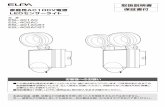

AC100-ESL manual-olTitle AC100-ESL_manual-ol Created Date 3/22/2016 10:42:21 AM

Professional Solution for Machine Tool Industry · Model M otr p w er (KW )R d cu t (A Bra k in g r...

Transcript of Professional Solution for Machine Tool Industry · Model M otr p w er (KW )R d cu t (A Bra k in g r...

Professional Solution for Machine Tool Industry

Shenzhen Veichi Electric Co., Ltd. is a high-tech enterprise that is professionally engaged in the development,

manufacturing and marketing of industrial automation control products, and committed to becoming a global

leading provider of industrial automation control products and system solutions.

The company owns powerful R&D team, relatively perfect production system, independent intellectual property

and manufacturing bases in Shenzhen and Suzhou. To improve our R&D strength, we keep on introducing

advanced overseas technology and broadening our partnerships with first-class universities and research

institutions.

The main products of Veichi Electric include a variety of Variable Frequency Drive (VFD), Servo Drive System,

Photovoltaic Inverter, PLC, HMI, Automation Equipment, etc, which are widely used in industries such as oil &

gas, chemical industry, ceramic, crane & hoist, metallurgy, electrical cable and wire, plastic, print and package,

textile, metal work and cable, coal mining and municipal engineering. Suitable solutions and products are always

ready to meet the demands and improve comprehensive competitiveness of users.

With the spirit of "Innovation is the lifeblood of Veichi", we're committed to becoming one of the leading providers

of electric drives, industrial control and green energy products. Veichi has set up more than 40 branch offices in

China and dozens of partners in Asia, Europe and Africa. Veichi has been named Chinese Electric Industry's Top

Ten National Brands, Chinese Electric Industry Top Ten Satisfying Brands and Top Ten National Brands of

Inverter Industry. Veichi products have become the first choice of many enterprises.

Product overview

Product features

◎

01AC70-C Machine Tool Industry Purpose Variable Frequency Drive

Deceleration overexcitation function

If deceleration overexcitation is off, output current is small and deceleration time is long.

-01-

AC70-C is the latest development of a high performance machine tool purpose vector variable frequency drive. It

adopts leading magnetic flux algorithm and modular design to achieve high-performance and high-precision

motor drive control. Combining with the features of machine tool industry, the drive reliability has been enhanced

to meet the processing demands of different products.

Machine tool spindle adopts special macro parameter, which can simplify parameter setting.

With low frequency large torque output, torque dynamic response is fast.

With carrier smooth function, motor noise has been reduced effectively.

It is easy for the drive to deal with all kinds of severe environment with sealed design and thickened three anti-

paint treatment.

◎

◎

◎

According to the set deceleration overexcitation current, the output current can be kept constant, which not only

can quickly consume motor feedback energy to prevent over voltage of bus capacitor but also can produce large

resistance torque to stop motor quickly and improve processing efficiency.

If deceleration overexcitation is on, output current increases and deceleration time shortens.

Noise control

Random carrier is off.

R Auto M Pos:0000s

Rated value in 1 minute short time

Speed (%)

To

rqu

e (%

)

10030100

50

130

150 AC80

AC60

Large torque at low frequency

◎ The blue part

is the extended

running range

of AC80C.

-02-

Compared with high-pitched motor noise of fixed carrier, output voltage harmonic spectrum of random carrier is

evenly distributed in a wide frequency range, which can reduce motor noise effectively.

Random carrier is on.

In low frequency and weak magnetic field, torque

performance is optimized.

It has linear torque feature in the whole speed

range.

Torque dynamic response time is less than 20ms.

◎

◎

Load strain capacity

◎ Automatic current limit technology and automatic

frequency adjusting technology can response to load

sudden change.

Avoid frequent drive fault report to ensure its fast

response characteristics.

◎

Torque response characteristic diagram

Torque

Speed

Current

Rapid acc-eleration

Sudden 100% load

Sudden load reduction

Long life design

◎ PCB three anti-paint treatment: according to different

circuit board, the three anti-paint automatic spraying

equipment can design different spraying strategies,

and it can ensure three anti-paint coating thickness

uniformity and batch consistency.

With sealed design, it has good protection capability

in serve environment such as high resistance to

humidity, dust and vibration.

◎

Selection table

Model

AC70-T3-R75C

AC70-T3-1R5C

AC70-T3-2R2C

AC70-T3-004C

AC70-T3-5R5C

AC70-T3-7R5C

AC70-T3-011C

AC70-T3-015C

0.75

1.5

2.2

3.7

5.5

7.5

11

15

2.5A

AC70-T3-018C

AC70-T3-022C

18.5

22

750Ω/150W

400Ω/300W

250Ω/400W

150Ω/500W

100Ω/600W

75Ω/780W

50Ω/1200W

40Ω/1500W

32Ω/2000W

28Ω/2200W

3.7A

5A

10A

13A

16A

25A

32A

38A

45A

TA

TB

TC

+24V

Y1

_mA 20

10

0

-+

0

5

10V_

+ -

GNDA01

V

W

U

M~

E

W

V

U

VR

+10V

R

T

S

VS2

GND

AS

VS1

PUL

COM

X3

X4

X6

X5

X1

X2

PLC

+24V

S

T

R

GNDA02

Y2

COM

AC220V

AC0V

J1

J2J3

3A/240VAC

5A/30VDC

(0~5V)/(0~10V)

(0~20mA)/(4~20mA)

J4

J5

-03-

(REV)

AC70-C wiring diagram

AC

inp

ut

Breaker Contactor Input reactor

Frequency inverter

Output reactor

Note2

(Short connection when delivery)

Shield or armour cable(Ground near frequency inverter)

(Grounding resistor <10Ω)

Mu

lti-fun

ctio

n c

on

tact in

pu

t

(FWD)

(FWD JOG)

(RVE JOG)

(Free stop)

(Fault reset)

Note: The function description in bracket is inverter factory set value of frequency inverter.

Contact maximum output

Coil

Twisted shielded pair cableGround near frequency inverter

Pa

ssiv

e c

on

tact o

utp

ut

Twisted shielded pair cableGround near frequency inverter

Coil

Coil

Note:1. +24V terminal maximum output: DC24V/100mA 2. Y1 /Y2 terminal maximum output: DC24V/50mA

co

llecto

r ou

tpu

t in o

pe

n s

tate

Fre

qu

en

cy c

on

trol in

pu

t

Note 4Pulse input

Twisted shielded pair cableGround near frequency inverter

Current analog input

Min VR 2kΩ

Voltage analog input

Note1. +10V terminal maximum output: 50mA 2. VS1/VS terminal internal resistance: 89KΩ3. AS terminal internal resistance:250Ω

Toggle switch

Pin

selection

Twisted shielded pair cableGround near frequency inverter

Note 3

Note: when A01/A02 terminal is used as frequency and voltage type signal output, the maximum output is 2mA.

An

alo

g m

on

itorin

g s

ign

al o

utp

ut

Legend:1. The symbol ● stands for the main circuit;2. The symbol 〇 stands for control circuit terminal.

Motor power (KW) Rated current (A) Brake resistor

Product overview

◎

-04-

02 AC100-CS Spindle Servo

AC100-CS spindle servo system is a high-end product specific to the

machine tool industry developed by Shenzhen Veichi Electric Co., Ltd.

It adopts software and hardware platform to achieve full-closed-loop

servo control of motor, and high precision speed control and position

control of motor as well. As it can meet multiple control requirements of

spindle, it has wide application in machine tool industry.

Product features

Speed range 1:5000 with excellent low frequency torque.

Steady speed accuracy±1rpm and position accuracy±1 puls.

Achieve special functions such as spindle indexing, rigid tapping

and tread cutting etc. of machine tool.

◎

◎

Adaptive motor

Spindle servo motor, electric spindle and common three-phase

asynchronous motor etc.

Applications

CNC lathe, machining center, gantry milling, deep hole drilling and NC

boring machine etc.

AC100 - T3 - 004 CS

Input voltage class

S2: single phase 220V

T3: three phase 380V

Technical specifications

Items

Po

we

r inp

ut

-05-

Drive model

Code: spindle servo

Power class

Series name: AC100 series

Main

circuit

outp

ut

Sig

nal in

put

and o

utp

ut

Spin

dle

fu

nctio

ns

Main

contro

l perfo

rmance

Specifications

Voltage and frequency

Allowable fluctuation

Switching impulse current

Power factor

Inverter efficiency

Three-phase 380V 50/60Hz

Voltage: 320~440V; Voltage imbalance:<3%; Frequency:±5% The deformation rate meets the requirements of IEC61800-2.

Less than rated current

≥0.94 (with DC reactor)

≥96%

Output voltage

Output frequency range

Overload capacity

Rated output: three phase, 0~380V input voltage, error less than 5%

0-650Hz

150% rated current in 1 minute, 180% rated current in 10 seconds, 200% rated current in 0.5 seconds

Digital input/output

Analog input

Analog output

7 transistor input channels, 1 transistor output channel, 2 relay output channels

3 input channels, VS channel 0 ~ 10V, AS channel 0 ~ 20Ma, AI channel current and voltage input are optional

2 input channels, 0~10V,0~20Ma, 4~20mA optional

Speed control

Spindle indexing

Rigid tapping

Other functions

0~12000rpm

Achieve multiple position control (terminal has 8 points index at most) through terminal or external pulse

Achieve tapping function with feed axis and the error is 2%

Thread cutting, electronic gears and position carry etc.

Motor control mode

Modulation mode

Carrier frequency

Speed control range

Steady speed accuracy

Start torque

VC without PG, VC with PG, V/F without PG, V/F with PG

Optimize space vector PWM modulation

0.6~15.0kHz, random carrier modulation

VC with PG, rated load 1:5000

VC with PG: ≤0.01% rated synchronous speed

Flux VC without PG: 180% rated torque at 0.5Hz Flux VC with PG: 200% rated torque at 0Hz

Protection function Over voltage,under voltage,current limit,over current,over load,electronic thermal relay,over heating, over voltage stall,data protection

Status monitoring

Fault alarm

Output frequency, given frequency, output current, input voltage, output voltage, motor speed, PID feedback value, PID given value, module temperature, input and output terminal status etc.

Over voltage, under voltage, over current, short circuit, loss phase, over load, over heat, over voltage stall, current limit, data protection damage, current fault operation status, history fault

Ke

yb

oa

rd

dis

pla

y

Installation site

Temperature and humidity

Vibration

Storage temperature

Installation

Protection grade

Cooling method

Indoor; the altitude is not more than 1000m; non-corrosive gases and direct sunlight

-10 ~ +40℃ 20%~95% RH (not frost)

Less than 0.5g below 20H

-25 ~ +60℃

Wall mounted, vertical cabinet

Ip20

Forced-air cooling

Am

bie

nt

AC100-CS selection table

Model Motor power (KW) Braking resistorRated current (A)

AC100-T3-1R5CS

AC100-T3-2R2CS

AC100-T3-004CS

AC100-T3-5R5CS

AC100-T3-7R5CS

AC100-T3-011CS

AC100-T3-015CS

1.5

2.2

4.0

5.5

7.5

11

15

AC100-T3-018CS

AC100-T3-022CS

18

22

250Ω/400W

150Ω/500W

100Ω/600W

75Ω/780W

50Ω/1200W

40Ω/1500W

32Ω/2000W

28Ω/2200W

3.7A

5A

10A

13A

16A

25A

32A

38A

45A

Drive dimension

Drive modelMounting hole

AC100-T3-004CS

AC100-T3-5R5CS

AC100-T3-7R5CS

AC100-T3-011CS

Outline dimension

W H D D1W1 H1

159 246 157.5 148147.2 236 Φ5.5

195 291 167.5 158179 275 Φ7

W1

W

H1 H

D1

D

WW1 D

H H1

H2

AC100-T3-015CS

AC100-T3-018CS

AC100-T3-022CS

AC100-T3-030CS

AC100-T3-037CS

AC100-T3-045CS

AC100-T3-055CS

W H D D1 W1 H1

235 345 200 311 160 331.5 Φ7

255 410 225 370 180 395 Φ7

305 570 260 522 180 550 Φ9

AC100-T3-1R5CS

AC100-T3-2R2CS122 182 154.5 145112 171 Φ5

24Ω/3000W

-06-

Mountingdiameter

Drive modelOutline dimension Mounting hole Mounting

diameter

Mounting diameter

AC100-CS wiring diagram

TA1

TB1

TC1

+24V

Y

GNDA01

V

W

U

M~

E

W

V

U

+10V

R

T

S

AI

GND

AS

VS

COM

X3

X4

X6

X5

X1

X2

PB

AC100-CSS

T

R

GNDA02

COM

3A/240VAC

5A/30VDC

(0~5V )/(0~10V)

(0~20mA)/(4~20mA)

+( )

X7PUL

+24V

PLCCOM

TA2

TB2

TC2

A+

B-

120Ω

A-A+

B-B+

Z-Z+

PE

COM5V

PLPEP+P-D+D-

OA+OA-OB+

0-10v/4-20mA/

OB-OZ+

OZ-

50mA/24VDC

PE

-07-

AC

inp

ut

Breaker Contactor Input reactor

External breaking resistor

Output reactor

Grounding resistor <10Ω

Mu

lti-fun

ctio

n c

on

tact in

pu

t

FWD

REV

Accurate stop

Multifunction input

Multifunction input

Multifunction input

Rigid tapping/Pulse position

Rs485 communication

Fault input

Accurate stop arriving

Contact maximum output

Pa

ssiv

e c

on

tact o

utp

ut

An

alo

g in

pu

t

Current analog input

Voltage analog input

Voltage/current analog input

Mode switch completionContact maximum output

Co

llecto

r ou

tpu

tA

na

log o

utp

ut

Pu

lse

inp

ut

Fre

que

ncy d

ividin

g o

utp

ut

Pulse input

Frequency dividing output

Encoder ABZ signal input

En

co

de

r sig

na

l inp

ut

Common asynchronous motor mode

Spindle servo motor mode

V

W

U

M~

E

W

V

UPB+( )

A-A+

B-B+

Z-Z+

PE5V

OA-

OA+

OB-

OZ+

OB+

OZ-

CNC AC100-CS

COM

VS

GND

X3

X4

X6

X5

X1

X2

COM

TC1

TA1

TC2

TA2

V

W

U

M~

E

W

V

U

D+

D-

X3

COM

X1

X2

PB+( )

A-A+

B-B+

Z-Z+

PE5V

OA-

OA+

OB-

OZ+

OB+

OZ-

VS

GND

P+

PG

CNC

P-

COM

X7

TA1

TA2

TC2

TC1

AC100-CS

-08-

AC100-CS application solution

I/O s

ign

al

FWD

REV

Accurate stop

Accurate stop selection terminal 1

Accurate stop selection terminal 2

Accurate stop selection terminal 3

Public terminal

Fault signal

Accurate stop arriving

External braking resistor

Grounding resistor <10Ω

An

alo

g s

ign

al

Analog speed signal

Encoder frequency division output E

nco

de

r fee

db

ack

Encoder signal input

I/O s

ign

al

An

alo

g s

ign

al

En

co

de

r fee

db

ack

Encoder frequency division output

Analog speed signal

FWD

REV

Accurate stop

External braking resistor

Grounding resistor <10Ω

Accurate stop arriving

Fault signal

Public terminal

Encoder signal input

Spindle

Pu

lse

sig

na

l

Pulse signal

Pulse position / Rigid arch wire

Veichi Electric was established in

2005 and headquartered in

Shenzhen, China. In October

2013, Suzhou Veichi Electric Co.,

Ltd. was founded in Suzhou,

Jiangsu province which formed

two major production bases. Our

sales and service network spread

all over the country including

more than 40 offices and service

c e n t e r s t o e n s u r e t i m e l y

response of customer needs.

Domestic Marketing Service Network

International Sales Network

-09-

Headquarter in Shenzhen

Ha Er Bin

Shen Yang

bei jing tangshan

Ji NanQing Dao

Zheng Zhou

Xi An

Wu Han

Chang Sha Nan Chang

Gui Yang

Chong Qing

cheng du

Kun Ming

Nan Ning

Guang Zhou

Fo ShanDong Guan

Shen ZhenAo Men

Xiang Gang

Hai Kou

Fu Zhou

Tai BeiQuan Zhou

Tai Zhou

He Fei Wu Xi

Hang Zhou

Shang HaiSu Zhou

Nan Jing

Tai YuanShi Jia Zhuang

Tian Jin

Chang Chun

Hu He Hao Te

Bao Tou

Yin Chuan

Lan Zhou

Xi Ning

Wu Lu Mu Qi

Xin Jiang Wei Wu Er Zi Zhi Qu

Xi Zang Zi Zhi Qu

VietnamThailand

MalaysiaIndonesia

Iran AfghanistanJordan

Turkey

Lebanon

Kazakhstan

Russia

South Africa

Egypt

Tunisia

Morocco

Tanzania

Pakistan

Sri lanka

Bangladesh

India

Mexico

Brazil

Poland

Romania

*Version: March 2017 Edition

Shenzhen Veichi Electric Co., Ltd. all rights reserved,

subject to change without notice.

Block C, Wentao Science and Technology Park, Shiyan

Yingrenshi Community, Baoan District, Shenzhen, China

Tel: +86-0755-2968 5610 (EXT 835)

Fax: +86-755-2968 5615 E-mail: [email protected]

http://www.veichi.org

No.100 Songjia Road, Wuzhong Economic and Technological

Development Zone, Suzhou, China

Tel:+86-512-6617 1988

Fax:+86-512-6617 3610 Service hotline: 400-600-0303

http://www.veichi.com

Shenzhen Veichi Electric Co., Ltd. Suzhou Veichi Electric Co., Ltd.