ProjectPlan Bookcase Traditional

Transcript of ProjectPlan Bookcase Traditional

1 WWW.FAMILYHANDYMAN.COM

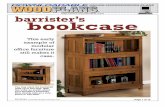

TraditionalBookcaseProject Plan

Createyourownclassicbookcasewithsimpletoolsinfiveeasy-to-followsteps.

byDavidRadtke

Createyourownclassicbookcasewithsimpletoolsinfive

Traditional

byDavidRadtke

Bookcaseeasy-to-followsteps.

The bookcase construction isstraightforward and basic, so it’s easyto cut and fit the pieces. The fixedshelves add stability and are designedto hold a variety of average-sizedbooks, but you can customize theshelf heights to suit your collection.

Our bookcase ismade primarilyfrommaple plywood and detailedwithsolidmaple boards and regular lum-beryardmaple colonial stopmolding(Fig. A). Ifmaple isn’t your favoritewood, you could opt for birch and oakplywood andmoldings. They too arecommonly stocked in full-service lum-beryards and good home centers.

The grooved vertical front pieceson each side (fluted casing) may lookchallenging, but with a shop-made jigand a router, you’ll get perfect results.For details, see “Make Your OwnFluted Casing—The EasyWay,” p. 8.Figure on about a day and a half forcutting and assembling, plus a coupleof evenings for sanding and finishing.

DDon’t make the samemistake I madewhen I moved into my new house. Ileft my books stacked in boxes fortwo years before I finally got aroundto building bookcases. I can’t tell youhowmany times I rummagedthrough those boxes looking for ref-erence books or that mystery novel Iwanted to revisit.

When you’re ready to displayyour literary favorites, don’t go to afurniture store and settle for apoorly constructed bookcase withzippo for detail. For about the costof a cheap bookcase ($300), you canbuild this handsome and solid heir-loom-quality piece.

This project is too challenging fora beginner. Don’t tackle it unlessyou’ve used a router and a dowelingjig and feel confident with your circu-lar saw.We’ve broken the project intofive easy-to-follow steps and givenyou the option of selecting your owntrim and finish.

2 WWW.FAMILYHANDYMAN.COM

This article originally appeared in The Family Handymanmagazine. For subscription information, visit www.familyhandyman.comAddresses, phone numbers, prices, part numbers and other information may have changed since original publication.Copyright ©2005 Home Service Publications, Inc. All rights reserved. Unauthorized reproduction, in any manner, is prohibited. The Family Handyman, Handy Hintsand Great Goofs are registered trademarks of RD Publications, Inc. Ask Handyman, Handyman Garage, How a House Works, Re.Do, Re.Mod, TFH Reports, The HomeImprovement Authority, Using Tools, Woodworks, Wordless Workshop, Workshop Tips, You Can Fix It, You Can Grow It are trademarks of RD Publications, Inc.

THE FAMILY HANDYMAN APRIL 1999 3

ALL YOUNEED ARE SIMPLEHANDAND POWER TOOLSThe only power tools you’ll need are a7/8-hp router, a circular saw (Photo1) with a fine-toothed plywood blade,a drill, a power miter saw and anorbital sander. (And you could sub-stitute a handmiter saw for the powerone.) You’ll also need other wood-working tools like C-clamps, barclamps, spring clamps, a screwdriver,drill bits and a doweling jig (Photo 5)with a 3/8-in. brad point bit.Although you could get bywithout it, a24-in. Clamp&Tool guide (Photo 2)is great for routing perfectly straightgrooves (dadoes) to support the shelves(see the Buyer’s Guide, p. 11). This toolclamps firmly to the edges of the ply-wood and leaves an unobstructed pathto push your router fromone side tothe next. It’s not a tool you’ll get anduse only once. TheClamp&Tool guidehas dozens of uses, such as helping youmake super-straight crosscuts (perpen-dicular cuts to thewood grain) on lum-ber and plywood.

Build thebasicbox,p. 4

Makethedecorativefrontpieces,p.7

Applythefronttrim,p.10

Makeyourownflutedcasingtheeasyway,p.8

WipeonabeautifulDanishoilfinish,p.11

Step2

Step1

Step3

Step4

Step5

3 WWW.FAMILYHANDYMAN.COM

GLUE AND SCREW the ply-wood shelves to the sideswith 1-5/8 in. wood screws.Drill pilot and countersinkholes no more than 3/4 in.from the front and back toaccept the screws. Thescrews will be covered bymolding later. Next, align the1/4-in. plywood back (C) andsquare the assembly by nail-ing into the back of the sidesand shelves.

SAWBASE

RIPGUIDE

TOP PIECE OFRIP GUIDE

FACTORYEDGELOWER EDGE

OF RIP GUIDE

ALIGNYOUR MARKWITH THIS EDGE

PIECE BEING CUTFROM SHEET

EDGEGUIDE

23/32"GROOVES

A

RIP 3/4-in.hardwood ply-wood into11-1/4 in. widepieces for thesides and theshelves. Cutthese pieces tolength to makethe two sidesand the sixshelves. Alsocut the 1/4-in.plywood backto width andlength whileyou have theedge guideset up.

MARK ANDCUT the 1/4-in.dadoes in thesides. Use aspecial23/32-in. widestraight-cutrouter bit for atight fit for thethinner-than-3/4-in. ply-wood.

GET STRAIGHT RIP CUTSWITH A HOMEMADE JIGIf you’ve got a fancy setup for achiev-ing perfectly straight cuts (rips) froma sheet of plywood on a table saw orsomething else, all the better. If youdon’t, this simple jig (Photo 1) iswhat you need.

Construct the jig by screwingtogether two scraps of either 1/2- or3/4-in. plywood. The top narrowpiece (2-1/2 in. wide) must have onefactory straightedge. Leave the bot-tom piece a few inches wider thanyour saw base (in most cases, that willmake the bottom piece about 10 in.).Screw the top piece to the bottomwith drywall screws every 5 in. Nowyou need to trim the lower piece per-fectly straight.

Now, clamp the jig to the entirepiece of 3/4-in. maple plywood, set-ting it to the correct width. Rip-cut(lengthwise) the two bookcase sides(A), then cut them to length (cross-cut). Rip two additional lengths andcrosscut them (outer sides “A” facingup) into 31-7/8 in. lengths for theshelves. Cut the 1/4-in. plywood back(C) to the dimensions in the CuttingList, p. 7.

A

B

BOTTOMSHELF (B)

Step1Building thebasic box:Sides, shelves andback

B o o k c a s e

3

2

1

4 WWW.FAMILYHANDYMAN.COM

STOPMOLDING(E)

DIVIDERMOLDING(D1)

ROUT THE 1/4-IN. DEEP SHELFSLOTS INTO THE SIDESThe shelves (B) lock into 1/4-in. deepslots (dadoes) in the upright sides(A). Tomake the dadoes, install a23/32-in. straight-cut router bit (seeBuyer’s Guide, p. 11) in your routerand set the depth of cut to 1/4 in. Thespecial 23/32-in. router bit is thesame width as 3/4-in. plywood, so theslots it cuts will make a nice snug fitfor the shelves. Don’t substitute a 3/4-in. bit; you’ll be unhappy with thesloppy fit.

Clamp your edge guide (Photo 2) toa scrap piece of plywood and rout a testdado. Thenmeasure the distance fromthe edge guide to the near edge of thedado. Thiswill give you the distanceyou’ll need for setting up each dadogroove.Mark and cut (see Fig. A) all the1/4-in. deep dadoes on the inside faceof each part A. TIP:When you cutdadoeswith a router and straightedge,clamp the edge guide to the left of yourintended groove, then push the routerbase away fromyou as you rout thegroove. This keeps the router tightagainst the edge guide as the bit rotatesthrough the cut. Finish-sand all the ply-woodpieces nowwith 150-grit sandpa-per; otherwise, you’ll strugglewithsanding in tight spaces after assembly.

APPLY thedivider and stopmolding to thesides of the

bookcase. Glue,then nail the

divider moldingto the sides

with 6d finishnails (two perpiece). Glue thestop molding to

the sides asshown in Fig. A.Further securethe moldingwith 7/8-in.brads spaced

every 12 in. Setthe brads with anail set. You’llfill the holes

later with woodputty.

GLUEANDSCREWTHESHELFENDS INTOTHESLOTTEDSIDESIt’s essential to have a flat surface forassembly so you can align the shelvessquarely to the sides. The shelves (B)should fit tightly into the grooves.Test the fit. If the shelf won’t slip intothe dado, wrap some fine sandpaper(150-grit) around a 1/2-in. squareblock about 3 in. long and sand thesides of the grooves until you get asnug fit.

Once you’re sure everything fits,you’ll have to work fast to completethe assembly. You’ll need to get theshelves glued into the dadoes andthe 1/4-in. plywood back nailed

DETAIL THE SIDESOF THE BOXWITHMOLDINGNow it’s time to detail the sides withthe divider moldings (D1 and thelower D2; Fig. A) and the colonial topmoldings. The divider molding, withthe stopmolding (Photo 4), breaksthe strong vertical line to give thebookcase a distinct architectural look.It has a base section, a main verticalsection and a top section similar tothe cornice of a building.

To begin detailing the sides, firstcut the divider molding,then glue and nail it (use6d finish nails) to the sides(Photo 4). Drill pilot holesthrough the molding toprevent splitting. The colo-nial stop molding (E) andthe backside of the dividermolding must be appliedso they align flush with the1/4-in. plywood back. Glueand clamp this molding tothe side. Drive 7/8-in. wirebrads through the stopmolding into the sidesevery 12 in., then set them.

into place before the glue sets(about 15 minutes). This means youneed to get your drill, countersinkbit and a power screwdriver andscrews ready to go.

Spread a light coat of glue on oneshelf side and into the dado, then fiteach shelf into its dado. Have a moistcotton rag handy to wipe away anyoozing glue. Next, screw the shelf tothe side as shown in Fig. A, p. 84. Thescrew holes for each shelf side must bepredrilled within 3/4 in. of the frontand the back. The screwheads will becovered later by the molding. Followthis procedure for each shelf.

Now, before the glue sets, grab the1/4-in. plywood back (C) to squarethe assembly. There’s no need to gluethe plywood back to the shelves orsides. First nail the back along oneentire side using a 1-in. panel nailevery 5 in. Then align the top of theother side flush with the top edge ofthe plywood; this will square theassembly. Nail along this side, thennail the rest of the back into the back-side of the shelves. Let the glue dry forat least two hours before continuing.

B o o k c a s e

4

5 WWW.FAMILYHANDYMAN.COM

FIG. A

6 WWW.FAMILYHANDYMAN.COM

APRONASSEMBLY

STOPMOLDING(E)

STOPMOLDING(E)

DOWELINGJIG

CORNERBLOCKS(F)

APRON(G)

CUT THE CORNER BLOCKSAND THE CURVED APRONANDGLUE THEM TOGETHERThe decorative upper and lower cornerblocks (Photo 6) are simple tomakefrom3/4-in. wide x 5-1/2 in. longpieces of solidmaple. The detail on thefront of the corner blocks ismade bygluingmitered colonial stopmoldingto each block face. First cut the fourcorner blocks (F) and the two curvedaprons (G). Use a 27-1/2 in. radius tomark the curve onto the aprons. A nail,a wire and a pencil will work fine. Drill

Step2

DRILL 3/8-in. dowel holes in the cor-ner blocks and corresponding holes inthe aprons. Glue and clamp thisassembly after you glue the stopmoldings to the front of the blocks.

GLUE the stop molding to the front ofthe corner blocks. Be very preciseabout the miter cuts. A simplewooden handsaw miter box worksgreat for these small, hard-to-holdpieces. After the glue is set, sand theedges of the block with 100-grit, then150-grit, sandpaper. Glue the doweljoints and clamp the corner blocks tothe apron to complete the apronassemblies.

Making thedecorative frontpieces: Corner blocks, curvedaprons

the dowel holes into the inside edge ofthe blocks and corresponding holesinto the end of each apron. Don’t gluethese parts together yet.Mark thebackside of each block and apron soyou knowwhich piece goes where.

Now to detail the corner blocks,miter the stopmolding to fit theperimeter of each block. I used awooden handsawmiter box for con-trol. Avoid cutting small pieces withthe power miter saw. Once you’ve cutall the pieces, glue them to the blocksand clamp themwith spring clamps(Photo 6). When the glue is dry, sandthe edges of each block clean and gluethe doweled joints for each upper andlower apron assembly. Clamp eachassembly for at least two hours.

Cutting List

KEY PCS. SIZE & DESCRIPTIONA 2 3/4’’ x 11-1/4’’ x 78’’ maple

plywood sidesB 6 3/4’’ x 11-1/4’’ x 31-7/8’’

maple plywood shelvesC 1 1/4’’ x 32-3/4’’ x 76’’

maple plywood backD1 6 3/4’’ x 1-1/2’’ x 13’’

maple divider molding*D2 2 3/4’’ x 1-1/2’’ x 35-7/8’’

maple divider molding*D3 2 3/4’’ x 1-1/2’’ x 4-5/8’’

maple divider caps*E 80 7/16’’ x 1-1/4’’ colonial stop

ln. ft. molding (allows for waste)F 4 3/4’’ x 3-1/2’’ x 5-1/2’’ maple

corner blocksG 2 3/4’’ x 5-1/2’’ x 26-3/4’’ maple

curved apronsH 2 3/4’’ x 3-1/2’’ x 64-3/4’’ maple

fluted casingJ1 1 3/4’’ x 12-15/16’’ x 35-3/4’’

maple plywood topJ2 5-1/2 3/4’’ x 3/4’’maple edge

ln. ft. banding*K1 2 3/4’’ x 1-1/2’’ x 4’’ maple

front feet*K2 2 3/4’’ x 1-1/2’’ x 2’’ maple

back feet*L 2 3/4’’ x 5-1/2’’ x 11-1/4’’

support strips

*Have the lumberyard cut these piecesto width from a 1x6.

B o o k c a s e

6

5

7 WWW.FAMILYHANDYMAN.COM

Step3JIGBASE

5/16" x 3/4"HARDWOODRUNNERS

3/4" x 2"SIDES

1-1/2"

CENTERLINE

WIDTH OFROUTER BASE

13/16"

ALIGNTHE SIDESTO THE BASE

Making decorative flutes for cabinet trim was atask I dreaded for years. My first attemptsinvolved an edge guide attached to a router base.Invariably I’d slip up, the router would wander(usually on the last flute), and I’d have to start allover. Later I tried a router table. But as I reposi-tionedmy hands while feeding the board over thebit, burnmarks would appear, and they’d takehours to sand out. But now that I’ve built this jigfor my hand-held router, I’ve overcome thoseproblems. Now I enjoy churning out perfectlyfluted pieces.

BUILD THE FLUTING JIGFROM 3/4-IN. PLYWOODAND TWOHARDWOOD STRIPSUse one-third of a sheet (lengthwise) of 3/4-in.cabinet-grade plywood for the base and sides ofthe jig and two strips of hardwood for the runners(Photo 1). Here’s how tomeasure, cut and assem-ble the jig:� Measure the base of your router plus two thick-nesses of your plywood sides (usually 23/32 in.each, or 1-7/16 in. total) to get the right width forthe jig base.� Rip the measured jig base width lengthwise(8 ft.) from your plywood sheet. Accuracy is criti-cal; use your cutting guide for your circular sawor a table saw.� Rip the two plywood sides 2 in. wide.� Rip two runners 5/16 in. wide from a 3/4-in.thick hardwood board.� Cut the 5/16-in. wide dadoes into the two sidesusing either a dado blade or multiple passes with astandard table saw blade. The dadoes must be3/8 in. deep.

BLANK

FLUTELOCATIONS

1/2" MINIMUMFROM FRONTEDGE

CENTERLINE

DRILL holes 1-1/2 in. on both sides of the center line of your jig. Keepthe holes about 4 in. back from each end and spaced about 2 ft. aparttoward the middle. The holes are spaced 1-1/2 in. from the center toavoid having screw holes show through your flutes. If you rout a dif-ferent width or number of flutes, you may need to change the hold-down screw locations. After drilling the holes, flip the jig over andcountersink them to accept screws for holding the workpiece.

MARK your flute locations 1 in. apart on each end of your 1x4blank. Align the center mark of the workpiece with the center line ofthe jig and screw the blank to the jig from underneath. Do the sameon the opposite end and be sure to install the hold-down screwstoward the middle as well. If your blank has a slight bow or crook,the hold-down screws will hold it straight and flat as you rout.

Makeyourownflutedcasing—theeasyway

7

8

B o o k c a s e

8 WWW.FAMILYHANDYMAN.COM

THE FAMILY HANDYMAN APRIL 1999 9

FINALFLUTE

CENTERLINE

5/16" DEEPCUT

ROUT each side fluteusing the same two-pass method as withthe center flute. Whenthe blank is positionedto the side of the jig,only one row of hold-down screws isnecessary.

ROUT the first pass of thefirst flute 5/32 in. deep. Don’ttry to take the whole depthat once, because you mayget some tear-out and chat-ter. For a smooth cut, keepthe router moving all theway to the other end in onecontinuous pass.

ROUT a second passwith the router bit setat 5/16-in. depth. Besure to check yourrouter depth gauge

so you can repeat theexact depth for the

final pass on the nextflutes.

� Glue (carpenter’s glue worksbest) and screw the jig sides tothe jig base (Photo 7). The sidesmust be flush with the base oneach side. Drill pilot and coun-tersink holes for the screws. Usea 1-1/4 in. screw every 8 in. alongeach side.� Secure the hardwood runnersinto the dadoes using carpenter’sglue and spring clamps. Set thejig aside to dry.

Once the jig is assembled, testthe fit of your router base. Moveit along the chute from end toend. It must glide freely along therunners without binding on thesides. Youmay have to sand thesides a bit if the router is too tightin the chute. Conversely, ifthere’s play between the routerand the sides, install a strip ofveneer on one side. (See theBuyer’s Guide, p. 11.)

Now that you’ve made the jig,follow the instructions in Photos7 – 11 and practice on somescrap pieces. To ensure consis-tent depth (you’ll make twoprogressively deeper passes foreach flute), familiarize yourselfwith the depth gauge on yourrouter. It’s usually a dial or ringon the housing.

5/32" DEEPCUT

9

10

11

B o o k c a s e

9 WWW.FAMILYHANDYMAN.COM

CUT THE PLYWOOD TOPANDGLUE SOLIDMAPLESTRIPS TO THE EDGENow cut and glue the stopmold-ing (E) to the top of the plywoodback. Use spring clamps to hold itin place.While the glue is drying,cut the plywood top (J1) and the3/4 x 3/4-in. edge banding (J2) tolength. Glue themolding aroundthe front and sides of the plywoodtop. Usemasking tape to hold theedging in place until the glue dries.Once the glue has dried, sand theedging flush to the plywood on thetop and bottom. Screw the topassembly to the sides (A). Use 4dfinish nails to secure the top to thestopmolding in the back. Now cutthe stopmolding strips to coverthe cut-edge shelf fronts. Securethemolding with glue and 7/8-in.brads. Set the brads and fill theholes with wood putty.

GLUE ANDNAIL YOUR DETAIL MOLDINGSTO THE BOOKCASE FRONTTurn the bookcase on its back to glue the front trim piecesin place. Start by aligning the bottom edge of the lowerapron assembly even with the bottom edge of the sides (A).Let the apron overhang the sides an equal amount. Markthis location. Next, glue and clamp the assembly (Photo12) in place. Next, cut and glue the fluted casing pieces inplace. Be sure they overhang the same distance as the lowerapron assembly. For added insurance, nail the casing to theplywood sides with six 6d finish nails (Fig. A, p. 6) spacedevenly along the length.

Now glue and nail (Photo 13) the divider caps (D3) tothe top of the fluted casing and to the side pieces of dividermolding (D1) with 4d finish nails. The caps are a continua-tion of the divider molding and establish an end point forthe fluted columns. After the upper apron assembly is gluedin place, glue the upper full-length divider molding (Fig. A)to the top of the apron assembly and then nail the miterjoints together with 4d nails.

Applying the fronttrim, topand feet

GLUE the upper apron assembly to the sides after nailingthe divider cap molding to the top of the casing. Once theapron assembly is glued, the next step is to glue, nail andclamp the top center section of the divider molding in place.

ALIGN the bottoms of the fluted side casing with the cornerblocks. Glue, clamp and nail the casing to the bookcasesides. Use six 6d finish nails per side. Set the nails and fill thenail holes.

SCREW THEFEET TO THEBOTTOM FRONTAND BACKTo complete theassembly, cut thefront and back feetand secure eachwith two 1-5/8 in.wood screws. Besure the supportstrips (L) are gluedto the underside(Fig. A, p. 6) first tohelp support thefeet. Cut the frontand back feet andscrew them to thebottomwith 1-5/8in. wood screws.

APRONASSEMBLY(TOP)

DIVIDERMOLDING(FRONT) (D2)

1/4" PLYWOODBACK (C) DIVIDER

CAP (D3)

FLUTEDCASING (H)

DIVIDER MOLDING(FRONT) (D2)

APRONASSEMBLY(BOTTOM)

Step4

12

13

B o o k c a s e

10 WWW.FAMILYHANDYMAN.COM

Step5WipeonabeautifulDanishoil finish

Bookcase projects like this are reallytough to finish with a brush-on var-nish after assembly, so I used a wipe-on oil/varnish commonly called Dan-ish oil. You can select coloredoil/varnish or clear. The combinationoil/varnish is as easy to apply as an oiland buffs to a nice luster like abrushed-on varnish. Apply the finishaccording to the manufacturer’sinstructions, using a cotton rag andkeeping a brush on hand to get intothe corners. Fill all the nail holes afterthe first coat of finish is dry. Use col-ored putty sticks to match the sur-rounding wood tone.Two coats offinish will be adequate but a third willgive you a bit more luster and depth.NOTE:Hang the oil-soaked rags out-side to dry to prevent combustion.

Although stable on hard flooring,tall narrow cabinets like thisbookcase can be unsteady whenset on wall-to-wall carpeting. The1/4-in. thick tackless wood stripbelow the carpeting and near thewall can slightly elevate the backof the cabinet and make thebookcase tippy. You can remedythis problem by reducing thethickness of the back feet by 1/4in. and attaching an 18-gaugesteel safety wire, as shownbelow, near the center back ofthe cabinet. Fasten the other endof the wire to a stud.Mark your bookcase height on

the wall. Screw in a 2-1/2 in. dry-wall screwwith a finish washerhalfway into the wall stud, wrapthe wire around the screw, thentighten the screw to the drywall.Drive a 1-in. screw and finishwasher near the back of thebookcase into the plywood top.Position the bookcase and windthe wire tight around the screw.Tighten the screw and finish wiredown and cut the excess wire.Now you can pile on the books.

Photography • BILL ZUEHLKEIllustration • EUGENE THOMPSONProject Design • DAVID RADTKE

Buyer’s Guide

BOOKCASE� Clamp & Tool guide is available from Toolson Sale (800-328-0457). Catalog No. CT24C,$24.95.� The 23/32-in. router bit is available fromTrend-lines (800-877-7899). The 1/4-in. shankis Catalog No. CT1097K, $10.95; 1/2-in. shankis Catalog No. CT1098K, $10.95.

FLUTE JIG� Pressure-sensitive veneer strips: CatalogNo. 77925, $3.99.� Polycarbonate base blanks: Catalog No.24935, $14.99.� 1/2-in. core-box bit: Catalog No. 90924,$12.69.All available from Rockler Woodworking andHardware, (800) 279-4441.

Shopping List

ITEM QUANTITY3/4’’ x 4’ x 8’ maple plywood 1-1/4 sheets1/4’’ x 4’ x 8’ maple plywood 1 sheet1x4 x 7’ maple 21x6 x 5’ maple 4Colonial stop molding 80 ln. ft.7/8’’ brad nails 1 pkg.1’’ panel nails (for plywood back) 1 pkg.Carpenter’s glue 1/2 pint1-5/8’’ wood screws 1 lb.6d finish nails 1 lb.4d finish nails 1 lb.Colored wood putty sticks 2Router bits (see Buyer’s Guide)

B o o k c a s e

safetywire

2-1/2" DRYWALL SCREW

CABINETTOP

WIRE

FINISHWASHERSSCREW

WALLSURFACE

DRYWALL

WALLSTUD

Anchor yourbookcasewith a

11 WWW.FAMILYHANDYMAN.COM