Pur Date: 18.05

Transcript of Pur Date: 18.05

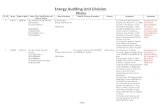

File No. 28(19)/2019/Pur Date: 18.05.2021

Revised Technical specifications & clarifications issued after the Pre-Bid Conference Dated 04.05.2021 for Supply, installation

and commissioning of Pretreatment system and Monitoring Equipment for Pyrolysis unit

S. No Components Purpose Technical Specification Unit Quantity

1. Belt Conveyor To feed waste

to shredder

Belt conveyor system with trays to transfer the fibrous waste such as banana

peduncle, tender coconut etc., to the shredder.

Motor rating not less than 3 HP, IP65

Belt width not less than 500 mm

Rubber belt thickness not less than 10 mm

Length and height to suit the site conditions (Min 6.0 m length)

Belt material – synthetic rubber belt (MRF/Dunlop/Duro/Equivalent)

MoC – MS Epoxy coated

SS 316 Cleat arrangements in the belt have to be provided.

Energy efficiency of motor - IE2, Motor Make: Bharat Bijlee / Marathon /CGL / Equivalent

Gear Box: Premium greaves / Power build / Equivalent

Suitable civil foundation to be provided. Equipment basement level with

required machine foundation (as per supplier requirements) should be

atleast 1 feet above the road adjacent to site

No 1

2. Primary Shredder To shred the

bigger waste

The equipment should be capable to shred fibrous organic waste (75 mm

thick wood materials, Banana peduncle, and full tender coconut) with the

No 1

S. No Components Purpose Technical Specification Unit Quantity

materials

(75mm thick

wood

materials /

peduncle and

tender

coconut) into

smaller

particles.

capacity of 250 kg per hour with suitable MS-FRP coated hopper.

The shredded Particle size should be less than 75 mm

Materials of Construction

Housing: MS Epoxy coated and plate thickness not less than 16mm

Internal housing should not be less than 600x450mm (length x width)

Shaft MoC: D2/4140 hexagonal hardened Steel

Cutters MoC: D2/4140 hardened steel

Cutter blade plate thickness: 16mm

Cutters Arrangement: Cartridges / single piece

Cutters Type: 3 to 5 teeth

Each shaft drive should have separate gear box and separate motor

Mechanical Seal: Tungsten

Motors rating – not less than 5 HP each, IP65, Energy efficiency - IE2

Provision for VFD to adjust the RPM from 40 to 80

D2/4140 Hardened steel cleaning comb arrangement has to be provided.

Suitable hopper in MS with FRP coated.

Provision for auto reverse and forward operation

Corrosion resistant structural framework has to be provided for placing both primary and secondary shredders (top and bottom respectively).

Platform, ladder arrangement and handrail have to be provided. Cutter and Housing Make: Shreddo / Ecoster/ Alphatherm / Equivalent

Motor Make: Bharat Bijlee / Marathon / CGL / Equivalent

S. No Components Purpose Technical Specification Unit Quantity

Gear Box: Premium greaves / Power build / Equivalent

3. Secondary

Shredder

For further size

reduction

The equipment should be capable to shred fibrous organic waste with the

capacity of 250 kg per hour with suitable MS with FRP coated hopper.

The shredded Particle size should be less than 25 mm

Materials of Construction

Housing: MS Epoxy coated and plate thickness not less than 16mm

Internal housing should be not less than 600 x 400 mm

Shaft MoC: D2/4140 hexagonal hardened material

Cutters: D2/4140 hardened steel

Cutters Arrangement: Cartridges / single piece

Cutter blade plate thickness: 10 mm

Cutters Type:13 to 16 teeth

Mechanical Seal: Tungsten

D2/4140 Hardened steel cleaning comb arrangement has to be provided.

Motor rating – not less than 7.5 HP, IP65, Energy efficiency - IE2

Provision for auto reverse and forwarding operation

Suitable structural framework has to be provided to integrate with

primary shredder.

Platform, ladder arrangement and handrail have to be provided for supervision and maintenance of the equipment.

Cutter and Housing Make: Shreddo / Ecoster / Alphatherm / Equivalent

No 1

S. No Components Purpose Technical Specification Unit Quantity

Motor Make: Bharat Bijlee / Marathon /CGL / Equivalent

Gear Box: Premium greaves / Power build / Equivalent

4. Screw Conveyor -1 To convey the

shredded waste

from shredder

to the

dewatering

system.

Screw conveyer system with suitable hopper. The bottom of the

hopper has to be connected with screw conveyor inlet.

Inclined - U type screw conveyor with removable lid

U plate thickness – 5mm

Screws MoC – SS304

Screw diameter – 350 mm

Screw thickness – 3 mm

Screw Pitch – 150 mm to 200 mm

Shaft diameter – 60 mm

Motor rating – not less than 3 HP, IP65, Energy efficiency - IE2

Hopper size – 800x 800 mm, MS with FRP coated

Length and height to suite the site conditions (Length: 5 minimum)

Motor Make: Bharat Bijlee / Marathon /CGL / Equivalent

Gear Box: Premium greaves / Power build / Equivalent

Suitable civil foundation and basement to be provided for integrating

screw conveyor, primary and secondary shredders. Equipment basement

level with required machine foundation (as per supplier requirements)

should be atleast 1 feet above the road adjacent to site

No 1

5. Dewatering system To dewater the To dewater the fibrous organic waste for a capacity of 250 kg per hour No 1

S. No Components Purpose Technical Specification Unit Quantity

fibrous organic

waste

Capable of dewatering the fibrous materials

Continuous discharge wedge type screw press

Equipped with adjustable RPM

Provision for VFD to adjust the RPM from 10 to 30

All parts MoC – SS304

Pneumatics adjustable back pressure for moisture control

Suitable compressor for pneumatic system

Motor rating not less than 7.5 HP, IP65, Energy efficiency - IE2

The height of the dewatering system has to be raised so that the

dewatered waste should fall directly into the pan mixer with weighing

load cell.

Dewatering system make: Jash / Geeli / Shree Engineers / Equivalent

Motor Make: Bharat Bijlee / Marathon /CGL / Equivalent

Gear Box: Premium greaves / Power build / Equivalent

Compressor Make: Anest Iwata /Elgi /Ingersoll rand / Equivalent

Suitable civil foundation to be provided. Equipment basement level with

required machine foundation (as per supplier requirements) should be

atleast 1 feet above the road adjacent to site

6. Solid Mixer To mix the

fibrous organic

Mixer for homogenization of dewatered fibrous waste and sewage

sludge No 1

S. No Components Purpose Technical Specification Unit Quantity

waste and

sewage sludge

Type – Pan type, open type mixer, Pan MoC – MS FRP

Dia/size – 1200mm, Height – 500mm, free board – 100mm

Min. distance above tank – 100mm

Total shaft length – 300 mm

Bottom clearance – 100 mm

Shaft dia – 90 mm

MoC shaft – SS304

Minimum No of vanes – 6

Propeller type - Plough Type with adjustable blades

MoC propeller - SS304

MoC Lantern support – MS/CI

RPM @ full load - 30 rpm +/- 10%

Bottom Guide – 1, Gear box type – Helical

Energy efficiency - IE2

Motor – not less than 7.5HP, IP 65

Motor Make: Bharat Bijlee / Marathon /CGL / Equivalent

Gear Box: Premium greaves / Power build / Equivalent

Suitable civil foundation to be provided. Equipment basement level with

required machine foundation (as per supplier requirements) should be

atleast 1 feet above the road adjacent to site

S. No Components Purpose Technical Specification Unit Quantity

7. Screw conveyor - 2

To transfer the

dewatered

sludge to the

mixer

Screw conveyer system with suitable hopper of size 800x800m (Hopper

- MS FRP coated)

Inclined - U type screw conveyor with removable lid

MoC of all the components – Mild Steel with epoxy coated

U plate thickness – 5mm

Screw diameter – 300mm

Screw thickness – 3mm

Screw Pitch – 150mm

Shaft diameter - 60mm

Motor rating – not less than 3 HP, IP65, Energy efficiency - IE2

Hopper size – 800 x 800mm

Length and height to suit the site conditions (Min. length 2.0 m)

Motor Make: Bharat Bijlee / Marathon /CGL,

Gear Box: Premium greaves / Power build.

No 1

8. Weighing Load cell To fix below

the mixer for

the weight

calculation.

Load cell – 4 Nos

To suit the size of mixer equipment (Approx. 2.00m x 2.00 m)

Rated capacities 200 kg to 5.0 ton capacities

“Thru or “threaded load hole configurations

Low sensitivity to axial loads

Sealed to IP67 standards

Factory Mutual System Approved for Classes I, II, III; Divisions 1 and 2;

Groups A through G. Also, non-incentive ratings (No barriers).

No 1

S. No Components Purpose Technical Specification Unit Quantity

Trade certified for NTEP Class III: 5000d, IIIL: 10000d and OIML R-60

3000d available

Four Load Cell Junction box – 1 No

With Surge Protector

MOC: Stainless Steel 316

Digital weight Indicator

Serial Communication: RS232 (automation ON/OFF system has to be provided in the panel board based on the set value)

Analog output: 4-20mA (or) 0 -10V

Two Opto – Isolated set Point

Display: 6 Digit/ 7 Segment LED

Digital Height: 14mm

Suitable civil foundation to be provided. Equipment basement level with

required machine foundation (as per supplier requirements) should be

atleast 1 feet above the road adjacent to site

9. Screw Conveyor - 3 To transfer the

waste from

solid mixing

system to solar

dryer.

Screw conveyer system with suitable hopper

Inclined - U type screw conveyor with removable lid

MoC of all components – MS with Epoxy coated

U plate thickness – 5mm

Screw diameter – 350mm

Screw thickness – 3mm

Screw Pitch – 150mm to 200mm

No 1

S. No Components Purpose Technical Specification Unit Quantity

Shaft diameter - 60mm

Motor rating – not less than 3 HP, IP65, Energy efficiency - IE2

Hopper size – 800x 800 mm

Hopper MoC – MS FRP

Length and height to suit the site conditions (Length: 4 metre minimum)

Motor Make: Bharat Bijlee / Marathon /CGL / Equivalent

Gear Box: Premium greaves / Power build / Equivalent

Suitable civil foundation to be provided. Equipment basement level with

required machine foundation (as per supplier requirements) should be

atleast 1 feet above the road adjacent to site

10. Screw Conveyor - 4 To transfer the

dried waste

from solar

drier to silo

hopper.

Screw conveyer system

Inclined - U type screw conveyor with removable lid

MoC of all components – MS with Epoxy coated

U plate thickness – 5mm

Screw diameter – 350mm

Screw thickness – 3mm

Screw Pitch – 150mm to 200mm

Shaft diameter - 60mm

Motor rating – not less than 3 HP, IP65, Energy efficiency - IE2

Length and height to suit the site conditions (Length: 6 metre minimum)

Motor Make: Bharat Bijlee / Marathon /CGL / Equivalent

Gear Box: Premium greaves / Power build / Equivalent

No 1

S. No Components Purpose Technical Specification Unit Quantity

Suitable civil foundation to be provided. Equipment basement level with

required machine foundation (as per supplier requirements) should be

atleast 1 feet above the road adjacent to site

11. Portable Flue Gas

Analyzer

To identify the

composition of

gas liberated

during the

pyrolysis.

The following parameters has to be measured on sensor based.

CO – 0 to 10000 ppm and CO in percentage upto 10%, if the conc. of CO higher than 10000 ppm

CO2 – 0 to 40% (IR bench based)

NO – 0 to 5000 ppm

NO2 – 0 to 1000 ppm

SO2 - 0 to 5000 ppm

HC- 0 to 5000 ppm (IR triple bench sensors for CO, CO2 and HC)

NOx – calculative method

Pressure measurement for temperature upto 1000oC

Dual pumps for pumping of gas

Filtering systems for chemicals, dust, water and air traps filters needs to be provided.

Sampling Probe: 1 metre, Sampling Hose: Min 6 metres (to match the site conditions).

25 or more lines of data has to be displayed.

Software for datalogging & downloading and Transfer live analyzer readings has to be recorded in the PC/data acquisition system.

In-built Printer to print the data shall also be included for remote operation and submission of report.

No 1

S. No Components Purpose Technical Specification Unit Quantity

TUV Certification should be provided for the quoted model.

Make: Testo / Nova / Kane / Geotech / Fujitstu.

12. Electrical Control

panel

Electrical power

supply and

distribution for

the pilot plant.

Supply, fixing, testing and commissioning of MCC panel board (indoor system with exhaust arrangements) with control switches, contactors, VFD drives (for primary shredder, dewatering system, for one existing screw conveyor (3HP)), voltmeter, Ammeter, selector switch, phase LED indicators, energy meters (2 Nos for main panel and Pyrolysis Unit), suitable electrolytic copper bus bar, cable entry shall be from bottom or top etc., with all accessories as required for the complete plant.

Panel MoC: 2.0 mm cold rolled (CRCA) sheet with powdered coated metal etc., conforming to IS standards.

All electrical materials should be of suitable flame proof.

Local push buttons should be provided for all the Mechanical equipment

Two number of copper earthing system to be providing with appropriate earthing arrangement.

Contactor Make: Schneider, ABB and L&T (for control switches, MCCB, MCB) / Equivalent

VFD make: Danfoss / ABB / Schneider /Equivalent

Cable make: polycab/ finolex/ orbit/ equivalents

Supply and Laying of 3.5C x 70 sq.mm XLPE power cable of 1.1 kV grade (Approx. length 100m) of following size direct in ground including excavation, sand cushioning, protective covering and refilling the trench etc. as required (along with test certificate).

Supply and laying of cable for pyrolysis unit panel (18kW) and existing

No 1

S. No Components Purpose Technical Specification Unit Quantity

screw conveyor (3 HP) for the proposed panel will also be scope of the bidder.

Appropriate electrical items are also to be provided for the pyrolysis unit and existing screw conveyor in the proposed panel.

Supplying and making end termination with brass compression gland and aluminium lugs for selected cable size as required.

Before fabrication of panel, GA drawing may be obtained approval from CLRI.

Automatic ON and OFF provision for equipment has to be provided based on the output of load cell (weight basis).

Digital Clamp Meter with following specifications with test certificate

AC Current: 200, 1000A

AC Voltage: 250V, 750VAC

DC Voltage: 200, 1000V DC

Resistance: 2MOhm

Frequency: 2KHz

Continuity buzzer and diode checking.

13. Personal Protection

Equipment (PPE)

Personal safety The PPE such as gloves, goggles, masks, safety helmets, Toe PVC Safety Shoe should be provided (4 numbers each).

Lot 1

14. Safety Measures Safety ABC Fire extinguisher portable type, 6 kg – 4 Nos.

Fire extinguisher Make: Cease fire/ Equivalent

Sand bucket with stand - 2 Nos

Lot 1

S. No Components Purpose Technical Specification Unit Quantity

Four Bucket in Stand to hold 7 Kg of sand in each bucket

15. 20 feet container To fix the

electric control

panels and

monitoring

systems

20 feet length x 8 feet x 8.6 feet

Age – Not more than 10 years old with date of manufacturing /certificate

Used container without any damage and properly painted with primer and enamel.

High quality steel / corrosion resistant corten steel with corrugated two end fixed walls

Lifting hooks - 4 Nos.

Interior Works

35mm wooden frame

25 mm thick rock wool or glass wool insulation (compressed size)

8 mm MDF paneling

Door: 7 ft x 3 ft Aluminum Flush Door – 1No.

Window: 3 ft x 3ft aluminium siding windows 3Nos.

Electrical Works

Supply and installation of prewired electrical fittings with 15/5A sockets, switch boards and all accessories.

28 watts LED slim fit tube light - 3 Nos.

1.5 Ton split A/C (four star rated) with metal coat socket & top with MCB (Make: Voltas, Haier and blue star) - 1No.

400 mm sweep wall mounted fans - 2Nos.

18 watts LED bulket fitting – 1No.

No 1

S. No Components Purpose Technical Specification Unit Quantity

40A MCB, DP-1No, 16 A and 10 A MCB – each 2Nos., Distribution Board with earthing to connecting 8 SWG GI earthing wire

Suitable civil foundation to be provided. Equipment basement level with required machine foundation (as per supplier requirements) should be equal to top of road adjacent to site

16. Buffer Water tank

for pyrolysis

system

Water Tank capacity – 3000 litres

MoC – rectangular FRP tank to withstand maximum temperature of 100 oC.

No 1

17. Shed for storage To store the

sewage sludge

Shed Size 3.0m x 3.0m with Galvalume sheeting

Appropriate structural support has to be provided No 1

18. Plant lighting

system

For night

operation of

the pilot plant

Supply, installation, testing and commissioning of prewired 60watts LED

street light fitting complete with all accessories. IP65

Light Make: Crompton, Havells, Philips / Equivalent

Providing and fixing of 6m single arm street light pole, bottom side

150mm dia and top side 70mm dia, thickness 3mm MS powder coated

pipe with suitable base including SMC box, MCB controller and pole

earthing. Cylindrical pole is preferable.

Suitable foundation with min 400mm dia and 800mm depth plain

cement concrete foundation should be provided.

LED light fittings (36W) inside the plant at the machineries at higher

elevation and outside containers (3 Nos).

Interconnecting cables for the street light will be the scope of the

Set

(LS) 1

S. No Components Purpose Technical Specification Unit Quantity

supplier.

Single ON or OFF switch for each street light with Dinrail, MCB and Sintex

box of IP65.

Number of Street Lighting with pole – 6 Nos with analog timer, contactor

and suitable sintex box etc., as required (1 set)

Number interior plant light fittings – 3 Nos with MCB

19. Data acquisition

and Processing

system

To store the

data from the

monitoring

systems

Processor – i7, 10th Gen or Latest with 2.9 GHz to 4.7 GHz or higher, 16

MB Cache, 8 Cores or more

RAM – 16 GB, DDR4@2933MHz SDRAM (1 x 8GB) with expandability of

64 GB

Memory Slots – 2 DIMM

Hard Drive – 4TB 7200 RPM HDD SATA III 6Gbps

Network – Onboard Gigabit 10/100/1000 Mbps LAN

WLAN - Onboard Wi-Fi and Bluetooth Combo card

Ports – Front: Minimum 2 super speed Type-A; Minimum 2 USB Super

Speed, Type – A; 1 VGA; 1 HDMI 1.4; 1 Display port 1.4; 1 audio-out; 1

power connector; 1RJ-45

Expansion slots – As per OEM specifications

Drive bays – Minimum 3 Base Bays

Form factor - As per OEM specifications

Optical drive – Integrated slim DVD-Writer

No 1

S. No Components Purpose Technical Specification Unit Quantity

Keyboard – USB Keyboard, Mouse – USB optical mouse

Monitor – 27-inch Monitor FHD (1920 x 1080 @ 60Hz)

Aspect Ratio – 16:9

Webcam: HD Webcam with audio

Ports: 1 Display Port 1.2; 1 VGA; 1 HDMI 1.4(with HDCP Support) or

higher, Minimum 3 USB 3.0, 1 Microphone; Graphics – Integrated Intel

UHD Graphics 630

Audio – Integrated audio with internal speakers mounted in cabinet

Power supply – 180W or higher

Security Management – Trusted platform module TPM 2.0 embedded

security chip with windows 10; Serial, USB enable/disable (via BIOS);

Power-on password (via BIOS); Set up password (via BIOS);

Operating system – Genuine windows 10 Pro 64bit with recovery

partition or recovery media

Warranty – 3 Years onsite comprehensive warranty

Make: Dell/HP/ Lenovo/Equivalent

20. Trays/ Crates MoC: HDPE

Nos. :30 Nos

Capacity: 50L each, Type: Non-perforated Crate

Make: Sintex/Nilkamal/Equivalent

Nos 30

21. Fencing with RCC

Post

Supply and fixing of fencing around the site (Approx 95 metres) with RCC

poles as detailed below: Lot 1

S. No Components Purpose Technical Specification Unit Quantity

R.C.C. Standards post/ struts/rails/ pales of mix 1:1.5:3 (1 cement: 1.5

sand and 3 graded stone aggregate) of 4” x 4” size with 4nos. of 6mm dia

rods @ 8’ C/c with 6mm dia rings@6” C/c.

Height of the pole should be 2.5 metre above the adjacent road level

PVC coated, 4 mm dia G.I. chain link fabric fencing of mesh size 50x50

from ground level to top of fencing post with horizontal stiffeners of

suitable MS flat at 3 levels (Top, middle & bottom)

Height of the fencing 2.5 metre above the adjacent road level. Suitable

light weight gate of size 3.0m width with required supporting

arrangements to be provided. MS gate shall be with MS angle section of

required stability with welded mesh arrangement

Note:

The technical specifications and data sheet all units shall be submitted with the technical bid

The bidder shall provide one-year warranty for all the equipment supplied from actual date of commissioning.

Any item which is necessary but inadvertently omitted shall be included at any stage of work within the total quoted tender cost. Hence, the tendered price shall be deemed to include all items which are mandatorily required for the comprehensive physical and functional completion of the offered items in all respects to meet the scope of work as mentioned in this tender document.

Length and inclination of the screw conveyors shall be provided to match the GA drawing of the machinery & plant and also the site conditions.

Suitable civil foundation to be provided. Equipment basement level with required machine foundation (as per supplier requirements) should be atleast 1 feet above the road adjacent to site.

Supply, Installation and commissioning of the plant should be completed within 4 months from the date of purchase order

Power and water supply will be provided by CLRI during installation, commissioning, operation and maintenance for a month.

A display board in the entrance of the Pilot plant with structural support indicating the project details with the help of CLRI.

Revised Payment terms

20% of the work order against completion of detailed engineering and submission

of drawings and against equivalent bank guarantee

40% of the work order cost against the delivery of all equipment at site and

acceptance by CLRI

20% of the work order cost against the erection, commissioning and testing

13% against successful trial run for a month of operation and maintenance of the

plant during that period

7% of the cost after the warranty period of One Year from date of installation and

commissioning which can be paid to you after the trial run and maintenance

period in case an equivalent bank guarantee is submitted.

The bid prepared by the Bidder shall include documents as under:

1. Cover – 1 – Fee/Prequal/Technical (Techno-Commercial Details of Supply, installation and

commissioning of Pre Treatment System and Monitoring Equipment for Pyrolysis Unit

(Document Type .pdf)

1. EMD exemption certificate or Bid Securing declaration (Annexure V) or proof

of RTGS / NEFT details or Bank Guarantee (.pdf)

2. Bidder Information Form – Annexure – I; and if applicable Documentary

evidence about the status of the bidder i.e. whether MSE or not, owned by

SC/ST or not and whether the MSE is owned by a women entrepreneur or

not. (.pdf)

3. Format for declaration by the Bidder for Code of Integrity & conflict of

interest (Annexure II) (.pdf)

4. Manufacturer’s Authorization Form–Annexure – III; (.pdf)

5. Deviation statement Form – Annexure – VII (.pdf)

6. Format for Affidavit of Self Certification regarding Local Content in letter

head (Annexure XII) (.pdf)

7. Certificate with regard to the bidder not having a land border with India

(Annexure XIV) or Certificate with regard to the bidder having a land border

with India (Annexure XV) (.pdf)

8. Minimum of 2 works with value of Rs.15 Lakhs each of Supply, installation

and Commissioning of mechanical devices / equipment for pre-treatment

before waste management with their completion certificate within the

period of 7 years.

9. Catalogue / Brochure of the Model Quoted (.pdf)

10. Schedule of Requirement – Chapter – 3 (.pdf)

11. Bid form – Annexure – IX; (.pdf)

2. Cover – 2 – Finance (Price bid for Supply, installation and commissioning of Treatment System and Monitoring Equipment for Pyrolysis Unit ) (Document Type .xls)

Clarifications issued after the Pre-Bid Conference Dated 04.05.2021 for

Supply, installation and commissioning of Pretreatment system and

Monitoring Equipment for Pyrolysis unit

Clarifications issued to M/s. B-Sustain Energy Project Pvt Ltd.

Query 1 Whether all the motors supplied for machineries should have protection category either IP55 or IP65.

Reply All motors need to be provided with IP65 configurations as the system is to be installed as outdoor unit.

Query 2 In serial No. 2 & 3, component Primary & secondary shredder, please specify MOC for both the shredder D2/4140.

Reply The MoC of the both primary and secondary shredders shall be D2 or 4140 hardened steel.

Query 3 In serial no.3, component secondary shredder, shredded particle output from secondary shredder can be in the range of 20 to 25mm, please clarify.

Reply Yes, the output of the secondary shredder shall be less than 25 mm

Query 4 In serial no.3, component secondary shredder, MOC of Cleaning comb either we can have D2 or 4140.

Reply Yes, the MoC of the cleaning comb arrangement shall also be D2 or 4140.

Query 5 In serial no.6, component solid mixer, MOC of pan can be MSEP or MSFRP and the RPM can be in the range of 25 to 30

Reply The MoC of the solid mixer pan shall be Mild Steel fibre reinforced concrete. The RPM is already provided in the tender as 30 RPM

Query 6 In serial no.11, component portable flue gas analyzer, please confirm whether the CO2 measurement percentage ranging from 0to 20% or 0 to 40% or 0 to 50%.

Reply The CO2 measuring range shall be in the range of 0 – 40% and the details specifications are provided in the revised tender specifications.

Query 7 In serial no.12, component electrical control panel, whether we can have non-compartment panel and VFD controller/regulator can be mounted in panel front door side for easy RPM adjustment.

Reply The electrical panel board may be either non-compartmental or compartmental type, but the regulator for RPM controllers should be kept in front of the door so that the controllers can be accessed easily and also should have minimum noise and vibration while operation.

Query 8 In serial no.15, component container, please let us know the container specification with all other interior & exterior accessories, no. of doors & windows, insulation, no. of wall fan, A/C capacity, either exhaust fan is required, no.of lights (watts required).

Reply Please refer the revised technical specifications for the required details.

Query 9 In serial no.19, component plant lighting system, please consider the lighting pole either octagonal/polygonal or cylindrical pipe with bottom dia minimum 130 mm and top dia minimum 50 mm. Please let us know the scope of cable supply & scope of cable laying for each pole.

Reply The shape of the pole shall be preferably cylindrical. However, it can either polygonal or octagonal based on the supplier’s preference. The supply & cable laying for each pole are under the scope of the bidder (FRLS wiring arrangement).

Query 10 If fencing is required, please let us know the fencing material specification.

Reply The specifications are provided in revised technical specifications

Query 11 Please let us know the electrical incoming cable scope of supply, cable laying and termination for main electrical control panel.

Reply Electrical incoming cable supply, laying and termination for main electrical control panel are under the scope of the bidder and the details are provided in revised specifications.

Query 12 As a MSME enterprise, please consider the payment terms 20% in advance on submission of documents with bank guarantee, 50% on supply of machineries, 20% on Erection & commissioning and 10% after one month operation & maintenance against bank guarantee.

Reply Revised Payment terms

20% of the work order against completion of detailed

engineering and submission of drawings and against

equivalent bank guarantee

40% of the work order cost against the delivery of all

equipment at site and acceptance by CLRI

20% of the work order cost against the erection,

commissioning and testing

13% against successful trial run for a month of operation and

maintenance of the plant during that period

7% of the cost after the warranty period of One Year from date of installation and commissioning which can be paid to you after the trial run and maintenance period in case an equivalent bank guarantee is submitted.

Clarifications issued to M/s. R. V. Engineering Industries

Query 1 There are 2 nos. of shredders mentioned in the technical specifications-one for shredding the raw material to 75mm size, and the 2nd one to further shred it to 15mm size. Can this be integrated to a single shredder which shreds the raw material directly to 15mm size?

Reply The two shredders have been provided to avoid bubbling of waste like tender coconuts are circular in shape. Hence, two shredders with primary shredder with less number of teeth and secondary for size reduction has been provided.

Query 2 Time period for completion shall be 4 months from the date of approval of drawings and receipt of advance payment. Please clarify

Reply The completion time period of 4 months will be from the date of issue of purchase order.

Query 3 Site clearance shall be obtained immediately after the issue of purchase order.

Reply The site is already clear without any bushes and trees, the work can be started as soon as the purchase order is issued.

Query 4 Details of pyrolysis plant is required with its drawing to confirm the integration of pre-treatment plant to the pyrolysis plant.

Reply In the revised specifications, the integration part of the pyrolysis plant will be required only for supply and laying of the power cable to the pyrolysis unit for a power capacity of 18kW and existing screw conveyor from proposed electrical control panel.

The tender specification would stand changed to the above extent.

Tender Closing Date: 9th June , 2021 upto 3.00 P.M. (IST)

Technical Bid Opening Date: 10th June, 2021 at 3.00 P.M. (IST)