Municipal wastewater purification by phytotreatment and water recovery

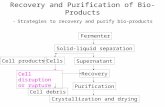

Recovery and Purification of Bio-Products

description

Transcript of Recovery and Purification of Bio-Products

Recovery and Purification of Bio-Products

- Strategies to recovery and purify bio-products

Fementer

Solid-liquid separation

Recovery

Purification

SupernatantCellsCell products

Cell disruption or rupture

Cell debris

Crystallization and drying

Cell DisruptionDisruption: the cell envelope is physically broken, releasing all intracellular

components into the surrounding medium

Methods: Mechanical and non mechanical

- Mechanical

- Ultrosanication (sonicators)bacteria, virus and spores suspensions at lab-scale

Electronic generator→ultrasonic waves→mechanical oscillation by a titanium probe immersedin a cell disruption.

http://www.biologics-inc.com/sd-models.htm

Cell Disruption- Mechanical

Milling: continuous operation,

Algae, bacteria and fungiLarge scale, up to 2000kg/h liquid and solid

Principle of operation:

A grinding chamber filled with about 80% beads.

A shaft with designed discs or impellers is within the chamber.

The shift rotates at high speeds, high shearing and impact forces from the beads break the cell wall.

http://www.cbmills.com/Products/horizontalmills.htm

Dyno-Mill(liquid)

Cell Disruption- Mechanical

Ball Mill: solid Frozen cell paste, cells attached to or within a solid matrix.Large scale

http://www.unitednuclear.com/mills.htm

Cell Disruption- MechanicalHomogenization: suspension, large scale

To pump a slurry (up to 1500 bar) through a restricted orifice valve.

The cells disrupt as they are extruded through the valve to atmosphere pressure by

- high liquid shear in the orifice

- sudden pressure drop upon discharge

i.e. French press, Gaulin-Manton, Rannie high-pressure homogenizer

High pressure

orifice

Cell Disruption- Nonmechanical

- Chemicals: use chemicals to solubilise the components in the cell walls to release the product.

Chemical requirements:- products are insensitive to the used chemicals.- the chemicals must be easily separable.

Types of chemicals:- surfactants (solubilising lipids):sodium

dodecylsulfate.

- Alkali: sodium hydroxide, harsh

- Organic solvents: penetrating the lipids and swelling the cells. e.g. toluene.

Cell Disruption

- Nonmechanical

- Enzymes: to lyse cell walls to release the product.gentle, but high cost

i

i.e. lysozyme (carbohydrase) to lyse the cell walls of bacteria.

- Osmotic shockOsmosis is the transport of water molecules from high- to a low-concentration region when these two phases are separated by a selective membrane.

Water is easier to pass the membrane than other components.When cells are dumped into pure water, cells can swell and burst due to the osmotic flow of water into the cells.

Cell Disruption

Challenge: Damage to the product

- Heat denaturation

- Oxidation of the product

- Unhindered release of all intracellular products

Recovery and Purification of Bio-Products

- Strategies to recovery and purify bio-products

Fementer

Solid-liquid separation

Recovery

Purification

SupernatantCellsCell products

Cell disruption or rupture

Cell debris

Crystallization and drying

Separation of Soluble ProductsLiquid-liquid extraction:

- Difference of solubility in two immiscible liquid

- Applicable: separate inhibitory fermentation products such as ethanol and acetone-butanol from fermentation broth.antibiotics (i.e. solvent amylacetate)

- Requirements of liquid extractants :

nontoxic, selective, inexpensive, immiscible with fermentation broth and high distribution coefficient: KD=YL/XH

YL and XH are concentrations of the solute in light and heavy phases, respectively.

The light phase is the organic solvent and the heavy phase is the fermentation broth.

Heavy, XH

Light, YL

Separation of Soluble Products• Liquid-liquid extraction:

When fermentation broth contains more than one component, then the selectivity coefficient (β) is important.

βil = KD,,i/KD,j

KD,,I and KD,j are distribution coefficients of component i and j.

The higher the value of βil is, the easier the separation of i from j.

pH effect, multi-stage extraction

Heavy, I, j

Light, i, j

Separation of Soluble Products

Precipitation

Reduce the product solubility in the fermentation broth by adding salts.

- Applicable: separate protein or antibiotics from fermentation broth

- Methods:- salting-out by adding inorganic salts such as ammonium sulfate, or sodium sulfate at high ionic strength (factors: pH, temperature)

- salts interact more stronger with water- cause little denaturation- inexpensive

Separation of Soluble Products

Precipitation

- Isoelectric precipitation:

Precipitate a protein at its isoelectric point.

- Solubility reduction at low temperature by adding organic solvents (T< -5oC)

Reduce the dielectric constant of the liquidMay cause protein denaturationSolvents: acetone, ethanol, methanol.

- HeatRemove undesired proteins

Separation of Soluble Products

Adsorption

Adsorb soluble product from fermentation broth onto solids.

Approaches: physical adsorption, ion exchange

Adsorption capacity: mass of solute adsorbed per unit mass of adsorbent

Affected by properties of adsorbents: functional groups and their numbers, surface properties

by properties of solution: solutes, pH, ionic strength and temperature

- Difference of Affinity of product in the solid and liquid phase.

- Applicable: soluble products from dilute fermentation

Separation of Soluble Products

CHALLENGE!

SCREENING ADSORBENTS: THE MOST PROMISING TYPES

- high capacity- reusable

0

2

4

6

8

10

12

14

0 10 20 30 40 50

Equilibrium solute concentration in liquid (mol/l)

Equ

ilibr

ium

sol

ute

conc

enta

tion

on

solid

(m

ol/g

ads

orbe

nt)

Adsorption Isotherms

Saturated uptake

affinity

C1

Cs1

Cs2

Adsorbent 1

Adsorbent 2

Separation of Soluble Products• Models of adsorption equilibrium

Freundlich isotherm:

Cs=KFCL1/n

Cs and CL are equilibrium concentration of solute in solid and liquid phases, respectively.

KF and n are empirical constants.Langmuir isotherm:

Cs=CsM

CL/(K+CL)

CsM

is the maximum concentration of solute adsorbed on the solid phase. K is a constant.

Limitation: the above model constants are dependent on the solutions seriously limiting the prediction capability of these models over more extended sorption conditions.

Modeling the effect of pH on Cr uptakes

00.10.20.30.40.50.60.70.80.9

1

0 2 4 6 8 10

Equilibrium Cr concentration (mM)

Cr U

ptak

e (m

mol

/g)

pH2.5

pH2.0

Langmuir model fitting curve

pH3.6

corr. coef.: 0.999relative dev.: 2.4%

error bar: 95% confidence interval

ANION BIOSORPTION EQUILIBRIUM MODEL DESCRIPTION

BNH + zH+ + HxMpLqZ- = BNH2

+ HxMpLqZ- H+

z-1

BNH + H+ + Cl- = BNH2+ Cl-

-log i = -0.507*Z2 ( )

[M]T = (speciation), mass & charge balance

ZS

ZZ

H

ZZ

sad

SHBNH

HSBNHK

][)]]([[

][ 12

II

I3.0

1

z

qi

pX LMH

Attributed all non-ideality to the liquid phaseConsidered the interference of Cl-

Ks: adsorption equilibrium constant s: metal or Cl speciesBNH: weak base binding sites HxMpLq

Z- : anionic metal species

i : activity coefficient of solution sp.i Z: charge of species

I: ionic strength in the solution [M]T: total metal concentration in the solution.

Modeling the effect of pH on Cr uptakes

00.10.20.30.40.50.60.70.80.9

1

0 2 4 6 8 10Equilibrium Cr concentration (mM)

Cr

Up

take

(mm

ol/g

)

pH2.5

pH2.0

model fitting curve

BNH + H+ + HCrO4 - = BNH2

+HCrO4 -

BNH + 2H+ + Cr2O7 2- = BNH2

+Cr2O72-H+

pH3.6

corr. coef.: 0.999relative dev.: 2.4%

error bar: 95% confidence interval

Separation of Soluble Products

Membrane separation:

- Microfiltration: 0.1 - 10 µm, bacterial and yeast cells.

- Ultrafiltration: macromolecules (2000 <MW< 500,000)

- Dialysis: removal of low-MW solutes: organic acids (100<MW<500) and inorganic ions (10<MW<100).

- Reverse osmosis: a pressure is applied onto a salt-containing phase, which drives water from a low to a high concentration region. MW < 300.

The common features of the above methods:- Use membrane - Driving forces: pressure