Pumping Apparatus Driver/Operator Handbook 3rd Edition · Proportion foam concentrate at rates form...

Transcript of Pumping Apparatus Driver/Operator Handbook 3rd Edition · Proportion foam concentrate at rates form...

Pumping Apparatus Driver/ Operator Handbook

3rd Edition

Chapter 14 — Foam Equipment and Systems

Summarize facts about principles of foam.

Learning Objective 1

14–1

Mechanical foams are the most common foams in use.

14–2

Click image to

play

Foam concentrate

Foam proportioner

Foam solution Foam

Driver/operators must understand the meaning of these terms.

14–3

CAUTION

Failure to match the proper foam concentrate to the type of fuel may result in an unsuccessful suppression attempt that could endanger firefighters.

14–4

Hydrocarbons Polar solvents

Specifically formulated foams should be used on each class of fire.

14–5

Class B fuels are divided into two categories

NOTE

Many modern fuels, including gasoline, are blended with up to 15 percent solvent additives. Treat these products as polar solvents during emergency operations.

14–6

Separates

Cools

Suppresses or smothers

Foam extinguishes and/or suppresses vapors by the following methods.

14–7

Proportioning is the act of mixing water with foam concentrate to form a foam solution.

14–8

Most foam concentrates are formulated to mix with 94 to 99.9 percent water

• Uses pressure of a water stream to induct (draft) foam concentrate into fire stream

Induction

Foam is proportioned using one of four basic methods.

14–9

(Cont.)

• Uses an external pump to force foam concentrate into fire stream at the proper ratio in comparison to the flow

Injection

• Simple but potentially inaccurate method of mixing foam concentrate and water

• Occurs when an appropriate amount of foam concentrate is poured directly into a tank of water

Batch mixing

Foam is proportioned using one of four basic methods.

14–10

(Cont.)

NOTE

It may be difficult to maintain the accuracy of batch mixing, especially after the initial batch has been used.

14–11

• Premeasured portions of water and foam concentrate are mixed in a container

• Used with portable and wheeled extinguishers, skid-mounted twin-agent units, and apparatus-mounted tank systems

Premixing

Foam is proportioned using one of four basic methods.

14–12

Pails Barrels Totes Apparatus tanks

There are four common methods of storing foam solution for most fire service applications.

14–13

REVIEW QUESTION

What are the various ways that foam works?

14–14

Distinguish among types of foam concentrates used in fire fighting.

Learning Objective 2

14–15

WARNING

Use Class A foam only on Class A fuels.

14–16

Formula includes hydrocarbon surfactants that reduce the surface tension of water in the solution

When used in conjunction with compressed air foam systems (CAFS), Class A foam provides excellent insulation qualities

Class A foam technology has only recently been widely accepted and used.

14–17

(Cont.)

CAUTION

As with any method of fire attack, the correct flow in gallons per minute (L/min) must be applied to safely and efficiently extinguish the fire.

14–18

May be used with

• Fog nozzles• Aerating foam nozzles, medium and high expansion devices• Compressed air foam systems

Shelf life can be as long as 20 years when stored properly

Because product is used in such small percentages, generally not a significant environmental concern

Class A foam technology has only recently been widely accepted and used.

14–19

As ratios are increased, expansion and drainage

characteristics of finished product will change performance

Follow commonly used guidelines for application

Class A foam concentrates may be mixed to as little as 0.1 to 1.0 percent.

14–20

Rates of application

Common application needs of Class A foam

Drain time plays a major role in effectiveness

Elements that affect breakdown

Be aware of these considerations when applying Class A foam.

14–21

Also used to suppress vapors from unignited spills involving these liquids

Concentrates consist of a synthetic or protein base

Shelf life

Different brands of concentrates should not be mixed together for storage

Same type concentrates may be mixed together for immediate use

Foam concentrates of the same type, manufactured to U.S. Military specifications may be mixed at any time

Impact on the environment may vary depending on product and manufacturer

Class B foam is applied to suppress fires involving flammable and combustible liquids.

14–22

Correct proportion for specific product is found listed on the outside of each container

May be used at different concentration depending on which fuel is involved

Some foam is formulated for use on both hydrocarbon and polar solvent fuels

Concentration for hydrocarbon fuels is normally one or three percent, while three to six percent is used for polar solvents

Class B foams are mixed in proportions from one to six percent.

14–23

Method used to aerate foam solution will create varying degrees of expansion

Generally described as being low, medium, or high

NFPA® 11 states that low expansion foam contains an air/solution ratio of up to 20 parts finished foam to foam solution

Medium expansion foam is commonly used at a rate of 20:1 up to 200:1

High expansion foam is used with an expansion rate from 200:1 to 1000:1

Foam expansion is an important characteristic to consider when choosing a foam concentrate.

14–24

Type of concentrate used

Whether or not fuel is on fire

Type of fuel that is on fire

Whether the fuel is contained or uncontained

The rate at which foam is applied depends on several variables.

14–25

To calculate the application rate available from a specific nozzle, divide the flow rate by the area of the fire.

14–26

WARNING

Do not enter a spill of unignited flammable liquid. An ignition source may cause the spill to ignite at any time.

14–27

Unignited spills do not require the same application rate

Ensure that sufficient foam production components required to achieve tactical objectives are available at the point of proportioning

Once application has begun, it should continue without interruption, from an uphill and upwind position until extinguishment is complete

Consider the following when applying Class B foam.

14–28

Some may create a thick heat resistant blanket, while others are thinner and spreading more rapidly

Certain foams produce a vapor sealing film or membrane

Other foam products may be used in large volumes to flood surfaces, or fill confined areas

Suppressing (smothering) prevents the release of additional flammable vapors

Types of foam are selected based on their properties and performance for likely applications and incidents.

14–29

Regular protein foams

Fluoroprotein foam

Film forming fluoroprotein foam (FFFP)

Aqueous film forming foam

(AFFF)

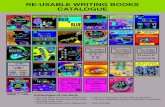

There are many types of foam used in the fire service.

14–30

When AFFF and FFFP foam is applied to a hydrocarbon fuel fire, several actions will occur.

14–31

CAUTION

When applying foam, be aware of the potential for burnback in previously covered areas where contact with hot objects may be present. This effect may be more apparent with AFFF foam.

14–32

Alcohol resistant AFFF concentrate is commonly available for use on polar solvents.

14–33

Generally used at a concentration of three or six percent

May be used on hydrocarbon fire at one to six percent proportion

When applied to polar solvent fuels, a membrane is created over the fuel

Should be applied gently to allow the membrane to form

Aspirating nozzles are generally best for preserving the membrane that forms on the surface of these products

Low water content provides less runoff and minimizes water damage

Common applications for high expansion foam include• Concealed space fires• Fixed extinguishing systems for specific industrial

hazards• Class A fire applications

High-expansion foam contains a detergent base and low water content.

14–34

REVIEW QUESTION

What are the uses of Class A foam and Class B foam?

14–35

Explain the operation of low energy foam proportioning systems.

Learning Objective 3

14–36

• Venturi effect created by pressure of water stream flowing through a restricted orifice

• Pressurized proportioning device injects foam concentrate into a water stream

Foam proportioning

devices operate by one of two

principles

• Reaches the nozzle• Discharged from the nozzle

This type of system

introduces air into the foam

solution when it either

Low energy foam systems impart pressure on the foam solution with the use of the main fire pump.

14–37

Follow manufacturer’s guidelines that specify the pressure and distance between eductor and appropriate nozzle

Uses Venturi principle to draft foam concentrate into the water stream

Several operating guidelines must be followed to achieve properly proportioned finished foam

In-line foam educators are basic foam proportioners that are designed to be attached to the pump panel or hose lay.

14–38

Built into self-educting nozzle rather than

attached to the hoseline

Requires foam concentrate be available at the point

where the nozzle is operated

Foam nozzle eductors operate under the same principle as an in-line eductor.

14–39

CAUTION

Use of a foam nozzle eductor may compromise firefighter safety. Firefighters cannot quickly move the hoseline and must abandon the supply of concentrate should they need to withdraw rapidly.

14–40

Pickup tube is located in the center bore of the nozzle

Design produces an overproportioned solution diluted by deflector plates in the nozzle

Major advantage is that pressure drop is much lower than most standard foam nozzle eductors

Self-educting master stream foam nozzles use a modified Venturi design to draw concentrate into its water stream.

14–41

Allows operator of fire pump and maintainer of foam concentrate supply to do so from a considerable distance

Supplied through hoseline from main fire pump

Water flowing through JRC creates Venturi effect

Overproportioned solution is further proportioned with water also supplied by the fire pump

Jet ratio controller (JRC) may be used to supply foam concentrate to a self-educting master stream.

14–42

REVIEW QUESTION

What types of portable foam proportioners are used in the fire service?

14–43

An installed in-line eductor system operates under the same principles as portable in-line eductors.

14–44

In some installations, a bypass proportioner is installed to reduce the friction loss across the eductor.

14–45

Around-the-pump proportioners are one of the most common types of installed proportioners used in modern apparatus.

14–46

NOTE

In order to prevent excess foam concentrate from being drawn into the eductor, the driver/operator must close the bypass valve whenever the line is not flowing.

14–47

Bypass-type balanced pressure proportioners feature the ability to monitor demand for foam concentrate.

14–48

Foam concentrate ratio is controlled by speed of positive displacement foam concentrate pump

Proportion foam concentrate at rates form 0.1 to 3 percent

Not usable with alcohol resistant foam concentrates

Offer ability to proportion any flow rate or pressure within design limits of equipment

Variable-flow variable-rate direct injection proportioners generally operate off of the apparatus electrical system.

14–49

Consists of a variable speed mechanism that operates a foam concentrate pump

Has advantage that the flow of concentrate matches the pressure demand

Has ratio controllers installed in the discharges, reducing the discharge area

A variable-flow demand-type balanced pressure proportioning system is also known as a pumped/demand system.

14–50

Generally used with Class A foam and regular AFFF concentrates

When refilling water tank, foam residue leftover on interior surface may cause frothing

Disadvantage of batch mixing is the entire tank is converted to foam solution

Difficult to maintain correct ratio when refilling unless tank is completely empty

Batch mixing or the dump in method is the simplest method of proportioning foam.

14–51

CAUTION

Conduct flushing operations in accordance with the SDS supplied by the foam manufacturer.

14–52

REVIEW QUESTION

What types of apparatus-mounted foam proportioners are used in the fire service?

14–53

Describe high energy foam generating systems.

Learning Objective 4

14–54

Tactical advantagesReach of fire stream is considerably longer than those

of low energy systems

CAFS system produces small uniform air bubbles that are very durable

Foam produced adheres to a fuel surface and resists heat longer than low energy foam

Hoselines containing high energy foam weigh less

May provide safer fire attack that allows effective reach from a greater distance

High energy systems introduce compressed air into foam solution prior to discharge.

14–55

(Cont.)

Limiting factorsIncreases the purchase price and maintenance

cost of new apparatus

Hoseline reaction may be erratic if the foam solution is not supplied to the hoseline in

sufficient quantities

In the event that a hose bursts, the compressed air will intensify the reaction of the hoseline

Additional training is required for personnel

High energy systems differ in that they introduce compressed air into foam solution prior to discharge.

14–56

CAUTION

To protect the attack team when using Class A foam, nozzle flow rates should be the same as those for plain water.

14–57

REVIEW QUESTION

What are the advantages and limitations of compressed air foam systems?

14–58

Distinguish among portable foam application devices.

Learning Objective 5

14–59

When using low energy foam systems, aeration and discharge functions are completed by the

aerating foam nozzle

Low expansion foams may be delivered by handlines or master

stream appliances

Once the foam concentrate and water have mixed, the solution must be aerated and delivered to the fuel.

14–60

NOTE

Foam nozzle eductors and some self educting master stream foam nozzles may also be considered portable foam nozzles. Those devices were described earlier in this chapter.

14–61

Firefighters often use handlines during foam fire fighting operations.

14–62

Smooth bore nozzle Fog nozzle

Cou

rtesy

of S

had

Coo

per/W

yom

ing

Sta

te F

ire M

arsh

al’s

Offi

ce.

(Cont.)

Firefighters often use handlines during foam fire fighting operations.

14–63

Air-aspirating foam nozzle

Large-scale flammable and combustible liquid fires often require delivery of an amount of foam beyond the capability of handlines

Perform in a similar manner to handline nozzles

Industrial foam pumpers and ARFF apparatus are often equipped with aerating foam master stream nozzles

Fixed flow or automatic fog master stream appliances may be used to deliver foam.

14–64

Water aspirating devices Mechanical

blowers

There are two basic types of medium-and high-expansion foam generators.

14–65

REVIEW QUESTION

What are the major types of portable foam application devices?

14–66

Identify reasons for the production of poor quality foam or the lack of foam production when using an in-line proportioner.

Learning Objective 6

14–67

Incorrect match between eductor and nozzle flow, resulting in no pickup

Air leaks at fittings may cause a loss of suction

Clogged proportioning equipment

Partially closed nozzle will result in a flow rate that will not allow the Venturi effect

Too long of an attack line on the discharge side of the eductor

Be aware of different causes of poor quality foam when placing a foam line into operation.

14–68

(Cont.)

Kinked hose

Nozzle placed too far above the eductor, resulting in excessive elevation pressure

Different manufacturers’ foam concentrates should not be mixed together

Different classes of foam should not be mixed

Be aware of different causes of poor quality foam when placing a foam line into operation.

14–69

REVIEW QUESTION

What are some causes of the production of poor quality foam or the lack of foam production?

14–70

Identify foam application techniques.

Learning Objective 7

14–71

Follows the same procedure as direct attack with water

Usually more effective due to Class A foam’s enhanced

extinguishing capabilities

A direct method of fire attack with Class A foam consists of applying finishing foam directly on burning material.

14–72

The roll-on method involves directing a Class B foam fire stream on the ground near the front edge of a burning liquid.

14–73

The bank-down method involves directing a foam fire stream onto a vertical surface near or within a pool of ignitable liquid.

14–74

The rain-down method is the most common method of application for aboveground storage tank fires.

14–75

REVIEW QUESTION

What are the differences between the direct application, roll-on, bank-down, and rain-down methods of applying foam?

14–76

Explain the environmental impact of foam.

Learning Objective 8

14–77

Severity of impact may vary based on concentration and type

Biodegradability is determined by the rate at which natural bacteria can degrade the foam

May result in destruction of vegetation and aquatic life in water

No foam concentrates, solutions, or finishing foam should be discharged into any body of water

The primary concern regarding the environmental impact of foam is the effect of finished foam after application.

14–78

REVIEW QUESTION

What can occur when foam solution makes its way to a natural water source?

14–79

Identify durable agents.

Learning Objective 9

14–80

Durable agents

Used as extinguishing agents and to pre-treat structures threatened by fire spread

Structurally and chemically different from Class A foam

Pose no adverse environmental impact

Once applied, surfaces become very slippery

Can be rehydrated for extended protection

Durable agents retain their fire retarding properties longer than Class A foam.

14–81

REVIEW QUESTION

What are some characteristics of durable agents?

14–82