MASAAG Paper 120 Guidance on Helicopter Operational Data ...

Rd 120 Paper

description

Transcript of Rd 120 Paper

AN EXAMINATION OF THE RD-120 ROCKET

ENGINE AND DETAILED MIXTURE RATIO TRADE STUDY ANALYSIS

JOHANN SCHRELL THE GEORGIA INSTITUTE OF TECHNOLOGY

AE6450 FALL 2009 DR. MITCHELL WALKER

ii

TABLE OF CONTENTS

TABLE OF CONTENTS ________________________________________________________________ ii

TABLE OF FIGURES AND TABLES ______________________________________________________ ii

INTRODUCTION ____________________________________________________________________ 1

ANALYSIS _________________________________________________________________________ 3

Specific Impulse (Isp) ___________________________________________________________________ 4

Flame Temperature ____________________________________________________________________ 4

Thrust Coefficient and Thrust ____________________________________________________________ 4

Characteristic Velocity C* _______________________________________________________________ 5

Delta-V Δv ____________________________________________________________________________ 5

RESULTS AND ASSUMPTIONS________________________________________________________ 13

CONCLUSIONS ____________________________________________________________________ 14

REFERENCES ______________________________________________________________________ 14

TABLE OF FIGURES AND TABLES

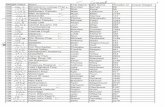

Figure 1. Isp Results From CEA With Variation in O/F at Vacuum and Sea Level ______________ 6 Figure 2. Flame Temperature With Variation in O/F _____________________________________ 7 Figure 3. Thrust Coefficient From CEA With Variation in O/F ______________________________ 8 Figure 4. Thrust With Variation in O/F at Vacuum and Sea Level___________________________ 9 Figure 5. C* With Variation in O/F at Vacuum and Sea Level _____________________________ 10 Figure 6. Delta-V With Variation in O/F at Vacuum and Sea Level ________________________ 11 Figure 7. Delta-V/c with Variation in Mass Ratio _______________________________________ 12 Table I. RD-120 Engine Dimensions ____________________________________________________ 2 Table II. RD-120 Performance Parameters ______________________________________________ 3 Table III. Results of Analysis Using Design Mixture Ratio _________________________________ 13

1

INTRODUCTION

The RD-120 engine is a Russian liquid fuel rocket engine developed and used 1976-1982. The developing company is NPO Energomash, previously Gasdynamic Laboratory - Experimental Design Bureau. The engine is designed to operate at altitude as an upper stage and incorporates a large exit area ratio nozzle to accommodate this. The engine was used on the Zenit launch vehicle second stage. It has a non-vectorable nozzle. The propellant delivery is provided via one main and two boost turbopumps. Ignition and turbopump operation is accomplished by using a single preburner. The engine was extremely reliable during its service. 177 RD-120s were built and tested 560 times for a total common operating time of 139186 sec.

The RD-120 produces over 833,565.25 N of thrust operating at about 162.7962 bar of chamber pressure. The engine’s specific impulse (Isp) in vacuum is listed as 350 sec. Though the Isp of the Kerosene/LOX combination is lower of similar engines running on LH/LOX, its Isp density is greater. The RD-120 operates at a nominal propellant flow rate of 242.9 kg/sec and is able to throttle down to 85% nominal thrust. This allows for less fuel volume to be carried on the vehicle. Dimension of the engine are detailed below in Table I.

2

Table I. RD-120 Engine Dimensions

Engine Dimensions

Characteristic Dimension (mm, kg)

Length 3872

Diameter 1954

Dry Mass 1125

Wet Mass 1285

Chamber Diameter 320

Characteristic Length, L* 1274

Contraction Ratio 1.74 (unitless)

Throat Diameter 183.5

Exit Diameter 1895

Exit Area Ratio 106.7 (unitless)

Chamber Length 2992

3

ANALYSIS

A review of the performance of this engine is desired. To accommodate this, a trade study of mixture ratios was run using the same operating pressure and real configuration’s dimensions to find the optimum performance. This was then compared to the predicted and actual performance of the real configuration of the RD-120. The real contraction ratio, throat diameter, exit area ratio, and dry mass were used in analysis. The real mass flow rate was also used. One mixture ratio that is desired to be analyzed is the stoichiometric mixture ratio. The equation for this is shown below.

12 24 2 2 2( ) 18 ( ) 12 ( ) 12 ( )C H l O l CO g H O g

Equation 1. RP-1 and LOX Reaction Equation

This equation yields a mixture ratio of 3.429 using the equation below.

ox oxOF

fuel fuel

N MW

N MW

Equation 2. Molecular Mixture Ratio Equation

Along with the stoichiometric mixture ratio, the real configuration mixture ratio will be analyzed. Other mixture ratios from 0.5 to 5.0 will be analyzed as well for a good characterization of the rockets performance. The system’s level of control of the mixture ratio is a property of the feed system and is rated at ±10%. Since the real configuration’s mixture ratio is O/F=2.6, this means that the mixture ratio is really anywhere between 2.34≤O/F≤2.86. A list of the real configuration’s performance parameters is shown in Table II.

Table II. RD-120 Performance Parameters

Engine Performance Parameters

Parameter Value

Mixture Ratio Control, % ±10

Throttling, % 85

Thrust (vacuum), N 833,565.25

Burn Time, sec 315

Specific Impulse (vacuum), sec 350

Propellant Mass Flow, kg/sec 242.9

Mixture Ratio, O/F 2.6

Combustion Flame Temperature, K 3670

Chamber Pressure, bar 162.7962

Nozzle Exit Pressure, bar 0.127491

Thrust Coefficient (vacuum) 1.95

4

Specific Impulse (Isp)

The vacuum and sea level Isp was calculated using NASA CEA with the methods previously described. The vacuum Isp is our primary data set of interest as the RD-120 was used as an upper stage in vacuum conditions. Values for the sea level performance are not available for the real engine to compare to. In Figure 1 it is seen that the optimum mixture ratio is 3 and produces an Isp of 376 sec. Also shown on this figure are the values for the stoichiometric and real configuration mixture ratios. It is seen that in this case the stoichiometric mixture ratio does not produce the best performance. The real configuration mixture ratio also does not produce the largest optimum specific impulse. However, it will be seen in further investigation why this mixture ratio was chosen by the designers.

Flame Temperature

The flame temperature was also calculated using the NASA CEA code and the results are plotted versus mixture ratio in Figure 2. The mixture ratio, 3, that produced the highest specific impulse also has the highest flame temperature of 3835 K. This becomes a heat transfer management problem. In this case there are two options, increase the mixture ratio (fuel lean) or decrease the mixture ratio (fuel rich). In either case there is a sacrifice that must be considered in trading heat management with lower specific impulse. In the real case, 0.8% in Isp is lost but the temperature is also dropped 1.1%. It is also seen that the stoichiometric mixture ratio produces a higher flame temperature and lower Isp than the real configuration mixture ratio. This is more evidence as to why the designers decided to go fuel rich instead of fuel lean.

Thrust Coefficient and Thrust

The thrust coefficient is an important parameter in nozzle design and represents the amplification of thrust due to the supersonic expansion of the nozzle compared to if the nozzle exit area were equal to the throat area. In Figure 3 the thrust coefficient has been plotted with the mixture ratio. It seen that this curve can have a rather strange shape. This dip in the value prior to rising again is mainly due to the gas properties at those particular mixture ratios. A sharp change in pressure ratio and specific heat ratio occurs that forces the thrust coefficient lower. This however does not affect the thrust as seen in Figure 4. Also first notice that the thrust coefficient is not at its highest for the real mixture ratio. This means that some improvement in the nozzle sizing could be made. Once again, the best performing mixture ratio is 3, showing the highest thrust. However, it is also seen again that the real mixture ratio performed better than the stoichiometric mixture ratio, producing over 886 kN of thrust. The thrust was calculated using the ideal thrust equation shown below.

2 2 2F mv P A

Equation 3. Thrust Equation

5

Characteristic Velocity C*

The characteristic velocity was calculated using the effective exhaust velocity and thrust coefficient obtained from NASA CEA according to the equation below.

*F

cC

C

Equation 4. Characteristic Velocity Equation

The optimum mixture ratio seen in Figure 5 producing the highest C* is 2.5 and the real mixture ratio is very close with a C*=1876 m/sec. The characteristic velocity is a function of the propellant combustion and acts as a measure of how well the combustion chamber is designed. This means that since the C* is near its highest for the real mixture ratio, the chamber of the RD-120 was properly designed for optimum combustion at the design mixture ratio. Because some energy is lost through the nozzle exhibiting incomplete combustion during real tests, it is beneficial to look at C* efficiency. This is a ratio of the actual C* and the theoretical C* and is a measure of the completion of energy release in the propellants and creation of high temperature and high pressure gases. The C* efficiency for the real mixture ratio is 94% which is in the typical range of 92-99.5%.

Delta-V Δv

The delta-V is the amount change in velocity the rocket engine would produce if it was to fly with just its own mass plus fuel mass. It was calculated using the equation below and plotted in Figure 6.

lnf b

f

m mt

v cm

Equation 5. Delta-V Equation for Rocket Only

In this equation mf represents the dry mass of the engine and the added term represents the mass of propellant consumed. The plot shows confirmation that the real mixture ratio provides one of the highest values of over 15 km/sec. On a vehicle this number would be lower due to the structural mass and payload. The calculated inverse mass ratio for the RD-120 is 69.012 and it can be seen in Figure 7 how much delta-V can be expected when taking the effective exhaust velocity into consideration.

6

200

220

240

260

280

300

320

340

360

380

400

0 1 2 3 4 5 6

Mixture Ratio O/F

Sp

ecif

ic Im

pu

lse Isp

(sec)

Vacuum

Sea Level

Figure 1. Isp Results From CEA With Variation in O/F at Vacuum and Sea Level

Real O/F = 2.6 Isp = 373 sec

Stoichiometric O/F = 3.429

Isp = 371 sec

7

0

500

1000

1500

2000

2500

3000

3500

4000

4500

0 1 2 3 4 5 6

Mixture Ratio (O/F)

Te

mp

era

ture

(K

)

Figure 2. Flame Temperature With Variation in O/F

Real O/F = 2.6

T = 3793 K

Stoichiometric

O/F = 3.429 T = 3816 K

8

1.5

1.6

1.7

1.8

1.9

2

2.1

0 1 2 3 4 5 6

Mixture Ratio O/F

Th

rust

Co

eff

icie

nt

Cf

Figure 3. Thrust Coefficient From CEA With Variation in O/F

Real O/F = 2.6 CF = 1.95

Stoichiometric O/F = 3.429

CF = 1.99

9

0

100000

200000

300000

400000

500000

600000

700000

800000

900000

1000000

0 1 2 3 4 5 6

Mixture Ratio O/F

Th

rust

(N)

Vacuum

Sea Level

Figure 4. Thrust With Variation in O/F at Vacuum and Sea Level

Real O/F = 2.6

F = 886 kN

Stoichiometric O/F = 3.429 F = 881 kN

10

0

200

400

600

800

1000

1200

1400

1600

1800

2000

0 1 2 3 4 5 6

Mixture Ratio O/F

Ch

ara

cte

ris

tic

Ve

loc

ity

C*

(m/s

ec)

Vacuum

Sea Level

Figure 5. C* With Variation in O/F at Vacuum and Sea Level

Real O/F = 2.6

C* = 1876 m/sec Stoichiometric

O/F = 3.429 C* = 1822 m/sec

11

0

2000

4000

6000

8000

10000

12000

14000

16000

18000

0 1 2 3 4 5 6

Mixture Ratio O/F

Delt

a-V

( m

/sec)

Vacuum

Sea Level

Figure 6. Delta-V With Variation in O/F at Vacuum and Sea Level

Real O/F = 2.6

Δv = 15412 m/sec Stoichiometric O/F = 3.429

Δv = 15387 m/sec

12

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

0 10 20 30 40 50 60 70 80 90 100

1/MR

Delt

a-V

/c

Figure 7. Delta-V/c with Variation in Mass Ratio

Mass Ratio for Max Mass Flow Rate and 315 sec Burn Time,

1/MR = 69.012 Delta-V/c = 4.234

13

RESULTS AND ASSUMPTIONS

The analysis performed here makes some assumptions and they are listed below.

Combustion is adiabatic and isentropic

There are no heat losses to the engine materials

The ambient pressure is 0 bar

Propellant mass flow rate is constant and at 100% capacity

The given thrust and thrust coefficient are experimental values

Chamber pressure is constant and at 100% capacity

Rocket is operating in gravity free, drag free space It is desired to compare the results of this analysis with the performance values provided in Table II. After performing the mixture ratio trade study there is agreement that the design mixture ratio O/F=2.6 is an appropriate value to use. Additional analysis was performed at this mixture ratio using the mixture ratio control. This gives results for performance parameters in the domain of 2.34≤O/F≤2.86. These results are summarized in Table III.

Table III. Results of Analysis Using Design Mixture Ratio

Results of Analysis

Parameter Real Calculated

O/F 2.6 2.34 2.6 2.86

Isp (vacuum), sec 350 366 373 376

Flame Temp, K 3670 3700 3793 3815

Thrust Coeff 1.95 1.91 1.95 1.98

C*, m/sec 1760 1870 1876 1860

Thrust, kN 834 870 886 892

Exit Pressure, bar .127 .084 .103 .120

In this table it is seen that the values are close but do not match those of the real engine. In most cases the values are larger than those of the real engine. This is due to the assumptions that are stated previously as well as a few other possibilities. One main possibility for losses is the efficiency of which the propellants are injected into the combustions chamber and mixed prior to combusting. There is no such thing as perfect mixing of propellant in rockets. Also, due to boundary layer effect, the effective aerodynamic throat of the real rocket in use will be smaller than that of the physical throat.

14

CONCLUSIONS

No real safety issues have been found with the RD-120 rocket engine. Liquid engines of this size have some inherent risk. The engine requires a complex turbopump system to deliver the propellants at high flow rates. This involves a lot of plumbing that is subject to leaks. Also, this rocket uses staged combustion so it is likely there are hot preburner exhaust gases flowing in very close proximity to the propellants in the feed system. In 1983 a fuel system leak led to the destruction of Soyuz T-10-1 on the launch pad. The RD-120 was not used on this vehicle however. From the analysis completed it appears there is only a little room for improvement via optimizing the mixture ratio. Some extra performance could be obtained with little increase in system risk it appears. The areas for improvement on a rocket engine of this size include materials studies. A trade could be performed to see if only the throat region and chamber need to be regeneratively cooled and the exit cone made of an ablative composite such as carbon/carbon or carbon phenolic. This would save weight and reduce system complexity. The combustion chamber could have small dimensional changes with test to determine a configuration with more complete combustion, however the current design probably already resulted in much testing for this as well as combustion stability. Because the RD-120 already uses staged combustion, an extremely efficient system, it is already a very well designed engine with similar characteristics as the LH2/LOX fueled Space Shuttle Main Engines.

REFERENCES

1. “Combustion Chemistry”. http://www.innovatia.com/Design_Center/rktprop2.htm. 2. “RD-120”. http://www.npoenergomash.ru/eng/engines/rd120/. 3. Sutton, George P., Biblarz, Oscar. Rocket Propulsion Elements. John Wiley & Sons.

2001. 7th Ed.