Presentation Redesign Analysis of Distillation Column

Transcript of Presentation Redesign Analysis of Distillation Column

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

1/27

Redesign Analysis of a

Distillation ColumnPresented By: Michael Hoepfner

University of Utah 2006

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

2/27

Introduction

Why care about redesign?

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

3/27

Outline

Objective

Theory

ExperimentResults

Aspen Analysis

RecommendationsConclusion / Summary

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

4/27

Objective

Scope

Isopropyl Alcohol (IPA) and Water to Ethanol

(EtOH) and Water

Purpose

Is the switch possible?

What are the limitations?

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

5/27

Outline

Objective

Theory

ExperimentResults

Aspen Analysis

Recommendations

Conclusion / Summary

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

6/27

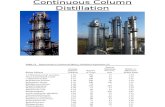

Theory

Distillation

Is among the most common of separations

Separates compounds based on volatility

Utilizes multiple equilibrium separations

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

7/27

Theory (cont.)

175

180

185

190

195

200

205

210

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Mole Fraction IPA

Temerature(F)

Bubble Line

Dew Line

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

0.4

0.45

0.5

0.55

0.6

0.65

0.7

0 0. 05 0. 1 0. 15 0. 2 0. 25 0. 3 0. 35 0. 4 0. 45 0. 5 0. 55 0. 6 0. 65 0. 7Liquid Fraction IPA

VaporrFractionIP

Equilibrium Line

45 Degree Line

T-x-y Diagram x-y Diagram

Source: Perrys Chemical Engineering Handbook, 7th Ed.

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

8/27

Theory (cont.)

McCabe-Thiele

Simple and useful

tool for defining a

distillation column Three lines can

characterize the

conditions

Source: Seader, 2006

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

9/27

Theory (cont.)

Source: Seader, 2006

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

10/27

Theory (cont.)

Efficiency

Liquid samples, therefore, liquid efficiency

nini

nini

ML

xx

xxE

,1,

,1,

*

Source: King, 1971

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

11/27

Theory (cont.)

Refractive Index (RI)

was used to

measure the

concentration

1.33

1.335

1.34

1.345

1.35

1.355

1.36

1.365

1.37

1.375

1.38

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

Mole Percent IPA

RefractiveInde

Source: CRC Handbook of Chemistry and Physics, 64th Edition

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

12/27

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

13/27

Experiment

Apparatus

12 Trays with 3

inch bubble

caps Total Condenser

Partial Reboiler

Thermal couple

at every tray

Source: Ong, 1952

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

14/27

Experiment (cont.)

Operate at total reflux

Collect samples for efficiency determination

Operate at 2 times the minimum reflux

Collect samples for efficiency determination

Model results in Aspen for ethanol and

water

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

15/27

Outline

Objective

Theory

ExperimentResults

Aspen Analysis

Recommendations

Conclusion / Summary

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

16/27

Results

Obtained samples on three separate occasions

Samples are numbered by the date collected

10/30/2006

First run of total reflux

11/01/2006

Second run of total reflux

11/06/2006

Only run of partial reflux

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

17/27

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

18/27

Results (cont.)

Efficiency

Two

reasonably

reliable data

sets

All error is at a

95%

confidence

interval

Total Reflux

10/30/2006

Partial Reflux

11/06/2006

Tray ML Error ML ML Fixed Error

Distillate - - - - -

2 15.7 6.5 109.8 0 -

3 20.2 4.1 94.9 94.9 156.3

4 32.4 3.1 480.3 0 -

5 18.6 2.5 -93.2 0 -

6 27.0 2.0 -7.4 0 -

7 97.8 0* 4885.2 0 -

8 91.5 0* -84.2 0 -

9 0 - 82.5 82.5 125.9

10 0 - 492.5 0 -

11 0 - 132.6 0 -

12 0 - 20.2 20.2 26.0

Bottoms 0 - -113.8 0 -

Average 25.3 3.7 18.0 102.8

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

19/27

Outline

Objective

Theory

ExperimentResults

Aspen Analysis

Recommendations

Conclusion / Summary

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

20/27

Aspen Analysis

Aspen Used average stage

efficiency for everystage

It is possible to doseparation

Limited by totalcondenser load

Max condenser load:27811 kW

Max reboiler load:241020 kW

COMPLEXFEEDC

TOPSC

BOTTC

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

21/27

Aspen Analysis (cont.)

FeedFlow

(gpm)

Condenser

Duty (kW)

DistillateFlow

(kmol/hr)

BottomsFlow

(kmol/hr)

ReboilerDuty

(kW)

SteamFlow

(kg/min)

Upper 7.85 289.19 20.68 53.93 401.09 10.58

Average 7.55 278.29 19.90 51.89 385.96 10.18

Lower 7.26 267.27 19.11 49.84 370.70 9.78

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

22/27

Outline

Objective

Theory

ExperimentResults

Aspen Analysis

RecommendationsConclusion / Summary

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

23/27

Recommendations

Ethanol separation is possible

Max feed 7.550.30 GPM of 15 mole %

ethanol

Reboiler steam required 10.180.40 kg/min

By redesigning the condenser, capacity can

be greatly increased

Reboiler only at ~1/6th

of capacity

Allow more time for partial reflux efficiency

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

24/27

Outline

Objective

Theory

ExperimentResults

Aspen Analysis

Recommendations

Conclusion / Summary

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

25/27

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

26/27

Sources

Weast, Robert C, Editor. CRC Handbook of Chemistry and Physics,64th Edition. CRC Press, Inc. Boca Raton, 1983. p. D-253.

King, C. Judsen. Separation Processes. McGraw-Hill, NewYork,1971. p 603.

Ong, John N. Jr, Jack M. Whitney. The Operation of a LaboratoryBubble-Plate Distillation Column. University of Utah, June,1952.

Perry, Robert H., Editor. Perrys Chemical Engineering Handbook.7th Edition. McGraw-Hill. New York, 1999. p. 115.

Seader, J. D., Ernest J. Henley. Separation Process Principles, 2ndEdition. John Wiley and Sons. Hoboken, 2006. p. 193-294.

Silcox, Geoff. Basic Analysis of Data. Unpublished student aid.University of Utah, 1999.

-

7/29/2019 Presentation Redesign Analysis of Distillation Column

27/27