Real-Time Simulation of BLDC-based Wind Turbine Emulator Using RT-lab

-

Upload

rodrigo-mesquita -

Category

Documents

-

view

16 -

download

0

Transcript of Real-Time Simulation of BLDC-based Wind Turbine Emulator Using RT-lab

-

Abstract-- A novel wind turbine emulator (WTE) based on a torque controlled Brushless DC (BLDC) motor is presented, which can emulate the steady-state and dynamic characteristics of an actual wind turbine. Variable wind speeds, turbine inertia and torque oscillation caused by tower shadow and wind shear are all considered in the construction of the actual wind turbine model and the torque controlled BLDC model . A PI regulator is employed to make sure that the output torque of BLDC tracks the reference torque. The simulation results based on RT-LAB real-time simulation platform verify the validity of the proposed WTE.

Index Terms-- brushless DC, real-time simulation, torque control, wind turbine emulator

I. INTRODUCTION Wind energy is one of the most promising renewable

energies and wind power generation is developing fast as serious environmental concerns and energy crisis are on the rise. For the researches of control strategies and hardware design of wind power generation, field or wind tunnel experiments are required. In this way, the performances of wind turbine, generator and control system can be tested and evaluated. However, they are not suitable for the early stages of research because of uncontrollable environment and expensive costs. Therefore, it is necessary to build a controlled test bench with a wind turbine emulator (WTE) that represents the output characteristics of an actual wind turbine (WT) and drives the WT generator in the laboratory condition.

A WTE is usually a torque closed-loop controlled motor that outputs the same mechanical power as an actual WT does. In traditional emulation method, the motor speed feedback and a given wind speed are used to calculate the WT torque according to the steady-state model of the WT. Then, the output torque of the motor tracks the WT torque to accomplish the steady-state emulation effectively. However, if the output torques of the WTE and the WT are completely the same, the dynamic processes of speed variation between the two systems will be different due to the differences of friction coefficient and moment of inertia. To solve this problem, a few methods have been presented in the literature [1-3]. In order to increase the moment of inertia of WTE, a large inertia disk is coupled to rotor shaft of the WTE through a flexible coupling as discussed in [1]. But this solution is lack of flexibility when emulating different WT rotors. Another method compensates the reference

This work was supported by National Basic Research Program of

China (973Program 2007CB210302)

torque of the motor such that the WTE will produce the same acceleration as the actual system. In [2], a 2nd order observer is employed to observe the state variables of emulation system and determine the compensation value. However the control method is complicated to realize. In [3] the compensation value is obtained by calculating the product of acceleration and inertia difference, which is easy to realize. However the solutions hereinbefore neglect the difference of friction coefficient. So errors exist in emulation process. To reproduce steady-state and dynamic behaviors of actual WT, the following three parts should be comprised in an integrated WTE.

1) A real time model simulator (RTMS), in which the steady-state and dynamic mathematical models of WT and wind speed are built.

2) A torque closed-loop controller (TCC), which compares the output torque of WTE with the reference torque received from the RTMS and determines the driving signal.

3) A motor with associated driver, which responds to the driving signal from the TCC, used as a prime mover.

Duo to definite mathematical relationship between output torque and armature current, the DC motors with accurate control of electromagnetic torque are generally used in the WTE. In [2], a permanent magnet DC motor supplied by a four quadrant chopper is used to realize emulation. A close loop control of the motor armature current is developed and the electromagnetic torque of the motor is precisely controlled through the armature current. In [4], the method that uses a separately-excited dc machine to emulate the WT is developed. The speed range of emulator is extended by flux-weakening control. However an additional speed loop is added that needs both controls of the field and armature winding, making the system complex and unpractical. In [5]-[6], the three-phase full-bridge thyristor is adopted to drive the DC motor. But the 6th order voltage and current harmonic in the armature of the dc motor are produced, resulting in a torque fluctuation that differs from the actual WT. Furthermore, existences of commutators and brushes in the DC motor add to structure complexity and low power density, which makes it bulky, expensive and needs frequent maintenance.

Compare with the DC motor, the induction motor (IM) and the sinusoidal permanent magnet synchronous motor (SPMSM) have the advantages of simple structure and high power density. In [8]-[9], a WTE using the IM motor is presented. However the realization method of torque closed loop control is not presented. In [10], based on the detailed analysis on the mathematical model of

Real-Time Simulation of BLDC-based Wind Turbine Emulator Using RT-LAB

Honghao Guo, Bo Zhou, Jichen Li, Fangshun Cheng, Le Zhang Aero-Power Sci-Tech Center, Nanjing University of Aeronautics and Astronautics, Nanjing, China

-

IM, the motor torque is controlled by regulating the stator current and the slip frequency. However the poor performance of the torque tracking results in torque error existing in the dynamic process and the proposed WTE can only generate the static characteristic of WT. In [11]-[12], a SPMSM based on the vector control of rotor magnetic field orientation is used as the WTE. The torque can be regulated by controlling the q axis current. However the coordinate transformation is needed and the control method is complex.

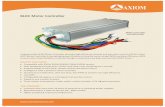

The brushless DC motor (BLDCM) have the advantages of simple control likes DC motor and high power density likes other AC motors [14]. Thus it is an effective tool to emulate the actual behavior of a WT. This paper adopts BLDCM as a new type of WTE. Considering the practical factors such as variable wind speed, turbine inertia, friction coefficient, and torque oscillation caused by tower shadow and wind shear, a WTE which reproduces the steady-state and dynamic behaviors of the actual WT is designed. A real time simulation model of the WTE-generator system is constructed. The control scheme of the WTE discussed in this paper was implemented with a RT-LAB real-time distributed simulation platform that allows for easy adaptation to Hardware-in-the-Loop (HIL) or Rapid Control Prototyping (RCP) simulation with I/O cards.

II. WIND TURBINE MODEL In the actual wind power generation system, the WT

captures the kinetic power contained in the fluid air and converts it to mechanical energy to drive the generator via a gear box or a transmission shaft directly as shown in Fig.1 (a). In the emulation system, the BLDCM is connected with a generator to emulate the wind power generation system as shown in Fig.1 (b). The BLDCM is required to have the same characteristics as an actual WT, thus accurate models of WT and drive train are necessary to insure the authenticity of emulation.

(a) Wind power generation system

(b) Wind turbine emulation system

Fig. 1. Sketch of actual system and emulation system

A. Aerodynamic Characteristic of WT According to the aerodynamic characteristic of WT,

the average torque T produced by a WT is a function of the wind speed (v) and the torque coefficient (CT()), which can be expressed as (1) where R is the radius of the turbine and is the air density.

T=0.5R3CT()v2 (1) The torque coefficient of the fixed pitch WT is related

mathematically to the tip speed ratio (TSR) only, which can be seen from Fig.2 (a) and the TSR is defined as the ratio of line speed at rotating blade tip to wind speed

=WTR/v (2) where WT is the rotating angular speed of WT.

The TSR is a significant parameter that represents the operation state of WT. For a fixed pitch WT, the output power will be maximum when the WT works at optimum TSR (opt), and this value is unique. Furthermore, the maximum power curve of WT can be obtained by linking all the maximum power points under different wind speeds. Based on (1), (2), and Fig.2 (a) the average torque-speed curve produced by a WT under different wind speeds can be plotted as Fig.2 (b).

(a) (b)

Fig. 2. CT()- and torque characteristic curve of wind turbine

For a common three-blade, horizontal axis WT, due to the structural resistance of the tower, the wind speed may decrease and even generate turbulent flows as the wind passes by the tower. This effect is called tower shadow. Besides, wind speed gradient exists with the height, which can cause an effect called wind shear. Both factors influence the output aerodynamic torque of WT and add a periodic changed ripple to the average torque produced by a WT[13]. Thus, the output aerodynamic torque TWT, considering tower and wind shear, can be calculated as [7]

TWT=Tm+Tosc=Tm(1+asin(WTt)+bsin(3WTt)) (3) where Tosc is the periodic torque ripple and a=0.2, b=0.4

B. Dynamic Model and Torque Compensation When the generator is connected to the WT through a

transmission shaft directly, the dynamic process of WT is determined by WT torque and generator torque jointly. So the moments of inertia, friction coefficients of WT and generator need to be considered to ascertain the dynamic characteristic of WT. The mechanical equation is given by (4), which describes the dynamic behavior of the actual system. Similarly, the mechanical equation of the WT emulation system is expressed as (5)

TWT =TL + BWTWT + ( JWT +JG)dWT/dt Te=TL + Bmr + ( Jm +JG)dr/dt

(4) (5)

where TL and Te are the torques of generator and BLDCM, BWT and Bm are the friction coefficients of the actual system and WTE system, r is the rotating angular

-

speed of BLDCM, Jm, JWT and JG are the moments of inertia of BLDCM, WT and generator, respectively.

Owing to different inertias and friction coefficients of the actual and the emulation systems, some differences exist in the dynamic changing processes of the rotating speed when the WT and the BLDCM have same output torque. The dynamic process of the emulation systems is faster since the inertia of BLDCM is usually much smaller than that of the WT. However, the rapidly changing processes of the rotating speed make a higher demand on the response speed of the generator controller, which is absolutely unnecessary.

To make r perform the same dynamic process of WT, the BLDCM reference torque should be modified as

Tref =TWT +(BmBWT)r+( Jm JWT)dr/dt = TWT + TCOM

(6)

where, TCOM is the compensation torque. Compensation torque consists of two parts: inertia

compensation and friction coefficient compensation. The inertia compensation operates in dynamic process only, because the dWT/dt is equal to zero for a steady rotating speed. So the inertia difference has no influence on the steady-state emulation effect. Under the steady-state condition, the friction coefficient compensation makes the WTE connected generator get the same torque and power as connecting to an actual WT. Fig.3 gives the simulation model of the reference torque generation with torque compensation and periodic torque ripple caused by wind shear and tower shadow. Besides, a low pass filter is necessarily used to suppress the high frequency noises caused by the derivative of the rotating speed.

Fig. 3. Torque reference with torque compensation

III. TORQUE CLOSED-LOOP CONTROLLED BLDCM The electromagnetic torque of the BLDCM should be

closed-loop controlled for a BLDCM based WTE. Therefore, researches on the torque characteristic and appropriate control strategy of the BLDCM are needed.

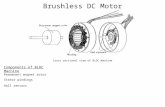

A. BLDCM Electromagnetic Torque Calculate Discarding the commutators and brushes of DC motor,

the BLDCM has inherit the predominant performance of

the traditional motor such as the high power density, high efficiency, easier control and without exciting wastage. Different from the SPMSM, the BLDCM has a trapezoidal back EMF due to different armature winding arrangement of the stator and different shaping of the magnets mounted on the rotor. For any rotor position, the back EMF per phase is proportional to the rotating speed and expressed as

2 ( ) rpWe

= (7)

where p is the number of pole pairs, is the pole-arc coefficient, W is the effective series turns per phase, is the rotor electrical angle, is the flux.

The shape function of back EMF is defined as 2( ) ( )pWf

= (8)

The back EMF shape function is related to the rotor electrical angle and independent of the rotating speed. Each phase of the BLDCM has a certain back EMF shape function that can be measured by normalizing the back EMF to the mechanical rotating speed or by finite element analysis. As a result, the function of back EMF related to the rotor electrical angle is expressed as

ex()=fx() r (9) where the subscript x stands for a, b, and c phase. Fig.4 shows the relationship between ex() and fx() where E, F are the peak values of ex() and fx(), respectively.

Fig. 4. Back EMF and shape function

Therefore, the electromagnetic torque produced by the

BLDCM can be expressed as

( ) ( ) ( )

a a b b c ce

r

a a b b c c

e i e i e iT

f i f i f i

+ +=

= + +

(10)

where ea, eb, ec, ia, ib, ic are the a, b, and c phase back EMFs and armature currents, respectively. The BLDCM torque is functionally related to the three-phase armature currents and the rotor electrical angle.

B. Torque Control strategy The current closed-loop control is usually used in the

BLDCM, which regulates the output torque indirectly. In a BLDCM with two-phase feeding system, for example, if a-b phase conduct, the fa() and fb() are in the positive and the negative flattened region of the trapezoidal wave

-

respectively, as the region from /6 to /2 shown in Fig.4, where fa()= fb()=F, ib= ia, ic=0. So the torque is represented in (11)

Te=[fa() fb()] ia=2Fia (11) Set Tr as the reference torque. The reference current ir

of closed-loop controller used to regulate the torque can be expressed as

ir= Tr/2F (12) It is seen that the torque control of the BLDCM is

simple as that of the DC motor in the two-phase conducting period. However in the commutation period, due to the influence of armature inductance, the phase current cant change suddenly and three-phase simultaneous conduction appears. At the same time, commutation-torque-ripple occurs due to different slopes of current increase and decrease, which is an unexpected ripple torque in the WTE. As a result, the indirectly torque regulation through current closed-loop control disagree with the demand of WTE.

The output torque of the BLDCM should track the reference torque calculated from WT model smoothly to implement the accurate emulation of WT. Therefore a direct torque closed-loop controller is employed which enhances the torque tracking performance and reduces the torque ripple of the BLDCM by proportional-integral (PI) control. Fig.5 shows the integrated simulation model of BLDCM with associated driver, electromagnetic torque calculation and torque closed-loop control.

Fig. 5. Torque closed-loop control of BLDC

IV. REAL TIME SIMULATION According to the BLDCM feedback speed and a given

wind speed, reference torque is calculated from (6). Then the BLDCM based WTE is constructed through the PI torque controller that forces the output torque of BLDCM tracking the reference torque. The scheme of the proposed WTE is shown in Fig.6.

RT-LAB is a distributed real-time platform of which the software part is integrated with Matlab/Simulink to build simulation models and the hardware part equipped with multi-core PC processors to conduct real-time simulation of those models, relying on high performance of parallel data processing. Comparing to the traditional simulation of Matlab/Simulink, the RT-LAB speeds up model execution and enhances the efficiency of simulation. In addition, RT-LAB can be used for

hardware-in-the-loop simulation system or rapid control prototyping for the real objects control with the D/A, A/D modules.

Fig. 6. Torque control scheme of the proposed WTE

To validate the feasibility of the proposed method,

real-time simulation of the WTE-generator system is carried out in RT-LAB with three CPUs. As shown in Fig.6, the system model is divided into three parts conducted synchronously in different CPUs. Further, the CPUs are running at 2.5GHz and simulation step is set to 10s.

The simulation results confirm that the BLDC based WTE can reproduce the steady-state and dynamic characteristics of an actual WT.

A. Simulation of Steady-state characteristics Constant wind speeds of v1=5m/s, v2=6.5m/s, v3=8m/s

are selected to verify the emulation validity of steady-state characteristic with torque closed-loop controlled BLDC under no-load condition. The simulation results are shown in Fig.7 where the green, red, and blue curves stand for theoretically steady-state torque-speed characteristic of the WT under the three wind speed condition and the symbols of *, , are corresponding characteristic of the WTE.

Fig. 7. Simulation result of WTE under steady-state

Under the same wind speed and rotating speed, the

BLDCM torque fits well with that of the actual WT, which can be seen from Fig.7, where the errors are caused mainly by different sampling times. Due to the output torque of the BLDCM is regulated by a PWM controller, the torque ripple exists and the average torque is different from the instantaneous torque that is just shown in Fig.7. There are more sampling points in high speed region, where the instantaneous torque values fluctuate within a narrow range around the theoretical

-

curve and the average torque is equal to the WT torque actually. Furthermore, with a high switch frequency (20 kHz), the torque ripple can be filtered by moment of inertia and has no influence on the rotating speed of WTE.

B. Dynamic performance of WTE In the wind power generation system, the generator

torque is regulated by the control algorithm. Different generator torque decides the efficiency of WT and the generated power. Accordingly, the maximum power point tracking (MPPT) is realized by the generator torque control in the wind power generation with fixed pitch blades. In the simulation, maximum power curve of WT is used as the generator power-speed characteristic and the generator torque is

5 2 22

( )0.5 T optgenopt

CT R k

= = (13)

Considering the tower shadow and the wind shear effects, Fig.8 shows dynamic simulation results with a step changed wind speed that causes the WT torque and the rotating speed to change correspondingly. Finally, with the MPPT control, the system operates at the maximum power point with a steady-state rotating speed. Without compensation torque, the WTE have the larger acceleration and the faster transient process than actual WT because of the smaller inertia of BLDCM but the same steady-state condition as the actual WT.

(a) Wind speed curve

(b) Dynamic processes of WTE and WT

(c) Value of compensation torque

Fig. 8. Simulation results of dynamic process while wind speed changes

The compensation torque eliminates the differences of

dynamic changed speeds between the WTE and the actual WT as shown in Fig.8 (b). Furthermore, as a result of the same rotating speed of the two systems, the generators obtain accordant torque and power according to (13). So from the perspective of generator, connection with the WTE and the actual WT are same. Fig.8 (c) shows the compensation torque. As the wind speed increases the compensation torque is below zero equally decreasing the output torque and speed rising rate of WTE. And the contrary compensation effect appears as the wind speed descends.

Fig.9 shows the amplification of Fig.8 by expanding the time axis from 1.9s-2.34s where the wind speed is constantly 8m/s. The tower shadow and the wind shear affect the rotating speed even under the constant wind speed condition. And the fluctuant range of the WTE is larger than that of the actual WT, which increases the output power fluctuation of the WTE connected generator, resulting in inaccurate emulation. By adding the compensation torque shown in Fig.9 (b) to the controller, the dynamic processes of the two systems become properly accordant, which can be seen from the black and the red curves of Fig.9 (a).

(a) Wind shear and tower shadow caused fluctuation of rotating speed

(b) Value of compensation torque

Fig. 9. Influence of wind shear and tower shadow

Fig.10 shows the simulation results of the wind speed, rotating speed, generator power, and compensation torque from top to bottom when the average wind speed is equal to 8m/s and the fluctuation is 2m/s. The actual wind speed is stochastic causing the rotating speed of WT fluctuates. So the torque compensation should be carried through the whole time range of emulation, as shown in Fig.10 (d), to make the WTE reproduce the dynamic process of actual WT and the generators output the same power which can be seen from Fig.10 (b), (c) where the black and the red curves stand for the WTE and the WT, respectively.

-

(a) Wind speed curve

(b) Rotating speed of WTE and WT

(c) Generator power

(d) Value of compensation torque

Fig. 10. Simulation result of WTE and WT with fluctuant wind speed

V. CONCLUSIONS This paper introduces a novel WT emulator based on

the BLDCM and associated controller used to reproduce the steady-state and dynamic behaviors of the actual WT. The following conclusions are obtained.

(1) The electromagnetic torque of the BLDCM can be determined by the three phase armature currents and rotor electrical angle. Compared with the traditional current control, the torque closed-loop control accurately regulates the output torque of the BLDCM.

(2) To emulate the dynamic behavior of the actual WT, differences of mechanical parameters are needed to be considered. The compensation torque is used to reduce the speed changing rate and without the compensation torque, the fluctuant range of the WTE will be larger than that of the actual WT which influences the control effect of the WTE connected generator.

(3) The torque closed-loop controlled BLDCM emulates the steady-state and dynamic characteristic of the actual WT effectively. It has been considered as an

essential and efficient tool for the research and design of the wind power generation in laboratory condition.

REFERENCES [1] M. Arifujjaman, M.T. Iqbal, and J.E. Quaicoe, An

isolated small wind turbine emulator. Proc. of CA. Conf. on Electrical and Computer Engineering (CCECE 2006), Ottawa (Canada), May. 2006, pp.1854-1857.

[2] B. Gong, and D.W. Xu., Real time wind turbine simulator for wind energy conversion system, Proc. of Power Electronics Specialists Conference (PESC 2008), Rhodes (Greece), June. 2008, pp.1110-1114.

[3] S. Seung-Ho, J. Byoung-Chang, L. Hye-In, K. Jeong-Jae, O. Jeong-Hun, and G. Venkataramanan, Emulation of output characteristics of rotor blades using a hardware-in-loop wind turbine simulator, Proc. of Applied Power Electronics Conference and Exposition (APEC 2005), Austin (America), March. 2005, pp.1791-1796.

[4] R.II. Ovando, J. Aguayo, and M. Cotorogea, Emulation of a low power wind turbine with a DC motor in Matlab/Simulink, Proc. of Power Electronics Specialists Conference (PESC 2007), Orlando (America), June. 2007, pp.859-864.

[5] Q.H. Liu, Y.K. He, and R.D. Zhao, Imitation of the characteristic of wind turbine based on DC motor, Proceedings of the CSEE, vol. 7, pp.134-139, 2006(in Chinese).

[6] W.W. Li, D.G. Xu, W. Zhang, and H.F. Ma, Research on wind turbine emulation based on DC motor, Proc. of 2nd Int. Conf. on Industrial Electronics and Applications (ICIEA 2007), Harbin (China), May. 2007, pp.2589-2593.

[7] A.C. Luiz, J. Lhuilier, A. Mukherjee, and M.F. Khokhar, A wind turbine emulator that represents the dynamics of the wind turbine rotor and drive train, Proc. of Power Electronics Specialists Conference (PESC 2005), Recife (Brazil), June. 2005, pp.2092-2097.

[8] B. Neammanee, S. Sirisumrannukul, and S. Chatratana, Development of a wind turbine simulator for wind generator testing, J. Int. Energy, vol. 8, pp.21-28, 2007.

[9] Y.Q. Jia, Z.A. Wang, and Z.Q. Yang, Experimental study of control strategy for wind generation system, Proc. of Power Electronics Specialists Conference (PESC 2007), Orlando (America), June. 2007, pp.1202-1207.

[10] H.M. Kojabadi, L. Chang, and T. Boutot, Development of a novel wind turbine simulator for wind energy conversion systems using an inverter-controlled induction motor, IEEE Trans. on Energy Conversion, vol. 19, pp. 547-552, Sept. 2004.

[11] D.S.L. Dolan and P.W. Lehn, Real-time wind turbine emulator suitable for power quality and dynamic control studies, 2005 Proc. of Int. Conf. on Power Systems Transients (IPST 2005), Montreal (Canada), June. 2005.

[12] W.H. Hu, Y. Wang, X.W. Song, and Z.A. Wang, Development of wind turbine simulator for wind energy conversion systems based on permanent magnet synchronous motor, Proc. of 11th Int. Conf. on Electrical Machines and Systems (ICEMS 2008), Wuhan (China), Oct. 2008, pp.2322-2326.

[13] D.S.L. Dolan, P.W. Lehn, Simulation model of wind turbine 3p torque oscillations due to wind shear and tower shadow, IEEE Trans. on Energy Conversion, Vol. 21, pp.717-724, 2006.

[14] P. Pillay and R. Krishnan, Application characteristics of permanent magnet synchronous and brushless DC motors for servo drives, IEEE Trans. on Industry Applications, Vol. 21, pp.986-996, 1991.

/ColorImageDict > /JPEG2000ColorACSImageDict > /JPEG2000ColorImageDict > /AntiAliasGrayImages false /CropGrayImages true /GrayImageMinResolution 200 /GrayImageMinResolutionPolicy /OK /DownsampleGrayImages true /GrayImageDownsampleType /Bicubic /GrayImageResolution 300 /GrayImageDepth -1 /GrayImageMinDownsampleDepth 2 /GrayImageDownsampleThreshold 2.00333 /EncodeGrayImages true /GrayImageFilter /DCTEncode /AutoFilterGrayImages true /GrayImageAutoFilterStrategy /JPEG /GrayACSImageDict > /GrayImageDict > /JPEG2000GrayACSImageDict > /JPEG2000GrayImageDict > /AntiAliasMonoImages false /CropMonoImages true /MonoImageMinResolution 400 /MonoImageMinResolutionPolicy /OK /DownsampleMonoImages true /MonoImageDownsampleType /Bicubic /MonoImageResolution 600 /MonoImageDepth -1 /MonoImageDownsampleThreshold 1.00167 /EncodeMonoImages true /MonoImageFilter /CCITTFaxEncode /MonoImageDict > /AllowPSXObjects false /CheckCompliance [ /None ] /PDFX1aCheck false /PDFX3Check false /PDFXCompliantPDFOnly false /PDFXNoTrimBoxError true /PDFXTrimBoxToMediaBoxOffset [ 0.00000 0.00000 0.00000 0.00000 ] /PDFXSetBleedBoxToMediaBox true /PDFXBleedBoxToTrimBoxOffset [ 0.00000 0.00000 0.00000 0.00000 ] /PDFXOutputIntentProfile (None) /PDFXOutputConditionIdentifier () /PDFXOutputCondition () /PDFXRegistryName () /PDFXTrapped /False

/CreateJDFFile false /Description > /Namespace [ (Adobe) (Common) (1.0) ] /OtherNamespaces [ > /FormElements false /GenerateStructure false /IncludeBookmarks false /IncludeHyperlinks false /IncludeInteractive false /IncludeLayers false /IncludeProfiles true /MultimediaHandling /UseObjectSettings /Namespace [ (Adobe) (CreativeSuite) (2.0) ] /PDFXOutputIntentProfileSelector /NA /PreserveEditing false /UntaggedCMYKHandling /UseDocumentProfile /UntaggedRGBHandling /UseDocumentProfile /UseDocumentBleed false >> ]>> setdistillerparams> setpagedevice