Project Landing Gear - Report

-

Upload

abdul-hafiz -

Category

Documents

-

view

219 -

download

1

Transcript of Project Landing Gear - Report

-

7/28/2019 Project Landing Gear - Report

1/81

Hogeschool van AmsterdamAmsterdamse Hogeschool van Techniek

Aviation studies

2008

Imad Aarrass

Omer Badal

Jordi van de Bogaart

Sara van Grieken

Ahmet Pehlivan

Benjamin Wennink

Reha Yali

Project Landing gear- Boeing 737-800

Gear down, 3 green

-

7/28/2019 Project Landing Gear - Report

2/81

Preface

This project group report is produced by group 2A2E. The process of making the report was a educating and challengingone. The group would like to take this opportunity to thank Mr. P. van Langen for his guidance and assistance during theprocess of making this report. We would also like to thank Mrs. Wentzel for providing the guidance of proper reportingtechniques and Benjamin Vlijm for his part of the project and we regard the fact that he had to stop early on.

The group 2A2E consists out these seven persons:

Ahmet Pehlivan Sara van Grieken Benjamin Wennink Benjamin Vlijm (ex member) Omer Badal Reha YaliJordi van den Bogaart Imad Aarrass

-

7/28/2019 Project Landing Gear - Report

3/81

Table of contents

Summary ....................................................................................................................................1

Introduction...............................................................................................................................2

1. Landing gear Boeing 737-800 NG ..................................................................................31.1 Purpose ....................................................................................................................................31.2 Structure ..................................................................................................................................3

1.2.1 General overview................................................................................................................41.2.2 Nose landing gear struts .....................................................................................................51.2.3 Main landing gear struts......................................................................................................71.2.4 Wheels and tyres................................................................................................................7

1.3 Functioning ...............................................................................................................................91.3.1 Extension and retraction mechanisms...................................................................................91.3.2 Brakes.............................................................................................................................121.3.3 Steering...........................................................................................................................14

1.4 Regulations .............................................................................................................................151.4.1 General ...........................................................................................................................16

1.4.2 Shock absorption..............................................................................................................161.4.3 Retracting/extending mechanism .......................................................................................161.4.4 Brakes.............................................................................................................................171.4.5 Wheels and tyres..............................................................................................................171.4.6 Steering systems..............................................................................................................18

2. Analysis landing gear Boeing 737-800 NG ..................................................................192.1 Design aspects ........................................................................................................................19

2.1.1 Durability.........................................................................................................................192.1.2 Safety .............................................................................................................................20

2.2 Forces on the landing gear during landing..................................................................................202.2.1 Pre-calculations ................................................................................................................202.2.2 Forces during landing........................................................................................................22

2.2.2 Forces and kinetic energy during landing ............................................................................232.3 Forces during a rejected take-off...............................................................................................232.3.1 Forces during take-off.......................................................................................................232.3.2 Forces during rejected take-off ..........................................................................................25

2.4 Vibrations ...............................................................................................................................282.4.1 Occurring forces...............................................................................................................282.4.2 Stress..............................................................................................................................28

3. Troubleshooting.............................................................................................................303.1 Malfunctions............................................................................................................................30

3.1.1 Main wheel tyre thread separation .....................................................................................303.1.2 Nose gear collapse ...........................................................................................................313.1.3 Insufficient lubrication of the nose landing gear ..................................................................33

3.2 Maintenance............................................................................................................................34

3.2.1 Checks ............................................................................................................................343.2.2 Maintenance manual.........................................................................................................35

3.3 Costs......................................................................................................................................353.3.1 General costs ...................................................................................................................353.3.2 Costs for tyres and brakes.................................................................................................36

3.4 Conclusion ..............................................................................................................................36

Bibliography.............................................................................................................................38

List of abbreviations................................................................................................................39

List of appendices....................................................................................................................40

-

7/28/2019 Project Landing Gear - Report

4/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 1 -Project group: 2A2E

Summary

Airline Amstel Leeuwenburg Airlines has assigned the engineering department to perform an investigation of possible malfunctions whichcan occur in the landing gear and related systems. Therefore an analysis of the landing gear functions and lay-out need to be performed.In addition to this the influence on the aeroplanes dispatch, to be precise the airworthiness, is investigated.

This investigation is specified to one type of aeroplane that Amstel Leeuwenburg Airlines possesses; the Boeing 737-800 NG. The Boeing737-800 NG landing gear is based on a conventional tricycle gear, involving two main gear assemblies and one nose gear assembly. Thelanding gear fulfils two main tasks; supporting and manoeuvring the aeroplane.The nose and main gear structure consist of three strut assemblies. This structure is based on a four bar undercarriage system involving;shockstruts, drag struts and side struts. This system is designed to support the weight of the aeroplane, to absorb the landing shock,provide damping and keeping the landing gear extended during different phases of operation. The landing gear is equipped with wheels toprovide a smooth manoeuvring ability and some damping. The tyres need to provide grip and are mostly inflated with nitrogen gas which iskept between 117 and 205 psi of pressure.The landing gear is equipped with a retraction and extending mechanism to keep the aeroplane more operational efficient. The retractionand extension can be regulated with the landing gear lever. The locking mechanism keeps the landing gear in the desired position.Uplocks, downlocks and doors are linked to a light indicating system to provide information to pilots and a safe operation. The landing gearis provided with hydraulic actuators for the operation. Because of this an alternate extension mechanism is present in case of a hydraulicfailure. Other systems related to the landing gear are the brakes and the steering system. The brakes provide the abil ity to stop the movingaeroplane early so that there can be landed on shorter runways. On the Boeing 737-800 NG multiple disc brakes are used. The brakingsystem is provided with subsystems like; alternate brakes, auto brakes and the anti-skid system. These subsystems contribute to a moreefficient way of braking. The steering system is based on push and pull actuators which provide a movement to the left or right. Thesteering can be established by moving the rudder pedals or the nose landing gear steering wheel. The main landing gear wheels areequipped with a shimmy damper to control the vibrations of the wheels during manoeuvring.An airworthy landing gear has to comply with the regulations prescribed in Certification Specifications 25 of the European Aviation SafetyAgency. Regulations concerning shock absorption, locking mechanisms, brakes, wheels, and tyres and steering are analyzed for thespecifications of which the landing gear has to comply with.

Part of the analysis of the landing gear is the so called design aspects. These aspects describe the durability, safety and the costs of theaeroplanes materials and operation.The landing gear has to cope with the taxiing, landing and take-off forces. The dispatch of the aeroplane can be influenced by the extremeuse of the landing gear. Therefore an analysis of two extreme situations is made; forces on the landing gear during landing and forces onthe landing gear during take-off/Rejected Take-off. The forces on the landing gear during require a sophisticated calculation. Thereforeassumptions are made to simplify the calculations. Assumed is that the sum of the horizontal and vertical forces are equal to zero while theaeroplane maintains a constant velocity. When the aeroplane attempts to land a landing flare is performed just before touchdown. In this

extreme situation this will not be done. The vertical velocity will be higher and resulting in a force on the main landing gear shockstruts ofalmost twice the weight of the Maximum Landing Mass. When the aeroplane has touched down the brakes have to absorb kinetic energyfrom the aeroplane.The other extreme situation is when an aeroplane with a Maximum Take-Off Mass must perform a Rejected Take-off. The brakes must befully applied and a max deceleration rate of 4.27 m/s can be achieved. Here is also the kinetic energy calculated which the brakes mustabsorb from the aeroplane. This kinetic energy of the aeroplane is transformed to heat. The temperature change of the brakes during aRejected Take-Off is 462.2 Kelvin.An aeroplane during operation has to cope with different kinds of forces. These forces are; pressure forces, pull forces, tearing forces anddrag forces. These forces cause different kinds of stress on the materials and structure of the aeroplane. This has different consequencesfor the operation and durability of the aeroplanes materials.

Based on the definition of the landing gear and the analysis, three occurring malfunctions in terms of the landing gear are investigated;main wheel tyre thread separation, nose gear collapse and lubricating the steering system. Tyres are components which are exposed tohigh speeds and friction drag. This causes the tyre to wear during a certain time. When a tyre is worn out it can be recovered. The thread

of the tyre is replaced by a new one. When this is done more than four times the chance of the thread coming loose is large. When thishappens it mostly causes damage to the structure of the aeroplane. This sometimes results in an inoperative aeroplane. The nose landinggear is vulnerable when the aeroplane is towed or push backed. This can result in a nose gear collapse. This incident causes structuraldamage to the fuselage of the aeroplane and the nose landing gear. When this malfunction occurs the aeroplane is always inoperative andneeds to be repaired. When the nose gear is not lubricated properly it produces awkward noises. As a result of this is that somepassengers were worried about the flight safety. This malfunction is harmless but can cause some wear and tear due to friction on the part.When a malfunction is not urgent enough to immediately keep the aeroplane on the ground, the problem can be dealt with during amaintenance check. There are different maintenance checks that variate to a walk around check to a heavy maintenance check. Themaintenance crew makes use of different prescribed documents like the Dispatch Deficiency Guide and the Minimum Equipment List. Thereports of the malfunctions are reported and processed by the Operations Control Centre.The costs of maintaining a landing gear are not so high because the systems are tough and kept basic. Therefore not many reports ofmalfunctions concerning the landing gear are experienced. The brakes and tyres are the main parts that need regular maintenance. Theseparts are mainly responsible for the yearly costs of the landing gear, excluding unforeseen costs.

Concluding, the landing gear of the Boeing 737-800 NG is not very vulnerable to malfunctions which involve the dispatch of the aeroplane.When it does, the aeroplane is sufficiently damaged which influences the airworthiness.

-

7/28/2019 Project Landing Gear - Report

5/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 2 -Project group: 2A2E

Introduction

The first project in the second study year is about landing gear. The assignment is to choose an existing aeroplane andprovide an analysis of the layout and the operation of its landing gear. The failures that could occur on the landing gearsystem and the influence these failures could have on the airworthiness of the aeroplane as a whole are required to be partof the analysis as well. The end product of the group project is a report which meets the requirements concerning reportingtechniques. The report will be clarified by a group presentation.

The main part of the report is divided in to three chapters, in order to provide a proper analysis of the chosen landing gear.The aeroplane that is chosen for analysis is the Boeing 737-800 NG, that has a tricycle landing gear. The layout of the noselanding gear and the twofold main landing gear is designed regarding the construction of the rest of the aeroplane and theposition of the centre of gravity. The analysis of the operation is divided in to the analysis of separate components of thelanding gear. The components are the struts, the retracting and extension mechanism, the wheels, the brakes and thesteering system of the nose landing gear. (1)The forces that exist on the landing gear are included in the analysis of the landing gear. When performing a landing or arejected take-off, these forces reach their highest values. The vibrations due to movement of the aeroplane and applyingbrakes are relevant for analysing the landing gear as well. The design aspects of the landing gear consisting of the designdurability and safety are described to clarify the analysis. (2)Three malfunctions concerning landing gear are described. This is done by defining the malfunction and its causes. Than theinfluence the malfunctions have on the airworthiness and the solutions that are designed for the certain failures aredescribed as well. The maintenance of the landing gear is done at the hand of several checks. Maintaining and replacing thelanding gear brings certain costs. (3)

The main used sources for the project report are: Wentzel (2007) for reporting techniques, IJspeert (2008) for the definitionof the assignment (Appendix I)and the Aircraft Maintenance Manuals of the Boeing 737 for the knowledge of the landinggear. more sources are found in the bibliography (p. 38). All abbreviations are marked with a * and in italic. The abbreviationsare recited in a list (p. 39). A list of appendices is found on p. 40. It contains the pyramid model (Appendix II), the projectplanning (Appendix III) and the process evaluation (Appendix XXIX).

-

7/28/2019 Project Landing Gear - Report

6/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 3 -Project group: 2A2E

1.Landing gear Boeing 737-800 GThe landing gear of a Boeing 737-800 NG* (B737) is used to carry the aeroplane around on the ground during take-off,landing, taxiing, towing and parking. The landing gear is designed to support the weight of the aeroplane and absorb a partof the shock during landing. (1.1)The landing gear of a B737 consists of a three strut assembly and wheels and tyres. (1.2)The landing gear parts have different functions. The extending and retracting mechanism makes it possible to extent enretract the landing gear, the brakes makes sure the aeroplanes is able to stop while on the ground and the steeringmechanism to control the aeroplane while on the ground. (1.3)The European Aviation Safety Agency*(EASA) established regulations which have to be followed when designing and usinga landing gear. (1.4)

The main sources of this chapter are: Boeing 737 Aircraft Maintenance Manual and EASA document CS-25.

1.1 Purpose

The landing gear of the B737 is a conventional tricycle gear; this means that there is one gear assembly in the front of theaeroplane and two equally divided gear assemblies at the back. Looking form a top down view, the shape of the landing

gears connected to each other would have the shape of a triangle. The nose gear assembly contains two wheels and theMain Landing Gear* (MLG) contains two assemblies each with two wheels. The landing gear of the B737 supports theaeroplane on the ground and besides that it has several functions like, taxiing, landings and take-offs. The landing gear isretractable for efficient aerodynamic operation.To take-off and land, the aeroplane must taxi to and from the runway. Landing gear has to withstand take-off velocities andlanding impacts. An aeroplane must be capable of manoeuvring on the runway, platform and taxiways. The function of thelanding gear can be categorized in two functions:

1. Support2. Manoeuvring

Ad 1. SupportAn aeroplane needs support when it is in rest on the ground or airport platform. An element between the fuselage and theground prevents the aeroplane of damage and keeps the aeroplane in equilibrium (fig. 1). Landing gear also creates a space

for further ground handling (1). The weight of the aeroplane is supported by the landing gear (2).

1. Upward forces (landing gear)2. Downwards force (centre of gravity)

Figure 1: B737 in a equal static rest

Ad 2. Manoeuvring

The landing gear of the B737 is capable of manoeuvring on the ground. This process is also called taxiing. This can bearranged by its own propulsion or by towing. This can be achieved efficient by the wheels. In this situation the gear isextended and carries the weight of the aeroplane. The landing gear contains brakes and these stop the wheels turning bycreating friction.The B737 has to cope with take-off forces and velocities. The wheels enable the aeroplane to move over the ground. Thismanoeuvring is achieved with the nose gear steering system.

1.2 Structure

The landing gear of the B737 consist of three strut assemblies, these assemblies are equally divided in the shape of atriangle. Every assembly has its own structure, and that would mean that each landing gear is built up of a four barundercarriage system (1.2.1). The assembly in front of the triangle is constructed in a certain way in order to fulfil thepurposes of supporting and manoeuvring (1.2.2). The two equal assemblies at the back of the triangle is constructedparallel to each other and fulfil the similar function (1.2.3). Wheels and tyres are made to interact the strut efficiently over theground (1.2.4).

-

7/28/2019 Project Landing Gear - Report

7/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 4 -Project group: 2A2E

1.2.1 General overview

The construction of the landing gear of the B737 is a sophisticated system. This system fulfils functions like steering andkeeping the aeroplane level when it is on ground. The explanation of the overview is divided in two sections:

1. Nose landing gear2. Main landing gear

Ad 1. Nose landing gearThe NLG is responsible for steering and also bears shock impacts (fig. 2). It is located at the front of the aeroplane so theaeroplane can make the turns more lucrative. The gear has a wheel well in the fuselage. This wheel well stores the gearwhen it is in flight. The NLG consists of a shockstrut, with an inner- and outer cylinder for the shock absorption (1). Holdingthe NLG in an extended or retracted position is being done by the drag strut (2). The locking mechanism locks the drag strutin the upper or lower position of the landing gear(3). The lock actuator activates the locking mechanism when the gear is upor down (4). Retracting and extending the gear is done by the NLG actuator(5). The shockstrut contains oil and nitrogen forshock absorption, the gas and oil can be charged by the valves (6). The torsion link (7) prevents the inner- and outer strut ofinternal rotation. The heel of the NLG is attached to the integral Axle (8). If wheel replacement is necessary, the innercylinder can be lifted by the jack pad (9). Tow fitting is available if towing is necessary (10).The doors (11) on each side of the struts close the wheel well in flight and are connected to the shockstrut.

1. Shockstrut2. Drag strut3. Locking mechanism4. Lock actuator5. NLG actuator6. Oil/nitrogen valve7. Torsion link8. Integral axle9. Jack pad10. Tow fitting11. NLG doors

Figure 2: Nose landing gear and door B737

Ad 2. Main landing gearThe MLGis located at the back of the aeroplane. It contains two assemblys, on each side of the wing. When the aeroplaneretracts it gear the wheel retract sideways in the fuselage of the aeroplane (fig. 3, p. 5) Each MLG contains a shockstrut (1),and it can be considered as the primary supporting of the landing gear. The shockstrut is stabilized by the drag strut (2). Theside strut holds the gear in extended position (3). The strut contains oil and nitrogen for shock absorption, the gas and oil canbe charged by the valves (4). During an active actuator, the walking beam (5) decrease forces that goes to the aeroplaneconstruction. The shockstrut is connected to the fuselage by the reaction link (6). The torsion link (7) prevents the inner- andouter strut of internal rotation. Heavy vibrations during braking and taxi are decreased by the shimmy dampers (8). Thewheels and brakes can be attached to the axle assembly (9). If wheel replacement is necessary, the inner cylinder can belifted by the jack pad (10). The inner, outer and centre door(11) closes the fuselage in flight.

-

7/28/2019 Project Landing Gear - Report

8/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 5 -Project group: 2A2E

1.Schock strut2.Drag strut3.Side strut4.Oil/nitrogen valve5.Walking beam6.Reaction link

7.Torsion link8.Shimmy dampers9.Axle assembly10.Jack pad11.MLG doors

Figure 3: Right main landing gear B737, looking aft.

1.2.2 ose landing gear struts

The NLG is a four bar system. Meaning that the NLG uses three struts and the fuselage to extend, retract and support the

nose of the aeroplane. The four bar system is the most common setup for a retractable landing gear. This is due to the factthat a four bar system allows a landing gear to be relatively light and compact compared to other systems. While all thestruts in the NLG combined serve the purpose of supporting the nose of the aeroplane. Each separate strut of the NLG onthe contrary, fulfils a task to accomplish the main purpose of the NLG. In the struts of the NLG a distinction can be madebetween the following three struts:

1. Shockstrut2. Drag strut3. Torsion links

Ad 1. ShockstrutThe NLG shockstrut fulfils two functions, the main function is to support the weight of the nose of the aeroplane. The secondfunction is to absorb the landing shock which acts like a damper. The damper of the NLG is based on an oleo-pneumaticshockstrut (fig. 4, p. 6). It consists out an outer cylinder (1), which is attached to the aeroplane and an inner cylinder (2),

which is attached to the axle and tyres. The outer and inner cylinder can move in and out of each other. The outer cylinderfeatures two outer(3) and one centre (4) chamber that are filled with nitrogen or dry air. In the centre chamber this nitrogenor dry air is kept at a lower pressure than the two outer chambers. The inner cylinder has one chamber (5) filled withhydraulic fluid. The inner cylinder chamber is divided into two sections by and orifice (6) and a tapered rod (7) that can movein and out of the orifice.

-

7/28/2019 Project Landing Gear - Report

9/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 6 -Project group: 2A2E

1. Outer cylinder2. Inner cylinder3. Outer chambers4. Centre chamber5. Inner cylinder chamber6. Orifice7. Tapered rod

Figure 4: Shockstrut lay-out.

When the shockstrut is compressed during landing, the inner cylinder is forced into the outer cylinder. This will result into thecompression on the nitrogen in the upper chambers. This compression will absorb most of the energy that is created duringthe landing shock, thus absorbing the shock. The general gas law (Formula 1) explains why the landing shock is absorbeddue to the compression of the nitrogen. When the inner cylinder is forced into the outer cylinder the volume will decrease,this means that the pressure has to increase in accordance to the gas law. It can now be concluded that a certain amount ofvolume has been traded against a higher pressure, this change absorbs most energy of a landing impact. At the same time,when the inner cylinder is forced into the outer cylinder, the hydraulic fluid which is uncompressible will be forced through theorifice. During this process the energy from the compression will be converted into heat due to the friction between the fluidand the orifice. This conversion from energy is responsible for the damping of the aeroplane during landing. Note, that thetapered rod decreases the size of the orifice depending on the compression. This means that when the shock is compressed

further, more force is needed to force the hydraulic fluid through the orifice. This will automatically result in more friction, thusmore energy is converted which means more dampening. The two nitrogen chambers under different pressures make surethat when the shockstrut is decompressed, the decompression happens gradually.

Formula 1

p = Pressure [Pa]V = Volume [M3]T = Temperature [K]C = Constant

The shockstrut also features gas and oil changing valves. These valves allow personnel to pressurize the shockstrut andalso allow hydraulic servicing of the shockstrut.

The axle of the NLG is directly attached to the inner cylinder of the shockstrut. Thus meaning that when the axle has to bereplaced, the entire inner cylinder has to be replaced as well. The axle of the NLG also supports the possibility to be towedby a tow bar. A jacking pad is also provided to enable to jack the NLG and replace the tyres. A jack pad is basically a bulgeon the bottom of the shockstrut. This bulge fits into a bulge shaped hole on the top of a jack. When the shockstrut is jackedthis hole will be placed over the bulge, which makes sure that the jack can not move when the weight of the shockstrut iscarried by the jack.

Ad 2. Drag strutThe drag strutis used for holding the shockstrut in the extended position. This is accomplished by preventing the shockstrutfrom folding back into the retracted position. The drag strut consists out off an upper and a lower link and is hinged in thecentre. The upper link is connected to the nose wheel side wall structure, while the lower link is connected to the outercylinder of the shockstrut. During retraction and extension the drag strut will fold at the hinge, thus allowing the shockstrut toretract.

-

7/28/2019 Project Landing Gear - Report

10/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 7 -Project group: 2A2E

Ad 3. Torsion linksThe torsion links prevent the inner cylinder of the shockstrut from turning inside the outside cylinder of the shockstrut. Onlywhen a steering force is applied, is it possible to let the two cylinders turn inside each other. The torsion links do allowvertical movements of the shockstrut. Torsion links consists out of an upper link and are connected at the aft ends. Theupper link is connected to the outer cylinder, while the lower link is connected to the inner cylinder. When a steering force isapplied to the outer cylinder, the force will be transmitted through the upper link to the lower link. The lower link on its turn,

turns the inner cylinder, allowing the wheel to turn.

1.2.3 Main landing gear struts

The MLG consists out two identical gears placed on either side of the aeroplane. The MLG consists out a four bar typelanding gear. This results into the fact that each strut of the landing gear fulfils a part in supporting the aeroplane. The MLGconsists out the following struts:

1. Shockstrut2. Drag strut3. Torsion links4. Side strut5. Axle assembly6. Reaction link

7. Walking beam

Ad 1. ShockstrutThe shockstrut of the MLG supports most of the aeroplanes weight and is basically a bigger version of the shockstrut of theNLG. The MLG needs a bigger shockstrut because it supports more weight than the NLG and the B737 touches down withthe MLG first. Meaning that it needs to absorb a bigger shock.

Ad 2. Drag strutThe drag strut stabilizes the shockstrut of the MLG in a fore and aft position. The drag strut is an integral part of the MLGshockstrut.

Ad 3. Torsion linksThe torsion links on the MLG serve the same functions as the torsion links on the NLG. The torsion links on the MLG are

also installed exactly the same as on the NLG.

Ad 4. Side strutThe side struts fulfils the same functions as the drag strut does in the NLG, it holds the shockstrut of the MLG in theextended position. This is accomplished by preventing the shockstrut from folding back into the retracted position. The sidestrut connects to the shockstrut, the fuselage and reaction link and is hinged in the centre.

Ad 5. Axle assemblyThe axle assembly of the MLG attaches to the bottom of the inner cylinder of the MLG shockstrut. The axle assemblysupports the wheels and brakes and is removable in case of damage.

Ad 6. Reaction linkThe reaction links are responsible for transferring most of the side loads from the landing gear to the upper end of the

shockstrut. The transfer of forces is possible due to the connection with the side strut and shockstrut. The reaction linkconnects to the upper side of the shockstrut, the fuselage and the side strut.

Ad 7. Walking beamThe walking beam is used to decrease the forces that act on the aeroplanes fuselage when MLG actuator is used. This isaccomplished by directing a part of the forces that are acting on the fuselage back to the landing gear. The walking beam isattached to the fuselage and the top of the shockstrut.

1.2.4 Wheels and tyres

Each MLG strut of the B737 has two tyre and wheel assemblies. The NLG strut has also two tyre and wheel assemblies. Thewheels of an aeroplane makes it possible to operate on the ground and are attached to the axle of the strut (1.2.4.A). Toensure damping and grip on the ground, tyres are placed on the wheels (1.2.4.B).

-

7/28/2019 Project Landing Gear - Report

11/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 8 -Project group: 2A2E

1.2.4.A WheelsThe wheels of a B737 make use of the split wheel system (fig. 5). The advantage of this system is that a tyre can bereplaced very easily without damaging the tyre. Another system which can be used, are wheels with a detachable rim edge.It uses the same principle as the split wheel, the only difference is that the rim edge must be removed to place a tyre. Thewheels are made of a forged aluminium alloy, which makes the wheel strong but relatively light of weight.The split wheel system consists of two halves, an inner(1) and outer(2)half. Those two halves are jointed together by bolts

(3). The MLG wheels have four thermal fuse plugs (4), which are located in the inner wheel half. The purpose of the valve isto prevent tyre explosion, which can be caused by hot brakes. At a temperature of approximately 465 Kelvin, the plugs willmelt and as a result of that tyre pressure releases.

1. Outer half2. Inner half3. Bolts4. Thermal fuse plug

Figure 5: Main gear Wheel

There are two different types of valves which are assembled in the wheels: 1. Over pressure relief valve2. Tyre inflation valve

Ad 1. Over pressure relief valveThe NLG wheels (Appendix IV) and MLG wheels both have an over pressure relief valve. The valve ensures that all of thepressure in the tyre releases when the pressure increases more than 375-450 psi. The valve prevents high pressure in thetyres, and works the same for the NLG wheels and MLG wheels. The only difference is that, the over pressure relief valve ofthe NLG wheels is assembled in the outer wheel half. While the valve of the MLG wheels is assembled in the inner wheelhalf.

Ad 2. Tyre inflation valveThe MLG and NLG wheels also have a tyre inflation valve to release pressure. To ensures a maximize tyre life and minimize

runway stress, the pressure in the tyres needs to be correct. A high pressure in the tyres causes a relative small surface ofcontact between, the ground and the tyre. As a result of this the tyre shall mainly wear in the middle (Appendix V). A lowtyres pressure results in a wear to the outside edge of the tyre.

1.2.4.B TyresThe main functions of the tyres on an aeroplane are to provide grip on the runway and absorb part of the shocks duringlanding and take-off. The tyres of an aeroplane have to be made strongly, because the tyres need to support a full loadedaeroplane. The tyres need to withstand high temperatures.

The tyres are made out of different materials and structures, to make the tyres strong enough to bear great forces (fig. 6, p9). The tread is made of rubber and provides grip, it is resisted against high temperatures (1). The tread is reinforced on theinside with nylon layers (2). The profile ensures drainage of water(3). Furthermore the tyre exists out of a chord body, whichfollows the shape of the tyre (4). And out of a bead section, which consists of several wires made from steel (5). The purpose

of the tyre beads is to strengthen the tyre and retain it on the wheel rim.

-

7/28/2019 Project Landing Gear - Report

12/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 9 -Project group: 2A2E

1. Tread2. Nylon layers3. Profile4. Chord body5. Tyre beads

Figure 6: Tyre

There are several circumstances which influence the performances of the tyre, points which have influence on theperformances of the tyres are :

1. Size of the tyre2. The contents of the tyre3. Hydroplaning

Ad 1. Size of the tyreOn basis of the static loading case can be decided which size of main wheel tyre is going to be used. By means of theformula for the MLG load (Appendix VI), the size of the tyre can be determined. The total load on the strut is divided equallyover the tyres.

Ad 2. The contents of the tyreThe tyre can be filled with compressed air or nitrogen. Nitrogen is used on modern aeroplane tyres. The advantage of tyres

filled with nitrogen in comparison with compressed air, is that oxygen molecules are smaller than nitrogen molecules. Thisresults in a longer preserve of pressure, for tyres which are filled with nitrogen, than of those filled with oxygen. Anotheradvantage of tyres filled with nitrogen is to prevent fire in the event of a blow out. The tyre pressure is supposed to amountbetween 117-205 psi, which is equal to eight to fourteen bar.

Ad 3. HydroplaningHydroplaning is a phenomenon that can appear on a wet runway. When the aeroplane lands on a dry runway, the tyresmake directly contact with the runway. This ensures a high speed rotation of the tyres. But when an aeroplane lands on awet runway, the tyres first make contact with the water. As a result the tyres shall water-ski upon the water, which ensures alower speed rotation of the tyres. When the pilot slows down the temperature of the tyres will increase, as a result the waterevaporates and steam will develop. Generally this results in wear of the tyres (Appendix VII).

1.3 FunctioningThe several components of the landing gear all have their specific function. The goal for all the components together is tofulfil the main function of the landing gear as a whole. The retraction and extending mechanism (1.3.1) is responsible forletting the landing gear down or up. This system makes the aeroplane more aerodynamic when airborne. The wheels andthe brakes (1.3.2) make the aeroplane able to make touchdown and move on the ground. The brakes make sure that theaeroplane can decelerate in order to stop when landing and to control the speed when moving on ground. When on groundthe steering system (1.3.3) can direct the aeroplane in order to taxi to the destined apron. The NLG wheel is manlyresponsible for the steering on the ground. The NLG wheel steering is controlled from the cockpit.

1.3.1 Extension and retraction mechanisms

The landing gear of a B737 uses a number of components to extend and retract the landing gear (1.3.1.A). When all of the

actions of these components are combined, the extension and or retraction of the landing gear can be explained (1.3.1.B)

1

2

3

4

5

-

7/28/2019 Project Landing Gear - Report

13/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 10 -Project group: 2A2E

1.3.1.A ComponentsBoth the NLG and MLG use a number of components to ensure the gear can be extended and retracted safely. These sevencomponents are used to extend or retract the NLG and MLG:

1. Actuators2. Landing gear lever3. MLG Uplocks

4. MLG Downlocks5. NLG Locking mechanism6. Doors7. Manual extension

Ad 1. ActuatorsBoth of the NLG and MLG feature one actuator to extend or retract the landing gear. These actuators are powered byhydraulic pressure (Appendix VIII) from system A but can use system B to retract the landing gear in case of the loss ofpressure from system A. In the NLG the actuator is connected to the drag brace links. When the NLG has to be extended theNLG actuator will retract, thus pulling the drag brace links straight. This will force the shockstrut into its down position. Whenthe NLG has to be retracted The NLG actuator extends, thus folding the drag brace links. This will force the shockstrut intoits up position. The MLG on the contrary has an actuator that is attached to the shockstrut. During extension the actuator willretract and thus pulls the MLG out of its wheel well. During retraction, in the contrary the actuator will extend and will push

the MLG in its wheel well.

Ad 2. Landing gear leverThe landing gear lever (Appendix IX, fig.1) is responsible for the control over the landing gear. The landing gear leverconsists out of the control lever (1), four positions switches (2), lock mechanism (3) and the lever lock solenoid (4). Thecontrol lever has three positions, up, off and down. While the up and down position are self-explaining, the off position is not.When the lever is in the off position, all hydraulic pressure will be removed from the landing gear system. Thus meaning thatthe landing gear can not accidently deploy during flight. The four position switches determine in to which position the lever ismoved and relay this info to the Proximity Sensor Electronic Unit* (PSEU). The PSEU is an computer that has control overseveral systems, it task is to determine if the aeroplane is airborne or on the ground by a set of sensors. When it the PSEUknows the aeroplanes status it will activate or deactivate systems according to software. The lock mechanism ensures thatthe lever can not be moved into the up position while the aeroplane is on the ground and is operated by the lever locksolenoid. When the aeroplane takes-off, the solenoid will be powered and will move the locking mechanism to the unlocked

position. This system can be overridden by the override trigger(5). When the pilot wants to move the lever the pilot firstly haspull the lever, before he can select the desired position. When the lever is moved, it moves a push pull rod (6). Which on itsturn the forward quadrant (Appendix IX, fig.2) through a push-pull gearbox (2). The forward quadrant moves a cable (3)which is connected to the selector valve, which controls the hydraulic fluid to the landing gear.

Ad 3. Main landing gear uplocksThe MLG uplock mechanism is responsible for holding the landing gear in a secured up and locked position when thelanding gear lever is not in the down position. Each MLG has one uplock mechanism that is located on the ceiling of the MLGwheel well. A single uplock (Appendix X, fig 1) consists out of an uplock hook (1), two springs (2), a uplock actuator(3) andan uplock roller(4). During extension (Appendix X, fig 2)the uplock actuator(1) will retract thus releasing the roller out ofthe hook (2) and enabling the MLG to extend due to the MLG actuator, air loads and gravity. The two springs (3) hold thehook in an up and locked position when no hydraulic pressure is presented to the lock actuator. During retraction the rollerwill move into the hook, after which the actuator will extend thus closing the hook and locking the gear in place.

Ad 4. Main landing gear downlocksThe MLG downlock mechanism is responsible for holding the landing gear in a secured down and locked position when thelanding gear lever is in the down position. Each MLG has one downlock mechanism (Appendix XI) that is located betweenthe reaction links (1) and the side strut (2). A single downlock consists out of a hinged downlock link (3), two springs (4) anda downlock actuator(5). During extension the downlock actuator will retract, thus pulling the hinged downlink to the positionthat can be seen in the appendix. In this position the downlock link prevents the sidestrut from folding around its hinge. Thusmeaning that the entire MLG can not retract and is safely secured in the down position. During extension the downlockactuator will extend, thus forcing the downlock link the fold around its hinge. After the downlock is folded the sidestrut willregain the ability to fold and is thus able to retract. The springs hold/force the downlock in its down and locked position whenno hydraulic pressure is available.

-

7/28/2019 Project Landing Gear - Report

14/81

-

7/28/2019 Project Landing Gear - Report

15/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 12 -Project group: 2A2E

After the NLG is raised (3), the locking mechanism (3a) will again receive pressure to lock the drag brace (3c) links andshockstrut (3d) in their position. The NLG is now in the up and locked position.

When the gear lock sensors indicate that all gears are locked, the red lights will turn into green lights. During extension thesame process will occur, only in reverse.

The sensors that indicate if the landing gear is up or down and locked, are located in the up and downlocks. Each MLGuplock contains two sensors, as does each downlock. The NLG locking mechanism also features two sensors for the up andlocked position and two sensors for the down and locked position. All sensors use a target and a sensor to determine if thelock is in the correct position for a certain action. All the sensors report to the PSEU, which on its turn can illuminate thelanding gear lights or auxiliary lights. Also an audio warning can be given.

1.3.2 Brakes

When on ground, an aeroplane must be able to decelerate. This is done by brakes attached to the landing gear(1.3.2A). Onthe B737 only the MLG has brakes. The anti-skid system is an aiding system which prevents the wheels of skidding duringbraking applications (1.3.2.B). Besides the normal braking system, an alternate braking system (1.3.2.C) and an auto brakingsystem (1.3.2.D) are available.

1.3.2.A Normal brakesThe braking system of the landing on a B737 consists out multiple steel discs(fig. 7). Steel is chosen for constructing thebrake discs, because of its strength and its ability to withstand high temperatures. This is also the reason that multiple discsare better than a single disc. More steel can absorb more heat. These discs are driven by hydraulic actuators (1)powered byhydraulic system B. There are two kinds of discs: Rotor blades (2) that spin with the same velocity as the wheels and thestator blades (3) that do not spin. The brakes are controlled by the braking pedals in the cockpit. The top of the rudder pedalscan be pushed back which activates the left brake, the right brake or both brakes. When the brakes are activated, thehydraulic actuators press the discs together, which cause the wheel connected to the brake to decelerate. When anaeroplane is to be parked, the parking brake is activated by pushing the pedals to their maximum and pulling the parkingbrake lever. This locks the brakes into a braking position. To deactivate the parking brake, the pedals are pushed to theirmaximum again.

1. Hydraulic actuators2. Rotor blade3. Stator blade

Figure 7: Multiple steel disc brakes

1.3.2.B Anti-skid systemTo reduce the distance needed to stop after braking and to avoid wheel lockdown when activating the brakes, the B737 usesthe anti-skid system (fig. 8), which works automatically. Skidding is when the velocity of the wheel rotating is lower than thevelocity of the aeroplane. This means that the product of the angle speed and the radius of the wheel is smaller than thevelocity in the direction of the movement. Skidding is monitored by an anti-skid transducer(1), which is installed in the axis ofeach wheel. The anti-skid transducer is an electromagnetic device with an internal rotor. It measures the speed of the wheelits attached to. This signal is sent to the Brake System Control Unit* (BSCU) (2). This unit is also called the anti-skid/autobrake control unit. The BSCU is a computer which compares the input signals of the anti-skid transducers with the speed ofthe NLG wheel, which has no brakes, to monitor whether a MLG wheel is kidding or not.

-

7/28/2019 Project Landing Gear - Report

16/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 13 -Project group: 2A2E

A certain amount of skidding is always desired, because of the friction heat it reduces. If there is no skidding at all, the heatcaused by friction would be concentrated in one point of the wheel. This desired amount of skidding however is also presentat the nose wheel. The BSCU controls the anti-skid valves (3) which can regulate the amount of pressure to a brake. Theanti-skid valves are directly connected to the brake hydraulic cylinders (4). Anti-skid protection is provided for both MLGwheels individually.

1. Anti-skid transducer2. BSCU3. Anti-skid valves4. Hydraulic cylinders

Figure 8: Anti-skid system schematic

1.3.2.C Alternate brakesWhen hydraulic pressure is low or lost in the normal brakes, the alternate brakes are automatically activated by the BSCU.The alternate brakes are driven by hydraulic system A. Antiskid protection is available when the alternate brakes areactivated. However, in contrast to the normal brakes, the antiskid protection is not provided for each wheel individually. Whenthe alternate brakes lose pressure as well, the aeroplane can still apply brakes. In this situation the brake accumulator isactivated automatically. The accumulator is a cylinder with stored hydraulic pressure and it can provide pressure for sixbraking applications. When the hydraulic pressure in system B is lost, pressure in system A closes an isolation valve, thusstoring pressure in the accumulator. The parking brake can be activated by pressure provided by the accumulator as well.

1.3.2.D Auto brakesOn B737 aeroplane automatic brakes are provided. These automatic brakes are activated by the air/ground logic system.This system detects whether the aeroplane is airborne or on ground by two sensors in each strut. These sensors aretriggered by weight changes. The sensors in struts of the landing gear detect the compression in the struts when the weightof the aeroplane presses on the ground. These input signals are send to the PSEU. The PSEU sends the signals to theBSCU, which activates the brakes. Other systems activated by the air/ground logic system are the landing gear positionindication and warning system and the landing gear compression system.When performing a landing, the auto brakes are immediately activated when the aeroplane touches the ground and when thethrust levers are returned to idle. There are several modes that can be selected concerning auto brakes. Before landingmodes 1, 2, 3 and max can be selected depending on the deceleration rate that is desired. This can be done by the autobrake selector. The Rejected Take-Off*(RTO) mode is selected prior to take off. The auto brakes will be triggered when thethrust levers are pulled to idle during take off. The relation between selected modes, maximum brake pressure and

deceleration rate is shown in (table 1).

Table 1: Auto brakes

Auto brake Selector Max Pressure at Brakes (PSI) Deceleration Rate (ft/sec)

1 1250 4

2 1500 5

3 2000 7.2

Max 3000 12 (below 80 knots*(kts)

Max 3000 14 (above 80kts)

RTO Full Not Controlled

-

7/28/2019 Project Landing Gear - Report

17/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 14 -Project group: 2A2E

1.3.3 Steering

There is a NLG steering system placed to manoeuvre during taxiing. The NLG wheel steering system supplies the grounddirectional control of the aeroplane (1.3.3.A). The NLG wheel can be controlled by two different mechanics; the first one isthe captain or first officer steering wheel and the second one are the rudder pedals. The steering system makes use of twohydraulic systems on different conditions (1.3.3.B). When the aeroplane is in the air it is dangerous that the steering system

is active. To prevent nose wheel steering in the air a rotary actuator and centring cams are placed (1.3.3.C). The steeringmetering valve controls the flow of hydraulic pressure to the steering actuators (1.3.3.D). During a high speed taxiing will thevibrations on the MLG will influence the steering. To prevent the vibrations on the MLG a shimmy damper placed (1.3.3.E).

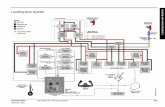

1.3.3.A ControlsThe NLG wheel can be controlled by two different mechanisms (fig. 9), these are; the rudder pedals (1) and the NLGsteering wheel (2). The maximum reach of the rudder pedals is 7 degrees on left and right direction. The NLG wheel steeringwheel of the captain and the first officers and the rudder pedals are connected with a cable loop (3). The range of thesteering wheel is 78 degrees on the left and the right direction. The reason of the limitation of the turning range is because ofthe steering action. At large angles it will eliminate the use of steering actuators. The steering wheel of the captain is coupledon the steering wheel of the first officer. Moving the NLG wheel steering wheel will pull the control cables of the steeringsystem. The movement of the cables goes to the summing mechanism (8) at the NLG wheel. The summing mechanismmixes steering wheel input and NLG gear position feedback to control the NLG wheel steering metering valve (9). The NLG

wheel steering metering valve controls the hydraulic flow to the steering actuators (7). When the steering metering valve getsa signal from the summing mechanism it will move the NLG wheel to the desired direction.

1. Rudder pedals2. Steering Wheel3. Cable loop4. Steering quadrant5. Rotary actuator6. Shockstrut cylinder7. Steering Actuator8. Summing lever9. Steering metering valve

Figure 9: Nose wheel steering system

1.3.3.B HydraulicThere are two hydraulic system on board, hydraulic system A and B. To switch between the hydraulic systems an alternateNLG wheel steering switch is placed. The NLG wheel steering switch has a normal position and a alternate. It will activatethe transfer valve which changes the pressure supply on the NLG wheel. When the NLG wheel steering switch is on thealternate position will the transfer valve change the pressure supply on the NLG wheel. If there is a technical problem withthe hydraulic system A the pilot can switch to the alternate position, the alternate position makes use of the hydraulic systemB.

1.3.3.C Rotary actuatorThe function of the rotary actuator(5) is to disconnect the steering arm from the steering quadrant (4). The rotary actuator

engages the rudder pedal steering when the NLG is on the ground and disengages it in the air. When the aeroplane goes into the air, a signal from the air/ground logic system sends power to the rotary actuator. This causes a disconnection betweenthe NLG steering systems. The ground procedure is almost the same but otherwise.

-

7/28/2019 Project Landing Gear - Report

18/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 15 -Project group: 2A2E

1.3.3.D Steering metering valveThe steering metering valve controls the hydraulic flow to the steering actuators. The steering metering valve gets an inputfrom the rudder pedals, this will activate the steering metering valve to send the pressure to the NLG wheel steering actuatorand that will turn the NLG wheel to the desired direction. The metering valve is connected to the shockstrut (6) of the NLG.

1.3.3.E Shimmy damper

The shimmy damper is placed at the MLG wheel and it decreases vibrations between the outer and the inner cylindersduring high speed taxi and heavy brake use. The shimmy damper is attached between the torsion links. The function of theshimmy damper is to prevent the inner and outer cylinder from turning inside each other. This causes the shimmy damperpiston (2) to move from side to side inside the housing assembly. When the piston moves, hydraulic fluid moves through thedamping orifices (7). This decreases the piston movement. The damper connects to the return line of the MLG. Thecompensator (1) maintains system pressure between 18 and 23 PSI. The inlet check valve (3) controls the hydraulic fluidflow rate into the damper 50 PSI. The relief valve (5) protects the compensator if the pressure increases to more than240PSI. The two bleed plugs (6) are used to remove trapped air in the piston house. The check valve is used to block thereverse flow of the oil that comes from the inlet check valve (Fig 10).

1. Compensator (18-23 PSI)2. Damper piston3. Inlet check valve4. Check valve5. Relief valve6. Bleed plug7. Damping orifice

Figure 9: B737 shimmy damper

1.4 Regulations

A landing gear has to comply with regulations that are set up by the European authority. The EASA is responsible for thecertification of large aeroplanes. The regulations for the certification are prescribed in the EASA book CertificationSpecifications* (CS)-25. The different regulations concerning the landing gear are divided into different subjects. Before alanding gear is airworthy, it has to comply with the general regulations (1.4.1). To withstand the forces occurring on thelanding gear shock absorbers need to absorb the shocks on the landing gear. The landing gear has to support the aeroplanein different phases of the flight like landing (1.4.2). Large aeroplanes must have an retractable landing gear. Therefore

regulations are set up (1.4.3). The brakes have to be approved and must have back-up procedures in case of failure (1.4.4).The forces on the wheels and tyres of the aeroplane have to be tested with the maximum design weight (1.4.5).

-

7/28/2019 Project Landing Gear - Report

19/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 16 -Project group: 2A2E

The steering systems must be easy to handle by the pilot and must not interfere with the extending and retractingmechanism when accidently used while extending or retracting (1.4.6).

1.4.1 General

The landing gear system must be designed so that if it fails due to overloads during take-off and landing the failure mode is

not likely to cause a fire hazard in the event of: Aeroplanes with a passenger seating configuration (excluding pilots seats) of ten or more.

When the aeroplane is under control it can be landed on a paved runway with one or more landing gear legs notextended without causing a structural component failure.

The landing gear has to comply with the regulations above to be certified as airworthy. Analysis, tests or both may be shownif the aeroplane complies with the provisions.

1.4.2 Shock absorption

The analytical representation of the landing gear dynamic characteristics that is used in determining the landing loads mustbe validated by energy absorption tests and must also comply with:

The energy produced on the shocks during landing must be absorbed. Therefore the aeroplanes designed landingor take-off weight must be used, whichever produces the greater value of landing impact energy

The reserve energy absorption capacity descent velocity of 3.7 m/s (12 fps) at the design landing weight may notresult in a landing gear failure. This assuming that the aeroplanes lift is not greater than the aeroplanes weightduring landing impact.

1.4.3 Retracting/extending mechanism

The retracting and extending mechanism consists of different parts that have to comply with the regulations of CS-25. theseparts are: general, landing gear lock, emergency operation and position indicators. For aeroplanes with retractable landinggear the following regulations are applicable:

Ad 1. General The landing gear retracting mechanism, wheel well doors and supporting structure must be designed so that it can

support the loads occurring in the flight conditions when the landing gear is in the retracted position. Also includingthe combination of friction loads, inertia loads, brake torque loads, air loads and gyroscopic loads resulting from thewheels rotating at peripheral speed.

The landing gear doors and supporting structures must withstand the yawing manoeuvres in addition to theconditions of airspeed and load factor.

Ad 2. Landing gear lock

The landing gear locks must keep the landing gear extended in flight and on the ground. Also in the air the gearand doors must be held in the correct retracted position.

Ad 3. Emergency operation

In the event of an hydraulic, electrical or equivalent energy supply failure the landing gear must able to beextended.

Ad 4. Position indicators

For retractable landing gear, position indicating lights for down and locked and up and locked need to be visibleto the pilots.

Warnings must be given when a landing is attempted and the gear is not locked down so that a go-around can bemade in time.

A clear indication or warning must be provided whenever the landing gear position is not consistent with thelanding gear selector lever position.

Ad 5. Protection of equipmentEquipment that is essential for the safe operation of the aeroplane and which is located on the landing gear and in the wheel

wells must be protected from the damaging effects of:

-

7/28/2019 Project Landing Gear - Report

20/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 17 -Project group: 2A2E

A bursting tyre.

A loose tyre tread.

Possible wheel brake temperatures.

1.4.4 Brakes

The brakes are explained in CS 25.735. The regulations about the brakes can be divided in the following:1. Brakes2. Brake controls3. Parking brake4. Anti-skid system5. Severe landing stop6. Brake wear indicators7. Over-temperature burst prevention

Ad 1. Brakes

Each assembled brake need to be approved.

When the braking system and/or the hydraulic system fails the aeroplane has to be able to stop and this stop mustnot be more than twice the distance of a normal stop.

If the hydraulic system fails and leaks, because of a failure in the brakes, this leak must be insufficient to cause ahazardous fire during the flight or on the ground.

Ad 2. Brake controls

The brake controls must be designed and constructed so that it can be handled without using excessive controlforce.

The pilot must be able to arm and disarm the automatic braking system and the pilot must be able to override thesystem when braking manually.

Ad 3. Parking brake

The aeroplane must be equipped with a parking brake.

The parking brake of the aeroplane, when selected on, must be able to prevent the aeroplane from rolling on level

and dry paved runway while using maximum thrust on one engine or maximum ground idle thrust on any or all theengines.

A system in the cockpit must indicate the pilot when the parking brake is not fully released.

Ad 4. Anti-skid systemThe anti-skid system on the aeroplane must be working in all expected kinds of runway conditions, without the system needsexternal adjustments.

Ad 5. Severe landing stopIt must be demonstrated that during the first five minutes after an emergency stop, no conditions may occur that couldprevent the safe and complete evacuation of the aeroplane.

Ad 6. Brake wear indicators

An indicating system must be installed that provides for each brake assembly an indication when the heat sink is worn to thepermissible limit. This indicator must be reliable and easy to check.

Ad 7. Over-temperature burst preventionThere must be means in each braked wheel to prevent the tyre to burst, the wheel to fail or both, because of elevated braketemperatures.

1.4.5 Wheels and tyres

The regulations about the wheels can be divided in two parts:1. Wheels2. Tyres

-

7/28/2019 Project Landing Gear - Report

21/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 18 -Project group: 2A2E

Ad 1. Wheels

The regulations about the wheels are in CS 25.731.

Each wheel used on the NG and MLG must be approved by EASA.

The wheels have to be tested with the maximum design weight and the critical centre of gravity. In this test themaximum static load rating on each LG wheel must be more or the same than the corresponding static groundreaction and the maximum limit load rating must be more or the same then the maximum radial limit load.

The wheels have to be protected against overpressure burst. Excessive pressurisation and tyre assembly maycause the tyre to burst or fail, every tyre needs means to prevent this from happening.

Ad 2. Tyres

In CS 25.733 the regulations about the tyres on the LG are described.

On each wheel used on the NG and MLG the suitable tyre have to be assembled.

The forces on the NG and MLG must be tested while the aeroplane carries the maximum design weight. Whenretracted every tyre assembled on the LG must be clear from the surrounding structure and systems.

The braked tyres on the B737 have to be filled with dry nitrogen or any other gas that does not consist of more than5% of oxygen, unless it can be shown that when heated the material will not produce a volatile gas or thetemperatures do not reach unsafe levels

1.4.6 Steering systems

The steering systems are described in CS 25.745.

The steering mechanism of the NG must be easy to handle during landing and take-off without the use ofexceptional skill even in the case of cross winds and in the event of sudden power-unit failure. This must be shownby tests.

If the pilot accidently uses the steering controls while the LG is retracting or extending, this must not interfere withthe retracting or extending of the LG.

When the steering mechanism fails to work, the wheel have to have a position that will not cause a dangeroussituation.

The NG must be designed to prevent damage to the steering mechanism when towed.

-

7/28/2019 Project Landing Gear - Report

22/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 19 -Project group: 2A2E

2.Analysis landing gear Boeing 737-800 GThe landing gear of the B737 has had several changes since its design in the year 1964. Over almost four decades the B737was manufactured in almost nine different types. The wishes and comfort of the airliners always had the priority by designingthe aeroplane. (2.1)By making the right manoeuvrings the B737 can make a landing without disadvantages consequences. (2.2)When the B737 has to break roughly, the struts of the landing gear also has to cope with horizontal forces. (2.3)By applying regularly forces on the construction of the landing gear, it must have the characteristic to deal with stress. (2.4)The wishes of customers never stand still, neither does the technical development of the B737.

The main sources of this chapter are: Airplane Characteristics Boeing 737 (2005) and Binas (2004).

2.1 Design aspects

When designing a landing gear it is important to following some guidelines. These guideline are called design aspects. Whenparts of the landing gear have a really short durability the parts have to be replaced often, this will cost a lot of money andman hours (2.1.1). When the landing gear is not working properly it is important to have back-up possibilities (2.1.2).

2.1.1 Durability

The durability of the landing gear depends mostly on the different types of take-offs and landings the landing gearexperiences. Some parts of the landing gear have a longer durability than others. The landing gear is designed in the side-life design. This means that the system is designed to work properly for years without any major repairs. Described are thethree following parts:

1. Gear2. Brakes3. Wheels and tyres

Ad 1. GearThe gear is designed to cope with hard landings and vibrations. The shockstrut is made out of titanium. Titanium is strong,light (table 2) and corrosion-resistant material. This material is capable of handling big temperature differences. These

characteristics make titanium durable and ideal for the landing gear.

Table 2: Comparison steal and titanium

Characteristic Steel Titanium

Density [kg/m3] 7800 4540

Pull strength [psi] 50000 80000

Ad 2. BrakesThe B737 has steel brakes. In 1996 new steel brakes where designed with improved durability because of increased energyabsorption and a shorter cool down time. The new steel brakes have a new friction material, this increases the durability with30%. The newest B737 have carbon brakes. The durability of the carbon brakes is twice as long as the steel brakes and thecarbon brakes are 300kgs lighter than the steel brakes (table 3). The carbon brakes absorb the heat better than the steelbrakes, because of this the carbon brakes last longer. The carbon brakes are more expensive but this compensates with thelonger durability and the extra weight the aeroplane can take.

Table 3: Comparison steal and carbon

Characteristic Steel Carbon

Density [kg/m3] 7800 2620

Ad 3. Wheels and tyresWhen one of the two NLG tyres has to be replaced because of worn down tyres, both have to be replaced, otherwise thereplaced tyre will wear down faster because of the difference in size. This is called mismatch tyres. In the MLG this makes nodifference because there are more tyres to divide the forces and weight.The durability of the tyres depends on the landing conditions and the brake conditions. When the tyres are worn down themanufacture off the tyres will retreat them. The tyres are retreaded after approximately 300 landings. The wheels and tyres

are completely replaced in the d-check, this is once in the five years.

-

7/28/2019 Project Landing Gear - Report

23/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 20 -Project group: 2A2E

2.1.2 Safety

When designing a landing gear the designers keep fail safe in mind. Fail safe means that if the landing gear fails to work itwill cause no harm or the harm is minimized. The safety features of the following two parts are described:

1. Gear2. Brakes

Ad 1. GearWhen the aeroplane is on the ground the landing gear cannot be retracted because of the landing gear lever lock. In case ofan emergency this lock can be override by a override trigger. When trying to extent the landing gear and the landing gearlever has no effect there is a manual gear extension access hatch (fig. 11)in the cockpit. The pilots have to open the hatch(1) and pull a handle (2) in the cockpit 61 centimetres, this will extend and lock the landing gear manually.

1. Hatch2. Handle

Figure 11: Manual gear extension access hatch

If the three green landing indicator lights in the cockpit are not working properly the pilots can check if the gear is extendedand locked with an extra set of green gear down lights. The second set of lights are located in the overhead panel in thecockpit and are on a different circuit than the normal indicator lights.

Ad 2. BrakesHydraulic system B is used for the brakes. When this system fails system A takes over. When both fails there is a brakeaccumulator which has enough hydraulic pressure stored to use the brakes. The accumulator stores air pressure, it is

pressurised by hydraulic system B . The stored air pressure can be used for six brake applications when both the normalbraking system and the alternate braking system fails. The accumulator is also used to make sure the hydraulic pressuredoes not fluctuate and an instantaneous flow of fluid to the brakes. The B737 only has one accumulator on board.

2.2 Forces on the landing gear during landing

To ensure a safe landing the landing gear has to cope with several forces. Before any force can be determined some pre-calculations and assumptions need to be made for the points of implement, forces and values (2.3.1). With use of theassumptions and calculated forces and values the forces on the aeroplane during the approach and landing can becalculated. Therefore different equations are used, like the second law of Newton; the force equals the product of mass andacceleration. In this way there can be determined which forces are dealt with in terms of the landing gear (2.3.2). The energythat a moving aeroplane or a part of a aeroplane has, can be calculated by the kinetic energy. Energy can transformed in aother kind of energy (2.3.3). These processes proves that the landing gear is a solid, but also a very dynamic component.

2.2.1 Pre-calculations

The calculations of the forces on the landing gear during different stages of the flight is a sophisticated procedure. To simplifythis some assumptions need to be made (2.2.1.A). The forces like lift and thrust apply in different points. Therefore the pointsin which they apply must be determined (2.2.1.B). Values like the landing mass and the landing velocity can be predetermined. This will be used later on with the actual force calculations (2.2.1.C).

2.2.1.A AssumptionsThere are dozens of aspects involved in terms of forces on the aeroplane and in particular the forces on the landing gear.These aspects can not all be taken into account. Therefore some assumptions need to be made to be able to calculate thepoints of implement, forces during the approach, forces before landing impact and the forces in the shockstruts duringlanding impact. These assumptions are:

-

7/28/2019 Project Landing Gear - Report

24/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 21 -Project group: 2A2E

The first assumption is that the most extreme situation is used. This means that the aeroplane has its Maximum LandingMass* (MLM) and that the aeroplane has a vertical velocity which is in range of the maximum vertical velocity which thelanding gear must survive. In this case the aeroplane that lands does not flare. This means that the vertical velocity will notbe reduced by slowing down the vertical velocity to reduce the landing impact shock.

The second assumption is that the Centre of Gravity*(CG) lies in the middle of the aeroplane. In the horizontal plane theCG has an angle of 15 with the MLG. When the aeroplane is flying an approach it is assumed that the CG shifts another 15

with the MLG. This will eventually be the assumed position of the CG in the horizontal plane. By assuming this, the positionof the payload and the fuel is at an fixed position. This will simplify the calculations because the CG is not at a variabledistance from the MLG.

The third assumption is that the Centre of Pressure* (CP), which is located between 9,4 and 27% of the MeanAerodynamic Cord*(MAC), now lies at 27% of the MAC. The MAC is assumed to be in the middle of the aeroplane so thatthe CP is at the same height as the CG. When the aeroplane is flying an approach it is assumed that the CP does not shiftforwards or backwards.

The fourth assumption is that the aeroplane flies the approach with a pitch attitude of 3 nose up. The aeroplane follows theGlide Path*(GP), which has an angle of 3 degrees between the CG and the runway. In this situation the aeroplane descentswith a constant velocity and a constant acceleration. The aeroplane does not flare when the landing impact is made.The fifth assumption is that the thrust settings at 15 flaps is 48% N1. This is because the aeroplane does not land with highdrag forces when the flaps are 40 out. When the B737 has the maximum flap position the percent of N1 will be 80%.

2.2.1.B Points of implementIn the simplified aeroplane, which is used for the calculations, there are three points of implement:

1. Centre of gravity2. Centre of pressure3. Centre of thrust

Ad 1. Centre of gravityThe CG depends on different factors. Factors like payload septum, angle of attack and fuel quantity and placement.Therefore the assumptions are made. According to this, the position of the CG during an approach and landing can bedetermined (Appendix XVI). First the distance from the MLG in the horizontal plane is calculated with the 15 angle. Secondthe distance in the horizontal plane when the aeroplane is making an landing and approach is calculated. This results in ahorizontal distance of 0.771 m.

Ad 2. Centre of pressureThe CP is the point where the lift and drag component applies. This point has a certain dimension in the horizontal plane.The distance from the beginning of the wing to the MLG is known. The CP is located several percents of the MAC. It isassumed that the CP does not shift when the aeroplane is flying at an angle towards the undisturbed incoming airflow.According to this, the position of the CP during an approach and landing can be determined (Appendix XVII). The MAClength is 3.96 m, this value is multiplied times a factor 0,27 to calculate the position of the CP on the MAC. The height of theCP is assumed to be 2.878 m and the angle between the CP and the height is 3, now the horizontal distance form the MLGcan be calculated. This results in a horizontal distance of 0.151 m.

Ad 3. Centre of thrustThe centre of thrust is the point where the thrust force applies. It is assumed that this point is at the front of the engine. Thedistance from the MLG to the front of the engine is 6.33 m. It is assumed that the centre of thrust applies in the middle of theengine. This distance is 1.34 m. The distance becomes then 1.672 m. Because the approach is flown at an angle of 3 nose

up the height can be determined (Formula 2).

Formula 2

Tan () = o / a = angle [degrees]o = opposite side [m]s = diagonal side [m]

Tan (3) = o / 6.33O = Tan (3) 6,33 = 0.332 m

Total height (h) = 0.332 +1.34 = 1.672 mh = 1.672 m

-

7/28/2019 Project Landing Gear - Report

25/81

Hogeschool van Amsterdam Aviation Studies

Landing gear - 22 -Project group: 2A2E

2.2.1.C Forces and valuesThe forces like the landing mass and the thrust settings are available. Only the correct values must be calculated for thedetermination of the forces. The landing speed value is a standard value set up in a table.

1. Maximum landing mass2. Thrust3. Approach speed