Pro-Steel Brick Slip Bolt Up Soffits ab-steel Brick Slip Bolt Up Soffits 1.0. Background LIMITED The...

Transcript of Pro-Steel Brick Slip Bolt Up Soffits ab-steel Brick Slip Bolt Up Soffits 1.0. Background LIMITED The...

Pro-SteelBrickSlipBoltUpSoffits1.0. Background

ThePro-Steelrangecomprisesbrickslipsbondedexclusivelytoaperforatedstainlesssteelcarrierorchassis.Thestainlesssteelcomponentsarepurchasedfromoursupplychainpartnerswhoundertakethedesign,fabricationandweldingoftheunitsinlinewithBSEN1090Design,WeldingandFabricationunderaCertifiedFactoryProductionControlSystem.Allbrickcutting,bondingandfabricationareexclusivelycarriedoutbyFab-SteelusingourBBAaccreditedepoxyresinformulatedfortheadhesionofbricktostainlesssteel.OurfactoryisauditedbyboththeBBAandourqualitycontrolspecialistconsultantQMS.

Aspartofthedesignservice,Fab-Steelreviewcustomers’requirementsandproducelayoutandsectiondrawingsillustratingthedesignoftheproductsrequiredtoachievethespecifiedbrickfeatures.Theseproductscanbeeitheralintelorboltup.Thedesignofthetwosystemsisfundamentallythesameinthatthesamebrickslipsarebondedtoaperforatedstainlesssteelcarrierusingthesameresinforeitherdesign.Thedifferencebeingthatthecarriercaneitherbeproducedwithanintegratedchannelsectiontoallowittobeboltedtoanothercomponent(Pro-SteelBoltUp)oritcanbeweldedtoalintelmeaningthatthebricksslipfeaturebecomesanintegralpartofthelintelassembly(Pro-Steellintel).

2.0. Pro-SteelBoltUps

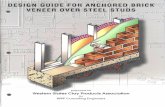

TheIllustrationbelowshowsatypical‘boltup’applicationwheretheboltupisfixedtoamasonrysupportshelfangle.Squarenutsarelocatedwithinthechannelsectionwhichisweldedintothecarrier.M12buttoncapheadsarethenusedtofixtheboltuptotheslotsinthemasonrysupportangle.

ab-steelL I M I T E D

2.1. BoltUpComponents

Boltupassembliesareproducedtoprovideachassistofacilitatethebondingofbricksslipsinaparticularbondpatternorconfigurationasspecifiedbythearchitect,designerorspecifier.Thesecarriersaremadeupofstandardpartsthatarelasercut,folded,fabricated,weldedorotherwiseassembledintotheseconfigurations.Thestandardpartsthatmakeupanassemblyaredetailedbelowalongwithanimageofafabricatedcarrier.

3mmGRPHorseshoeShim 31/21CurveChannel

ButtonHead&SquareNut

ProfiledPerforatedSteelCarrier

WeldedGusset/Stiffener

31/21Channel

Perforationsareconstructedfromellipticalholes6.00mmx4.00mmgenerallyarrayedat35mmthroughoutthebondedfacesofthecarriers.

Eachchassisandstiffenerhasauniquereferenceandsalesordernumberetchedintothepartfortraceability.

2.2. Pro-SteelBoltUpFixingsFixingsaredesignedandsuppliedaspartofoursystem.AllfixingsconformtotherequirementsofBSENISO3506,corrosionresistantstainlesssteelfastenersandconsequentlycarrythemarkingA2orA4-70alongwithauniquemanufacturersmarking.A2isgenerallyequivalenttograde1.4301andA4isgenerallyequivalenttograde1.4401gradesofstainlesssteel.Thegradeselectedwilldependonthearchitects,engineers,ordesignersmaterialspecificationfortheproject.Allcomponentswillbemanufacturedfromthegradespecifiedbutgenerally1.4301/304/A2unlessspecifiedotherwise.

ExtractfromSCIPublication-StructuralDesignofStainlessSteel-SCIP291

2.3. Materials

AllsteelcomponentsarecutandfabricatedfromstainlesssteelplateconformingtotherequirementsofBSEN10088parts1and2.

Allcomponentsthataremanufacturedfromstainlesssteelplatesaregenerallyproducedfromgrade1.4301or1.4307(304/304L)unlessgrades1.4401or1.4404(316/316L)arespecifiedforsitesthatmaybesubjecttoexposuretoslightlymoreaggressivecorrosiveenvironmentssuchascoastalsites.

AspartofoursupplychainpartnersISO9001QualityManagementSystem,allmaterialMillCertificatesarecheckeduponreceiptofadeliveryagainsttheordertoensuretheymeetwithrequirements.TheMillCertsarethenstoredwithintheMRP/ERPfactorymastersystem.

3.0. BoltUpCarrierTypicalDetail

Stiffeninggussetsareweldedintothechassisatamaximumof300mmcentrestoaddrigiditytothechassisandprovideaapertureforthechanneltobeinstalledandweldedinto.

3.1. WorksDrawingswithLaserEtchedGussets