Perspec-tive Related to Germicides, Infection Control Symposium:Influence of Medical Device Design, HHS Publication FDA95-4260

(6) Danielson, J.W. (1993)J. AOAC Int.76, 355–360

(7) Ascenzi, J.M., Ezzell, R.J., & Wendt, T.M. (1986)Appl. En-viron. Microbiol. 51, 91–94

(8) Danielson, J.W., Peeler, J.T., & Oxborrow, G.S. (1994)J.AOAC Int. 77, 53–57

(9) Method EK 8648 (1992) Eastman Kodak Co., Rochester, NY(10) Anderson, P.J. (1967)J. Histochem. Cytochem.15, 652–661(11) Frigerio, N.A., & Shaw, M.J. (1968)J. Histochem.

Cytochem.17, 176–181(12) Smith, D.M., & Mitchell, J., Jr (1950)Anal. Chem.22,

750–755(13) Thompson, R.D. (1993)Lab. Inf. Bull.No. 3800, U.S. Food

and Drug Administration, Rockville, MD(14) Springthorpe, S.V., Thuswaldner, L.L., LaFlamboise, D.M.,

Burke, T.J., & Sattar, S.A. (1993) AOAC INTERNA-TIONAL 107th Annual Meeting and Exposition,Washington, DC, Presentation 360

(15) Textbook for an Introductory Course in Microbiology andEngineering of Sterilization Processes(1987) 6th Ed., I.J.Pflug (Ed.), Environmental Sterilization Laboratory, Minne-apolis, MN, p. 6.6

(16) American Public Health Association (1992)StandardMethods for the Examination of Water and Wastewater,18thEd., Washington, DC, pp 9-33–36

(17) Danielson, J.W., Thompson, R.D., & Bell, E. (1999)J.AOAC Int. 82, 151–159

(18) Miller, J.C., & Miller J.N. (1984)Statistics for AnalyticalChemistry, E. Horwood, West Sussex, UK, Chapter 3,pp 56–57

DANIELSON ET AL.: JOURNAL OF AOAC INTERNATIONAL VOL. 83, NO. 1, 2000 155