Project on Rolling Mill

-

Upload

subhash031 -

Category

Documents

-

view

274 -

download

1

Transcript of Project on Rolling Mill

-

8/3/2019 Project on Rolling Mill

1/11

Department: MECHANICALENGINEERING

INDUSTRIAL TRAINING ON Alfoil

Prepared bySubhash kumar

-

8/3/2019 Project on Rolling Mill

2/11

Training experience at India Foils Limited has been truly afulfilling and rewarding one. Many people have contributedtowards making this project a success. The text below is my

humble & heartfelt expression of gratitude to all those who havecontributed to this project by their valuable suggestions,inspiration, support and co-operation.

I would like to thank Mr. Debashis Halder, Manager-Human

resource department whose encouraging cooperation have madea great success to fulfill our project and providing all kind ofsupports.I would also be thankful to Mr. Pranab Basu Roy for givingeffortless guidance at our training .

-

8/3/2019 Project on Rolling Mill

3/11

Characteristics of Aluminium

Aluminium is a soft, durable, lightweight, ductile andmalleable metal with appearance ranging from silveryto dull gray, depending on the surface roughness.Aluminium is non-magnetic and non sparking. It isalso insoluble in alcohol, though it can be soluble inwater in certain forms.

The yield strength of pure aluminium is 711MPa,while aluminium alloys have yield strengths rangingfrom 200MPa to 600MPa

-

8/3/2019 Project on Rolling Mill

4/11

USE OF GRAPHITE IN ALUMINIUM FOILS

PRODUCTION

Graphite is the most stable form of carbon under

standard conditions. Therefore, it is used inthermochemistry as the standard state for defining theheat of formation of carbon compounds.

Graphite spray is used in the time of casting and

formation of sheet metal of aluminium.

-

8/3/2019 Project on Rolling Mill

5/11

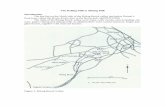

Formation of Al sheet from Ingot

Molten material of Al aresend to the the Holdingfurnace. It solidifed and startrolling for convertion intosheet form(width 1490mmand thickness 7.2 mm).

Casting speed is about 0.82m/min.

-

8/3/2019 Project on Rolling Mill

6/11

Rolling Aluminum Metal

the metal passes through aseries of rolling mills with

a gauge reduction of 50%or more for each passthrough each mill.

Reduction of thickness in

ACHENBACH MACHINEare formed in six pass.

-

8/3/2019 Project on Rolling Mill

7/11

Rolling mill

Rewinding machine: raw materialscoming to the industry are aluminiumrolls of thickness 300-600 microns. It

comes on cardboard spool rolled andpacked. But cardboard spool cannot bemounted on the machines because itcannot be hold by the chuck. so a

rewinding machine is used to roll it ona spool of diameter 660 mm.

ACHENBACH MACHINE: It is a 4high universal rolling machine.

-

8/3/2019 Project on Rolling Mill

8/11

Aluminium Foil Separator

The Aluminium Foilseparator machine isused to open/separate

the paired foils into tworolls of maximum 600mm diameter. A sideslitting system is also to

provided with themachine for finalmaterial at re-winder.

-

8/3/2019 Project on Rolling Mill

9/11

Aluminium foil conversion

VMCH Coating Machine: It is three roll coating

system V.M.C.H coating is done on Aluminium foil.High velocity VMCH drying system equipped withinsulated drying tunnel of 10000 mm length. VMCHtunnel is distributed in 8 Heating zones & 2 coolingzones having individual air blower for bettertemperature control.

-

8/3/2019 Project on Rolling Mill

10/11

-

8/3/2019 Project on Rolling Mill

11/11

CONCLUSION

From this project we have come to know that howaluminium foils of low thickness are made. Morespecifically how a rolling mill works. The different steps to

reduce the thickness as written earlier are clearlyunderstood. As this is a very vast industry and only 1 monthis not enough to understand it fully we have tried our levelbest to get valued information in this span of time.

This company as a great heritage and it has contributed alot in the upcoming of Aluminium foils business in India.