Problem 2 Fluid Mechanics

Transcript of Problem 2 Fluid Mechanics

Problem 2 – Fluid Mechanics

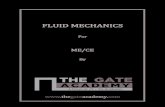

Ethanol flows from Tank 1 through the following pipe system and enters Tank 2. The fluid is being

transported in 250 mm ID stainless steel piping.

open gate valve

42 m of pipe

45 ° elbow

16 m of pipe

45 ° elbow

20 m of pipe

90 ° elbow

1 m of pipe

εSS = 2.00∙10‐7 m EtOH = 789 kg/m3 μEtOH = 1.20∙10‐3 Pa∙s g=9.81 m/s2

1. Write a MATLAB script to plot the system curve (total head Loss (m) vs 𝑄 (m3/s) at flow rates between

0 and 200 L/s, in 10 L/s increments.

In your code, you will need to produce the output vectors for the variables specified below:

Output vectors required (in units of) Variable name

Flow rate (m3/s) Q Velocity of fluid (m/s) v Reynolds number Re Darcy friction factor f Total head loss for pipes (m) h_pipe Total head loss for fittings (m) h_fittings Total head loss of system (m), including the elevation h

Plot the head loss data as red square points and a connecting red solid line to make the system

curve [hint: only use a single line plot command e.g. plot(x,y,'c+‐‐')]. Include a title and axes labels

for the plot.

Caution when performing calculations:

All calculations should be done purely using vector arrays (e.g. .* and ./), you are not allowed to

use loops.

Do not use if/else selection statement to check flow regime. Directly apply the appropriate

formula for the friction factor calculation.

All calculations to be performed in MATLAB. Manually calculated values that are entered into

MATLAB are not accepted.

For constants, use applied MATLAB functions e.g. pi instead of 3.142.

100 m

h1 = 7 m 1

2h2 = 20 m

20 m

Pump

D = 500 mm

pipe

system

h2=20m

h1=2m

2. A pump with the following pump curve is going to be used to overcome the losses of the system

above.

Flow [L/s]

0 25 50 75 100 125 150 175 200

Head [m]

21.0 20.2 18.8 16.9 14.6 11.7 8.3 4.4 0

Plot the pump curve onto the same axis as the system curve from Q2 using blue circles and a

connecting solid blue line. Use a legend to differentiate the curves.

Define your pump variables as:

Pump curve parameters (in units of) Variable name

Pump flow rate (m3/s) Q_pump Pump head (m) h_pump

Based on the two plots, determine the operating point of the system by reading the flow rate of

the intersection point of the two plots. Store your answer as variables Q_op and H_op.