Question 1: A steel machine part is statically loaded and...

Transcript of Question 1: A steel machine part is statically loaded and...

Question 1: A steel machine part is statically loaded and has a yield strength of 320 MPa. For each of the following stress states find the factor of safety using each of the three static failure theories. a) σx = 60 MPa σy = -30 MPa σz = -20 MPa τxy = 40 MPa b) σx = 70 MPa τxy = 30 MPa c) Solution: Steel is a ductile material so we will use the ductile static failure theories. First the principal stresses for the given stress state should be calculated. (refer to Tutorial 2 - Question 1)

( ) ( ) σ⋅τ−τ−τ−σσ++σσ+σσ+σ⋅σ+σ+σ−σ 2zx

2yz

2xyzyzxyx

2zyx

3

( )2xyz

2zxy

2yzxzxyzxyzyx 2 τσ−τσ−τσ−τττ+σσσ− = 0

32

21

3 III −σ+σ−σ = 0 a) Inserting the known stresses to the given eqn.

I1 = 10 I2 = -4000 I3 = 68000

68000400010 23 −σ⋅−σ⋅−σ = 0 Recall the roots of the equation provides the principal stresses. Solving and arranging; σ1 = 75.21 MPa σ2 = - 20 MPa σ3 = - 45.21 MPa Factor of safety for each failure theories :

i) Maximum Normal Stress Theory: (Theory states that failure occurs if any of the principal stresses exceeds the yield strength of the material.)

n

Symax =σ =>

21.75320n = => n = 4.26

ii) Maximum Shear Stress Theory: (Theory states that yielding starts whenever the maximum shear stress at any point becomes equal to the maximum shear stress in a tension test specimen of the same material when that specimen starts yielding)

n2

Symax =τ

2)21.45(21.75

231

max−−=

σ−σ=τ = 60.21 MPa

Static Failure

σ MPa( )

40−

30

0

30

60−

0

0

0

10−

:=

21.602

320n⋅

= => n = 2.66 (minimum)

iii) Distortion Energy Theory: (Theory states that yielding occurs whenever the distortion energy in a unit volume reaches the distortion energy in the same volume corresponding to the yield strength in tension or compression)

the von Mises stress 2/12

312

322

21

2)()()(

σ−σ+σ−σ+σ−σ=σ′ =

nSy =>

2/1222

2)21.4521.75()21.4520()2021.75(

320n

+++−++= => n = 2.91

b) For the given stress state

I1 = 70 I2 = -900 I3 = 0

σσσ ⋅−⋅− 90070 23 = 0

Solving and arranging; σ1 = 81.1 MPa σ2 = 0 MPa σ3 = -11.1 MPa

Factor of safety for each failure theories : i) Maximum Normal Stress Theory:

nS y=maxσ =>

1.81320=n => n = 3.95

ii) Maximum Shear Stress Theory:

nS y2max =τ

2)1.11(1.81

231

max−−=

−=

σστ = 46.1 MPa

1.462

320⋅

=n => n = 3.47 (minimum)

iii) Distortion Energy Theory:

2/1231

232

221

2)()()(

σ−σ+σ−σ+σ−σ=σ′ =

nSy

2/1222

2)1.111.81()1.110()01.81(

320

++++−=n => n = 3.67

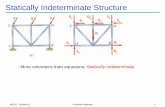

σB Sy

DET

MSST

MNST 81.1 σA -11.1 Sy=320

-Sy

Note: The result according to Maximum Normal Stress Theory is a misleading result as the stress

state falls into the 4th quadrant in the BA σσ − graph. The result according to Maximum Shear

Stress Theory can be interpreted as the most conservative one whereas the one obtained by

Distortion Energy Theory is slightly greater and a more realistic one when compared with

experimental results.

c) is the matrix representation of the stress state of an element. For the given stress state,

I1 = -110 I2 = 2500 I3 = -15000

150002500110 23 −⋅+⋅− σσσ = 0

Solving and arranging; σ1 = -10 MPa σ2 = -18.4 MPa σ3 = - 81.6 MPa

σ

σxx

τyx

τzx

τxy

σyy

τzy

τxz

τyz

σzz

:=

σzz

Factor of safety for each failure theories : i) Maximum Normal Stress Theory:

(max. in compression) n

)S(S ycymax

==σ =>

6.81320

−−=n => n = 3.92 (minimum)

ii) Maximum Shear Stress Theory:

n2

Symax =τ = 35.8 MPa

8.352

320⋅

=n => n = 4.47

iii) Distortion Energy Theory:

the von Mises stress 2/12

312

322

21

2)()()(

σ−σ+σ−σ+σ−σ=σ′ =

nSy =>

2/1222

2)106.81()6.814.18()4.1810(

320

+−++−++−=n => n = 4.72

Question 2: A steel LPG tank is shown in the figure. The wall thickness of the tank is 15 mm and has a yield strength of 340 MPa. The full weight of the tank is 6500 kg and the internal pressure is 3 MPa. Calculate the factor of safety of the tank according to the distortion energy theory.

(checking 201

501

75015

rt <== the tank can be treated as thin-walled pressure vessel)

B

4 m

1.5 m15

2)6.81(10

231

max−−−=−= σστ

Solution: First the principal stresses should be calculated for both cylindrical and spherical sections. For cylindrical vessel: For point A:

tangential stress 157503

tPr

t⋅==σ = 150 MPa radial stress 3. −=−= pArσ MPa

longitudinal stress 1527503

t2Pr

⋅⋅==σ

� = 75 MPa

bending stress due to weight of the tank: (consider weight as a concentrated force which is a conservative assumption compared with the distributed weight assumption)

( ) ( ) 10444i

4o 10929.114701500

64DD

64I ⋅=−π=−π= mm4

4.210929.1

)15750(10766.6310

6

, ≅⋅

−⋅⋅==IMc

Abσ MPa

At the bottom of the tank the tensile stresses will be larger, so the bottom mid-point is critical. Recalling there will be no traverse shear stress due to weight at the bottom fiber, the axial stresses are to be taken as principal stresses. Arranging as 321 σ>σ>σ ;

150t1 =σ=σ MPa 5.77b2 =σ+σ=σ�

MPa 3r3 −=σ=σ MPa After calculating the stress state we can find the factor of safety using the distortion energy

theory: 2/12

312

322

21

2)()()(

σ−σ+σ−σ+σ−σ=σ′ =

nSy

2/1222

2)3150()35.77()5.77150(

340n

++++−=

For point B: tangential stress =tσ 150 MPa radial stre longitudinal stress =

�σ 75 MPa

5.210929.1

75010766.6310

6

, ≅⋅

⋅⋅==IMc

Bbσ Mpa

4000 mm

6500 kg

F F

=> n = 2.56

ss 0. =Brσ

Nmm 10766.632

400031883M

N 318832

81.96500F

6⋅=⋅=

=⋅=

z

x y

F = 1.5 i – k kN

φ30

φ45

R6

200

100

Comment: Since a thin walled cylinder is used, as it can be seen in above equations, bending moments at point A and B can be considered to be equal. Also, pressure in the tank is small which results in small radial stress at point A compared to longitudinal and tangential stresses. Therefore checking safety factor according to stress element at point A is sufficient for this problem. For the spherical cap: on spherical shells stresses in orthogonal directions are same:

1527503

t2Pr

t2l ⋅⋅==σ=σ=σ = 75 MPa

7521 =σ=σ MPa 3pr3 −==σ=σ MPa

2/1222

2)375()375()7575(

340n

++++−= n = 4.36

Factor of safety used for the production of the tank is 2.56 (the smaller of the two factors calculated above). Question 3: A cast iron structure is loaded as shown in the figure. The material has Sut = 325 MPa and Suc = 912 MPa. Find the factor safety of the structure using brittle failure theories at the points A and B (Coulomb-Mohr and Modified Mohr).

Solution: The maximum bending moment on the shoulder is to be calculated using My (in N.m).

For machine elements made of brittle materialsstress concentrations should be considered. Theneck for this case is critical.

Mx = Fz . 100 = 100000 N.mm My = Fx . 200 = 300000 N.mm T = Fx . 100 = 150000 N.mm Fz = 1000 N Fx = 1500 N

T

MyMx

Fz

x

y

A

B

Fx

σA

σA

σy= 0

σB

σy= 0

The transverse shear due to Fx at points A and B is zero.

As stated before, the stress concentrations should be considered on brittle elements. Certain fillets, notches, holes, grooves on the element should be checked as critical sections, as the stress concentrates around these sections.

For 5.13045

dD == and 2.0

306

dr == => Kt.axial = 1.57 (Fig E-1, Norton, pp.994)

Kts.torsion = 1.25 (Fig E-3) Kt.bending = 1.4 (Fig. E-2)

Stresses at the maximum tension (point A) and compression (point B) points on the critical section, respectively:

AF

KI

McK zaxial.tbend.tA ⋅−⋅=σ (tens.+comp.)

AF

KI

McK zaxial.tbend.tB ⋅−⋅−=σ (comp+comp)

JTcK torsion.ts0 ⋅=τ (same for all points)

44 30

64D

64I π=π= = 3.976.104 mm4 J = 2.I = 7.952.104 mm4 =π= 2D

4A 706.86 mm2

At point A: 86.706

100057.110976.3

15103004.1 4

3

A ⋅−⋅

⋅⋅⋅=σ = 156.2 MPa

At point B: 86.706

100057.110976.3

15103004.1 4

3

B ⋅−⋅

⋅⋅⋅−=σ = -160.7 MPa

shear stress 4

3

0 10952.7151015025.1

⋅⋅⋅⋅=τ = 35.37 MPa (show the direction on the cube below !)

Recall in 2D stress analysis; 2zy

2yxyx

3,1 22τ+

σ−σ±

σ+σ=σ

Point A: 22

3,1 )37.35(2

0156.2

20156.2 +

−±+=σ

σ1 = 163.84 MPa σ2 = 0 MPa σ3 = -7.64 MPa

Point B: 22

3,1 )37.35(2

0160.7

20160.7 +

−−±+−=σ

σ = 7.4 MPa σ = 0 MPa σ = -168.1 MPa

σB 1 2 3

Coulomb-Mohr Theory:

n1

SS uc

3

ut

1 =σ

−σ (note Suc is treated as positive)

for point A: n1

91264.7

32584.163 =−− => n = 1.95 (minimum)

for point B: n1

912168.1

325.7.4 =−− => n = 4.65

Modified Mohr Theory: Point A

Sut

Suc

-Sut

σ1

σ3 163.84

-7.64

S

Suc

-Sut

σ37.4

-168.1

S3

D

F

G

Sut

uc

σ1

σ3163.84

-7.64

7.4

-168.1

A

B

S

utσ11

E

Point B

H

S

Point A: ==σ

=84.163

325Sn

1

ut 1.98 (minimum)

Point B: 3

3

1

1 SSn

σ=

σ= (S1 and S3 is to be found) =>

7.4 168.1

SS 31 =

using similarity of triangles DEF and FGH. 3uc

utuc

1

ut

SSSS

SS

−−

= => 31 S912

325912S

325−−=

solving the equations : S1 = 37.2 MPa S3 = 844.8 MPa (= -844.8 MPa)

2.37Sn

1

1 =σ 7.4

= => n = 5.03 or 168.1

844.8

3

3 ==σS

n ⇒ n = 5.03

You can also use the equations 12.c, 12.d, 12.e in pp. 274 of Norton to obtain the same result.

Question 4. The steel crankshaft is loaded statically as shown in figure. The steady force is counterbalanced by a twisting torque T and by reactions at A and B. The yield strength of the material is 420 MPa. If the factor of safety according to maximum shear stress theory is to be 2.0, what should be the minimum diameter of the crankshaft? (Note: In practice such problems are dealt with dynamic considerations. Here it is taken as a static example.) At point C, there is normal stress in axial directiondue to bending (max. moment). At point D, both axial stress due to bending and shear stress due to torsion exist.

At point C:

M = 1250 . 90 = 1.125 . 105 N.mm 2dc = 4d

64I π=

3

6

4

5

b d10146.1

d64

2d10125.1

IMc ⋅=

π

⋅⋅==σ MPa b1 σ=σ 032 =σ=σ

Recall , for max shear stress theory: 10522

4202

=⋅

==nS y

allτ MPa and τall = τmax

1052

0d

10146.1

2

3

6

31max =

−⋅

=σ−σ

=τ MPa => d3 = 5457 mm3

which gives d = 17.6 mm

FA = FB = 2500 / 2 = 1250 N T = 2500 . 45 = 1.125 . 105 N.mm Sections at points C and D should be checked.

90 90

48

45

BA

F = 2.5 kN

T

FA

C

DFB

At point D:

M = 1250 . 48 = 6 . 104 N.mm 2dc = 4d

64I π= J = 2 . I

3

5

4

4

10112.6

64

2106

dd

d

IMc

bending⋅=

⋅⋅== πσ MPa 3

5

4

5

1073.5

32

210125.1

dd

d

JTc

tortion⋅=

⋅⋅== πτ

2xy

2yx

max 2τ+

σ−σ=τ 105

22420

2=

⋅==

nS y

allτ MPa τall = τmax

105d

10494.6d

1073.5d2

10112.63

52

3

52

3

5

max =⋅=

⋅+

⋅=τ MPa => d3 = 6185 mm3

which gives, d = 18.36 mm Checking both points, point D found to be more critical. The minimum diameter of the shaft should be 18.36 mm. But it should be better to get used to accept preferred numbers in machine elements design, so it can be set as d = 20 mm.