Product Market Combination for small farmers in Indonesia ... · For two years Dutch seed company...

Transcript of Product Market Combination for small farmers in Indonesia ... · For two years Dutch seed company...

1

vegIMPACT report 30. Production Market Combination carrot - Enrekang

extension

Product Market Combination for small farmers in Indonesia: High Quality carrot from Enrekang for modern retail in Makassar

Marijn van der Laan, Riky Sianipar, Novianto, Marcel Stallen

vegIMPACT Report 30

December, 2016

2

vegIMPACT report 30. Production Market Combination carrot - Enrekang

vegIMPACT is a program financed by The Netherlands’ Government promoting improved

vegetable production and marketing for small farmers in Indonesia, contributing to the food

security status and private sector development in Indonesia. The program builds on the results of

previous joint Indonesian-Dutch horticultural development cooperation projects and aligns with

recent developments in the horticultural private sector and retail in Indonesia. The program

activities (2012 – 2016) include the Development of Product Market Combinations, Strengthening

the Potato Sector, Development of permanent Vegetable Production Systems, Knowledge Transfer

and Occupational Health.

Wageningen University & Research, The Netherlands:

- Wageningen Plant Research, Lelystad

- Wageningen Centre for Development Innovation (CDI), Wageningen

- Wageningen Plant Research, Wageningen

- Wageningen Economic Research, Den Haag

Wageningen University & Research

Contact person: Huib Hengsdijk, [email protected]

Indonesian Vegetable Research Institute (IVEGRI, Indonesia)

Contact person: Witono Adigoya, [email protected]

Fresh Dynamics (Indonesia)

Contact person: Marcel Stallen, [email protected]

Website: www.vegIMPACT.com

© 2016 Wageningen University & Research, Wageningen Plant Research, P.O. Box 16, 6700 AA

Wageningen, The Netherlands; T +31 (0)317 48 07 00; www.wur.nl/plant-research .

Stichting Wageningen Research. All rights reserved. No part of this publication may be reproduced,

stored in an automated database, or transmitted, in any form or by any means, whether

electronically, mechanically, through photocopying, recording or otherwise, without the prior written

consent of Stichting Wageningen Research.

DLO is not liable for any adverse consequences resulting from the use of data from this publication.

3

vegIMPACT report 30. Production Market Combination carrot - Enrekang

the dates business is doing fine

Product Market Combination for small farmers in Indonesia:

High Quality carrot from Enrekang for modern retail in

Makassar

Marijn van der Laan, Riky Sianipar , Novianto, Marcel Stallen

(PT Fresh Dynamics Indonesia)

4

vegIMPACT report 30. Production Market Combination carrot - Enrekang

Contents

Abbreviations and Acronyms ........................................................................................................................... 5

1 Introduction PMC Carrot .......................................................................................................................... 6

1.1 vegIMPACT Product Market Combinations ....................................................................................... 6

1.2 Carrot – market development and demand in South Sulawesi .......................................................... 6

1.3 PMC Carrot - the business proposition ............................................................................................ 10

2 Product Market Combination (PMC) Carrot: Participants, approach, interventions ............................... 11

2.1 PMC participants ............................................................................................................................ 11

2.1.1 Farmers ..................................................................................................................................... 11

2.1.2 Trader ........................................................................................................................................ 12

2.1.3 Retailers .................................................................................................................................... 13

2.1.4 Seed company ........................................................................................................................... 13

2.2 The PMC activities and interventions .............................................................................................. 14

2.2.1 Agronomic interventions ............................................................................................................ 14

2.2.2 Organizational interventions ...................................................................................................... 15

2.2.3 Marketing and Sales interventions ............................................................................................. 15

3 PMC results and evaluation ................................................................................................................... 17

3.1 Agronomy ...................................................................................................................................... 17

3.1.1 Situation pre- PMC, location and practices ................................................................................. 17

3.1.2 Agronomy training and results ................................................................................................... 18

3.1.3 Continuous supply of carrots ...................................................................................................... 19

3.1.4 Introduction new variety ............................................................................................................ 21

3.1.5 (Post) harvest and logistical interventions .................................................................................. 22

3.2 Group development ....................................................................................................................... 23

3.3 Marketing and sales ....................................................................................................................... 24

3.3.1 Contract and sales trajectory ...................................................................................................... 25

4 Discussion and conclusions .................................................................................................................... 30

4.1 Overall result business proposition ................................................................................................. 30

4.2 PMC contribution to vegIMPACT objectives .................................................................................... 30

4.3 Norma carrot production: comparative analyses between PMCs .................................................... 31

ANNEX I: Training plan PMC wortel ............................................................................................................... 33

ANNEX II: Post Harvest handling of mature carrots ........................................................................................ 34

5

vegIMPACT report 30. Production Market Combination carrot - Enrekang

Abbreviations and Acronyms

BRI Bank Rakyat Indonesia

DC Distribution Centre

Deptan Departemen Pertanian

IDR Indonesian Rupiah (currency; 1 Euro = 15,000 IDR, July 2014)

MRL Maximum Residue Level

PMC Product Market Combination

PoS Point of Sales

SoP Standard Operational Procedure

6

vegIMPACT report 30. Production Market Combination carrot - Enrekang

1 Introduction PMC Carrot

1.1 vegIMPACT Product Market Combinations Within the vegIMPACT program, a Product Market Combination (PMC) is a pilot project implemented with partners in the supply chain, including small farmers (<2 ha), who produce vegetables in a coordinated way and according to specific market demands. A PMC contains innovative aspects, for example the use of improved varieties, a new marketing concept, packaging materials, branding of the vegetables or the supply chain configuration itself. In a PMC supply chain partners make mutual arrangements with regard to improving existing market linkages or to create new market opportunities. PMC’s are considered as a “proof of concept“ to show that innovations and cooperation in market-oriented supply chains potentially can benefit all supply chain partners and in particular small farmers.

National and international vegIMPACT PMC staff facilitate this process from carrying out initial market surveys, developing business propositions in collaboration with supply chain partners, facilitating the implementation of the supply chain until the marketing of the product.

Farmers and supply chain partners in a PMC are supported by vegIMPACT project staff to improve critical issues in their supply chain such as agronomy aspects, post-harvest issues, organizational weaknesses and marketing. To this end a pre-project (training) needs assessment and supply chain analysis are conducted by vegIMPACT staff and interventions for improvement proposed.

Product Market Combinations contribute to the following vegIMPACT objectives: increased vegetable productivity; reduced pesticide use per unit product; reduced production costs per unit product; increased financial margins for farmers and reduced occupational health problems and risks. In this report the approach, facilitation process and results of the “PMC carrot” are described and the impact on the relevant vegIMPACT objectives assessed.

Chapter 1 provides an overview of the development of the carrot market and the demand for carrots in South Sulawesi, as well as the business opportunity that this PMC carrot wants to capture. In Chapter 2 the characteristics of the PMC carrot, the supply chain actors and other stakeholders are presented and the arrangements between partners and the market proposition (the PMC interventions) are described. In Chapter 3, after a summary of the current agronomy and supply chain practices, the results of the PMC carrot interventions are presented and discussed. In Chapter 4 conclusions and the contribution of the PMC carrot to the vegIMPACT objectives are presented. Chapter 4 also contains a comparison of the results with this (second) PMC with carrots as compared with the PMC carrot in Cianjur (West Java, vegIMPACT report 29).

1.2 Carrot – market development and demand in South Sulawesi Traditionally, carrot production is concentrated in West Java (Lembang and Cipanas), but has spread to other regions in and outside Java such as Sumatra and Sulawesi. In 2014, the total harvested carrot area in Indonesia was 30,762 hectares, resulting in a total production of 495,798 ton and an average productivity of 16.12 ton/ha (Fig. 1.1). Productivity increased steadily over the last five years.

7

vegIMPACT report 30. Production Market Combination carrot - Enrekang

Figure 1.1 Carrot production in ton/year (left) and productivity in ton/ha (right) in Indonesia. Source: Deptan.

The most important production provinces (in area and value) are located on Java, Sumatra and Sulawesi (Table 1.1).

Province 2010 2011 2012 2013 2014

1 West Java 106,951 143,424 121,744 159,415 142,731

2 Middle Java 113,576 115,296 121,373 125,044 125,646

3 East Java 53,798 142,241 90,583 66,193 48,844

4 North Sumatra 44,285 28,180 29,995 37,275 43,456

5 Bengkulu 25,366 25,980 26,531 33,701 42,559

6 Middle Sumatra 15,989 18,772 22,637 22,252 24,270

7 South Sulawesi 11,031 16,677 18,210 25,416 21,927

8 North Sulawesi 8,700 4,531 4,695 17,028 18,637

9 Lampung 6,501 6,777 5,333 6,869 5,910

10 South Sumatra 3,985 5,275 6,894 4,242 4,224

Table 1.1 Top ten carrot producing provinces (ton) in Indonesia. Source: Deptan.

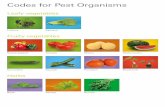

Next to a considerable national production volume, carrots are also the fifth largest fresh vegetable commodity that is being imported into Indonesia, with an imported volume of 41,527 ton in 2014 mainly from China. When imported and locally produced carrots are compared it appears that imported carrots are larger, have a smoother skin and a larger diameter of up to 4-5 cm. Local carrots in general are tall, have an irregular shape, have a small diameter and are less crunchy (bite). Imported carrots have a more intense orange colour (Fig. 1.1).

Examples of imported carrots Examples of locally produced carrots

Figure 1.1 Imported carrot and local carrot in the Jakarta market.

8

vegIMPACT report 30. Production Market Combination carrot - Enrekang

For two years Dutch seed company Bejo Zaden BV from Warmenhuizen, in cooperation with their Indonesian distributor Primasid experimented and tested new carrot varieties in Indonesia. Early 2014, after evaluating all test results, Bejo and Primasid decided that the Bejo variety ‘Norma’ was fit for commercial testing and introduction at a small scale. Results of field testing of ‘Norma’ under farmers conditions were promising, with yields as high as 40 tonnes/hectare and carrot quality resembling imported carrots. Based on this a PMC pilot with carrot was geared up in the Cianjur region in West Java within the vegIMPACT program and from mid-2014 onwards ‘Norma’ carrots were produced commercially for the first time. Within the PMC, farmers were trained and connected with a trader. These carrots were sold in modern supermarkets in Jakarta. Reactions from the market showed that market potential for the ‘Norma’ carrot in Indonesia is large (vegIMPACT report 29). Some lessons learnt from the first commercial PMC project with ‘Norma’ carrot seed in Cianjur, West Java are:

The average expected yield is 30 tonnes/hectare if the recommended Standard Operational Procedures (SoPs) for production are followed strictly.

On a small commercial production scale, the % of grade A carrot is smaller than the results of the Bejo testing fields, i.e. slightly below 50%.

The ‘Norma’ carrot is very sensitive for water shortage.

If the tops of the carrots are not properly covered with soil they turn red tops, which is often not accepted by modern markets.

Modern retail is very enthusiastic about this carrot that is perceived as similar to the imported carrot with regard to its appearance and taste.

In Cianjur, training activities only covered a small number of production aspects and farmers faced problems with consistently following the recommended SoPs.

The farmer group in Cianjur was not strong enough to jointly manage a planting schedule. It was concluded that the farmer group needs to be strengthened to make the proposition successful.

Following the high demand for this type of carrot in West Java, the PMC team explored the feasibility of a similar business proposition in the province of South Sulawesi. Carrot market in South Sulawesi The province of South Sulawesi has a land area of 62,482 km2 and a population of 8.2 million. South Sulawesi is the 7th largest province in Indonesia and the largest province outside Java and Sumatra. In 2014, the area with carrots was 1,521 hectares in South Sulawesi and the average productivity was 14.42 ton/hectare (Table 1.2).

2010 2011 2012 2013 2014

Harvested area (ha) 1,086 1,290 1,229 1,732 1,521

Production (ton) 11,031 16,677 18,210 25,416 21,927

Productivity (ton/ha) 10.16 12.93 14.82 14.67 14.42

Table 1.2 Characteristics of carrot production in South Sulawesi. Source: Deptan.

Vegetables grown in the region are among others cabbage, shallot, potato, hot pepper, carrot, cauliflower, leek and tomato. Most vegetables are grown in the Gowa and in the Enrekang regency. After an exploratory trip to both regions, the PMC team decided to choose the Enrekang district for this PMC. Farmers in Enrekang are more community-oriented and displayed a larger interest in participating in a joint project. The location also allows for year-round production of most vegetables,

9

vegIMPACT report 30. Production Market Combination carrot - Enrekang

where as in Gowa activities normally stall during the rainy season. According to the local dinas pertanian of the Enrekang regency the harvested area with carrots was 239 ha in 2014. Vegetables from Enrekang are currently mostly sold to collectors at farm gate or via the local wholesale markets in Alla. Most products from Enrekang end up either on transport via the port of Pare-pare to other close by islands in East Indonesia (with truck onto boats), or to end markets in Central Sulawesi. When products are sold to collectors (up to 80% of the produce), farmers and collector often do not agree on the price beforehand but afterwards. It regularly happens that collectors return for payment after 2-3 weeks and that they offer a very low price, which the farmers have no influence on. Occasionally collectors also do not pay farmers at all and without administration or formal agreements there is not much the farmers can do. Also if the product is sold at the local wholesale market in Alla, the buyers dictate the price and farmers are “price takers”. The buyers in Alla make a “phone call” to their subsequent buyers at end markets in Kalimantan and beyond and base their price offer on this price level in the end market. This seems a sound approach, but it is common knowledge that the buyers at the Alla market make price agreements among each other to keep prices low and to maximize their own profits. Only a very small portion of the vegetables from Enrekang go to Makassar (5-7 hrs’ drive). Farmers are not aware of demands for vegetables in Makassar and of the price level of certain products at modern markets. Till date supermarket supplying traders in Makassar do not source vegetables from Enrekang. If vegetables are sourced locally, Gowa is the preferred sourcing location (2-3 hrs drive). Makassar is a distribution/transit point for vegetables throughout Eastern Indonesia, from Kalimantan to Moluccas, all the way up to Papua (Fig. 1.2). From Makassar transport is mostly done with containers and/or trucks on ships, depending on the destination. Only the very best and high value produce is transported by airplane. Carrots are only transported by truck/container.

Figure 1.2 Domestic destinations of vegetables from Makassar (left), local production areas South

Sulawesi (right).

In recent years supermarkets have mushroomed in Makassar and next to some local chains, all major national supermarket chains now have a presence in the city such as Lotte, Giant, Hero, Carrefour, and Hypermart. Supermarkets have different demands in terms of supply, quality and volume than the traditional markets. Currently, supermarkets in Makassar are not able to source enough fresh produce from the region resulting in a steady flow of vegetables from (East) Java to Makassar. As transport costs are considerable (about IDR 13,000/Kg for transport from Surabaya to Makassar by air) this offers opportunities for local producers in the region, provided that they can create some economies of scale and they are able to continuously supply supermarkets with high quality vegetables. Under such conditions traders and buyers of supermarkets are expected to switch to locally produced vegetables because of the lower prices.

10

vegIMPACT report 30. Production Market Combination carrot - Enrekang

The buyers of supermarkets in Makassar that were interviewed by the vegIMPACT PMC team indicated that quality carrots are always sourced from importers in Java and that the supply is irregular. Carrot of a similar quality as imported carrots are not produced in Indonesia. In addition carrot prices are volatile, because of seasonality of locally supplied carrots in addition to the fluctuating supply of imported carrots. Supermarkets showed an interest in the proposition for continuous supply of “import type” carrot from local farmers in South Sulawesi. However, farmers are adamant about the contract prices with supermarkets that need to be flexible and must be set on a weekly bases. Makassar is growing fast, its population is becoming more urban and sales through supermarkets is expected to increase further in the coming years. National supermarket chains with outlets elsewhere in East Indonesia often centralize distribution to those outlets in Makassar, this offers upscaling opportunities for a carrot PMC in the region.

1.3 PMC Carrot - the business proposition Farmers and trader agreed on a contract for a weekly supply of ‘Norma’ carrot against a minimum base price of 6,000 IDR /kg for grade A quality carrots with agreed and defined quality specifications (Table 1.3). The actual prices would depend on the prevailing market price. The contract volume was fixed at an continuous supply of 400 kg carrot of A quality per week (total expected harvested volume would be 800-1000 kg per week).

Demanded quality specifications grade A

Size : length in between 18 - 20 cm

Colour : deep orange

Form : straight

Surface : smooth skin and clean

Fruit stalk : cut off

Reject indicators : traces of diseases, bent, colour too pale, cracked, and multiple roots

Table 1.3 PMC contract quality specifications carrot.

Based on the results of the pilot in Cianjur, the business proposition was expected to result in a profit margin of 35% for the farmers. The project was started with an inventory trip in February 2015 and wrapped up in February 2016.

Table 1.4 shows the expected benefits for the participating farmers and the trader in the carrot PMC.

Participants Expected benefits

Farmers Introduction to new carrot variety with promising profit prospects

Constant (stable) carrot prices and stable, weekly income

To obtain training in new modern production techniques

To become a more professional farmer group

Trader Guaranteed weekly supply of carrot

Reliable source of high quality carrot at fixed price.

Professional support in creating a new brand & label for carrots

Table 1.4 Expected benefits of PMC business proposition.

11

vegIMPACT report 30. Production Market Combination carrot - Enrekang

2 Product Market Combination (PMC) Carrot: Participants, approach, interventions

2.1 PMC participants

Figure 2.1 shows an overview of the participants in the business propositions’ supply chain of the PMC carrot Enrekang.

Figure 2.1 Supply chain and actors PMC carrot - Enrekang.

2.1.1 Farmers Previous PMC’s made very clear that the solidness and strength of the participating farmer group is crucial for the success of a PMC pilot, therefore in the Enrekang regency eight farmer groups were pre-selected based on “intake” interviews during an inventory trip and on recommendation of the local dinas pertanian. The four most promising groups were invited for a focus group discussion after which farmer group Kuang dewata was selected to participate in the carrot pilot.

During the Focus Group Discussions (FGD) the farmer group was informed in detail on the expectation, the business proposition and the related risks of the pilot. The farmers were very eager to join the PMC.

Picture 2.1 Farmer group Kuang Dewata at assessment.

12

vegIMPACT report 30. Production Market Combination carrot - Enrekang

The selected farmer group, Kuang Dewata, located in the Enrekang regency consisted of 27 farmers who together cultivated about 10 hectares of land. The group meets once a month. The members of the Kuang Dewata group normally grow cabbages, tomatoes and carrot. Most also have 1-2 goats and some coffee plants. Harvested products are mostly sold to local collectors and traders.

The farmers have experience with growing carrot and they mainly use locally propagated and farmers’ saved seed. Sometimes farmers use commercially available seed (Takii or Sakata seed) and one of the farmers recently also experimented with a one off sample of EWINDO carrot seed.

Farmers mentioned the following major constraints for carrot production: fluctuating prices, quality of the seed, nematodes (reducing % of grade A carrots) and the cost of weeding (labour intensive). All farmers in the region wash the carrots manually, sometimes by using a brush. Farmers mentioned that the average production cost per kg carrot is about 2,000 IDR. Farmers in Enrekang do not use much pesticides for growing carrots, but if they spray they normally mix several pesticides in one tank.

Local post-harvest practices consist of cutting off half of the carrot leaves after harvest. Leaving on the remaining half of the leaves is believed to enhance shelf live and it allows the carrots to be stored without cooling for one full week, and thus surviving transport to Kalimantan (2 days) with some shelf life left. Some regional traders ship up to two tons of carrots to Kalimantan on a weekly bases.

Participating farmers never used ‘Norma’ carrot seed before and ‘Norma’ was also not available at the market.

2.1.2 Trader It was not easy to find a trader that was interested in and fit for cooperation in a PMC pilot, as the South Sulawesi market is dominated by a large number of traditional traders that were unwilling to change their current practices. But the PMC team succeeded to find a trader, Rodeo Fresh that was willing to cooperate. Before the start of the PMC the trader was extensively interviewed to assess his suitability for inclusion in the pilot.

Rodeo Fresh is a vegetables and fruits trading company established in 1997 and based in Malang, East Java. It sells vegetables to retail partners in East Java and several cities on islands in East Indonesia, such as Bali, Lombok, Kalimantan and Sulawesi. All vegetables are traditionally sourced in East Java and transported by air or ship to the other islands. Transport costs are consequently high and vegetable price levels in supermarkets in Kalimantan and Sulawesi are consistently above the price levels in Java.

In Malang, Rodeo Fresh has eight staff members for logistics, packing and grading. Distribution of products in East Java is managed from Malang, but on the other islands, Rodeo Fresh works with contracted extension workers. They receive products, and if necessary re-pack products and arrange delivery to the local supermarkets. Rodeo Fresh works together with about 30 small producers in the Malang region. Cooperation with the farmers is based on informal agreements and prices are in general based on cost price of farmers with a top up standard margin of 2,000 IDR/kg.

During the intake interviews, the director of Rodeo Fresh admitted that working with small farmers can be troublesome, but he was willing to start working with farmers in Sulawesi, for a certain pilot trial period. This would be the first time that Rodeo Fresh would source products outside of East Java.

In East Java Rodeo Fresh usually buys vegetables in bulk from growers, after which grade A and B quality products are sold to retailers in the region. The remainder is sold at the local traditional market. Rodeo Fresh proposed to apply the same practice in the Makassar region, even though at the start of the PMC pilot he did not yet have a network of buyers at traditional markets in Makassar. Rodeo Fresh was planning to build a packing house and distribution centre in Makassar to professionalize its supply to local retail markets and he expected to be up and running once the first carrots would be launched at the market.

Supplying Makassar from East Java is costly. For example, transport of vegetables/fruits from Surabaya to Makassar by airfreight costs IDR 13,000 IDR/kg. This was one of the main reasons why Rodeo Fresh

13

vegIMPACT report 30. Production Market Combination carrot - Enrekang

was interested in sourcing vegetables from South Sulawesi, provided that the vegetables were of good quality and are competitively priced as compared with imported products from East Java. However, the director of Rodeo Fresh was very hesitant to fix a contract price, and would rather agree on a base price, plus the promise to add a reasonable amount per kg at times when market prices were high.

Based on his current contracts with supermarkets in Makassar Rodeo Fresh was ready to absorb 300-500 kg grade A quality carrots per week. If the project would be successful, he intended to source more vegetables from the farmers in Enrekang such as eggplant, chayote, chayote shoots (pucuk labu), celery, spinach, bell pepper, beef tomatoes and mushroom. He agreed to buy all carrot grades from the farmers, lower grades would be sold by the trader at the traditional market in Makassar.

Rodeo Fresh was also interested in receiving support to rebrand and strengthen the marketing of their products. In East Java Rodeo products carried a small “Rodeo Fresh” sticker and outside of Java another brand was used ‘We one’ (Pic. 2.2). The company was in particular not happy with the current ‘We one’ sticker and was struggling with the positioning of their products both in Java and other places.

Picture 2.2 Logo stickers of Rodeo fresh used before the PMC intervention.

2.1.3 Retailers Hero Supermarket is the largest supermarket (retail) chain in Indonesia and was established August 23, 1971. Nowadays Hero operates more than 700 retail locations in Indonesia, under various brands: Hero and Giant supermarkets and Starmart Convenience Stores.

The Hero supermarkets are positioned to serve the middle-upper consumers’ market, whereas the Giant supermarket serve lower consumers’ markets. If supplied products do not fit the stringent Hero quality guidelines, sometimes internally the products will be shifted to Giant supermarkets at a lower price.

During PMC implementation, Makassar had only one Hero supermarket and three Giant supermarkets. Hero buyers in Makassar can make autonomous decisions without consulting the head office in Jakarta. The buyers in Makassar also coordinate the sourcing of fresh produce for Hero supermarkets in the rest of East Indonesia.

2.1.4 Seed company In this PMC the seed company played an important role. Bejo is a leading, worldwide operating company in breeding, production and sales of vegetable seeds with operations in more than thirty countries. It is an internationally oriented family-owned business with about 1,500 employees with head office in Warmenhuizen, The Netherlands.

In Indonesia, Bejo seed is represented through the distributor PT Primasid, which is an Indonesian seed producing and selling company. It also distributes various other international branded hybrid seeds. It manages research fields at various locations in Indonesia. Primasid services the market via a team of extension workers that are locally based all over Indonesia. Its extension team covers around 70% of the Indonesian territory.

14

vegIMPACT report 30. Production Market Combination carrot - Enrekang

2.2 The PMC activities and interventions The pilot was started in February 2015 and wrapped up in February 2016. The training interventions took place between May 2015 and December 2015. First sowing at farm side and thus the start of the planting schedule was May 2015. The results of the planting schedule till 26 February 2016 were analysed.

2.2.1 Agronomic interventions

Cultivation training and coaching activities

In order to supply carrot as described in the business proposition, farmers were trained on all cultivation aspects, including integrated pest and diseases management (IPM) and rational fertilizer use. Training was organized and conducted in cooperation with Bejo and external experts from IVEGRI (Annex I).

Based on the results in the first PMC carrot in Cianjur (vegIMPACT report 29), the farmers also received an intensive training on general vegetable production techniques. In Cianjur all training activities were conducted by the extension workers of the seed company and the activities were only focussed on the target commodity. The PMC team felt that without imbedding this specific knowledge in a wider understanding of modern vegetable production techniques, the farmers would not properly understand the need for following SoP guidelines as was the case in Cianjur. An external trainer from IVEGRI was hired for two general vegetable training modules. All training activities (including the fee for the external trainer) were sponsored by Primasid/Bejo.

Taking into account the remote location of the farmers and the proximity of one other PMC in the same region (focussed on broccoli), a junior local vegIMPACT supply chain facilitator was hired to coach and support farmers. During the entire pilot period this junior facilitator was present on location for at least 2 days a week. At the start of his contract he had an intensive training with Primasid at Java and he also visited the carrot PMC pilot in Cianjur to familiarize himself with the activities.

Continuous supply

For a continuous supply of a carrot volume of 500 kg of grade A carrots per week, during a (sales) pilot period of 6 months, a planting schedule was developed in cooperation with farmers, trader and Bejo (Fig. 2.2). Every week two sachets of ‘Norma’ seed for 400 m2 was sown.

Figure 2.2 Planned planting schedule.

20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 1 2 3 4 5 6 7 8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

Nov-15 Dec-15 Jan-16 Feb-16May-15 Jun-15 Juli 15 Aug-15 Sep-15 Oct-15

15

vegIMPACT report 30. Production Market Combination carrot - Enrekang

The start of the planting schedule was May 2015, in order to generate continuous supply from August 2015 onwards.

Introduction of new carrot variety

Farmers were used to grow carrots from locally propagated seed or from the locally available commercial carrot seed varieties. However, these seeds did not result in a high quality, import like type of carrot, which was the production target in this PMC.

Bejo seeds were not distributed in South Sulawesi as the area was not covered by the extension services of its distributor Primasid. For this pilot the first batch of ‘Norma’ seed was hand carried by the PMC facilitator and later the farmers were coached to order seed directly from Primasid by email. After payment of the seed, Primasid would courier the seeds to the farmers.

Post-harvest and logistical interventions

In cooperation with the trader vegIMPACT delivered a tailor-made harvest and post-harvest training to the farmers (Annex II). As the production sites in this pilot were located at considerable distance for the destination market Makassar, an expert was asked to list some key post-harvest points of attentions for the logistical process.

2.2.2 Organizational interventions

After a first assessment of the group by a professional external expert, the group was ranked in in the first stage of the maturity ladder (Fig. 2.3).

To strengthen the group and enable them to manage the carrot business proposition the farmers received a package of five organizational training modules.

2.2.3 Marketing and sales interventions

Quick market scan

In the early stages of the project a quick market scan was performed in Makassar to determine the characteristics of the market and the demand for carrots.

Marketing and positioning

The director of Rodeo fresh and his wife had an introduction to strategic marketing positioning and received tips for labelling and branding. Following this introduction, in close cooperation with the trader, vegIMPACT facilitated the design of a new logo for the company and a label for the carrots. Also marketing materials such as a leaflet, banners and posters were designed to support the introduction of the carrot in the supermarkets of Makassar.

Figure 2.3 Farmer group maturity ladder.

16

vegIMPACT report 30. Production Market Combination carrot - Enrekang

Providing loan

The trader was not willing to support farmers with loans or credit. Therefore, vegIMPACT offered small loans to the farmers on soft conditions for seed and a cultivator.

Contract farmers – trader - supermarket

The farmers were facilitated to conclude a contract with Rodeo Fresh and they were coached during the implementation of the contract.

The trader claimed he had good relations with all major supermarkets in Makassar and would be able to sell the product independently without any support of vegIMPACT.

17

vegIMPACT report 30. Production Market Combination carrot - Enrekang

3 PMC results and evaluation

3.1 Agronomy

3.1.1 Situation pre- PMC, location and practices Main products produced by the farmers of Kuang Dewata (Enrekang) were carrot, hot pepper, cabbage and tomato. In addition, most farmers own one or two goats and some coffee plants. Farmers rotate up to two crops per year (for example, cabbage-hot pepper or tomato-cabbage) but at some fields they grow cabbage year-round. Commonly, vegetables are produced and sold individually to collectors and/or at the local Sudu wholesale market.

Luvisol/Acrisol soil types are prevalent in the Enrekang regency and the pH of the soil of farmers’ fields was on average between 6-7. The vegetable production locations were at an altitude between 800 to 1000 m above sea level.

The Enrekang regency has a significant rainfall year-round (Fig. 3.1) and an average annual temperature of 26.6 °C. The average precipitation is 2,410 mm. August is the driest month (138 mm) and January the wettest (316 mm).

Figure 3.1 Average precipitation in Enrekang regency. Source: www.climate-data.org.

Production techniques used in Enrekang are basic and farmers do not keep any records of their farm input and outputs.

The farmers experienced little problems with water availability. Except for three farmers, all farmers were connected to a rudimentary irrigation system of hoses to a water pond that was fed with piped spring water from a higher elevation. Some farmers also had built additional water reservoirs at their own premises.

Main problems with carrot production at the start of the pilot were:

- Pests such as cricket and Bemisia spp. - Diseases such as Downey mildew and soft rot. - Damage by animals such as chicken (seed), wild boar (carrot) and rats (carrot).

18

vegIMPACT report 30. Production Market Combination carrot - Enrekang

3.1.2 Agronomy training and results In addition to specific technical production aspects of ‘Norma’ carrot, the farmers also received two 2-day modules on general vegetable production techniques. After the final training the group was coached for about two days a week by the local vegIMPACT junior supply chain facilitator. Farmers were enthusiastic about the newly gathered knowledge and were eager to apply it in their fields.

At the early stages of the planting schedule it became apparent that many plots that farmers planned to use, consisted of heavy clay soils with lots of stones (during the assessment not all the widely dispersed locations of the farmers were visited). Without proper land preparation in the form of tillage, this soil type would result in a high percentage of substandard (small and malformed) carrots.

Two months into the harvest period, the carrots were still of disappointing quality (many cracked and malformed carrots) that did not meet the specification of the trader. The farmers were not able to manually prepare the land sufficiently for carrot production. To overcome this problem vegIMPACT facilitated the farmers to purchase a cultivator, to be shared by all farmers (Pic. 3.1). VegIMPACT provided a loan of 7,000,000 IDR that included a 50% grant. This intervention was successful and the carrots from the plots that were prepared by the cultivator were of a much higher quality and volume (Section 3.1.3).

Picture 3.1 Farmers with their new cultivator.

During the dry season the group encountered another problem. The water ponds of some farmers dried up, resulting in low water availability at some of the fields. This was especially problematic in the first weeks after sowing as it increased the percentage of non-germinated seeds. Lack of water at the end of the carrot production cycle results in shape and colour deficiencies.

During the dry season some fields were also heavily affected by crickets (Gryllotalpa spp.) that damaged freshly sown seeds. In some fields more than half of the seeds disappeared quickly after sowing. Farmers were advised to use pesticide preventively before sowing to control this problem. Using pesticide in a preventive way was new to farmers.

Similar to the Cianjur region, red tops were also a problem in Enrekang (Pic. 3.2). However due to the soil type in Enrekang, covering the tops with soil was not easy and once farmers predominantly sold most products to the local market (Section 3.2.2), there was little incentive to continue the laborious work of covering the tops with soil as traders at the local market had no problem with red tops.

19

vegIMPACT report 30. Production Market Combination carrot - Enrekang

Picture 3.2 Carrot with red top.

The following changes with regard to carrot production were observed before and after the vegIMPACT training interventions (Table 3.1).

Before PMC interventions /production practices local carrot varieties

After PMC interventions / production practices ‘Norma’ carrot

Broadcast sowing technique Precision sowing (price of commercial seed does not allow for broadcasting).

Minor land tillage because of soil texture, only some farmers tilled the top layer of old planting beds.

Deep tillage with cultivator and establishment of new planting beds at locations that could be reached with the cultivator.

Basic fertilizer top-dressed Two weeks before sowing potassium and manure was mixed in the top soil by some farmers

Mix pesticides in one tank Single spraying by some farmers

No preventive use of pesticide Preventive use of pesticide for control of Gryllotalpa sp.

Table 3.1 Production practices before and after PMC training intervention.

3.1.3 Continuous supply of carrots The planting schedule (Fig. 3.2) was implemented rather consistently and 17 farmers of the farmer group participated in the schedule. The results of 39 plots have been analysed.

20

vegIMPACT report 30. Production Market Combination carrot - Enrekang

Figure 3.2 Actual implementation of planting schedule at 39 plots (orange blocks indicated 100% damaged

fields).

The following factors influenced the planting schedule, the result and the carrot yields:

- Seed-eating insects (in June 2015 some entire fields were damaged). - Pigs damaging fields and harvest. - Stoney clay soils. Only after farmers started to use a cultivator for land preparation yields

increased. However, not all plots were accessible for the cultivator. - Not all farmers followed the SoP consistently (in particular proper soil tillage was a bottleneck). - Water availability in the dry season: some plots in the planting schedule were cancelled and in

September - October 2015 the planting schedule was temporally reduced to one sachet per week.

Continuous carrot supply was realized, but with fluctuating volumes. Only in the third month of the planting scheme the target volume was reached (Fig. 3.3). However, quality was below expectation and after three months (in January) the carrot volumes decreased again because of the lack of irrigation water in the dry season.

Figure 3.3 Total carrot production (kg / per month) as compared with the target volume grade A (red line).

Plot Sowing Harvest 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 1 2 3 4 5 6 7 8

1 11 May 2015 14 Agustus'15

2 16 May 2015 27 Agustus'15

3 20 May 2015 27 Agustus'15

4 23 May 2015 20 Agustus'15

5 27 May 2015 27 Agustus'15

6 27 May 2015 7 September'15

7 3 Juni 2015 7 September'15

8 3 Juni 2015 14 September'15

9 9 Juni 2015 14 September'15

10 10 Juni 2015 14 September'15

11 17 Juni 2015 21 September'15

12 20 Juni 2015

13 24 Juni 2015

14 24 Juni 2015

15 1 Juli 2015 12 Oktober'15

16 4 Juli 2015 5 Oktober'15

17 11 Juli 2015 12 Oktober'15

18 15 Juli 2015 26 Oktober'15

19 18 Juli 2015 19 Oktober'15

20 25 Juli 2015 26-Oct-15

21 4 Agustus 2015 09-Nov-16

22 8 Agustus 2015 16-Nov-15

23 13 Agustus 2015 12-Nov-15

24 23 Agustus 2015 07-Dec-15

25 29 Agustus 2015 07-Dec-16

26 02 September 2015 07-Dec-16

27 15 September 2015 21-Dec-16

28 26 September 2015 21-Dec-16

29 30 September 2015 28-Dec-15

30 15 October 2015 08-Jan-16

31 17 October 2015 15-Jan-16

32 01 November 2016

33 01 November 2015 22-Jan

34 08 November 2016 25-Jan

35 08 November 2016 01-Feb

36 08 November 2016 05-Feb

37 11 November 2016 08-Feb

38 11 November 2016 19-Feb

39 01 December 2016 26-Feb

Nov-15 Dec-15 Jan-16 Feb-16May-15 Jun-15 Juli 15 Aug-15 Sep-15 Oct-15

21

vegIMPACT report 30. Production Market Combination carrot - Enrekang

At the start of the PMC results of the individual plots were irregular (Fig. 3.4), but in due course the yields of the individual plots improved and were more regular, which was mainly caused by the introduction of the cultivator.

Figure 3.4 Carrot production of individual farmers’ plots (in kg per plot of 200 m2, dark blue bars are plots

of 400 m2).

Six months after finalization of the PMC pilot, the farmer group still maintained a joint planting schedule of one sachet per week.

3.1.4 Introduction new variety Based on the potential positive results of the other PMC carrot in Cianjur (West Java), the farmers agreed to start sowing ‘Norma’ carrot seed. The ‘Norma’ variety and the practice of precision sowing1 were completely new to the farmers whereas precision sowing is considered crucial for good results. Most farmers were very diligent in following the SoP with this regard.

However, the local circumstances in Enrekang were very different as compared with Cianjur and as a result the carrot quality remained far below the Cianjur quality and thus also below the import quality that was targeted. Main reasons were the heavy clay and stony soils that badly influenced the shape of the carrots in Enrekang. Consequently the % of grade A quality, as was set at the start of the project, was low. Only after introduction of the cultivator the carrot quality improved. The supermarket acknowledged that the quality of the Norma carrot, albeit below the quality of imported carrots, was still higher than the conventional local carrot supplied to them. Therefore, the supermarket continued with selling the Enrekang carrots in addition to the imported carrots and local carrots in their assortment.

The buyers at the traditional market both in Makassar and locally at the Enrekang market also acknowledged the superior quality of the ‘Norma’ carrot as compared with other locally available carrots. Local traders consistently paid about 2,000 IDR per kg on top of the local price for the other carrots.

1 Even if farmers worked with commercial seed, they practiced the broadcasting method for sowing.

22

vegIMPACT report 30. Production Market Combination carrot - Enrekang

3.1.5 Post-harvest and logistical interventions In cooperation with the trader, farmers were trained in post-harvest operations that would minimize the volume of rejected carrots by the trader and supermarkets.

Immediately after harvest, the leaves of the ‘Norma’ carrot were completely cut in the field and back at the farm the harvested carrots were washed manually. Women supported the farmers with the cleaning. Carrots were packed in carton boxes for transport to Makassar (Pic. 3.3).

Picture 3.3 Illustration of washing and packing of ‘Norma’ carrot at farm side.

The logistics were troublesome in the beginning of the pilot. For example, farmers were not used to pay for transport as normally carrots were either collected at farm gate or at the local traditional market.

During the PMC pilot Rodeo Fresh refused to assume responsibility for transport and PMC facilitators had to discuss various transport options with the farmers. As the trader demanded supply twice a week, the volumes were too small to economically arrange transport. In the end the group decided to transport the carrots by a long distance truck line at a cost of 400 IDR/kg. An alternative was identified by using public transport (bus) for 45,000 per box (one carton box would fit about 36 kg carrots). To get the supply to the market kick started vegIMPACT provided a small transport subsidy to farmers till the end of September 2015.

After arrival of the carrots in carton boxes in Makassar, they would be graded, wrapped and labelled by the extension staff of Rodeo Fresh. However, the extension worker preferred to sell the carrots on the local market as it saved him work and he was allowed to keep the profit of the sales to traditional market himself. Only carrot of grade A quality was to be delivered to the supermarket and would be paid out to the farmers through Rodeo Fresh, proceeds of sales at the local traditional market were directly managed and paid out by the extension worker.

In addition the extension worker did not communicate with supermarkets, but kept informing the farmers that the carrots supplied did not meet the specifications of supermarkets. Only in November 2015 when a deal was brokered with the HERO supermarket (Section 3.3.2) it turned out there were sufficient carrots that would meet grade A specification of Hero supermarket.

These communication problems between the extension worker of Rodeo Fresh and the farmer group created a lot of distrust. There was no transparent information exchanged with regard to the condition of the carrots upon arrival in Makassar, and naturally the carrot condition also influenced the percentage of rejected product. As a result farmers did not always believe the reasons given for rejection. To facilitate and improve communication between traders and farmers, simple smart

23

vegIMPACT report 30. Production Market Combination carrot - Enrekang

phones2 were provided by vegIMPACT that enabled them to send pictures of the physical state of the carrots at point of shipment and at point of delivery.

To minimise damage during transport and professionalize logistics, farmers were stimulated to use plastic crates3. At that time farmers used round shaped laundry baskets of soft plastic during the post-harvest activities of local carrots. VegIMPACT sponsored some plastic crates to the farmers, in order to experience the pros and cons of these crates before investing at large scale. The introduction of crates was not very successful as the crates did not fit on the back of a motorbike. Whereas for the round baskets the farmers devised a frame on the back of their motor for transporting 2 baskets.

In addition the transporter did not allow for a return system of the empty crates from Makassar and preferred to use carton boxes.

3.2 Group development

The process of developing farmer group Kuang Dewata in a mature group progressed very well. The group was committed to the pilot and on average 80% of the initial participating farmers attended the training interventions (Fig. 3.3). Halfway the pilot two additional farmers started to attend the vegIMPACT training activities.

Figure 3.5 Percentage of farmers that participated in the training interventions of initial 21 participating farmers.

The group matured considerably as became obvious during several steps of the PMC process:

- The planting schedule was implemented as planned and the majority of farmers participated (17 of the 21 farmers of the group).

- Because labour is expensive in the region, the farmers agreed to help each other with land preparation and during sowing. Through this cooperation no external labour was necessary, and farmers could reduce their (out of pocket) costs.

2 Currently smart phones are available in Indonesia from only about 340,000 IDR or 15 Euro per phone. 3 In East Java Rodeo Fresh already works with crates that are returned empty to the farmers. The investment to buy crates is borne by the farmers.

24

vegIMPACT report 30. Production Market Combination carrot - Enrekang

- The cultivator purchased during the pilot was used by the entire group. If farmers used the machine they deposited 50,000 IDR in cash for (future) maintenance.

- Joint selling was managed well and farmers were not allowed to sell independently on their own. They jointly agreed that if a farmer would be involved in side selling, he would lose his slot in the planting schedule and would no longer have access to centrally purchased seeds.

- Even although the trader paid irregularly and in the end stopped paying completely, the farmers remained committed to the contract and supply to Rodeo Fresh.

- At the end the group was legally registered and had a joint email address and a joint bank account.

The positive development of the group was also recognized by the local government and the farmer group was granted another cultivator and a three-wheel transport motor by the Government half way the PMC pilot.

The biggest challenge the group faced was the cooperation with the trader Rodeo Fresh. Selling on contract was new to the group and entailed an administrative process of sending invoices, checking bank accounts regularly, sending reminders if necessary, and paying out to farmers. These activities were new to the farmers and often resulted in problems such as:

- Invoices were often sent late. - The secretary did not check the joint bank account regularly. - The person responsible for marketing was not persistent with following up on unpaid invoices send

to Rodeo Fresh (if farmers did not give it urgency, Rodeo Fresh would also not give it urgency). - Rodeo Fresh paid the farmers irregularly and in small portions that were not labelled and did not

correlate with the invoices send to Rodeo Fresh.

At the time of wrapping up the PMC, when supply to Rodeo Fresh stopped, the farmers continued with selling carrots at the local traditional market (this was organized centrally by the marketing person of the farmer group) for cash and no administration was required any longer.

At the end of the project the farmer group was assessed by the vegIMPACT team and by the organizational expert to be at the second level of the maturity ladder (Fig. 2.3). It was concluded that especially the marketing and sales process still needed to be improved as farmers were unable to establish new contracts independently and to connect with other suppliers to modern markets. Also the problem solving ability of the group themselves was considered to be low.

3.3 Marketing and sales Even though the trader expressed to be interested in marketing support from vegIMPACT, he turned out to be very traditional. He was mostly interested in a new label. The potential benefits of working together with modern markets and promoting vegetables through banners, leaflets, posters and other in-shop activities was new to him. Also negotiations with regard to consumer price setting, based on the type of supermarket, was new. In his current contracts, the supermarket was the price setter and the trader a mere price taker. Unfortunately Rodeo Fresh was not open for an innovative and more strategic marketing approach. Also the fact that in Makassar Rodeo Fresh was represented by one of its extension workers, was not very supportive to establish good working relations and cooperation with supermarkets.

In Makassar the products of Rodeo Fresh were branded “We One”, on a small sticker. There was no logical thought behind the brand and the director was not able to explain why the company had chosen the words “We One”. In close cooperation with Rodeo Fresh a new logo was developed for the “We One” brand by vegIMPACT, and to give the brand more impact tagline was added “We are One in freshness ”. Additionally, matching point of sales material was designed, X banners, posters and a leaflet. The material was used during a brief introduction period around Christmas 2015 (Pict. 3.4).

25

vegIMPACT report 30. Production Market Combination carrot - Enrekang

Picture 3.4 Illustration in shop introduction activities.

The reaction of Hero Supermarket was very positive and they were happy with the labelled product and they welcomed the supporting PoS material (banner and leaflet).

3.3.1 Contract and sales trajectory Contract Farmers - Trader

Although Rodeo Fresh initially agreed with vegIMPACT to join the pilot, it was challenging to get the trader to formalize his contract with the farmers. During the development phase of the PMC the trader had mentioned a carrot price that would be interesting for him in the Makassar context, as it would save him the logistical cost of 13,000 IDR/kg to get carrots from Malang. But when the actual contract with the farmers was discussed, Rodeo Fresh decided to no longer use prices of products from East Java in the Makassar market as a starting point, but instead he proposed to use the prices of local carrots at the traditional Makassar market as a reference. Close to the first carrot harvest the trader:

- Was unwilling to provide loans to farmers (for seed). - Was unwilling to share the costs of transport and the logistical risks. - Did not want to cooperate to design mutually agreeable payment terms. - Demanded 2-3 deliveries per week (resulting in small volumes per delivery and thus high

transport costs). - Was unwilling to pay a fixed contract price and instead he demanded prices to be determined

on weekly bases.

From the end of November 2015 onwards, the trader finally agreed to commit to an acceptable contract price for grade A carrots of 6,000 IDR/kg for a 3 months contract (as an agreement with a firm contract price was also agreed between the trader and Hero supermarket, see next section). January 2016, Rodeo Fresh even offered to change the contract in a 6 months’ contract with a contract price of 15,000 IDR/kg, to be paid out once a month4, although this offer was never formalized on paper. But in February 2015 when local price for Norma carrot was 5,000 IDR/kg at the traditional market in Enrekang (price for conventional carrot at that time was only 3,000-4,000 IDR/kg) farmers still received 15,000 IDR/kg from Rodeo Fresh (and under the contract Rodeo Fresh sold it for 20,000 IDR/kg to Hero

4 At that time prices at the local traditional markets were 16,000 IDR/kg as well, but farmers were well aware that those prices fluctuated a lot and a contract price of 15,000 IDR/kg for a prolonged period was very interesting.

26

vegIMPACT report 30. Production Market Combination carrot - Enrekang

Supermarket). Even though, the volume was very low, (40-60 kg /week) it made the farmers realize why a contract price can be beneficial.

Figure 3.5 Meeting between director trader Rodeo Fresh and farmers to discuss contract specifications.

While Rodeo Fresh agreed with farmers verbally on prices (first on weekly, later on monthly bases), Rodeo payed very irregularly. At the end of the PMC pilot, from January 2016 onwards, payments even stopped completely. For weeks farmers continued to send their high quality carrots to Makassar, based on trust that eventually the trader would pay the verbally agreed contract price. At the end of February when the payment delays had resulted in a considerable backlog, the farmers where no longer able to get into contact with the trader in Malang, and the PMC team found out that the Rodeo Fresh extension worker in Makassar was not being paid out as well, the farmers stopped supply (most of the products were sold locally anyway as the % of grade A was small).

After the contract with the trader was discontinued the farmers were not able to establish agreements with other traders who were interested in a continuous Norma carrot supply. Instead the farmers continued to sell the carrot to traders at the traditional market in Enrekang, and they continued to be able to negotiate a price that was on average 2,000 IDR/kg above the local market price.

Contract trader - supermarket

In the design phase the trader agreed to sell the carrot to various supermarkets in Makassar, as he claimed to have deals with most supermarket chains in Makassar. Contracts with supermarkets were exclusively managed by the director of Rodeo Fresh in Malang and the extension worker of Rodeo Fresh in Makassar was merely an intermediate link. The Rodeo extension worker was not able, nor authorized to negotiate issues or to discuss more strategic cooperation with the supermarket. Similar to his common practice in Malang, the trader agreed to buy all grades from the farmers, and planned to sell the higher grades to supermarkets and lower grades to the traditional market. The selling at the traditional market was supposed to be done by the inexperienced extension worker.

During the first months of the PMC it became apparent that the Rodeo Fresh contracts with supermarkets were not as solid as expected, and at the same time the quality of the carrot from Enrekang was far below the quality the trader expected (Section 3.1.4). During the design phase of the PMC, the vegIMPACT team had presented a sample from the PMC project in Cianjur to the trader, based on which he agreed to cooperate and sell the carrots in Makassar. In reality the carrots from Enrekang never reached the same quality as in Cianjur.

In November 2015 the trader still claimed he could not get a good deal for the ‘Norma’ carrot with supermarkets, instead almost the entire crop was sold at the traditional market in Makassar.

These developments were rather disappointing for all participants because during the design phase of the pilot, PMC facilitators had pitched the ‘Norma’ carrot (based on samples from Cianjur) to several

27

vegIMPACT report 30. Production Market Combination carrot - Enrekang

supermarket buyers in Makassar and most of them showed a warm interest. When the quality of the carrots from Enrekang improved after three months, the PMC team decided to pitch the ‘Norma’ carrot again to supermarket buyers in Makassar, but this time with an actual sample of carrots from Enrekang. Supermarkets were still interested and based on the most interesting price option, the PMC facilitators brokered a contract between Rodeo Fresh and Hero Supermarket for grade A ‘Norma’ carrots with a monthly contract price. Promotional activities such as labels, display of banners, posters, leaflets and a cooking demonstration were part of the agreement. The trader, nor his extension worker was able to join the meetings with the supermarkets, but Rodeo Fresh was very happy with the contract and contract price, which was higher than the prices he normally fetched with supermarket. The promotional activities would be organized by vegIMPACT as part of the deal with Rodeo Fresh for participating in the pilot.

Unfortunately the first deliveries to Hero under the new contract were rejected by Hero as the quality was again below expectations and did not meet the Hero requirements. As result Hero was forced to sell the carrots through their Giant supermarket at a lower price.

End December 2015 the first carrots finally entered the shelves of the Hero supermarket, with labels and supporting banners and leaflets (Pic. 3.4). The cooking demonstration was postponed till the volume of grade A carrots would increase from February 2016 onwards.

However, as explained before the farmers stopped supplying carrots to Rodeo Fresh completely by the end of February 2016. Hero supermarkets still wanted to continue ordering carrots, and also complained with the PMC facilitators that supply had haltered without notification from Rodeo Fresh. However, without an intermediate party or middle men in Makassar the farmers were not able to independently continue supply to Hero.

Profitability Farmers

The first months of harvest of ‘Norma’ carrots were not profitable for the individual farmers (Fig. 3.6) for various reasons:

- Small volumes. - Farmers sold all their grades (A, B and C) to Rodeo Fresh, who sold all grades at low prices. (far

below prices that farmers would have fetched at the local traditional market in Enrekang). - The % of grade A carrot was very small.

Figure 3.6 Financial results (IDR) per plot of 200 m2 (dark red and dark green are plots of 400 m2).

28

vegIMPACT report 30. Production Market Combination carrot - Enrekang

When it took too long for the trader to broker a contract for Grade A carrots in Makassar and the extension worker of Rodeo Fresh continuously demonstrated that he was not able to sell the carrots for a good price at the traditional market in Makassar, the farmers became restless.

A change of strategy was needed and by the end of October 2015 the PMC facilitators made an overview of various options for discussion with the farmers:

- Continue to sell via Rodeo Fresh to supermarkets and at traditional market in Makassar. - Sell to traditional market in Enrekang. - Sell to collectors at farm gate. - Direct selling to super markets.

An inventory of the attractiveness of the options was made and discussed with the farmer group (Table 3.2).

Sell via Rodeo Fresh

Sell independently at local (traditional) market

Sell to collector at farm gate

Direct selling to supermarket Palopo

Payment -- + --- +

Management/admin -- ++

+/-

Logistics +++ +++ +/-

Stability price + -- --- +

Table 3.2 Comparison of various options for selling carrot by Enrekang farmers.

Farmers decide to continue selling grade A quality carrots to Makassar under the contract with Rodeo Fresh and the remaining grades independently as a group at the local traditional market in Enrekang. The PMC facilitators would support Rodeo Fresh with brokering a contract for ‘Norma’ with a supermarket.

As soon as famers started to sell the majority of carrots at the local market, they started to make a profit (Fig. 3.6 and 3.7). Demand for the ‘Norma’ carrot at the traditional market was strong and the carrot always fetched 2,000 IDR/kg more than the other carrots at the market. Only the carrot plots with production problems (such as diseases and water shortage) resulted in a financial loss (Fig. 3.6).

Figure 3.7 Volume kg per plot sold on contract to trader Rodeo Fresh (green) and volume sold outside of contract to local market (orange).

29

vegIMPACT report 30. Production Market Combination carrot - Enrekang

The overall carrot planting schedule resulted in a profit margin of 37%, which was slightly above expectation (Fig. 3.8). This included the first months when all plots resulted in a financial loss. Hence, it can be concluded that at the end of the planting schedule the weekly profit margin was even higher.

Figure 3.8. Overall profitability (in million IDR/ha) of the planting schedule in Enrekang.

In reality, due to delayed payments by the trader, the PMC propositions was less profitable than calculated on paper. Still as the majority of products were sold on the local market for attractive prices, at the end of the pilot, the farmers were very committed to continue production5.

Profitability trader

According to the records of Rodeo Fresh of the first two months of the selling period, he did not make any profits. Hardly any of the carrots were sold to supermarkets, instead they were sold at the traditional market by the extension worker of Rodeo Fresh who was unable to negotiate good prices. According to the trader he paid the minimum agreed price to the farmers during the initial weeks of the selling period, but he would not be able to do that much longer.

When a new contract was brokered with the supermarket, Rodeo Fresh agreed on a medium term contract (3-6 months) with the farmers, which was in principle profitable. However, there are no Rodeo records to support this.

Example

In December 2015 the trader offered the farmers 15,000 IDR/kg and he sold the carrots at 20,000 IDR/kg to Hero, resulting in a gross margin of 33%. Transport costs to Makassar were born by the farmers, so this margin is expected to result in a healthy net profit.

5 At the time of the first Idul Fitri, after wrap up of the PMC, the PMC team learnt the farmers still did not receive the backlog payment of Rodeo Fresh. The trader was still incommunicado and also the PMC team could not get in contact with the trader. The PMC team expected that the chance the trader would still pay was small. To compensate the farmers for this loss, the PMC team donated 50% of the money due to the group by Rodeo Fresh as Idul Fitri gift, with the condition that if the trader would start to pay after all the money would be used for farmer group activities that would benefit all.

30

vegIMPACT report 30. Production Market Combination carrot - Enrekang

4 Discussion and conclusions

4.1 Overall result business proposition The business proposition “High quality carrot produced by small farmers for modern retail in Makassar” was promising from the start, i.e. a dedicated farmer group, an innovative Norma carrot variety with proven performance and a trader from East Java that potentially would benefit from sourcing locally in South Sulawesi. The results of the PMC pilot support that this proposition is potentially profitable for both farmers and traders as described below.

Farmers

On average the overall planting schedule resulted in a profit margin of 37%, slightly more than the expected 35%.

The farmer group embraced the implementation of the ‘Norma’ carrot proposition. After some initial problems related to irrigation water availability, soil preparation, and pests and diseases, the yields and quality of the carrots improved. The farmer group was also successfully strengthened and developed to the second maturity level.

The PMC pilot’s planting schedule resulted in positive financial results for the farmer group and they continued growing ‘Norma’ carrot after the pilot was wrapped up. Unfortunately the group was not strong enough to independently connect with new modern market suppliers after the contract with the trader participating in the PMC failed.

Nevertheless, in view of increasing demand and price levels at the traditional market, carrot is still a profitable option for the farmers of Kuang Dewata.

Trader

Based on the limited information available, the trader would potentially be able to make a profit margin on the ‘Norma’ carrots. However, because of internal problems the trader was not able to commit to his agreements with the farmer group as well as with the Hero supermarket in Makassar. Cooperation was unilaterally cancelled by the farmers after the trader already stopped the payments for carrots that were supplied 6.

4.2 PMC contribution to vegIMPACT objectives

The pilot PMC carrot accomplished the following results:

Successful introduction of new carrot variety in the Makassar market. Introduction of modern production techniques for import-quality carrots including design and

implementation of planting schedule for continuous supply. Connecting farmers with traders and connecting trader with supermarket(s).

PMC carrot Enrekang has contributed to the following specific vegIMPACT objectives as presented in Table 4.1.

6 In October 2016, the PMC team learned that the trader had encountered problems with a national supermarket chain that led to a near bankrupt of the company. It was still financially recovering from this issue.

31

vegIMPACT report 30. Production Market Combination carrot - Enrekang

vegIMPACT objective PMC contribution Remarks

Increased vegetable productivity

+ Average yields of ‘Norma’ carrot under Enrekang circumstances are 17% higher than those of conventional carrot in South Sulawesi.

Reduced pesticide and fertilizer usage per unit product

+ Farmers were trained to use a rational amounts of fertilizers and pesticides. Farmer also switched to single pesticide spraying.

Reduced production costs per unit product

0 Production costs of ‘Norma’ carrot was similar to the production cost of local carrots in the Enrekang regency. 7

Increased financial margins for farmers

+ ‘Norma’ carrot, improved production and (post) harvest practices in combination with an innovative mode of cooperation between farmers and trader resulted on average in improved margins for the farmers compared with conventional carrots.

Explanation: + = PMC positively contributed to specific objective 0 = neutral; no effect of PMC was observed - = could not be measured Table 4.1 Summary of contribution PMC carrot to vegIMPACT objectives.

4.3 Norma carrot production: comparative analyses between PMCs

PMC Enrekang was the second carrot PMC that was implemented as part of the vegIMPACT programme. The results of the PMC wortel in Cianjur (West Java) have been compared with the results of PMC wortel in Enrekang (South Sulawesi) and were summarized in Table 4.2.

Both PMC’s resulted in similar average profit margins. The cost price in Enrekang was 80 % higher, but as the local price level for ‘Norma’ carrot was also considerably higher in South Sulawesi the overall results were similar. The higher production costs in Enrekang were related to among others the higher labour cost.

The potential for upscaling is much higher for the Cianjur farmers, because of the size and proximity of the potential markets in Jakarta as compared to the size and remoteness of the Makassar market for the Enrekang farmers.

The yields per sachet of ‘Norma’ seeds varied considerably between the two regions. The stony clay soil in Enrekang was less suitable for producing high (import) quality ‘Norma’ than expected. Average yields over the complete planting schedule in Enrekang were consequently much lower than in Cianjur. Still the farmer group in Enrekang benefitted to a much larger extend than in Cianjur. Almost all farmers of the farmer group in Enrekang participated in the planting schedule and all were able to realize a profit on their plots, whereas in Cianjur only one farmer really mastered to produce high quality carrots based on ‘Norma’ seed.

7 Costs for the purchase of the cultivator were excluded in the cost price.

32

vegIMPACT report 30. Production Market Combination carrot - Enrekang

Aspects PMC carrot Cianjur8 PMC carrot Enrekang

Cost price (IDR) per 200 m2 or one seed sachet

1,023,550 1,900,388

Profit margin farmers 35 % 37 %

Target volume based on 1 sachet /week 2 sachets /week

Soil Loose Heavy clay with stones

Land preparation after intervention

Manual, tillage and new beds Tillage with cultivator required for heavy soil, and new beds

Harvested plots at the time of wrap up and that were analysed.

44 plots 39 plots

Total land used (m2) 9,600 8,600

Training received Only focussed on ‘Norma’ General vegetable production techniques and ‘Norma’ specific techniques

Farmers involved in planting schedule

6 17

Average growing period (days) 105 95

Average yield using one sachet ‘Norma’ during entire planting schedule

490 kg (24.5 ton/ha) 331 kg (16.5ton/ha)

Contract selling Bargaining power stronger (but only by farm group leader)

Bargaining power low. Not equal to modern retail supplying traders

Farmer group strength. Disappointing, group failure Strong and committed, but still need to learn

Distance to modern market 3 hours 8 hours

Table 4.2 Comparison of PMC carrot Cianjur (West Java) with PMC carrot Enrekang (South Sulawesi) on selected aspects.

8 Based on the result of the farmers that implemented most plots of the planting schedule (vegIMPACT report 29).

33

vegIMPACT report 30. Production Market Combination carrot - Enrekang

ANNEX I: Training plan PMC wortel

When What Day(s)

spent

Whom

7 April’15 Facilitating Meeting Rodeo Fresh with Kelompok Sipakari Tutu

1 RS, Pak Ilud & Kelompok

10-11 May’15 Cultivation Module A

“Introduction Character of Norma F1, Cultivation Techniques

2 Pak Asep Primasid & RS

Week of 20, May’15 START Direct Sowing

23-25 May’15 Training Need & Rapid Assesment 1 Pak Alfa & RS

Organization Module 1

“Principles of Farmers Cooperation”

2

3-4 June’15 Cultivation Module B

“Soil & Field Preparations, Fertilizers & Fertilization”

2 Pak Tony M & RS

29-30 July’15 Organization Module 2

“Cooperative and Finance Administration”

2 Pak Alfa & RS

5-6 August’15 Cultivation Module C

“Harvest, Post Harvest Training (Processing, Packaging, etc)”

2 Primasid & RS or Pak Ilud (trader) &RS

Week of 33, August’15

SELLING PERIOD

29-30 August’15 Cultivation Module E

“Integrated Pest & Disease Management (Crop Protection)”

2 Pak Tony M & RS

16-17 September’15 Organization Module 3

“Cooperative Planning Strategy”

2 Pak Alfa & RS

8 October’15 Occupational Health Training 1 NN or RS

11-12 November’15 Organization Module 4

“Management Information System, Internal Quality Management”

2 Pak Alfa, RS

16-17 December’15 Organization Module 5 “Market Acces” 2 Pak Alfa, RS

18-19 January’16 Evaluation 2 VegImpact

34

vegIMPACT report 30. Production Market Combination carrot - Enrekang

ANNEX II: Post Harvest handling of mature carrots Points of attention for small growers in Sulawesi, Indonesia.

By Simon Schouten – free-lance CBI/WUR consultant