Production of Vit. B2

-

Upload

payee-biongcog -

Category

Documents

-

view

925 -

download

0

Transcript of Production of Vit. B2

170

APPENDIX 4.3(referred to in paragraphs 2.29, 4.21, 4.22, 4.23, 4.37 and 4.94)

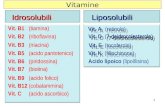

The production of vitamin B2

Chemical structure

1. The official chemical designation for vitamin B2 is riboflavin.1 It was discovered in 1920 and firstisolated in egg albumen in 1933. Its chemical structure, which was determined in 1935, has two distinctparts: a ribose sugar unit and a three-ring flavin structure, known as lumichrome. The chemical structureof vitamin B2 is shown below.

HN N

O

CH3

CH3O N N

CH2

HCOH

HCOH

CH2OH

HCOH

2. Vitamin B2 has been produced commercially by chemical synthesis, by fermentation and bymixed fermentation/chemical synthesis methods. Fermentation is the most recent and most cost-effectivemethod.

3. Figure 1 shows the current alternative production methods schematically.

Fermentation/chemical synthesis process

4. A number of chemical synthesis production routes have been used commercially.2 Currently,producers including Takeda and Shanghai Yongxing use a mixed fermentation/chemical synthesisprocess. (For brevity, we describe vitamin B2 produced by this route as chemically synthesized.) In thisprocess, a four-step reaction sequence is used, starting from glucose. First, ribose is produced fromglucose by fermentation. A reaction with xylidine is next used to convert ribose into a riboside, which isthen hydrogenated to produce ribamine. This intermediate product is next purified by crystallization.

5. The following stage involves a reaction between ribamine and a phenyl diazonium salt derivedfrom aniline, which produces phenylazoribitylamine. This compound is then crystallized, dried, andconverted into vitamin B2 by cyclocondensation with barbituric acid. An overall product yield of over60 per cent can be obtained.

6. Several of the chemical stages in this process involve the use of toxic reagents. The wasteproducts therefore require stringent environmental control and may need special forms of effluenttreatment.

7. Chemical synthesis produces approximately 96 per cent pure vitamin B2.

1The Commission of the Nomenclature of Biological Chemistry, 1960.2For a more detailed account see Ullmann’s Encyclopedia of Industrial Chemistry, VCH Verlagsgesellschaft mbH, 1996.

171

FIGURE 1

Methods of producing vitamin B2

Fermentation

8. The more recent single-stage fermentation route is used by a number of producers, includingBASF, Roche, and Hubei Guangji. As it has a single main stage, there are substantial cost savingscompared with the multi-stage chemical process. Each producer uses its own variant of the process withdifferent strains of micro-organism and different raw materials.

9. The fermentation plant itself is relatively straightforward as it typically uses simple mixing/stirring vessels and conventional purification technologies. After separating the biomass, and evaporatingand drying the concentrate, an enriched product with a vitamin B2 content of up to 80 per cent can beobtained.

Raw materials

10. The producers use different basic raw materials. Vegetable oil, glucose or molasses may act asthe source of carbon (the significant ‘building block’ for producing vitamin B2). They vary greatly inprice and carbon content.

Glucose

Ribose

Phenylazoribityl-amine

Raw riboflavin

Riboflavin (about96% pure)

Ribamine

Xylidine

Riboflavin (infermentation broth)

Aniline

Barbituric acid

Fermentation

Fermentation/chemical process Fermentation process

Glucose,

molasses or

soya bean oil

Riboflavin (about80% pure)

Fermentation

Source: BASF.

172

Strains of micro-organism used

11. Establishing a fermentation plant requires an effective production strain of micro-organism. Asnumerous strains of bacterium, fungus or yeast can be used, each manufacturer uses a different organismto convert raw material into vitamin B2. At present, the bacterium bacillus subtilis, the funguseseremothecium ashybyii and ashbya gossypii, and the yeasts candida flareri and saccharomyces cerevisiaeare all used for the fermentation of vitamin B2.

12. BASF told us that it considered the protection of its production strains of micro-organism to beparticularly important. Access to a strain may be achieved through in-house research and development(as in the case of Roche), contracted-out research and development or acquired from another source(Chinese producers are said to use a Russian strain). BASF told us that an investment of £2 million to£3.5 million would be likely to deliver a vitamin B2 fermentation strain capable of being used inproduction within three years. It considered that Chinese producers or outside laboratories could carryout research and development at a much lower cost than the Western manufacturers.

Productivity of micro-organisms

13. The productivity of biochemical processes is normally described in terms of their conversion rateand their space-time yield. The conversion rate is the proportion of the carbon-source raw material that isconverted into the finished product. It dictates the amount of raw material required. The space-time yieldis the amount of product made per unit volume per unit time. It determines the length of time required forthe fermentation and the size of vessels needed. Both measures vary greatly with the micro-organism andthe raw material used.

14. The micro-organisms used by different producers have a wide range of conversion rates andspace-time yields. A slow organism may take many days to complete the vitamin B2 fermentation. Inthis case, the manufacturer will need numerous fermenting vessels, resulting in additional capital costscompared with producers using faster organisms. Producers’ organisms also convert different amounts ofthe raw material into vitamin B2 before the fermentation stops.

15. Producers devote considerable effort to improving the productivity of their organisms, either bynatural mutation or by GM. GM may result in more productive organisms; the savings resulting from thisincreased productivity can offset the extra containment costs involved in working with GMOs (seeparagraph 17).

Effluent disposal

16. By contrast with the fermentation/chemical synthesis process, the fermentation method makeslittle use of toxic solvents or reagents. The main waste products are edible residues of the productionmicro-organism and its growth medium which (subject to containment requirements) can either be usedas animal feed or dealt with by a conventional sewage treatment plant. This significantly reduces thewaste disposal costs, particularly for producers using non-GM micro-organisms.

Containment

17. All producers need to have a plant containment system that prevents stray organisms orchemicals from entering the process and contaminating the fermentation. Those using safe wild-type orself-cloned micro-organisms need to minimize releases of the organisms into the environment. On theother hand, producers using GMOs need to design their plants and procedures to achieve highcontainment: that is the prevention of any escape of the GMO into the environment. This addssignificantly to plant complexity and effluent disposal costs.

173

Intellectual property rights

18. A number of stages in the vitamin B2 fermentation process are covered by patents. These stagesinclude: the isolation of vitamin B2 from the fermentation broth; improving yields from the microbialculture by using autolysis; the purification of vitamin B2; and the spray granulation of vitamin B2.

Feed-grade vitamin B2

19. The 80 per cent pure vitamin B2 produced by fermentation is suitable for use in animal feedwithout further refining. (The balance of the material consists of the edible residue of the productionmicro-organisms.) A higher proportion of vitamin B2 produced by fermentation is therefore used inanimal feeds than is the case for the chemically-synthesized product (see Chapter 4).

Food-grade product

20. Either fermented feed-grade vitamin B2 or chemically-produced raw vitamin B2 may act as thebase material for making the purer product required for human food or pharmaceutical use. The sametechnology is used to refine either the 96 per cent pure chemically-synthesized product or the 80 per centpure fermented product. In outline, the procedure involves the use of a simple vessel in which theunpurified product is dissolved in sodium hydroxide, crystallized with hydrochloric acid and thencleansed with a solvent.

21. Starting from fermented vitamin B2, the purification step needs to remove about 20 per cent ofthe material, which is of microbial or vegetal origin. BASF told us that the cost of purification couldexceed 40 per cent of total operating costs.

22. By contrast, starting from chemically-produced vitamin B2, only about 2 per cent of the materialneeds to be removed. The purification plant can consequently be smaller. Manufacturers using thechemical production route to produce vitamin B2 are therefore at less of a disadvantage if they producethe food-grade product rather than feed-grade vitamin B2. Some chemical-based producers occasionallysell this higher-grade product for feed use.

Main manufacturers of vitamin B2

23. Table 1 summarizes the production methods used by the various manufacturers.

24. BASF estimated the producers’ cash operating costs for feed-grade vitamin B2 in an internalbenchmarking exercise. Figure 2 illustrates our analysis of the pre-merger cost ranking that results fromcombining these with our estimates of plant capacities. No allowance was made for depreciation or anyreturn on investment. BASF’s analysis clearly demonstrates the wide range of cash production costs.

TABLE 1 Production methods used by vitamin B2 manufacturers

Supplier Process

Capacitytonnes per

yearMicro-organism

usedMain raw material(carbon source)

Productivity(space-time yield)

Fermentation yield(kg B2/kg carbon

source)% Comments

BASF existing

BASF proposed

Roche

ADM/Aventis joint venture Figures omitted. See note on page iv.

Takeda

Shanghai Yongxing

Hubei Guangji

Source: CC analysis of information from BASF and other suppliers.

Note: N/A = not applicable.

174

175

FIGURE 2

Ranking of feed-grade vitamin B2 production costs against capacity beforemerger

Details omitted. See note on page iv.

25. Figure 3 shows the corresponding estimates of comparative cash operating costs for feed-gradevitamin B2 after the merger and BASF’s planned investment. It demonstrates a substantial improvementin BASF’s cost competitiveness.

FIGURE 3

Ranking of feed-grade vitamin B2 production costs against capacity after mergerand investment

Details omitted. See note on page iv.

26. Figure 4 illustrates the ranking of the producers’ cash operating costs for food-grade vitamin B2before the merger, as estimated in the same internal BASF benchmarking exercise. No cost is shown forthe ADM/Aventis joint venture, as it does not produce food-grade vitamin B2 (see paragraph 37).

176

FIGURE 4

Ranking of food-grade vitamin B2 production costs against capacity beforemerger

Details omitted. See note on page iv.

27. Figure 5 shows the corresponding estimates of comparative cash operating costs for food-gradevitamin B2 after the merger and BASF’s planned investment. It again demonstrates a substantialimprovement in BASF’s cost competitiveness before allowing for depreciation and a return oninvestment.

FIGURE 5

Ranking of food-grade vitamin B2 production costs against capacity aftermerger and investment

Details omitted. See note on page iv.

177

BASF

28. BASF’s fermentation plant at Ludwigshafen has a capacity of [!] tonnes a year and [Detailsomitted. See note on page iv.]. BASF has fermented vitamin B2 for 13 years—longer than the otherproducers.

29. BASF has purification capacity to produce [!] tonnes a year of food-grade vitamin B2.

30. BASF carries out R&D into new strains and processes with a view to increasing output andreducing costs. This includes cooperative projects with university research institutes. Its annual R&Dbudget is around £1.3 million a year, or about [!] per cent of total sales. It has been able to enhance itsprocess over time through strain improvement (predominantly mutation) and media development. Overthe last ten years, this has resulted in a [!] per cent increase in its plant’s effective capacity and a[!] per cent saving in raw material costs.

31. BASF considers that the resulting process has a comparatively high yield and a potential costadvantage if used on a sufficient scale; it attributes this to using the most ‘efficient’ organism. Thefermentation process is, however, slow and BASF considers that the present plant’s low capacity leads tohigh unit fixed costs. Its main raw material, soya oil, is much more expensive than the glucose ormolasses used by other producers.

32. [

Details omitted. See note on page iv.

]

Takeda

33. Takeda manufactures 96 per cent pure vitamin B2 by chemical synthesis. Its plant at Hikari inJapan has a capacity of [!] tonnes a year. The main raw material is [

Details omitted. See note on page iv.]. Takeda’s production costs are high compared with those of

producers using the vitamin B2 fermentation process.

34. Takeda has purification capacity to produce [!] tonnes a year of food-grade vitamin B2.

Roche

35. Roche has recently started trial production of vitamin B2 by fermentation in a new plant atGrenzach, in Germany. This plant is due to come fully on stream during the summer of 2001 and itsultimate capacity is expected to be about [!] tonnes a year. [

Details omitted. See note on page iv.]

36. Roche has purification capacity to produce 900 tonnes a year of food-grade vitamin B2.

Archer-Daniels-Midland Company/Aventis SA joint venture

37. A joint venture of ADM and Aventis also produces vitamin B2 by fermentation in the USA. Itsplant has a capacity of [!] tonnes a year and exclusively produces feed-grade product. BASF consideredthat the organism used by ADM/Aventis was relatively inefficient. This disadvantage was offset byADM’s access to an advantageous in-house source of the main raw material (glucose). The effect of theintended sale of the Aventis vitamins business on this joint venture is unclear.

178

Chinese producers

38. As we have only been able to obtain limited information from the Chinese producers, we arelargely reliant on information supplied by the British Embassy in Beijing, BASF and Roche and onpublished sources. BASF told us it estimated that the current total capacity of vitamin B2 plants in Chinawas about 1,300 tonnes a year. Roche estimated their total capacity to be 1,850 tonnes a year. Untilrecently, all the Chinese producers had used a chemical synthesis process similar to that used by Takeda.However, BASF believed that about one-third of Chinese vitamin B2 capacity was now based on thefermentation process.

39. Within the last two years, Hubei Guangji has commenced production of vitamin B2 byfermentation. Its plant’s capacity is 600 tonnes a year and is expected to increase to 1,000 tonnes a yearbefore the end of 2001. Shanghai Yongxing also has a vitamin B2 plant with a capacity of 400 tonnes ayear. Although BASF thought that this company would also start using fermentation technology soon, itinformed us that it had no such plans. BASF added that, while there had been two other smallerproducers, Tianjin Hebei and Shannaxi Xi, that each had a capacity of about 200 tonnes a year, it thoughtthat these were not now in operation.

40. Chinese producers previously concentrated their exports on the food-grade vitamin B2 market, inwhich their chemically-manufactured product was most competitive. The introduction of a fermentationplant has recently enabled them to expand their production of feed-grade vitamin B2.

41. BASF told us that Chinese producers enjoyed considerable cost advantages. They had theadvantage of using the cheapest raw material (molasses being cheaper than glucose or soya oil). Chineseproducers also had lower labour and financing costs and less demanding environmental standards.

Potential for market entry

42. BASF estimated that the minimum capacity for an efficient new plant in the West would be2,000 to 3,000 tonnes a year for feed-grade vitamin B2. It added that a new vitamin B2 fermentationplant with a capacity of 3,000 tonnes a year would have a capital cost of between €[!] million and€[!] million (between £[!] million and £[!] million) in Western Europe. This included approximately€[!] million (£[!] million) for refining facilities to produce a food-grade product. A chemical produc-tion plant of similar capacity would cost slightly less but have significantly higher operating costs.