Pulp & Paper Canada July/August 2013

-

Upload

annex-newcom-lp -

Category

Documents

-

view

225 -

download

5

description

Transcript of Pulp & Paper Canada July/August 2013

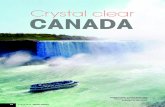

July/august 2013 www.pulpandpapercanada.com

An Official Partner of the Pulp and Paper Technical Association of Canada PAPTACPulp and Paper Technical Association of CanadaAssociation technique des pâtes et papiers du Canada

tour Domtar’s lignin Plant

PaPer machine clothing

PacWest revieW

Under PressUre

PulPPaPer

&

Over 100 years Of serving the industry

C a n a d a

Industry OutlOOk:

Canada +1 514 457 0000

US +1 800 347 1542

Kemira KemFlite™ Concept- Helps Your Paper Machine Take FlightKemira KemFlite™ concept has been developed specifically to address a sticky issue; wood pitch, white pitch, and stickies.

Kemira KemFlite concept combines our understanding of the papermaking process, broad deposit control product line and novel monitoring tools like Kemira Flyto™ and Kemira AutoFlite™ to create a custom solution for every sticky situation.

Our customers benefit with improved process and machine efficiency, less breaks, a cleaner process, and more first-grade tons. In addition, Kemira KemFlite reduces raw material usage resulting in cost savings. Simply put, with KemFlite you get improved paper quality and less customer complaints. For more information, please visit www.kemira.com/kemflite.

kemira oyj

kemira group

ad_PPC_Paper_eng_novdec_102212.indd 1 10/23/2012 9:36:19 AM

PPC JulyAug2013.indd 2 13-07-31 11:41 AM

www.pulpandpapercanada.com July/August 2013 PULP & PAPER CANADA 3

COVER STORY

12 Industry Outlook: Uneven GrowthFlush with cash and mounting demand for lumber products, forest products companies have the means and the opportunity to forge new business relationships and break out of traditional roles.

FEATURES

9 IT’s emerging role within maintenance’s best practices

The coming ISO 55000 standard for asset management could require significant IT involvement.

10 Betting on biochemicals: DomtarTruckloads of lignin are rolling out of Domtar’s Plymouth, N.C., mill. Taking a chance on large-scale production of lignin, Domtar has introduced this bio-based chemical to the market in a big way.

16 PacWest: Maximize your assetsThe industry’s Western conference delivered advice from experts and peers about reliability, maintenance and how to make the best of what you have.

MISSION STATEMENT: To promote the pulp and paper industry in Canada by publishing news of its people and their innovations in research, technology, management and financing, as well as forecasts of future trends.

Serving the industry since 1903.

July/August 2013 Vol. 114, No. 4A Business Information Group Publication

PRINT EDITION ISSN 0316-4004ON-LINE EDITION ISSN 1923-3515

For breaking news, visit www.pulpandpapercanada.com

PULPPAPER

&

OVER 100 YEARS OF SERVING THE INDUSTRY

C A N A D A

Cover image: Courtesy of www.naturallywood.com

20

Canada +1 514 457 0000

US +1 800 347 1542

Kemira KemFlite™ Concept- Helps Your Paper Machine Take FlightKemira KemFlite™ concept has been developed specifically to address a sticky issue; wood pitch, white pitch, and stickies.

Kemira KemFlite concept combines our understanding of the papermaking process, broad deposit control product line and novel monitoring tools like Kemira Flyto™ and Kemira AutoFlite™ to create a custom solution for every sticky situation.

Our customers benefit with improved process and machine efficiency, less breaks, a cleaner process, and more first-grade tons. In addition, Kemira KemFlite reduces raw material usage resulting in cost savings. Simply put, with KemFlite you get improved paper quality and less customer complaints. For more information, please visit www.kemira.com/kemflite.

kemira oyj

kemira group

ad_PPC_Paper_eng_novdec_102212.indd 1 10/23/2012 9:36:19 AM

IN EVERY ISSUE 4 Editorial

5 Opinion: FPAC

6 News

8 Opinion: FPInnovations

18 Technology News

20 Technology News – Paper Machine Clothing

21 Classified Ads

22 Bio-Economy

18

12

5

22

16

PPC JulyAug2013.indd 3 13-07-31 11:41 AM

Editorial

4 PULP & PAPER CANADA July/August 2013 www.pulpandpapercanada.com

EditorCINDY MACDONALD [email protected]

PublisherJIM BUSSIERE416-442-5600 ext. [email protected]

President, Business Information GroupBRUCE CREIGHTON

Vice President, Publishing ALEX PAPANOU

Executive Publisher, ManufacturingTIM DIMOPOULOS

PULP & PAPER CANADA (ISSN 0316-4004) is published by BIG Magazines LP, a div. of Glacier BIG Holdings Company Ltd., 80 Valleybrook Dr., Toronto, ON M3B 2S9

SUBSCRIPTION RATESCanada $52.95 per year; $71.95 for 2 years.Outside Canada $99.95 per year.Single copy $19.50. (All subscription prices exclusive of taxes.)

The editors have made every reasonable effort to provide accurate and authoritative information but they assume no liability for the accuracy or completeness of the text or its fitness for any particular purpose.

All rights reserved. The contents of this publication may not be reproduced in part or in full without the consent of the copyright owner.

From time to time, we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods. Phone: 1-800-668-2374; fax: 416-442-2191; e-mail: [email protected]; mail to: Privacy Officer, Business Information Group, 80 Valleybrook Dr., Toronto, ON M3B 2S9

POSTMASTER:Please forward 29B and 67B to 80 Valleybrook Dr., Toronto, ON M3B 2S9. Legal deposit Quebec National Library.

Publications Mail Agreement No. 40069240

A Business Information Group Publication Print edition ISSN 0316-4004 On-line edition ISSN 1923-3515

“We acknowledge the financial support of the Government of Canada through the Canada Periodical Fund (CPF) for our publishing activities.”

Sustaining member, Pulp and Paper Technical Association of Canada;

Member, Canadian Business Press and Audit Bureau of Circulation.

PRODUCTION

Art DirectorCAROLYN [email protected]

Circulation ManagerCINDI [email protected]

Market Production ManagerKIMBERLY [email protected]

Print Production ManagerPHYLLIS [email protected]

Reprint requests: MARISA SEMENTILLI 416-510-6829

News and Press Releases [email protected]

ADVISORY BOARDRichard Foucault Greg HayDr. Richard KerekesBarbara van LieropDr. David McDonaldDennis McNinchDr. Yonghao NiBryant ProsserDr. Paul StuartRoss Williams

EDITORIAL/SALES OFFICES80 Valleybrook Dr., Toronto, ON M3B 2S9Phone: 416-442-5600. Toll Free: cda 800-268-7742;

usa 800-387-0273

Observations from the road

Cindy MacdonaldEditor

I was on the road a lot in May and June, attending conferences and media events. While each voyage has a specific purpose

and will result in an article, mingling with other people involved in our industry always leads to unrelated newsworthy tidbits.

My visit to Plymouth, N.C., to celebrate Domtar’s entry to the lignin market, included a tour of the fluff pulp mill. Our tour guide, as we approached the end of the NC5 fluff pulp machine, pointed out some new equipment. Roll handling was upgraded to convert what used to be a manual movement of the pulp rolls to an automatic function. The tour guide proudly told us that the company made the upgrade specifically to reduce the incidence of soft tissue injuries. “There’s no other payback,” he said. Kudos to Domtar.

At the PwC conference, Don Roberts of CIBC suggested the Canadian industry should watch the development of cellulosic biofuels in the U.S. over

the next 24 months. Seeing which companies fail and which succeed will teach us a lot, he says.

I also spent a couple of days in Montreal at the BIO World Congress, learning about biochemicals and biofuels. It seems that wood biomass cannot compete with other raw materials in the production of ethanol.

A source at FPInnovations told me there is some research being directed to high-value chemicals derived from wood, but it will likely take 5-10 years to develop a market.

The market for green chemicals appears to be governed by some combination of policy decisions, ever-changing societal perceptions and corporate strategies. Right now, chemical com-panies are showing an interest in bio-based chemicals, so at least the corporate element is in our favor.

After attending the BIO conference, I’m convinced that wood is not a serious contender as a raw material for commodity green chemicals. If an application for forest-based biochemicals does emerge, it is not likely to be a high-value, high-volume application.

Successful applications of wood-based chemicals will likely be unique to local circumstances, such as using bio-char to filter tailings from Alberta’s oil sands, or adding Canadian crystalline nanocellulose to drilling mud. Success will come from supply and demand and knowledge all occurring in the same region.

After all my work-related travel, I spent a couple of days in July becoming intimate with the operations of an urban trauma centre when a close friend was injured. For patient care, this particular hospital chooses disposable wash basins and urinals made of molded pulp. Very cool to see pulp products in an environment dominated by plastics.

PPC JulyAug2013.indd 4 13-07-31 11:41 AM

Opinion

www.pulpandpapercanada.com July/August 2013 PULP & PAPER CANADA 5

During our 100th anniversary celebration at FPAC we’re hav-

ing fun hearing from former employ-ees and veterans of the forest indus-try from across Canada.

We established a Facebook page and are encouraging people to sub-mit photos and share stories from the past. If you have some stories or photos you think would be interest-ing additions to our timeline, please pass them along.

As I travel the country telling people about our proud past and our promising future, I’m always interested to hear local stories of adventure and entrepreneurship. I hear quiet Canadian pride – pride in their community and the contribu-tion they make to society. And I hear stories about interesting characters in our industry – we do seem to have lots of interesting personalities in this business.

One day I met a friend, George, for lunch and was telling him about my new job at FPAC. I explained

that 2013 is the 100th anniversary of FPAC and we had been looking through boxes of archives. One box contained costumes from the Pulp and Paper Pavilion at Expo ’67 in Montreal, back when the pulp and paper sector was Canada’s largest industry.

George looked at me and said, “My wife worked in that pavilion.” What a small world! Of course, I immediately said that she had to come into the office, see some of the archive materials and tell us a little about her experiences as the lead hostess at the Expo ’67 pavilion.

A couple of weeks later Donna Haynal came into our office and told me the Pulp and Paper Pavilion was one of the biggest hits at Expo ’67. The pavilion had three components. The first pod was a skit with a mix of animation projected on the walls and live actors telling the story of the pulp and paper industry. The second pod was a live-action skit of a ‘wacky professor’ in a white lab coat explain-

Remember the Pulp and Paper Pavilion at Expo ’67?By David Lindsay, President and CEO, Forest Products of Canada

ing the science behind the pulp- and paper-making processes. Finally, as you exited, you could work with some interactive displays to make your own paper.

One of the most interesting discoveries from our walk down memory lane was that Donna still fit in her old hostess costume (her initials were inked on the inside collar). Here is a 1967 photo from Donna and a photo we took of her in the same costume in the FPAC office.

This is an excerpt from the President’s Blog, a Dialog about the Forest Sector. To read more, go to: www.fpac.ca/index.php/en/blog.

PPC JulyAug2013.indd 5 13-07-31 11:41 AM

6 PULP & PAPER CANADA July/August 2013 www.pulpandpapercanada.com

Industry News

Molded pulp plant planning upgrades, switch to natural gasA $16.5-million upgrade is in the works for CKF Inc., an East Coast manufacturer of molded pulp and foam products. The project will include a conversion to use compressed natural gas, which is expected to save the company up to $1.8 million per year.

The government of Nova Scotia is supporting CKF Inc.’s plan to purchase new machinery and upgrade equip-ment. The province will lend CKF up to $8.7 million for the company’s $16.5-million expansion, and provide $2.6 million in incentives, if the com-pany completes the capital upgrades. “New equipment and the use of com-pressed natural gas will allow us to be more competitive, and a cleaner, greener operation,” said Michael Green, vice-president of finance at CKF. Green told the local newspaper, The Hants Journal, that the company plans to add a fourth moulding machine to the plant, upgrade sorting equipment and tap into the high demand healthcare sector — all

As part of an agreement with the new owners, the New Brunswick government may provide a repayable loan of up to $35 million with a matching loan from the majority ownership group. The New Brunswick government will convert pre-ferred shares in Twin Rivers to common shares, representing 5% of equity of owner-ship in the company as well as a restructur-ing of an existing letter of credit.

Digital archiving, cellulosic biofuels among disruptive technologiesA forecast of disruptive technologies in the pulp and paper supply chain has been released by Smithers Pira. The new study identifies and profiles the top 25 disruptive technologies most likely to impact the global pulp and paper supply chain over the next 10 years. With transition tables highlighting each technology’s likely impact on the global pulp and paper supply chain, this report details how current and emerging trends will shape the industries.

Some of the top 25 disruptive technolo-gies identified by Smithers Pira are: Internet shopping and e-commerce; news on the Internet; electronic books; innovative pack-aging; digital archiving; on-demand print-ing; tablet computing and texting; advances in computer power; green marketing and laws; cellulosic biofuels; and exporting of recovered fibres.

Ten-Year Forecast of Disruptive Tech-nologies in the Pulp and Paper Supply Chain to 2023 is available as a hard copy, an electronic version, and a global intranet license. Smithers Pira is a global testing, consulting and information services busi-ness with expertise in the packaging, paper and print industry supply chains.

Catalyst brings new coated grade to marketCatalyst Paper has expanded its mechani-cal printing paper range with the addi-tion of Ascent, a coated #3 paper. Made at the Port Alberni, B.C., mill on the only coated mechanical paper machine in Western North America, Ascent went from idea to market in the space of a few short months.

“Our product development team brought tremendous cross-disciplinary expertise to the initiative, along with the

while operating in an increasingly environ-mentally-friendly manner.

CKF Inc. is a family-owned company that manufactures Royal Chinet and other molded pulp and foam products for retail, food service, and packaging industries in the Canadian and U.S. markets.

Brookfield sells off its stake in Twin RiversTwo New York-based private investment firms have acquired a controlling interest in Twin Rivers Paper Company, Inc. from Brookfield Asset Management Inc. Terms of the agreement with Blue Wolf Capital Part-ners and Atlas Holdings were not disclosed.

“We are turning our attention to build-ing a growing, profitable business,” said Tim Lowe, newly appointed chief execu-tive officer of Twin Rivers Paper. “We are focused on bringing new resources, operational expertise and a commit-ment to the future of the business.” Twin Rivers produces specialty papers and lumber at facilities in Edmundston and Plaster Rock, New Brunswick, and Mada-waska, Maine.

Supreme Court opposes random alcohol testing in Irving caseA court case involving random alcohol testing by Irving Pulp and Paper Ltd. has been decided by the Supreme Court. The court ruled that the policy imposed by Irving at the company’s Saint John, N.B., kraft mill in 2006 was unreasonable and was properly rejected by a labour arbitration board.

Dave Coles, president of the Communications, Energy and Paperworkers Union of Canada, says the decision is a victory in the battle to protect workers’ privacy rights.

According to CEP, in 2006, Irving Pulp and Paper unilaterally adopted a policy of mandatory random alcohol testing for employees in safety sensitive positions. CEP Local 30 filed a grievance challenging the policy after a worker was chosen randomly by a computer program to take a breathalyzer test.

J.D. Irving issued the following statement: “We respect the decision issued today by the Supreme Court of Canada. We will be reviewing the decision and have no further comment at this time.

“Our focus has and continues to be the safety of our co-workers and communities where we have operations.”

Supreme Court decides on tax implications of selling a timber licenceA Supreme Court decision in late May decided a long-running tax battle between Daishowa-Marubeni International and the federal government in favor of the forest products company.

On May 23, 2013, the Supreme Court of Canada issued a decision in Daishowa-Marubeni International Ltd.’s case dealing with the tax treatment of future obligations that are assumed by a purchaser of assets.

According to a commentary on the case from Cassels Brock & Blackwell LLP, at issue the Daishowa case was whether the estimated cost of reforestation obligations assumed by a purchaser of a timber licence should be included in computing the seller’s proceeds of disposition. The Supreme Court held that the estimated cost of the reforestation obligations should not be included in the seller’s proceeds of disposition.

PPC JulyAug2013.indd 6 13-07-31 11:41 AM

www.pulpandpapercanada.com July/August 2013 PULP & PAPER CANADA 7

Industry News

understanding that a new product had to be hands down excellent to meet the qual-ity expectations of customers when there is so much choice in the marketplace,” said Tom Crowley, senior vice-president, sales and marketing.

Ascent is said to offer offers brightness, superior opacity and excellent printabil-ity making it suitable for magazines, cata-logues, brochures and commercial and direct mail applications.

Demo plant for cellulosic ethanol receives operating fundsWoodland Biofuels Inc. is receiving a contribution of up to $800,000 from the federal government to operate a plant that will produce low-cost biofuel from waste.

“We expect to the plant to show that we can produce ethanol from waste for about half of what it costs to produce gasoline at today’s oil prices,” said Greg Nuttall, president and CEO of Woodland Biofuels.

FedDev Ontario funding for Wood-land Biofuels has enabled the company to attract up to an additional $2 million in venture capital financing through the MaRS Cleantech Fund.

The process used by Woodland Bio-fuels involves gasification of the biomass, followed by catalyzed pressure reduction to convert the syngas to ethanol.

Woodlands’ vice-president of engineer-ing, Doug Gray, told KPMG’s In Business magazine (Feb. 2013) that the system requires no outside chemicals or extra hydrogen to produce the ethanol.

Metso pulp, paper and power units return to Valmet rootsMetso will resurrect the Valmet name as it splits off its pulp, paper and power busi-nesses from its mining, construction and automation units. Metso’s directors have approved a demerger plan to divide the operations into two companies: Metso Corporation and Valmet Corporation.

The company says a demerger offers the best potential for its businesses to utilize their respective strengths in their customer industries faster and more efficiently.

Pasi Laine will be president and CEO of the new company.

Metso Corp. was created in 1999 as the result of a merger between Valmet and Rauma.

Domtar continues to expand personal care divisionDomtar has acquired the largest manufac-turer and supplier of store brand infant diapers in the United States, Associated Hygienic Products (AHP), for $272 million.

“The acquisition of AHP will provide meaningful market expansion opportuni-ties and innovative product development

capabilities with our existing Personal Care business, as well as synergies to the bottom line,” said John D. Williams, president and CEO of Domtar.

This is Domtar’s fourth transaction in the personal care sector in two years. Wil-liams expects the company’s personal care division will reach more than $200 million in annualized EBITDA by 2017.

Pump failure delays Fortress co-gen projectThe turbine component of the co-generation project at Fortress Paper’s Specialty Cellulose mill in Thurso, Que., has operated successfully, but the failure of a high-pressure water pump has delayed the completion of the project. The co-gen plant was expected to be operational by the end of the second quarter of 2013.

Fortress Paper announced July 2 that the water pump and a backup pump had failed. The pump will be either repaired or replaced.

Prior to this setback, the turbine component of the cogeneration project was successfully synchronized to the power grid and had operated up to 4 megawatts without incident, Fortress reports.

Fortress re-thinking Lebel-sur-Quevillon mill conversionPresenting their first quarter results, Fortress Paper executives expressed confidence that the company’s dissolving pulp mill in Thurso, Que., can reach its operational targets, but there’s less confidence about the company’s second mill conversion project. Engineering design for the Fortress Global Cellulose conversion project at Lebel-sur-Quevillon, Que., is almost complete, but Fortress CEO Chad Wasilenkoff said the company is reviewing its options for the mill and “due to changing economics and market conditions, there is no assurance that the FGC mill project will proceed to completion as previously planned.”

Wasilenkoff said the company is evaluating strategic options for the Fortress Global mill, such as joint ventures or partnership opportunities, and is comparing the Lebel-sur-Quevillon project with other options for shareholder value creation.

“The economics of LSQ make sense, but it’s going to be challenging for us taking this on 100%.” The current estimate of the cost for the conversion project is $250 million, plus an additional $70-$100 million for working capital.

A decision regarding the LSQ mill is expected early in the third quarter.

Digester building at Fortress Paper’s sdissoving pulp mill in Thurso, Que.

PPC JulyAug2013.indd 7 13-07-31 11:41 AM

8 PULP & PAPER CANADA July/August 2013 www.pulpandpapercanada.com

Industry News

Commissioning underway for biomass co-gen at Port HawkesburyThe biomass-fueled Nova Scotia Power co-generation plant at the Port Hawkesbury Paper mill has already produced some power and was expected to be in full production by the end of June, according to the Cape Breton Post.

Roger Burton, the utility’s senior director of projects, told the newspaper that testing is underway on the different components at the $200-million facility located at the Port Hawkesbury Paper site in Point Tupper, N.S.

The facility will burn biomass to produce steam and electricity.

Resolute turns on turbine and green power output at Thunder BayResolute Forest Products Inc. officially inaugurated on May 14 a major power island producing green energy at its pulp and paper operation in Thunder Bay, Ont. The power island includes a refur-bished and upgraded wood-waste boiler and a new 65-megawatt condensing turbine. Approved by Resolute in early 2011, the $65-million project took just over 21 months to complete.

“The power island is a strategic addition to Resolute’s Thun-der Bay facility,” stated Richard Garneau, president and CEO. “It will reduce the mill’s energy costs as well as maximize our local woodlands, sawmill, pulp and paper, and energy operations by

fully utilizing forest-based biomass to produce green electricity.” The green power produced will be sold to the Ontario grid

under a power purchase agreement between Resolute and the Ontario Power Authority.

Catalyst sells Elk Falls mill siteCatalyst Paper has sold its Elk Falls industrial site and related assets to Quicksilver Resources Canada Inc., a Calgary-based corporation with extensive natural gas holdings.

The $8.6 million sale includes a fully serviced, 400-acre indus-trial site and adjacent property near Campbell River. The site formerly housed the Elk Falls pulp and paper mill which began operation in 1952, was indefinitely curtailed in 2009 and closed permanently in 2010.

FPAC and members still committed to boreal agreementDespite animosity between some of the participants, the companies who signed the Canadian Boreal Forest Agreement (CBFA) are still committed to its principles, says David Lindsay, president and CEO of the Forest Products Association of Canada (FPAC).

In mid-May, environmental groups involved with the CBFA declared they would no longer negotiate with Resolute Forest Products regarding areas in northwest Ontario and Quebec.

Although a relatively new development, 3D printing technol-ogy has already been

used to successfully make objects from food to jewellery, to clothes and art pieces.

A 3D printer lays down thin layers of material much like regular printers, except it deposits layers on top of lay-ers to create three dimensional objects. Increasingly, they are being used to make items out of plastic, metal, glass, ceramic, and even food items like sugar, chocolate, mashed potatoes and living cells.

Although it was first invented in the mid 1980s, 3D printing has seen tremen-dous growth only since 2009 and is now becoming a “must-have” technology in many industrial fields.

The process is considered by the global research firm McKinsey as one of 12 dis-ruptive technologies promised to deliver major economic impact to the future global economy.

FPInnovations has entered the 3D

printing adventure by purchasing a 3D printer and using it to demonstrate the potential applications of new biomateri-als such as cellulose filaments, crystalline nanocellulose and lignin.

“The increasing demand for printed electronics is bringing different indus-tries together: printing, paper, packag-ing and electronics. This is creating new applications and markets for paper-based products as they are green, disposable and biodegradable,” said Xuejun Zou, research manager, Paper, Packaging & Consumer Products, at FPInnovations. “The emer-gence of 3D printing will help accelerate the acceptance of biomaterials derived from wood fibres in the marketplace to replace oil-based products.”

Anticipated products include proto-types, building system parts and molds which can be found in virtually every industrial sector. 3D printed objects incorporating biomaterials promise great benefits, such as the development of products that have enhanced physical properties (hardness, stiffness, satisfac-

tion of tactile impression) and biodegrad-ability. One example in the electronics industry concerns 3D-printed interface components for electronic devices with a modified cellulosic nanomaterial that could integrate sockets, interactive fea-tures and actuators.

Printed electronics is a great example of technology where 3D printing can help decrease the time between R&D and mar-ket by many orders of magnitude.

True enough, biomaterials from the pulp and paper industry may be applied in the next generation of intelligent/smart packaging, flexible displays or low cost and disposable diagnostic devices, but investors and partners will need to experi-ence the product’s potential before buying into the adventure. 3D printing promises to do just that.

For more information, please contact Xuejun Zou ([email protected], 514-630-4132).

Additional reporting by Jean-Luc Bernier, scientific writer, FPInnovations.

3D printing: new opportunities for packaging and biomaterialsBy Jennifer Ellson, senior communications specialist, FPInnovations

PPC JulyAug2013.indd 8 13-07-31 11:41 AM

Opinion

www.pulpandpapercanada.com July/August 2013 PULP & PAPER CANADA 9

Within the next year, new ISO 55000 standards are expected. ISO 55000 is a set of three standards designed to create

common language, concepts and measures of quality in asset man-agement practice. It is an important step, as asset management impacts the financial performance, reliability, safety, environment and even the overall competitiveness of an organization. With so much at stake, the adoption of ISO 55000 to provide a structured asset management framework is critical. It can be anticipated that, like ISO 9000, ISO 55000 will become a standard that investors, insurers, and regulators will look for to ensure organizations are striving for best operational practices and performance.

The reason for the standard is clear: well-managed assets are essential for cost containment, price management, reliability, return on investment, and increased overall asset value. ISO 55000 compliance will help establish a competitive advantage by using a structured approach to asset management over an asset’s lifecycle. This standard methodology for controlled asset management can drive cost savings and reliability improvement.

While the role of maintenance and reliability are clearly defined within the standard, the role of IT is less obvious. ISO 55000 does not define the role of IT; in fact, the standard is very agnostic in terms of what systems are used or should be selected to facilitate compliance. No doubt, to achieve compliance standard IT support such as system availability, communication systems and reporting are required, but a closer look at the standard implies significantly more IT involvement.

There are four key areas IT can focus on to help a transition to ISO 55000:

1. Detailed knowledge of enterprise asset management (EAM) systemAs you might expect, the ISO 55000 standard does not dictate that a particular set of IT products be implemented; rather, it outlines specifications for IT governance and control that are typically met using applications capable of encompassing the entire asset life cycle and making information easily available to all stakeholders. This is the role of the enterprise asset management system (EAM).

Many asset management applications, such as IBM’s Maximo, SAP’s EAM, Invensys’ Avantis and others, have positioned them-selves to support ISO 55000 initiatives. These complex asset man-agement applications are very flexible in terms of maintenance practices, asset tracking, history recording, workflow, reporting and more. The issue becomes not whether such an application can be used for ISO 55000 compliance but if the IT team managing the system can configure it to do so efficiently.

Asset management reporting from within the EAM will require that data be readily accessible on asset condition, performance, activities, costs, and history. Further, asset lifecycle trending may be used as a basis for data-driven decision-making and creating a

predictive maintenance environment. From a financial perspec-tive, information about lifecycle costs, capital investment criteria, and operating cost is essential. All of this information needs to be reported from the EAM and depending on the asset, perhaps even in real time.

It will be the responsibility of IT to keep these systems run-ning, current, and configured to support ISO 55000 compliance. Just how do IT members know how to configure an application for ISO 55000 compliance? That brings us to the second point.

2. Detailed knowledge of ISO 55000In order to manage the asset management application effectively and to provide necessary asset reporting and standard compliance, it is very important for the IT team to have a clear knowledge of ISO 55000 and its goals and requirements. A detailed knowledge of the standard helps provide a better understanding of how the EAM application needs to be configured and managed. Familiarity with the standard enables IT to help align the asset management approach with overall business strategy and maximize uptime of mission-critical equipment. To do this, IT departments should understand:

• asset management best practices;• the asset life cycle;• the relationship between asset management and risk

management;• the functional condition and performance of assets;• the impact of downtime of an asset.

Perhaps most importantly, ISO 55000 awareness provides IT, and any others who study the standard, with an advanced level of understanding of the importance of asset management to the organization’s success.

3. Understanding of how an asset fits within the production environmentTo understand the types of reporting required and to support the asset within the ISO 55000 framework and the EAM, the IT team must understand how assets function within the production environment. Each asset may vary in terms of its importance to production and risk factor. Actively monitoring the condition of thousands of assets in a mill may be difficult, but pinpointing and focusing on those assets that are the greatest threat to production loss and downtime is a great place to start.

With knowledge of the standard and the asset itself and the ability to translate the ISO 55000 requirements into the EAM, it should be possible to:

• Monitor the condition of key assets: Built into the EAM are systems to detect defects or build reports to identify trends to isolate the condition of an asset.

IT’s Emerging Role within Maintenance’s Best Practices

By Mike Harwood and Alistair Skey, Zellstoff Celgar

Continued on page 11

PPC JulyAug2013.indd 9 13-07-31 11:41 AM

10 PULP & PAPER CANADA July/August 2013 www.pulpandpapercanada.com

Speakers at PacWest’s opening forum had concrete suggestions for the mill

personnel in the audience, suggesting they need to get out from the “tyranny of the urgent” and put in place better mainte-nance management systems.

The sage advice about mill operations and management continued throughout the four-day conference, dispensed by both experts and peers. The PacWest conference, an annual event of PAPTAC’s Pacific and Western Branches, ran from June 12-15 at Sun Peaks, B.C. The theme this year was “Improving performance through optimization and reliability.”

“A lot of us are finding this year that we are really focused on getting the most out of the assets we have, debottleneck-ing, etc.,” said conference chair Bill Adams (Domtar). The conference theme evidently struck a chord with other mill personnel. Almost 50% of the conference delegates work in pulp and paper mills.

PacWest program chair, Brian Grantham (West Fraser – Hinton Pulp), said: “The value in this conference is the gems you find and send back to the mill to put into action.”

There were 26 papers presented at

PacWest, in addition to several short courses, PAPTAC community meetings, the trade fair and roundtable meetings for maintenance managers and pulp machine superintendants.

A closer look at maintenanceReliability experts speaking at PacWest commented that the manufacturing world is familiar with KPIs to measure perfor-mance, but when it comes to reliability and maintenance, most companies are only looking a high-level measures that do not specifically evaluate the performance of the maintenance department.

On the subject of maintenance business practices, Robert Landau, senior princi-pal with Poyry Management Consulting, recommended the following performance indicators for the maintenance team:

• schedule attainment (world class: > 95%),

• emergency work (world class: < 5%),• work orders completed on time

(world class: > 95%),• startup effectiveness (world class:

> 95%),• rework (world class: < 5%).

Measures of this type give the maintenance

department a greater sense of account-ability and transparency, says Landau. Good maintenance business practices can reframe the definition of success for maintenance personnel, he added.

Ian McKinnon, as a principal partner in the training firm Reliabilty Solutions, teaches that if companies want reliability in their manufacturing operations, then maintenance and troubleshooting must always be performed in a known, precise, disciplined and documented manner. He noted that reliable manufacturing is not a core business value of most companies yet, although he has hopes that it will someday join safety and sustainability as core values for pulp and paper producers.

Capturing knowledgeA concern frequently aired among mill personnel at PacWest is the amount of knowledge being lost as experienced staff retire. One person noted, “We lost 22 years of experience in the last year.”

Peter Lovell of Canfor’s Prince George Pulp and Paper, commented that the mill’s implementation of an asset management program “put us on the path of knowing that we can’t rely on just the engineers

Reliabilty expert Ian McKinnon says maintenance and troubleshooting must be disciplined and documented.

New technologies and equipment can be explored at the PacWest trade show.

Maximize your assetsBy Cindy Macdonald, editor

Conference Report

PacWest delivered advice from experts and peers about reliability, maintenance and how to make the best of what you have

PPC JulyAug2013.indd 10 13-07-31 11:41 AM

12 PULP & PAPER CANADA July/August 2013 www.pulpandpapercanada.com

Market Trends

Betting on biochemicalsBy launching large-scale production of lignin, Domtar has introduced this bio-based chemical to the market in a big way.

By Cindy Macdonald, Editor

www.metso.com

Domtar successfully started-up the world’s first commercial installation of LignoBoost technology. The equipment is integrated with the Plymouth North Carolina pulp mill. The LignoBoost process separates and collects lignin from pulping liquor. This is an important breakthrough for Metso’s patented LignoBoost technology and provides the Plymouth NC mill with numerous benefits.

Successful cooperation - world’s first

Domtar

Plymouth

North Carolina

USA

L

Congratulationson the Start-upof the World’s First Commercial Installation of L ignoBoost

TM Technology

The Metso Team L

LignoBoost_PP.indd 1 13-06-20 10:42

Truckloads of lignin are rolling out of Domtar’s Plymouth, N.C., mill.

Employees in the lignin separation facility call the trucks headed to external customers “money trucks”, as opposed to the loads destined to be used within the mill site as a bio-based fuel.

Already, Domtar has completed com-mercial transactions for lignin with both regional and international customers, for prices in the range of US$600-US$900. The company says it has more than 100 active customers or potential customers engaged.

“We are very committed to the long-term future of this business,” said Domtar CEO John D. Williams at the ribbon-cut-ting ceremony in June for the new lignin removal plant.

Domtar’s long-term goal for the Bio-Choice lignin product line is to have mul-

tiple mills producing multiple grades, from different wood sources, including modified or upgraded lignin grades.

The Plymouth lignin separation plant has been operational since March. It cur-

rently produces about 30 tons/day of lignin, using Metso’s LignoBoost process. Produc-tion is expected to be 75 tons/day by the fourth quarter.

But even with commercial quantities available, it will take time to build mar-ket demand. Domtar senior vice-president Mike Edwards summarized the whole market development quandary for bio-chemicals this way: “Until we get a higher value for the lignin, it’s hard to justify [the investment].”

More lignin, more pulpThe mill in Plymouth has undergone various transformations since its inception in 1937. Under Domtar’s reign, the mill was repurposed in 2010. An investment of US$85 million changed it from a facil-ity with two fine paper machines and a

fluff pulp line to one that produces strictly fluff pulp (444,000 ADMT/y). CEO Wil-liams says the switch to fluff pulp “has enabled us to build out our busi-ness and invest in our customers,” referring to the genesis of Domtar’s personal care business, which includes the pur-chase of the Attends line of personal incon-tinence products and diaper manufacturer Associated Hygienic Products. This new rev-

enue stream is expected to bring in EBITDA of US$200 million by 2017. “This has had a huge influence on the whole strategy of our organization,” Williams states.

The changeover to fluff pulp left the

mill uniquely suited to this lignin project because the process was out of balance, with the recovery boiler loaded to more than 100%.

Because the lignin removal process reduces the load on the recovery boiler, it has the potential to allow the mill to pro-duce more pulp.

Since starting up the lignin separation facility, the mill has been able to increase the operating rates of the recovery boiler. “We’ve incrementally been able to push up the solids burning at the recovery boiler,” says Marty Brian. “We’re optimistic. The early returns are positive.”

In its latest configuration, the Plymouth mill is also leading the charge for Domtar’s fibre innovation projects. Bruno Marcoccia, director of R&D for the company, explains that in order to penetrate a market with a new product, you have to first demonstrate you can produce it regularly and with con-sistent quality. That’s the job of the crew at Plymouth.

Tour participants are shown here beside the vacuum press that is used to squeeze excess moisture from the lignin cake.

Domtar CEO John D. Williams with plastic parts molded from lignin. The injection molding was done by the National Research Council’s Industrial Materials Institute in Boucherville, Que.

PPC JulyAug2013.indd 12 13-07-31 11:41 AM

www.metso.com

Domtar successfully started-up the world’s first commercial installation of LignoBoost technology. The equipment is integrated with the Plymouth North Carolina pulp mill. The LignoBoost process separates and collects lignin from pulping liquor. This is an important breakthrough for Metso’s patented LignoBoost technology and provides the Plymouth NC mill with numerous benefits.

Successful cooperation - world’s first

Domtar

Plymouth

North Carolina

USA

L

Congratulationson the Start-upof the World’s First Commercial Installation of L ignoBoost

TM Technology

The Metso Team L

LignoBoost_PP.indd 1 13-06-20 10:42PPC JulyAug2013.indd 13 13-07-31 11:41 AM

14 PULP & PAPER CANADA July/August 2013 www.pulpandpapercanada.com

INDUSTRY OUTLOOK:

If you’ve been hearing “things are looking up for the forest products industry,” it

probably refers to the lumber sector, not pulp and paper.

The global wood products industry may be entering a “super-cycle” of flat log sup-ply and rising demand, but in pulp and paper growth is less vigorous. “The longer-term trend is still not a rosy picture for some paper grades,” says Bruce McIntyre, a consulting partner at PwC. “Bright spots for mature markets are tissue products and adult incontinence products.”

McIntyre was one of the experts speak-ing at PwC’s Global Forest Products Out-look Conference in Vancouver last May. He is Canadian leader of PwC’s forest, paper and packaging practice.

Rhetoric at this year’s conference was less about transformation of the forest products industry, and more about how to take advantage of the opportunities presented by changing conditions in the industry.

Michael Vermette, a partner and senior vice-president at PwC notes that many things have changed in the pulp and paper sector since the last period of good times. “It’s a very different landscape today from what it was seven years ago.” Major restruc-turings have occurred (Resolute Forest Products, Catalyst Paper) and we’ve seen a significant new owner emerge in the pulp

market (Paper Excellence).In times of rapid growth, says Vermette,

companies are going to have to figure out the optimal business combinations to over-come challenges.

“Ask yourself, are we ready for the great opportunities that are about to present themselves to the forest products industry?”

Conference participants were also advised that consolidation of the forest products industry and its supply chain is not over. McIntyre notes that forest prod-ucts companies’ current cash position will likely be used to pursue consolidation. As well, foreign companies are eyeing Cana-dian acquisitions.

Kevin Clarke, former CEO of Catalyst Paper Corp., agrees. He expects the consoli-dation of the manufacturing base and the sales channel will happen at the same time.

Companies have more cashThe forecast from Craig Wright, chief econ-omist for Royal Bank of Canada, is for 3.5 to four per cent global growth overall, with established economies running a few points less. He said some of the more extreme risks that were a concern six months ago have resolved themselves.

Wright noted that corporations are sitting on more cash than usual, equal to about 30 per cent of GDP. Consequently, we should see more of this money put

to work as share buybacks, mergers and acquisitions.

According to Wright, most commodi-ties are above their 25-year averages right now (such as pulp, zinc, potash, lumber). There’s been a long 10-year run of rising commodity prices, but Wright thinks this is starting to level off.

His forecast for the US dollar exchange rate is a little softer than parity, about 95 to 97 cents through to 2014.

Wright says he does not expect to see interest rates reach five per cent in the next 10 years. But, “at some point interest rates need to go back to normal. Keeping rates too low for too long is a risk.”

Supply/demand imbalanceEach year in May, the PwC conference joins forces with a few other forest indus-try events in Vancouver to form the Global Forest Products Summit. During another summit event, delegates at the Wood Mar-kets Global Softwood Log and Lumber Conference heard that the super-cycle is still considered to be two to three years away. Current market volatility is tied more to supply chain disruptions than to the longer-term supply/demand gap being forecast.

In short, the factors distinguishing the super-cycle from a normal recovery focus around flat (or even declining) global log

By Cindy Macdonald, editor

Cover Story

UNEVEN

Change is afoot. Flush with cash and rising demand for lumber products, forest products companies have the means and the opportunity

to forge new business relationships and break out of traditional roles.

GROWTH

PPC JulyAug2013.indd 14 13-07-31 11:41 AM

Cover Story

www.pulpandpapercanada.com July/August 2013 PULP & PAPER CANADA 15

supply occurring at the same time as global wood demand hits new highs.

Western Canadian companies, for exam-ple, have been exporting large amounts of wood products to China while the U.S. market languished. But will happen as the U.S. market picks up?

The experts say a generally upward trend in lumber prices could last up to five years if the U.S. housing market and global economy recover, and as the greatly reduced North American forest industry tries to expand to meet what is expected to be steadily growing demand. If the tension in timber supply and lumber production remains tight, then lumber prices will hit all-time highs starting as early as 2015.

B.C. wood supply: looking aheadWhile the impact of the B.C. Interior’s mountain pine beetle outbreak on local lumber production is now well-known, independent consultant Murray Hall pro-vided a broader perspective on the after-math of the outbreak for the Wood Markets audience. As B.C.’s wood supply dimin-ishes, a decline in Interior sawlog produc-tion will result in a reduction of residual wood fibre (chips, sawdust and shavings).

This will adversely affect the pulp, com-posite panel, and pellet industries in the B.C. Interior and pulp mills on the coast, which have required increasing quantities of Interior residuals in order to operate.

In 2016-2018, “there’s a gap between residual chip supply and pulp and paper mill demand,” says Hall. “So Interior pulp mills will be doing whole log chipping. That is the reality.”

There are not enough residuals for pel-let mills either, he explains. “They will be grinding roadside material to make pellets.”

Murray is bullish on pellets. “Europe is not going to turn back from their reli-ance on pellets.” He is confident Canadian pellet suppliers can keep their costs down to be competitive, because “there are very few places in the world that have the fibre basket to produce pellets.”

Staffing, green energy concernsGreen energy, biofuels and bioproducts were the subject of much discussion among the international panel of CEOs assembled for the PwC conference.

Dave Scheible, CEO of Graphic Pack-aging International Inc., is in a business that relies heavily on recycled fibre. Burn-ing biomass is a one-time use, and pellets are a “bad plan that doesn’t work without subsidies,” he comments.

Scheible went on to say that shale gas is not going away, and will continue to pull manufacturing back to the U.S. “[Amer-ica’s] energy profile is definitely coming down, and will continue to do so for the next 10 years.”

Brazilian pulp producer Fibria under-took a survey of the bio-economy several years ago, according to Marcelo Castelli, CEO. The company found 17 pathways, and selected those that were the best fit for Fibria, he noted.

One of those pathways is pyrolysis. Fib-ria took an equity position with Canadian pyrolysis firm Ensyn and formed a joint

venture for the development of facilities to produce cellulosic liquid fuels and chemi-cals in Brazil.

Castelli says Fibria also created a corporate venture capital fund. “We always have funding for good ideas.” In Canada, the green electricity market for pulp mills is nearing its end, says Jim Lopez of Tembec. He believes governments and utilities will have to pass along the higher costs of green electricity to consumers, and that there will be a backlash.

Canadian industrial firms are dependent on cheap electricity, reasons Lopez, and there’s a danger if our governments put all their focus on un-economical forms of energy.

Thinking along the same lines, Dave Scheible, of boxboard producer Graphic Packaging International, notes: “When our customers say sustainability, the mean ‘take out cost’.”

The work force was a chief concern for North American CEOs, but less so for executives representing Europe and South America. Kevin Clarke, former CEO of Cat-alyst Paper, comments that the industry’s greatest opportunity and its biggest risk is hiring, training and motivating the workers of the future.

For Catalyst, the transfer of knowledge has to happen in the next six years, he says due to the rate of attrition. “The transfer of knowledge has to be different than it was in the past, it has to be more effective.”

Similarly, Jim Lopez, CEO of Tembec, notes that a labour shortage plagues many Canadian businesses. At a recent meeting of executives from various industrial sec-tors, Lopez says, it became obvious that the skilled labour shortage is not an emerging issue, it’s an existing problem.

For the immediate future, pulp and paper industry executives will find them-selves reacting to external forces – a chang-ing wood supply, labour shortages, and declining markets for some paper grades. As PwC’s Micheal Vermette said, the glory times are returning for forest products, but they will not be the same as 2005, and the industry’s leadership needs to adapt.

With input from Alice Palmer, consultant, for Wood Markets conference coverage.

An assortment of statistics cited by presenters at the PwC Global Forest Products Outlook Conference.

$56 billion annual Canadian forest industry economic activity

$0.95-$0.97 value of Canadian dollar vs. US, to 2014, according to forecast of Royal Bank’s chief economist

50 m3/ha productivity of Brazil’s planted forests, according to Bracelpa

14 million ha projected increase in Brazil’s planted forests from 2010 to 2020, according to Bracelpa

240-300 million ha additional area of global forest that needs to come under commercial harvesting by 2050, according to WWF’s 2011 Living Forests report

6 average number of times the fibre in a cereal carton has been recycled, according to Dave Scheible

& FACTS FIGURES

PPC JulyAug2013.indd 15 13-07-31 11:41 AM

We’ll just let our customers explain it...

“...for our company, SMART Roll has evolved into a production optimization and process tool, similar to the reel scanners, where process variation is evaluated and immediate action can be taken. This was simply impossible before SMART. I recommend evaluating SMART Roll on your paper machines, and experiencing firsthand how it might be a good fit to optimize your process.”

“...our entire mill exclusively uses SMART Technology to control the presses on our machines. We no longer use the gauges on the control panel.”

“...since adopting SMART Technology in our presses, we’ve eliminated the guesswork and trial and error when identifying and correcting issues. We have refocused SMART from a “trouble-shooting tool” to a key component of our standard process control intelligence.”

Xerium.com/SMART

5.0

From the pioneers of intelligent nip technology.

Case StudySMART® 5.0 PM 6 UPM Schongau, Germany

UPM Schongau recently upgraded to SMART 5.0 on PM 6 for better control and visibility of nip conditions. (Fig. 1) Upon initial start-up following the SMART 5.0 installation, the SMART system captured a number of process changes including pressure differ-ences, edge overloading, nonuniform distribution of nip load, and others. SMART 5.0 provided rapid and accurate information so production engineers could make immediate adjustments where necessary, and acknowledge the need for other corrective mea-sures to be performed at scheduled downtimes.

Figure 2 shows a sectional enlargement from the long-term nip pressure measurement phase over a period of several days. It dis-plays the measured nip pressure prior to the scheduled PM down-time for changing felts and its changed condition after start-up. (To simplify the graph the actual period of downtime was filtered out.) With SMART 5.0, it’s immediately clear that there is an edge overloading condition on tending and drive sides which reduced proportionally during the break-in period of the felts, (green areas = increased pressure level). The insight and accuracy that SMART provided enabled engineers to quickly isolate the edge overload issue and accelerate corrective action.

Figure 3 shows the measured nip width prior to shutdown for changing of the bottom and pickup felts and double suction press roll. (Again, to simplify the graph, the actual period of downtime was filtered out.) SMART captured a minor change in the mea-sured nip width after start-up of the paper machine, despite the fact that there was a change of PMC and RC at the same time. After the break-in period of the felts, the nip width was significantly reduced, and a slight overloading effect on tending and drive sides was documented (more red = shorter nip width). Through the change of the double suction press roll, the nip decreased by ~2.5 mm, or ~10% of the prior nip width. That reduction could be

caused by differing cover hardness or a changed diameter of the installed spare roll cover. As an isolated effect this would not have any negative influence to the runnability or productivity, but the width reduction and overloading effect would have gone undetect-ed without SMART.

The SMART system provided UPM with real-time measurement information, which has never before been available, leading to an accelerated trouble-shooting process. Further quality improve-ments on PM 6 include the 3rd / 4th press and calender.

In summary, each grade of paper produced has an individual pressing environment in which an optimized peak pressure range has been established. Armed with this knowledge the Papermak-ers can utilize SMART 5.0 technology as a practical engineering tool to ensure the press section operates within this designed peak pressure range. Before SMART 5.0 technology, this was only possible through indirect analytical modeling based on inputs from the roll cover, clothing, and machine parameters. SMART 5.0 accurately identifies and isolates issues for rapid analysis and decision-making to improve the productivity and efficiency of the paper machine. Now, the papermaker will know whether the press nip is performing at peak optimization levels by observing the peak pressure range as a function of nip width. In addition to the press section, SMART technology is also suitable for nip analysis with; couch press rolls, soft calenders, multi-nip calenders, super calen-ders, size presses, and lamination and finishing applications.

At the end of 2012 Xerium had already sold more than 330 SMART Roll applications worldwide on a wide variety of Stowe roll cover concepts and paper machine types for practically every paper grade.

Authors:

• StephanCarda,Dir.ProductionPM6UPMSchongau• BillButterfield,CTO,XeriumTechnologiesInc.• AndreasPäch,Dir.Mkg&ApplicationEngineeringForming

FabricsandRolls,XeriumEurope

FormoreinformationvisitXerium.com/SMART.

In summary, each grade of paper produced has an individual

“We’reverysatisfiedwiththeSMARTSystem.Itprovidesuswithgreaterinformationtospeedupourtroubleshooting.WeplantoinvestinadditionalSMARTTechnologysystemsforotherpositions.”

Stephan Carda, Production Manager of PM 6UPM Schongau, Germany.

Fig. 1 - UPM Schongau PM 6 - 1,400 MPM

Fig. 2 - Nip pressure vs. felt change

Fig. 3 - Nip width vs. roll cover & felt changes

PPC JulyAug2013.indd 16 13-07-31 11:41 AM

We’ll just let our customers explain it...

“...for our company, SMART Roll has evolved into a production optimization and process tool, similar to the reel scanners, where process variation is evaluated and immediate action can be taken. This was simply impossible before SMART. I recommend evaluating SMART Roll on your paper machines, and experiencing firsthand how it might be a good fit to optimize your process.”

“...our entire mill exclusively uses SMART Technology to control the presses on our machines. We no longer use the gauges on the control panel.”

“...since adopting SMART Technology in our presses, we’ve eliminated the guesswork and trial and error when identifying and correcting issues. We have refocused SMART from a “trouble-shooting tool” to a key component of our standard process control intelligence.”

Xerium.com/SMART

5.0

From the pioneers of intelligent nip technology.

Case StudySMART® 5.0 PM 6 UPM Schongau, Germany

UPM Schongau recently upgraded to SMART 5.0 on PM 6 for better control and visibility of nip conditions. (Fig. 1) Upon initial start-up following the SMART 5.0 installation, the SMART system captured a number of process changes including pressure differ-ences, edge overloading, nonuniform distribution of nip load, and others. SMART 5.0 provided rapid and accurate information so production engineers could make immediate adjustments where necessary, and acknowledge the need for other corrective mea-sures to be performed at scheduled downtimes.

Figure 2 shows a sectional enlargement from the long-term nip pressure measurement phase over a period of several days. It dis-plays the measured nip pressure prior to the scheduled PM down-time for changing felts and its changed condition after start-up. (To simplify the graph the actual period of downtime was filtered out.) With SMART 5.0, it’s immediately clear that there is an edge overloading condition on tending and drive sides which reduced proportionally during the break-in period of the felts, (green areas = increased pressure level). The insight and accuracy that SMART provided enabled engineers to quickly isolate the edge overload issue and accelerate corrective action.

Figure 3 shows the measured nip width prior to shutdown for changing of the bottom and pickup felts and double suction press roll. (Again, to simplify the graph, the actual period of downtime was filtered out.) SMART captured a minor change in the mea-sured nip width after start-up of the paper machine, despite the fact that there was a change of PMC and RC at the same time. After the break-in period of the felts, the nip width was significantly reduced, and a slight overloading effect on tending and drive sides was documented (more red = shorter nip width). Through the change of the double suction press roll, the nip decreased by ~2.5 mm, or ~10% of the prior nip width. That reduction could be

caused by differing cover hardness or a changed diameter of the installed spare roll cover. As an isolated effect this would not have any negative influence to the runnability or productivity, but the width reduction and overloading effect would have gone undetect-ed without SMART.

The SMART system provided UPM with real-time measurement information, which has never before been available, leading to an accelerated trouble-shooting process. Further quality improve-ments on PM 6 include the 3rd / 4th press and calender.

In summary, each grade of paper produced has an individual pressing environment in which an optimized peak pressure range has been established. Armed with this knowledge the Papermak-ers can utilize SMART 5.0 technology as a practical engineering tool to ensure the press section operates within this designed peak pressure range. Before SMART 5.0 technology, this was only possible through indirect analytical modeling based on inputs from the roll cover, clothing, and machine parameters. SMART 5.0 accurately identifies and isolates issues for rapid analysis and decision-making to improve the productivity and efficiency of the paper machine. Now, the papermaker will know whether the press nip is performing at peak optimization levels by observing the peak pressure range as a function of nip width. In addition to the press section, SMART technology is also suitable for nip analysis with; couch press rolls, soft calenders, multi-nip calenders, super calen-ders, size presses, and lamination and finishing applications.

At the end of 2012 Xerium had already sold more than 330 SMART Roll applications worldwide on a wide variety of Stowe roll cover concepts and paper machine types for practically every paper grade.

Authors:

• StephanCarda,Dir.ProductionPM6UPMSchongau• BillButterfield,CTO,XeriumTechnologiesInc.• AndreasPäch,Dir.Mkg&ApplicationEngineeringForming

FabricsandRolls,XeriumEurope

FormoreinformationvisitXerium.com/SMART.

In summary, each grade of paper produced has an individual

“We’reverysatisfiedwiththeSMARTSystem.Itprovidesuswithgreaterinformationtospeedupourtroubleshooting.WeplantoinvestinadditionalSMARTTechnologysystemsforotherpositions.”

Stephan Carda, Production Manager of PM 6UPM Schongau, Germany.

Fig. 1 - UPM Schongau PM 6 - 1,400 MPM

Fig. 2 - Nip pressure vs. felt change

Fig. 3 - Nip width vs. roll cover & felt changes

PPC JulyAug2013.indd 17 13-07-31 11:41 AM

18 PULP & PAPER CANADA July/August 2013 www.pulpandpapercanada.com

Technology News

Alberta mill adds fiber recovery stages to NBSK hydrocycloningNoss Canada has received an order for new fiber recovery stages from a kraft pulp mill in Alberta. The new components are to be installed in the mill’s pulp cleaning system.

The new fiber recovery stages will replace the existing ones with the aim of considerably improving the fiber recovery rate.

The new equipment will complement the existing Noss approach flow system, installed ahead of the pulp dryer headbox in 2004.Noss Canada 514-697-2029, www.noss.com

Two-layer headbox for lightweight containerboardsThe cost-effective OptiFlo two-layer headbox makes it possible to produce lightweight containerboard with only one hybrid forming unit or with a Fourdrinier-type former. The latest two-layer hybrid forming headbox supplied by Metso came on stream at Liansheng Paper PM5 in Fujian province, China, on October 2012 with excellent performance.

The OptiFlo two-layer headbox tackles the challenges faced by boardmakers by combining lower basis weights, faster speeds and higher ash contents resulting from increased use of recycled fiber. This novel solution provides excellent layer coverage, considerably lower residual variation in basis weight and excellent formation with no streaks or tiger stripes.

High-strength, repulpable tape3M introduced at PaperCon 2013 Repulpable Super Strength Single Coated Tape R3177. The new tape delivers the highest tensile of all single coated tape offered by 3M and can be used for core starting and roll tabbing of coated and uncoated printing and writing papers.

R3177 is also suitable for use in the tough applications of core starting, temporary butt splicing and roll tabbing of paper board, liner board and fluff pulp stock used in food packaging. It allows the tape to stretch under stress and holds rolls closed better through stops and starts of automated roll handling.

3M’s line of single coated tapes for paper mills also includes two other tapes. R3187 offers the thickest high-tensile strength and elongation for printing and writing papers. R3127 is the thinnest for core starting and roll tabbing of lightweight newsprint, tissue paper and paper towel stock.

All three tapes comply with FDA regulations for repulpable tapes which may become components of food packaging. 3M, www.3M.com

The wet end operating costs of Liansheng Paper’s PM5 (headbox pumping cost, forming section drive power and vacuum power costs) are also lower with the two-layer headbox concept. The 7.25-m-wide PM 5 produces recycled light weight liner using local OCC as furnish on a basis weight range of 100-140 g/m2.

The design speed of the production line is 1,200 m/min and the annual production capacity yields 350,000 tonnes.

“The biggest advantage of PM 5 is the OptiFlo two-layer headbox, which enables the production of three-layer board by two forming units. Power consumption is also lower than expected,” says Xue Ron Jun, project manager at Liansheng Paper.

According to Metso, in two-layer headbox applications it is very important to guarantee layer coverage. All the hydraulic components of the OptiFlo headbox have been designed to minimize slice jet and board sheet disturbances. The design of the OptiFlo layering headbox hydraulics produces smooth forming board activity, without any mixing of individual layers.

The liner quality has been very good at Liansheng. According to Xue Ron Jun, the internal bond between the layers of the

lightweight linerboard produced by PM5 is excellent.

Hybrid forming with layering technology is a viable alternative technology for the production of lightweight containerboard grades, bringing the speed range up to 1,400 m/min. The new OptiFlo two-layer headbox technology is a compact, high-speed alternative to separate-ply multi-Fourdriniers. It offers lower investment costs than gap forming, and is suitable for rebuilds. Metso, www.metso.com

Kemira adds GE water technology to its product lineKemira’s Paper Segment can now furnish GE Water & Process Technologies’ boiler and cooling water chemical product technologies to the pulp and paper industry.

Kemira is actively expanding and broadening its pulp and paper offering. “Adding boiler and cooling treatment strengthens Kemira’s commitment to be a highly valued resource to our customers in every area of the mill”, says Joe Stockman, director of boiler and cooling treatment for Kemira’s Paper Segment.

Kemira customers will be able to utilize the GE Water & Process Technologies Service Reliability Center which provides monitoring of customer’s key process variables. Kemira 514-457-0000, www.kemira.com

Concentrated optical brightenerClariant has launched a highly-concentrated, urea-free liquid optical brightening agent (OBA) for printing and writing papers. Disulphonated Leucophor® ACK contains no environmentally-harmful additives, decreases OBA requirements for papermakers, and lowers transport costs and carbon footprint, according to the company.

Leucophor ACK is an ultra-concentrated aqueous solution specially designed to give state-of-the-art effectiveness while satisfying the most demanding environmental requirements. The unique, patented, urea-free optical brightener is primarily intended for stock application in sized and unsized papers.

Free of additives such as urea and glycols, the REACH-registered brightener contributes less to the overall nitrogen and COD content of backwaters and effluent.

From an efficiency perspective, papermakers look to use less active agent to achieve good brightness or whiteness for their application. The highly substantive, ultra-concentrated stilbene brightener exhibits impressively high build

PPC JulyAug2013.indd 18 13-07-31 11:41 AM

Technology News

www.pulpandpapercanada.com July/August 2013 PULP & PAPER CANADA 19

up, even at extremely low concentrations, thanks to its strength and high affinity to the paper fiber.

Compared to current disulpho chemistries, Leucophor ACK shows improved performance on stock addition to both virgin and recycled fiber, and in pigmented coating applications, particularly those containing PVOH as a secondary binder, Clariant says. Leucophor

ACK also allows greater flexibility and higher solids’ contents in CMC and starch/CMC pigmented coatings.

Leucophor ACK liquid is also

particularly suitable for unsized tissue, as well as neutral-sized and heavy loaded papers, the company says. It is also said to be one of the most effective OBAs for use in wood-containing grades, such as improved newsprint and SC grades.Clariant Canada, www.clariant.com

Dryer rebuild nets 17% capacity increaseAndritz has successfully completed a rebuild of PM2’s dryer section at Smurfit Kappa’s Hoya mill in Germany. As a result, Smurfit Kappa – one of the leading producers of paper-based packaging in the world– is able to achieve its goals for capacity, product quality, and energy consumption.

Andritz’s scope for rebuilding the testliner and fluting machine at Hoya included complete dismantling of the old dryer section and rebuilding it with new frame and rolls; installation of a PrimeRun web stabilization system; and installation of ropeless tail-threading (PrimeFeeder). A PrimeCoat Film film press replaced the old size press and a new energy-recovery hood was installed.

Even with the reduction in basis weight for the lighter weight packaging paper, capacity was increased by 17%. In addition formation was improved and energy consumption was significantly reduced.

For the project’s second phase, PM2’s output was increased by another 17%. Andritz Pulp & Paper moved the reel and enlarged the after-drying section by adding PrimeDry ST and PrimeDry

DT dryers along with a PrimeRun web stabilization system. The new components have a design speed of 1,200 m/min, at a width at reel of 7,600 mm.Andritz, www.andritz.com

Measurement of chemicals and fibreRecent innovations include the new TCT-2531, an open flow sensor for low fiber consistency applications such as measuring fiber losses; the Optical Bleach Plant for enhanced productivity and chemical savings in the fiber line; and the completely new Mütek PCD-05, the industry standard for charge measurement.

The Mütek PCD-05 is the successor to the PCD-04 and is available in three different versions. Worldwide, the PCD has established itself as the standard tool for charge measurement in the paper industry and for chemical suppliers alike. The level of chemical additives such as fixing agents or interfering substances can be determined quickly.BTG Americas Inc. 770-209-6940, www.btg.com

Kadant expands stock prep with Noss additionKadant Inc. has completed the acquisition of certain assets of the Noss Group, a Sweden-based developer and supplier of screening, hydrocycloning, and deaeration systems and equipment for both virgin and recycled fiber lines as well as for approach flow systems. The Noss product line extends Kadant’s stock-preparation product offerings.

Noss’ integration into Kadant is expected to provide customers with increased accessibility and expanded technical resources utilizing Kadant’s global platform.

Kadant Inc. is a supplier of stock-preparation, fluid-handling, and doctoring, cleaning, and filtration products.Kadant Canada Corp. 877-369-6111, www.kadant.com

Entry-level shaft alignment systemHamar Laser’s Stealth Series S-660T three-axis wireless laser shaft alignment system offers good value in entry-level shaft alignment laser systems. The powerful Couple6 shaft alignment software runs on the new generation PC industrial tablet with Windows 7 Professional operating system.

The unit enables highly accurate measurement of offset and angle simultaneously using two laser fans and two PSDs, providing full operating range

between laser and target.An internal Bluetooth® transmitter

sealed in IP67 housing has a range of up to 10 m from target. Spans of 3.05 m are easily achieved with the use of a fan type laser.Hyatt Industries Limited 604-736-7301,www.hyatt-ind.com

Greenhouse gas modeling for wastewater treatmentBioWin 4.0 provides rigorous mathematical models to simulate operations in wastewater treatment plants. Developed by EnviroSim Associates, BioWin 4.0 has capabilities to model nitrous oxide, methane and carbon dioxide emissions – key greenhouse gases (GHGs).

With its new capabilities, BioWin 4.0 allows plant designers, water companies and plant operators to calculate and predict GHG emissions from different plant designs and operating conditions.EnviroSim Associates Ltd. 905-481-2607

Headbox upgrade is 100th for GL&VGL&V Canada has won an order to supply a new BTF™ headbox to United Corrstack, Reading, PA. Start-up is set for the fall of 2013.

The headbox upgrade at United Corrstack is part of a modernization project designed to improve product quality, increase sheet width and increase production while reducing overall cost-per-ton. GL&V notes that, in this age of rapidly changing technologies, the success of their BTF technology underscores the obvious technological advantages of the system when compared to traditional headbox equipment.

GL&V has a worldwide installation list of 188 BTF units, 87 of which are BTF Dilution Profiling Retrofits which have been integrated into existing headboxes of every description.GL&V Canada Inc. 819-371-8265, www.glv.com

PPC JulyAug2013.indd 19 13-07-31 11:41 AM

20 PULP & PAPER CANADA July/August 2013 www.pulpandpapercanada.com

Technology News

Strong and effective dryer fabricsMaintaining drying efficiency and sheet runnability through the life of a dryer fabric is a key cost driver for the performance of a paper machine. Voith says its new Evaporite dryer fabrics impress with their outstanding durability and efficiency, their resistance to contamination and ease of cleaning. They feature a new CleanWeave design and SynStron material which has

a significantly higher durability than conventional polyester yarns.

The open structure, low yarn cross over points and minimum internal void volume are unique to the CleanWeave structure and thus reduce contamination of the fabric. Effective evaporation is ensured over the entire service life of the fabric. Moreover, the compact fabric structure makes cleaning of the surface easier either when manually cleaning or with online cleaning systems.

EvaporiteHigh is also part of this product line. This dryer fabric design is characterized in particular by an increased open surface and a high degree of web contact.Voith, www.voith.com/evaporite

Nonwoven, hybrid felts improve lifetime performanceFelts play a major role with regard to efficiency and cost savings. When purchasing a felt, going for a cheaper option might, in the worst case, result in additional costs during the felt running time. It is better to analyze a felt’s real effect on machine efficiency by looking at the felt costs per produced paper tonnes and the savings (e.g. energy reduction and saved production time) that can be achieved with certain felts, Metso advises.

Electricity usage in the press section is huge and adds up to hundreds of thousands of Euros every year. Metso calculates that about 20-30% of electricity usage is related to Uhle boxes. Their friction increases the energy consumption of drives, and the Uhle box vacuum increases vacuum energy consumption.

The company claims energy can be saved by using nonwoven and hybrid felts, which maximize nip dewatering, meaning that minimized or no vacuums are required in the Uhle boxes. Metso offers two standard nonwoven and hybrid felts: AquaMaster and EcoMaster.

AquaMaster’s immediately saturating structure allows a very

fast start-up and maximal nip dewatering. All the water is removed in the nip so Uhle boxes do not increase sheet dryness. Rewetting is minimized with a special layer.

EcoMaster is the combination of a woven and nonwoven structure. Its nip dewatering properties are excellent, but Uhle boxes can be used if necessary. Additional benefits compared with nonwoven felts include its smooth surface, insulation against marking, dimensional stability and less plugging.