Presentation quenching oil

-

Upload

oilmax-systems-pvt-ltd -

Category

Automotive

-

view

1.565 -

download

15

description

Transcript of Presentation quenching oil

CENTRIFUGAL OIL CLEANER FOR Quenching Oil

Oilmax

1

2

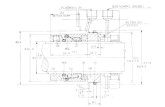

Oilmax Centrifugal Oil CleanerInstallation On Quenching Oil Tank

Sludge Collected In Centrifuge Rotor

3

Installation On Quenching Oil Tank

Sludge Collected In Centrifuge Rotor

4

Quenching Filtration

During quenching, the oil becomes contaminated with scales, soot & degradation products, which interfere with the performance of the oil and may result in unsatisfactory surface appearance or lower physical properties than specified.

Removal of these contaminants by filtration or centrifuging is necessary to restore the oil to a satisfactory condition for trouble free quenching and good product quality.

5

Advantages Of Centrifuge

Soot particles up to sub - micronic level are removed from quenching oil.

This results in better confirmation of cooling rate with TTD diagrams.

Oxidation of oil is substantially reduced, hence frequent top-ups are not required.

In absence of soot, dis-colorization of work piece is eliminated.

Sludge is caused by Quench Oil Thermal and Oxidative Degradation.

6

Sludge

One of the greatest problems with quench oils is sludge formation.

The presence of sludge may cause non-uniform heat transfer, increased thermal gradients and increased cracking and distortion.

Sludge may also plug filters and foul heat-exchanger surfaces.

The loss of heat-exchanger efficiency can cause overheating, excessive foaming and fires.

SLUDGE REMOVAL BY CENTRIFUGING SUBSTANTIALLY REDUCES OXIDATION PROCESS

7

Centrifugal force is capable of removing a wide range of particles extending into sub-micron range.

With its advanced design, centrifugal forces 2000 times greater than gravity are created in centrifuge rotor, which separates out the particles from oil.

Centrifugal cleaner works on the reaction turbine principle.

Oil enters the centrifuge under pressure and passes into the rotor via a hollow shaft.

The pressure and the flow are converted into rotational energy as the oil escapes thru’ the two jets, producing speeds up to 7000 RPM.

The resultant centrifugal force removes dirt from the oil depositing it on the inner wall of the rotor.

Clean oil returns to the sump by gravity.

Centrifugal Force

8

Performance Report

9

10

11

12

13

14

15

Installation List

Federal Mogul Goetz – Patiala x 2 Turbo Industries – Ludhiana

Milestone Gear – Goratiwala Vira Autoparts – Ludhiana

Eicher Tractors (Gear Divn) – Parwanoo

Bajaj Sons – Ludhiana

Sonalika Tractors – Hoshiarpur Accord Industries – Ludhiana

Sonalika Tractors – Patna Kay – Jay Forgings – Ludhiana N

Shriram Pistons, Bhiwadi Nicks India – Ludhiana

Shriram Pistons, Ghaziabad Hard Castle Petrofer – Mumbai

New Allenberry Works – Rudrapur Amtek Auto – Bhopal

Bajaj Motors – Rudrapur Arasana Industries – Mumbai

Escorts – Faridabad Hightech Gears, Bhiwadi

New Allenberry Works – Faridabad Shivam Autotech, Haridwar

Sadhu Forgings – Faridabad x 2 Metro Forge, Alwar

Shankar Forging – Faridabad x 2 Sona Okegawa – Gurgaon

Acufab – Faridabad JMT Auto, Jamshedpur X 2

Shiva Hardwell – Faridabad Ford India Ltd., Chennai X 3 Units

Nirupam Engineers – Ghaziabad x 2 Hyundai Motors, Kachipuram

Lakshmi Precision (LPS) – Rohtak Indo Chains – Raipur

Micron Precision, Rohtak ABC Bearings – Bharuch

Deepak Fasteners – Ludhiana x 3 Bharat Forge – Pune

D F L Fasteners – Ludhiana SKF Bearings – Pune

GNA Auto - Ludhiana Simmonds Marshall – Pune

Rockman Industries – Ludhiana Alfa Heat Tech – Pune

Highway Industries – Ludhiana APS Heat Treaters – Pune

16

Jyoti Heat Treaters – Pune Elecon – Anand

S K S Fasteners – Pune Rolcon Engineering Co. – Anand

Preci Forge & Gears – Pune SKP Bearings – Surendranagar

Echjay Forgings - Khopoli Metal Heat Enterprises , Belgaum

Padmavati Forge – Kolhapur Thermomet – Belgaum

Flame Industries – Kolhapur Fair Field Atlas – Belgaum

Sai Udyog – Kolhapur Stump, Schuele – Bangalore x 2

Mahabal Auto – Miraj Universal carburizing – Bangalore

Unique Treatments – Nasik Deepak Tools, Bangalore

M. D. Industries – Nasik Therelek Engineers, Bangalore

Shareen Auto – Nasik HEM Industries – Silvassa

Induction Hardening - Nasik N H B Ball Bearings – Navsari

Mahindra Sona - Nasik N N Precision Bearings - China

Atlas Copco – Nasik

Facor Steel – Nagpur

Fine Thread - Rajkot

Ravi Corporation – Rajkot

Bhawani Heat Treatments – Rajkot

Bhawani Industries – Rajlot

Bhuwaneshwari Heat Treaters - Rajkot

Maheshwari Carburising – Baroda

WI Heat Treaters – Anand

Metal Treat – Anand