Characterization of Cereals and Flours Properties, Analysis, And Applications

Protein quality evaluation ofAmaranthus wholemeal flours and protein concentrates

Transcript of Protein quality evaluation ofAmaranthus wholemeal flours and protein concentrates

J Sci Food Agric 1998, 76, 100È106

Protein Quality Evaluation of AmaranthusWholemeal Flours and Protein ConcentratesFeliciano P Bejosano and Harold Corke*

Cereal Science Laboratory, Department of Botany, University of Hong Kong, Pokfulam Road,Hong Kong

(Received 8 November 1996 ; revised version received 18 March 1997 ; accepted 13 June 1997)

Abstract : Based on the amino acid composition, Amaranthus seed protein isknown to be of higher quality than most of the major cereal grains. However,protein quality does not solely depend on amino acid proÐle but also on itsdigestibility. In this study we determined amino acid composition and in vitroprotein digestibility of wholemeal and isoelectric protein concentrates (IPC) fromÐve Amaranthus genotypes. Factors most likely to inÑuence protein digestibilitysuch as heating and presence of antinutrients were studied. Heating increasedprotein digestibility in wholemeals but slightly decreased it in IPCs. Trypsininhibitor level was negatively but weakly correlated to protein digestibility, andthe level of polyphenolic compounds was negatively and signiÐcantly correlatedto protein digestibility. A slight deÐciency in leucine was noted for wholemealsand in lysine for IPCs. However, based on both in vitro digestibility and aminoacid proÐle, Amaranthus proteins were conÐrmed to be of better quality thanthose of other cereals. 1998 SCI.(

J Sci Food Agric 76, 100È106 (1998)

Key words : Amaranthus ; wholemeal ; protein concentrates ; in vitro proteindigestibility ; amino acid proÐle ; trypsin inhibitors ; polyphenols ; Protein Digest-ibility Corrected Amino Acid Scoring (PDCAAS)

INTRODUCTION

A major factor determining protein quality is the aminoacid proÐle, and the quality of Amaranthus protein hasbeen reported in several studies to be better than mostcereal proteins in this respect (Becker et al 1981 ; Bress-ani 1989 ; Breene 1991). The other factor, as importantas amino acid proÐle, is protein digestibility. Even withan excellent amino acid proÐle, a protein would havelow nutritional value if digestibility was low because thebioavailability would be poor.

The best method to determine the digestibility of pro-teins is through in vivo animal feeding studies. In vitrotechniques have also been developed and proven to beuseful and reliable in estimating true protein digest-ibility. The in vitro techniques are based on the additionof proteolytic enzymes to the protein substrate, main-

* To whom correspondence should be addressed.

tenance at optimum incubation conditions for theenzymes, and measurement of the degree to which theprotein has been digested. Although preceded by anumber of similar methods, one of the most widely usedis that of Hsu et al (1977). This procedure involves theuse of a combination of three enzymes : trypsin, chy-motrypsin and peptidase.

Amaranthus has become a successful minor crop witha signiÐcant future potential in China (Yue et al 1993)presently grown for commercial grain production onsome 40 000 ha per year (Wu et al 1995), with a grainyield of 2200 to 5500 kg ha~1 depending on environ-mental conditions (Yue et al 1993). Amaranthus graincan be used directly in food products or for blendinginto composite Ñours, for products such as noodles, toimprove nutritional quality and alter taste proÐles (forrecent reviews of food uses, see Breene (1991) and Sch-netzler and Breene (1994). Our laboratory is studyingthe food-related properties of di†erent Amaranthus

1001998 SCI. J Sci Food Agric 0022-5142/98/$17.50. Printed in Great Britain(

Protein quality evaluation of Amaranthus 101

genotypes, especially those which have potential in agri-cultural production in China (Wu et al 1995). Starch isthe major product processed from Amaranthus grain,and may be produced by alkali wet milling. Using thatprocedure, the protein fraction can easily be recoveredand protein concentrate can be made from it.

Our aim in this study was to determine the quality ofAmaranthus protein in wholemeal and as concentratesfrom Ðve di†erent genotypes, using an in vitro proteindigestibility test and amino acid proÐle analysis.

MATERIALS AND METHODS

Plant materials

Five Amaranthus samples were supplied by the Instituteof Crop Breeding and Cultivation (Chinese Academy ofAgricultural Sciences, Beijing, PeopleÏs Republic ofChina). The genotypes were : K112, K350, K459 andR104 (all A cruentus with yellowish-brown seedcoat),and No 3 (A hybridus with a black seedcoat). R104 is awidely-grown grain variety, and K112 a widely-grownforage variety in China (Wu et al 1995). Wholemeal wasprepared by grinding in an Udy Cyclone sample mill(Udy Corporation, Ft Collins, CO, USA) Ðtted with a0É5 mm sieve.

Crude protein determination

Wholemeal Ñours and protein concentrates wereanalysed for total nitrogen using the Kjeldahl procedure(AOAC 1984) and converted to protein using a factor of6É25.

Preparation of isoelectric protein concentrates

An alkali wet milling procedure with subsequent iso-electric precipitation of the proteinaceous liquor wasused to make isoelectric protein concentrates (IPC) outof the Ðve Amaranthus samples. The procedure used wasbased on Method C of Perez et al (1993), essentiallythe same as used by Wu et al (1995). Protein recoveryfrom the procedure was fairly low, and only about37É6 ^ 7É4% of the total protein content of the rawmaterial was recovered. This was due to the largeamount of Ðbrous residue obtained which still containedsigniÐcant amounts of protein. Some protein was alsopresent in the crude starch fraction and in the liquidafter acid precipitation of the proteinaceous liquor.Methods for improvement of protein recovery are beingpursued. After acid precipitation of the proteinaceousliquor, a wet curd was obtained which was then

freeze-dried. The dried curd was then reduced to apowder using a mortar and pestle and defatted withpetroleum ether.

In vitro protein digestibility

This procedure was based on Hsu et al (1977). Theenzymes used were (a) porcine pancreatic trypsin (TypeIX) with 17 600 BAEE units per mg solid ; (b) bovinepancreatic chymotrypsin (Type II) with 52 units per mgsolid ; and (c) porcine intestinal peptidase with 102 unitsper mg solid. All enzymes were from Sigma ChemicalCompany (St Louis, MO, USA). Digestibility of proteinfrom whole grains (wholemeal Ñours) and protein con-centrates were determined in their raw state and afterheating by steam at 100¡C for 10 min. The sampleswere heated in the suspension form in preparation forthe digestibility test (ie at pH 8É0 and adjusted to have aprotein concentration of 6É25 mg ml~1).

Trypsin inhibitor activity

This was performed following Method 71-10 (AACC1983). Trypsin and benzoyl-DL-arginine-p-nitroanilide(BAPA) were from Sigma Chemical Company (St Louis,MO, USA).

Polyphenolic compound analysis

Polyphenolics were quantiÐed by the method of Priceand Butler (1977). However, the extraction mediumused was methanolÈHCl (99 : 1). This was chosenbecause using acetone or methanolÈwater (95 : 5) gavedoubtfully low results indicating inadequate extraction.The standard curve was plotted using tannic acid (BDHLaboratory Supplies, Poole, UK).

Amino acid analysis

Amaranthus wholemeal Ñours and protein concentrateswere analysed for their amino acid composition with aHitachi 835-50 High Speed Amino Acid Analyzer(Tokyo, Japan). The samples were hydrolysed at 110¡Cwith 6 M HCl. For sulphur-containing amino acids,samples were oxidised with performate to form cysteicacid and methionone sulphone and then hydrolysedwith 6 M HCl. Tryptophan was not determined.

Protein Digestibility-Corrected Amino Acid Score(PDCAAS)

PDCAAS was calculated based on Henley and Kuster(1994) as follows : (a) proximate nitrogen (N) content

102 F P Bejosano, H Corke

was determined ; (b) protein content was calculated(N] 6É25) ; (c) the essential amino acid (EAA) proÐlewas analysed ; (d) the uncorrected amino acid score(UAAS) was determined as mg EAA in 1 g of testprotein divided by mg EAA in 1 g reference protein(The reference protein EAA proÐle was the 1985FAO/WHO 2È5 year old requirement pattern) ; (e)protein digestibility was determined ; and (f) PDCAASwas calculated : PDCAAS\ lowest UAAS] proteindigestibility.

RESULTS AND DISCUSSION

Protein content

Protein content of wholemeal ranged from 124 g kg~1in K112 (the forage variety) to 168 g kg~1 in R104 (thegrain variety), and in the IPC from 674 g kg~1 in K112to 753 g kg~1 in K350 (Table 1). Plant breeding selec-tion has probably favoured high seed protein content ingrain varieties, but breeders have never selected for theprotein content of IPC. Screening and selection for thistrait could improve the quality of Amaranthus linesdeveloped for industrial use.

In vitro protein digestibility

The average protein digestibility of the raw Amaranthuswholemeal Ñours was 74É2% (Table 1). This is the sameas found by Guzman-Maldonado and Paredes-Lopez

(1994) in A hypochondriacus wholemeal using the samein vitro protein digestibility procedure. Among thegenotypes studied, K350 wholemeal had the highestdigestibility (76É2%) and K459 the lowest (73É0%). Afterheating the wholemeal Ñours at 100¡C for ten min theprotein digestibility was signiÐcantly increased (t-test :P\ 0É01) by an average of 2É7%. Even after heating,proteins of K350 wholemeal were most digestible andthose of K459 the least. The di†erences among geno-types for protein digestibility, while statistically signiÐ-cant, were fairly small.

Protein digestibility was signiÐcantly higher (t-test :P\ 0É001) in the raw IPC (average 80É8%) than in thewholemeals (average 74É2%). Surprisingly, proteindigestibility was slightly but signiÐcantly decreased (t-test : P\ 0É05) when the protein concentrates wereheated, unlike the result with the wholemeals. Again,overall variation in the protein digestibility among thegenotypes evaluated was small.

The reason for lower protein digestibility in thewholemeal is likely due to components (starch, Ðbre andfat) other than the protein itself, which interfere with theability of the enzymes to act. To overcome this, Bhattyand Whitaker (1987) treated crude protein fractions(albumin] globulin ; hordeins ; and glutelins) frombarley (contaminated with small amount of starch) witha-amylase which greatly improved their digestibility.This apparent resistance to proteolytic enzymes of thecarbohydrateÈprotein complex was also noted by Hsuet al (1977).

When the wholemeal was heated, we thereforeobserved a signiÐcant increase in protein digestibility,which could be ascribed to the opening of the

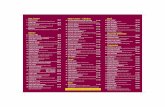

TABLE 1Crude protein content (g kg~1), in vitro protein digestibility (%), trypsin inhibitor activity (TIU) (sample basisand protein basis), and polyphenolics (as tannic acid) content (mg g~1) (sample basis and protein basis) of

wholemeals and protein concentrates from di†erent Amaranthus genotypes

Genotype Protein Digestibility T rypsin inhibitor activity Polyphenolics

Raw Heated Sample Protein Sample Protein

W holemealK112 124 73É4 76É1 1É98 16É0 5É2 41É5K350 128 76É2 80É3 1É90 13É8 4É6 35É9K459 156 73É0 75É5 1É75 11É2 4É6 29É5R104 168 74É4 76É3 1É49 8É9 4É5 26É8No 3 151 74É0 76É3 0É26 1É7 4É1 27É2LSD (P\ 0É05) 10 0É6 0É6 È È È È

Protein concentrateK112 674 78É7 77É7 2É68 4É0 17É7 26É3K350 753 81É1 80É3 1É76 2É3 13É5 17É9K459 692 81É7 81É0 5É24 7É6 11É6 16É8R104 718 82É0 82É0 5É45 7É6 7É2 10É0No 3 692 80É7 78É7 1É30 1É9 13É9 20É1LSD (P\ 0É05) 16 0É9 1É3 È È È È

Protein quality evaluation of Amaranthus 103

carbohydrateÈprotein complex and to the inactivationof antinutritional factors such as trypsin inhibitors (Hsuet al 1977 ; Oshodi and Hall 1993). However, it was notclear why a decrease in digestibility was observed whenthe protein concentrates were heated.

Although the in vitro test is an easier and more rapidtechnique, it is only an approximation of the trueprotein digestibility and not as accurate as the in vivomethod. Mitchell and Grundel (1986) compared theresults from the two methods and found that proteindigestibility tends to be underestimated with the in vitrotest. They attributed this to the sensitivity of theenzymes to minor changes in the protein structure suchas humidity-related damage shown by a reduction indye-bound lysine and an increase in browning activitywhich had no e†ect on in vivo digestibility. This indi-cates that the true digestibility of Amaranthus proteinsmay be higher than we obtained from the in vitro test,although usually, as in this study, the main objective isto detect di†erences in rank. In vivo testing would benecessary to directly conÐrm such rank di†erences.

Trypsin inhibitor activity

The amount of trypsin inhibitor activity (expressed inTIU) in the wholemeals as well as in the protein con-centrates appears to have considerable variabilityamong the Amaranthus genotypes (Table 1). This attrib-ute may be species-dependent because among thewholemeals genotype No 3 (A hybridus) had a muchlower TIU level compared to the other four which wereall A cruentus. The highest level of TIU among thewholemeals was found in K112 (1É98 TIU mg~1sample). However, among the protein concentrates,R104 had the highest (5É45 TIU mg~1 sample). Resultsfrom studies on soybeans using the same procedure thatwe used for determining trypsin inhibitor activityshowed that raw soy Ñour contained as much as 99É0TIU mg~1 ; soy concentrates had 12É0È26É5 TIU mg~1 ;and soy isolates 8É5È20É9 TIU mg~1 (Snyder and Kwon1987). Thus, despite the di†erences in trypsin inhibitorlevels among Amaranthus genotypes, the absoluteamounts are relatively insigniÐcant compared to thosefound in soybean.

Because of the direct e†ect of trypsin inhibitors onprotein, we also expressed their level in terms of theamount of protein in the sample (ie TIU mg~1 protein).On this basis, the level of trypsin inhibitor was onaverage 55% lower in the concentrates than in thewholemeals. Thus it appears that they were only par-tially co-extracted with the proteins, an additionalbeneÐt of the processing procedure.

The correlation between digestibility and TIU levelwas quite low (r \ [0É05 ; P[ 0É05 ; n \ 10), but con-sistent with the expected e†ect of trypsin inhibitors todecrease protein digestibility. The low correlation sug-

gests that there were other factors that inÑuence proteindigestibility. Further, although trypsin inhibitors areinactivated by heat, we observed a decrease in digest-ibility when we heated the protein concentrates.

Polyphenolic compounds

Another major factor that inÑuences protein digest-ibility is the presence of polyphenolic compounds.Hurrell and Finot (1985) noted that these compoundsreact with proteins to form precipitates hence reducingprotein digestibility.

We found 4É1 to 5É2 mg g~1 polyphenolics in whole-meals (Table 1), compared to Becker et al (1981) whoanalysed 10 Amaranthus genotypes using the Folin-Denis method and found a tannin content ranging from1É0 to 4É0 mg g~1, although the di†erence might bebecause of the di†erent assay procedure. Unlike trypsininhibitor, the level of polyphenols in wholemeals didnot vary much among the genotypes (Table 1). Express-ing polyphenol content relative to the amount ofprotein in the sample (ie mg polyphenol g~1 protein),there was a reduction in polyphenol content in theprotein concentrates by about 40% compared to whole-meal.

The correlation between protein digestibility andpolyphenol content was signiÐcant (r \ [0É83 ;P\ 0É01 ; n \ 10), indicating that reduction in proteindigestibility was probably more inÑuenced by the pres-ence of polyphenols than by trypsin inhibitors. Thiscould explain the reduction in protein digestibility afterheating the protein concentrates. Hurrell and Finot(1982) found that proteinÈpolyphenol reaction isa†ected by pH, oxygen level, time and temperature. Theprotein concentrates had a pH of 8É0 (in preparation forthe digestibility test) when they were heated. The slight-ly elevated pH and the high temperature accelerated theproteinÈpolyphenol reaction thus a decrease in digest-ibility was observed. However, this e†ect was notobserved in the wholemeals treated similarly. This isperhaps because of the more complex nature of thewholemeals. With all the other components still present(ie, fat, starch and Ðbre), the access to the proteins bythe polyphenols might have been restricted especiallybecause starch gelatinises during heating forming athick paste.

It is also possible that the reduced digestibility e†ectin IPCs might be caused to some extent by proteindenaturation during heating. Bhatty and Whitaker(1987) observed such results on di†erent protein frac-tions from barley. They assumed that lysine is destroyedby moist heat thus protein hydrolysis by trypsin isdiminished because this enzyme acts preferentially onthe lysyl and arginyl peptide bonds. Another possibilityis an increase in Maillard reactions which favour alka-line conditions and also have a preference for lysine.

104 F P Bejosano, H Corke

TABLE 2Amino acid proÐle of Amaranthus wholemeal (WM) and isoelectric protein concentrates (IPC) expressed in

mg g~1 protein (tryptophan was not determined)

Amino acid K112 K350 K459 R104 No 3

W M IPC W M IPC W M IPC W M IPC W M IPC

Aspartic acid 81 91 85 90 82 85 83 84 87 90Threonine 37 41 38 40 36 39 37 39 36 42Serine 54 51 59 51 58 49 54 49 72 53Glutamic acid 177 163 191 166 179 165 179 164 185 161Glycine 73 49 77 49 74 48 72 48 86 50Alanine 38 42 39 41 37 39 37 39 37 43Cysteine 18 12 19 12 20 13 19 12 19 10Valine 43 45 43 44 41 42 43 40 43 44Methionine 22 19 21 17 21 18 20 18 21 18Isoleucine 38 41 39 42 36 39 37 38 39 41Leucine 57 70 59 69 56 64 56 63 58 71Tyrosine 36 37 32 37 36 37 33 37 35 37Phenylalanine 45 50 50 52 45 47 46 48 47 49Lysine 58 53 59 50 58 51 57 50 56 51Histidine 26 29 27 29 25 30 26 30 26 29Arginine 92 94 96 97 94 98 92 99 95 96Proline 39 44 41 47 37 40 38 43 39 44

Hurrell and Finot (1985) pointed out that thepolyphenolÈprotein reaction particularly involves lysineas well. Therefore, it may not be the heat alone but alsothe combined action of polyphenols and the formationof Maillard products that caused a reduction in trypsinsusceptibility of the Amaranthus protein concentrates.

Amino acid proÐle

Generally, there appeared to be no signiÐcant variationamong the genotypes in amino acid proÐle of the

wholemeals or the IPCs (Table 2). There were a fewminor di†erences between the wholemeals and theprotein concentrates in the relative proportion of someamino acids, notably the decrease in glutamic acid andglycine, and increase in leucine in the IPCs.

The average level of essential amino acids in thesamples and the corresponding amino acid scores basedon the 1984 FAO/WHO suggested patterns for aminoacid requirements (Henley and Kuster 1994) was calcu-lated (Table 3). The level of leucine in the wholemealswas slightly inadequate, and the level of lysine wasslightly deÐcient in the IPCs.

TABLE 3Essential amino acid content of protein (Content) in Amaranthus wholemeal Ñours andprotein concentrates and their uncorrected amino acid score (Score), compared with standard

FAO/WHO 2È5 year old reference pattern (Standard)

Amino acid Standarda W holemeal Ñour Protein concentrates

Contenta Score Contenta Score

Threonine 34 37 1É09 40 1É18Methionine] cysteine 25 40 1É60 30 1É20Valine 35 43 1É23 43 1É23Isoleucine 28 38 1É36 40 1É05Leucine 66 57 0É86 67 1É02Phenylalanine] tyrosine 63 81 1É29 86 1É36Lysine 58 58 1É00 51 0É88Histidine 19 26 1É37 29 1É53Tryptophanb 11 (10)b (0É91) È È

a In mg g~1 protein ; amino acid content of sample divided by the reference pattern equalsthe uncorrected amino acid score (Henley and Kuster 1994).b Not determined ; taken from Becker et al (1981).

Protein quality evaluation of Amaranthus 105

Using the amino acid scores, we calculated anapproximate Protein Digestibility Corrected AminoAcid Score (PDCAAS) (Henley and Kuster 1994).PDCAAS replaces the previous PER (protein efficiencyratio) requirement for assessing the overall proteinquality. PDCAAS is the product of the lowest uncor-rected essential amino acid score and the protein digest-ibility. The protein digestibility test should be doneusing an animal assay. Nevertheless, we estimatedPDCAAS of Amaranthus proteins using the in vitro testresults, bearing in mind that the true digestibilitieswould probably be higher. The lowest amino acid scorein wholemeals was 0É86 for leucine while in protein con-centrates, it was 0É88 for lysine (Table 1). The PDCAASfor wholemeals would then be 0É86 ] 0É74 (proteindigestibility)\ 0É64, and for protein concentrates itwould be 0É88 ] 0É81 (protein digestibility) \ 0É71.Even these values are higher than those calculated forwholewheat (0É40), wheat gluten (0É25), oat (0É57),peanut meal (0É52) and canned lentil (0É52) proteins(FAO/WHO data cited in Henley and Kuster 1994).One of the bases used for protein quality evaluation isthe C-PER model, which is also based on essentialamino acid proÐle and protein digestibility analysis(Hsu et al 1978 ; Sullivan and Carpenter 1993). We usedthe present results to calculate C-PER for the whole-meals and IPCs. The calculation process was found tobe somewhat tedious and in places ambiguous due tothe multiplicity of steps and di†erent equations. Forwholemeals, C-PER was 1É8, and for IPCs it was 2É2.These values are higher than others on the literature (eg1É1 for cornmeal, 0É8 for wheat Ñour, and 1É3 for soyÑour) (Hsu et al 1978). In our experience the PDCAASmethod is preferable due to its simplicity.

CONCLUSIONS

The in vitro protein digestibility of Amaranthus whole-meal Ñours was shown to be signiÐcantly lower thanthat of protein concentrates. Moist heat increased thedigestibility of wholemeals but decreased it in proteinconcentrates. SigniÐcant levels of trypsin inhibitors andpolyphenols were detected in both wholemeals andprotein concentrates. Protein digestibility in wholemealswas lower than in protein concentrates because proteinis bound with other components which hampersenzyme action. The increase in digestibility after heatingthe wholemeals could be due to the breaking of suchcomplexes and to the inactivation of trypsin inhibitors.Digestibility and trypsin inhibitor level were weaklynegatively correlated. On the other hand, the amount ofpolyphenolic compounds in the samples was signiÐ-cantly correlated to protein digestibility indicating thisfactor has a stronger inÑuence on protein digestibilitythan trypsin inhibitors. This view was supported by thedecrease in digestibility resulting from heating the

protein concentrates, suggesting that this was broughtabout mainly by an accelerated polyphenolÈproteinreaction.

There were slight di†erences between the amino acidproÐles of the wholemeals and the protein concentrates.Nevertheless, the overall amino acid proÐle ofAmaranthus protein was extremely favourable. Thisattribute and its fairly good digestibility show thatAmaranthus is indeed a source of high quality proteins.

ACKNOWLEDGEMENTS

The authors thank Prof S X Yue and Prof H L Sun,Chinese Academy of Agricultural Sciences, for supply ofseed material and collaboration on Amaranthusresearch. Financial support was received from the Uni-versity of Hong Kong Committee on Research andConference grants and the Hong Kong Research GrantsCouncil.

REFERENCES

AACC 1983 Approved Methods of the American Association ofCereal Chemists (8th edn) : American Association of CerealChemists, St Paul, MN, USA.

AOAC 1984 Official Methods of Analysis (14th edn). Associ-ation of Official Analytical Chemists, Washington, DC,USA.

Becker R, Wheeler E L, Lorenz K, Sta†ord A E, GrosjeanO K, Betschart A A, Saunders R M 1981 A compositionalstudy of amaranth grain. J Food Sci 46 1175È1180.

Bhatty R S, Whitaker J R 1987 In vivo and in vitro proteindigestibilities of regular and mutant barleys and their iso-lated protein fractions. Cereal Chem 64 144È149.

Breene W M 1991 Food uses of grain amaranth. Cereal FoodsW orld 36 426È430.

Bressani R 1989 The proteins of grain amaranth. Food Rev Int5 13È38.

Guzman-Maldonado H, Paredes-Lopez O 1994 Production ofhigh-protein Ñour and maltodextrins from amaranth grain.Process Biochem 29 289È293.

Henley E C, Kuster J M 1994 Protein quality evaluation byprotein digestibility-corrected amino acid scoring. FoodT echnol 48 (4) 74È77.

Hsu H W, Vavak D L, Satterlee L D, Miller G A 1977 Amultienzyme technique for estimating protein digestibility. JFood Sci 45 1269È1273.

Hsu H W, Sutton N E, Banjo M O, Satterlee L D, KendrickJ G 1978 The C-PER and T-PER assays for protein quality.Food T echnol 32 69È73, 68.

Hurrell R F, Finot P A 1982 ProteinÈpolyphenol reactions. 1.Nutritional and metabolic consequences of the reactionbetween oxidized ca†eic acid and the lysine residues ofcasein. Br J Nutr 47 191È211.

Hurrell R F, Finot P A 1985 E†ects of food processing onprotein digestibility and amino acid availability. In : Digest-ibility and Amino Acid Availability in Cereals and Oilseeds,ed Finley J W & Hopkins D T. American Association ofCereal Chemists Inc, St Paul, MN, USA, pp 233È246.

Mitchell G V, Grundel E 1986 Nutritional value of proteins inpowdered infant formula : in vitro and in vivo methods. JAgric Food Chem 34 650È653.

106 F P Bejosano, H Corke

Oshodi A A, Hall G M 1993 In vitro multienzyme digestibilityof protein of some plant source Ñours blended with bovineplasma protein concentrate. J Sci Food Agric 63 323È327.

Perez E, Bahnassey Y A, Breene W M 1993 A simplelaboratory-scale method for isolation of amaranth starch.

45 211È214.Starch/Sta� rkePrice M L, Butler L G 1977 Rapid visual estimation and

spectrophotometric determination of tannin content ofsorghum grain. J. Agric Food Chem 25 1268È1273.

Schnetzler K A, Breene W M 1994 Food uses and amaranthproduct research : a comprehensive review. In : AmaranthÈBiology, Chemistry and T echnology, ed Paredes-Lopez O.CRC Press, Boca Raton, FL, USA, pp 155È184.

Snyder H E, Kwon T W 1987 Soybean Utilization. Van Nos-trand Reinhold Co, New York, USA, pp 189È193.

Sullivan D M, Carpenter D E 1993 Methods of Analysis forNutritional L abelling. AOAC International, Arlington, VA,USA, pp 425È428.

Wu H, Yue S, Sun H, Corke H 1995 Physical properties ofstarch from two genotypes of Amaranthus cruentus of agri-cultural signiÐcance in China. 47 295È297.Starch/Sta� rke

Yue S X, Sun H L, Tang F D (Eds) 1993 T he Research andDevelopment of Grain Amaranthus in China. Chinese Agri-cultural Science and Technology Publishing House, Beijing,PeopleÏs Republic of China.