PrimeTech launches the PT-300 with Tier 4 engine technology · 2018-06-01 · PrimeTech’s PT-300...

Transcript of PrimeTech launches the PT-300 with Tier 4 engine technology · 2018-06-01 · PrimeTech’s PT-300...

FAE Group S.p.A. - PrimeTech DivisionVia G. Marconi, 20 // 38011 Sarnonico (TN) // Italy // Tel. +39 0463 840 080 // Fax +39 0463 840 099

PrimeTech Shredding Equipment Ltd. - Branch Office110 Saskatchewan Ave - Spruce Grove, AB, T7X 3B4 // Canada // Tel. 780-948-8882 // Fax 780-948-8886

www.primetech.com // [email protected] brand of FAE Group

Cabin

· Second-to-none operator comfort: spacious, low-noise and low-vibration cabin, with excellent visibility and more headroom· Overall height of the cabin has been reduced so that the total height of the unit is now only 2785 mm (important in case of trucking in areas with height restrictions)· Even better and more ergonomic layout of controls· New digital 7” colour display to check and keep main parameters under control, as well as to customize functions and settings· Troubleshooting and diagnosing via display including data storage on a USB stick· Cabin is 30% more tiltable, allowing better access to the components located under the cabin.

PrimeTech’s PT-300 is a mid-size tracked carrier, now available with a Tier 4 engine. Along with installing a new engine some important modifications and improvements were made to this unit, however the main features the PT-300 is known for, remain the same: productivity, maneuverability, reliability, low ground pressure and comfort.

PrimeTech launches the PT-300with Tier 4 engine technology

Engine

· The engine is a robust and fuel efficient CAT C7 Acert 7l (428 in3) turbocharged and aftercooled engine, with 6 in-line cylinders, pro-ducing 302hp (225kw)

· The engine complies with the Tier 4F emission regulations and is equipped with Diesel Particulate Filter Technology (DPF), Diesel Oxidation Catalyst (DOC) and Selective Catalytic Reduction (SCR)

· The PT-300 has a separate AdBlue (DEF) tank. The Diesel Exhaust Fluid (DEF) is used by the Selective Catalytic Reduction (SCR) to reduce nitrogen oxide (NOx) emissions in the exhaust

· The higher power output of 302hp (225kw) is achieved at a lower rpm (2200), meaning better performance at lower fuel consumption

· A bigger fuel tank was installed (390 l) to ensure no filling up is needed even when working longer shifts

· 24V batteries are installed with a better cold start ability.

Engine compartment

· The bigger engine compartment with two large side doors on each side allows easy and quick access to any component

· Better layout of the components in the engine compartment and cleaner routing of hoses and wiring harnesses· Easy cleaning and daily maintenance through perfect accessibility to all service points and both engine and hydraulic filters

· A tool box in the engine compartment for storage of tools and teeth. For the convenience of the operator the tool box can be eas-ily removed.

a brand of FAE Group

Radiator

· One oversized radiator with enough cooling capacity for hy-draulic oil, air and water, even when worked in extremely hot climates

· The radiator comes with coarse fins, preventing them from get-ting plugged by dust and dirt and making cleaning much easier

· The radiator can be equipped with a proportional and reversiblefan (option) thus, based on radiator temperatures, the blades willautomatically adjust the pitch in the most efficient and effectiveway. This results in less power absorbed by the fan and eventu-ally in lower fuel consumption

· The sucker fan helps to keep dust out of the engine compart-ment and thus keep it clean

· The fan is hydraulic driven and the pitch of the blades get adjusted hydraulically, being a more reliable solution to belt driven fans with blades being adjusted by a separate air compressor.

Front attachments

A range of front attachments are available for the PT-300, making it a very versatile tracked carrier. Following attachments are available: forestry mulcher, subsoiler, stump cutter, rock crusher and asphalt grinder.The forestry mulcher underwent some major redesign and offers some very interesting new features:· New push-frame design to reach the ground for dragging and raking· Bolt-on counter blades for quicker change and reduced maintenance cost

· Adjustable skids to set required working depth· Reinforced frame and hood.

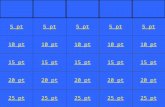

PT-300: Technical specifications

A Overall length without mulcher 195 in 4950 mm

D Ground clearance 18 in 467 mm

E Hitch angle 34°

F Overall length with mulcher on ground 240 in 6088 mm

G Transport length with mulcher on ground 257 in 6526 mm

G1 Transport length with mulcher on ground and winch 272 in 6900 mm

L1 Cab height 110 in 2785 mm

VERSION STD

Track width 26 in 660 mm

H Track gauge 67 in 1700 mm

I Overall track width 93 in 2360 mm

FAE ATTACHMENT 200/U-200

K Overall width 97 in 2464 mm

K1 Working width 81 in 2060 mm

• Max forward speed 4 mph 6.5 km/h

• Max reverse speed 4 mph 6.5 km/h

• Drawbar pull 40690 lbf 18100 daN

• Gradeability 100%

• Tracks control Danfoss Electronic Joystick

• Service hydraulic circuit control Danfoss Electronic Joystick

• Parking brake Negative, hydraulically activated

VERSION STD LGP

• Track width 26 in 660 mm 32 in 800 mm

• Operating weight 29630 lbs 13440 kg 31100 lbs 14110 kg

• Ground pressure 4.25 psi 0,30 kg/cm2 3.55 psi 0,25 kg/cm2

• Model CAT C7.1 Acert

• Gross power 302 HP (225 KW)

• Rating 2200 rpm

• Displacement 428 in3 7 l

• N° of cylinders 6

• Torque max 940 lbf-ft 1274 Nm @1400 rpm

• Fuel rate from 7 gal/h 28 l/h

• Emission Tier 4 Final / Stage IV

> REFILLING > UNDERCARRIAGE AND TRACKS

• Hydraulic oil tank 85 gal 320 l• Fuel tank 103 gal 390 l

• Undercarriage D4 - oscillating• Track shoes single grouser type: 26 in 660 mm

double grouser type: 32 in 800 mm

> HYDROSTATIC TRACKS TRANSMISSION > HYDROSTATIC MULCHER TRANSMISSION

• Pumps (2) Danfoss 78 cc

• Motors (2) Danfoss 80 cc

• Max pressure 6000 psi 420 bar

• Oil flow 104 gal/min 395 l/min

• Hydraulic emergency stop

• Pump Danfoss 147 cc

• Motors (2) Danfoss 110 cc

• Work pressure 5100 psi 350 bar

• Oil flow 98 gal/min 371 l/min

> DIMENSIONS

> MAIN KEYS

> DIESEL ENGINE

LGP

32 in 800 mm

67 in 1700 mm

98 in 2500 mm

200/U-225

107 in 2714 mm

91 in 2300 mm

> 200/U

> 300/U > 300/SC

MODEL

• Rotor diameter

• Overall width

• Working width

• Weight with options

• Max. working depth

• Grinding diameter (max)

• Quantity of cutting teeth

tungsten carbide type “C/3”

• Rotor rpm

• Hydraulic motor type (2)

MODEL

• Rotor diameter

• Overall width

• Working width

• Weight

• Max. working depth

• Grinding diameter (max)

• Quantity of cutting teeth

tungsten carbide type “B/3”

• Rotor rpm

• Hydraulic motor type (2)

MODEL

• Cutter wheel diameter

• Overall width

• Working width

• Cutter wheel width

• Weight

• Max. working depth

• Cutting height

• Swing angle

• Q.ty of carbide teeth

• Rotor rpm

• Hydraulic motor type (1)

200/U-200

20 in 500 mm

97 in 2464 mm

81 in 2060 mm

4960 lbs 2250 kg

3 in 80 mm

14 in 350 mm

42 + 2

2350

Danfoss 110 cc

300/U-200

24 in 600 mm

98 in 2494 mm

81 in 2064 mm

7341 lbs 3330 kg

4 in 100 mm

16 in 400 mm

72 + 2

1690

Danfoss 110 cc

200/U-210

20 in 500 mm

100 in 2554 mm

85 in 2160 mm

5192 lbs 2355 kg

3 in 80 mm

14 in 350 mm

44 + 2

2350

Danfoss 110 cc

200/U-225

20 in 500 mm

107 in 2714 mm

90 in 2300 mm

5578 lbs 2530 kg

3 in 80 mm

14 in 350 mm

46 + 2

2350

Danfoss 110 cc

300/SC

40 in 1020 mm

29 in 736 mm

79 in 2000 mm

6 in 156 mm

5027 lbs 2280 kg

41 in 1050 mm

39 in 990 mm

70° total (35° left, 35° right)

36

980

Danfoss 250 cc

> RSL/HY

> 200/S

MODEL

• Rotor diameter

• Overall width

• Working width

• Weight

• Max. working depth

• Grinding diameter (max)

• Quantity of cutting teeth

tungsten carbide type “R”

• Quantity of cutting teeth

tungsten carbide type “G/3”

• Rotor rpm

• Hydraulic motor type (2)

MODEL

• Rotor diameter

• Overall width

• Working width

• Weight

• Max. working depth

• Grinding diameter (max)

• Quantity of cutting teeth

tungsten carbide type “B/3”

• Rotor rpm

• Hydraulic motor type (2)

RSL/HY-200

23 in 595 mm

96 in 2430 mm

77 in 1960 mm

7408 lbs 3360 kg

11 in 270 mm

6 in 150 mm

138 + 16

62 + 6

400

Danfoss 250 cc

200/S-200

24 in 600 mm

93 in 2360 mm

82 in 2080 mm

6063 lbs 2750 kg

12 in 300 mm

12 in 300 mm

74 + 4

500

Bosch Rexroth 180 cc

RSL/HY-225

23 in 595 mm

105 in 2670 mm

87 in 2200 mm

7848 lbs 3560 kg

11 in 270 mm

6 in 150 mm

154 + 16

72 + 6

400

Danfoss 250 cc

200/S-225

24 in 600 mm

102 in 2600 mm

91 in 2320 mm

6989 lbs 3170 kg

12 in 300 mm

12 in 300 mm

82 + 4

500

Bosch Rexroth 180 cc

PT-300: FAE attachments

Spe

cific

atio

ns a

nd d

esig

n ar

e su

bjec

t to

chan

ge w

ithou

t prio

r no

tice

by F

AE

Gro

up. P

ictu

res

may

con

tain

opt

iona

l acc

esso

ries.

The

info

rmat

ion

in th

is c

atal

ogue

is c

onsi

dere

d no

n-bi

ndin

g.05

/17

L

H

I

K

K1

G1

DE

G

F

A