Prepared By - Welcome to Environment · NABET Sl. No.- 121 as on 05.09.2017 OCT 11TH, 2017....

Transcript of Prepared By - Welcome to Environment · NABET Sl. No.- 121 as on 05.09.2017 OCT 11TH, 2017....

PRE-FEASIBILITY R E P O R T

FOR

PROPOSED 356KM LONG, 18 INCH MULTI PRODUCT PETROLEUM PIPELINE FROM BINA TO PANKI (KANPUR) & AUGMENTATION OF TANKAGES AT RECEIPT TERMINAL,

KANPUR

FOR

ENVIRONMENTAL CLEARANCE (VIDE MOEF GUIDELINES NO. J-11013/41/2006-IA.II(I) DATED 30TH DECEMBER 2010)

OF

M/S BHARAT PETROLEUM CORPORATION LTD., MUMBAI

Prepared By

PROJECTS & DEVELOPMENT INDIA LIMITED (A Govt. of India Undertaking)

PO: Sindri - 828122, Dist: Dhanbad (Jharkhand) NABET Sl. No.- 121 as on 05.09.2017

OCT 11TH, 2017

CONTENTS

CHAPTER DESCRIPTION PAGE NO. 0.0 Executive Summary 1 - 5 1.0 Introduction 6 - 6 2.0 Project Proposal 6 - 10 3.0 Project Benefits 10 - 10 4.0 Pipeline Route 11 - 13 5.0 Project & Process Description 14 - 21 6.0 Water & Power Requirement 21 - 22 7.0 Environmental Aspects 22 - 23 8.0 Land form, land use and land ownership 23 - 23 9.0 Manpower Requirement 23 - 23 10.0 R & R Plan 23 - 24 11.0 Project Schedule & Cost Estimates 24 - 26 12.0 Conclusion 27 - 27

Projects & Development India Limited, Sindri 1 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

EXECUTIVE SUMMARY INTRODUCTION Bharat Petroleum Corporation Limited (BPCL) with an equity base of Rs.723.08 Crore, is a

leading player in the Petroleum Sector in the country. BPCL has a major stake in BORL (Bharat

Oman Refineries Limited) Refinery at Bina with complete marketing rights. The Bina refinery is

operating at capacity of 6 MMTPA and is undergoing low cost expansion to 7.8 MMTPA.

EIA CONSULTANT BPCL entrusted M/s Projects and Development India Limited (PDIL), Sindri, Dhanbad (a QCI-

NABET accredited EIA consultant) for Environmental Clearance (EC) activities.

PROJECT PROPOSAL BPCL proposes to lay a 356 Km long cross-country multi-product petroleum pipeline of 18” dia.

from its Bina Dispatch Terminal to Panki POL terminal (Kanpur). The proposed Bina -Panki

pipeline (BPPL) will replace Rail wagon transport there-by yield savings in fuel expenditure on

transport as well as reduce traffic on Bina-Kanpur rail sector.

The proposed BPPL will be able to supply HSD, MS, SKO & ATF to this terminal. The total

volume (including 25% common carrier volume)assessed for transportation through Bina-Panki

pipeline is as follows:

Commissioning Year: FY 2020-21: 2.78 MMTPA

Phase-1: FY 2025-26: 3.45 MMTPA

The existing Panki Terminal will be augmented with a pipeline receipt terminal facilities

consisting of receipt manifold, Control room, inter-tank transfer pumping facilities, Tank wagon

loading facilities including pump house and automation, additional product tankage of 1,60,416

KL in Phase- I and 52,900 KL in Phase- 2.

PROJECT BENEFITS Pipelines are by far the most superior mode of transportation for petroleum products,as they

have considerable advantage in being able to move large quantities quickly, economically and

reliably over long distances with fewer associated impacts on the environment. It is for this

reason that pipeline transportation is preferred over road and railway transportation.

PIPELINE ROUTE Four Alternatives A, B, C & D are proposed from Bina Dispatch Terminal, Sagar, Madhya

Pradesh to Panki Receipt Terminal, Kanpur, Uttar Pradesh.

Projects & Development India Limited, Sindri 2 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

In view of Sand mining, more undulation, more steep terrain, Close vicinity of stone quarries and

lesser distance from Wild life sanctuaries boundaries, Alternative A& C is not recommended.

Alternative B & D routes are having same features except in view of road approachability for

construction, Operation & Maintenance. Alternative D is having more accessibility through road

than Alternative B hence, Alternative D is selected as most feasible route.

Forest Crossings Sl. No. Name of Forest Length in Km State 1 Balabahat P.F. 0.98 Uttar Pradesh 2 Balabahat R.F. 5.54 UP 3 RichhaMaholi R.F. 0.80 UP 4 Gauna R.F. 1.20 UP 5 BaidauraP.F. 0.08 Madhya Pradesh Total Forest Length in MP 0.08

Total Forest Length in UP 8.52 Grand Total 8.60

Pipeline Crossings

NH

RAILWAY SH Other Roads

Village Roads

River Canal Nala Foreign Pipeline

3 6 6 143 229 11 65 68 1 PROJECT FACILITIES a) Dispatch station at Bina including booster pumps (1Working + 1 Stand by), mainline pumps

(1Working+ 1Stand by), basket filter, metering, Corrosion Inhibitor dosing and scrapper

launcher along with associated facilities.

b) Intermediate pigging station (IPS) including scrapper Receiver/Launcher, filter, metering,

Corrosion Inhibitor dosing and associated facilities.

c) 355km (approx.) Cross Country pipeline from Bina to Panki.

d) Receipt terminal at Panki including scrapper receiver, filter, metering and associated

facilities.

e) Sectionalizing Valve Stations as per code and profile requirement.

f) Providing SCADA (Supervisory Control & Data Acquisition), LDS (Leak Detection

System),CP (Cathodic Protection) & ESD (Emergency Shut Down), Telecom and

Instrumentation system etc.

PROCESS DETAILS Operation & Control Philosophy a) Instrumentation and Control system shall be provided for safe and efficient control of

petroleum products pipeline.

Projects & Development India Limited, Sindri 3 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

b) PLC (programmable logic control) based control system shall be provided at Dispatch

stations, Receipt stations for the process interlocks / shutdown logic / MOV’s (motor

operated valve) operation and station monitoring whereas panel based monitoring/ control

system (Working on 48V DC) shall be provided at intermediate pigging station. Control

panels are provided for mounting the flow computers & other instruments.

c) SCADA (Supervisory Control and Data Acquisition) system is envisaged to ensure effective

and reliable control, management and supervision of pipeline from centralized location using

Remote Telemetry Units (RTU) along the pipeline route.

d) All essential control parameters of receipt terminals shall be integrated suitably inSCADA

system and PLC control.

e) All supply operations for the pipeline system shall be under the control of dispatch stations

which shall ensure the supply of the product at normal operating conditions. The dispatch

station shall make all necessary arrangements for the petroleum products dispatch and

ensure proper lining up of the system in conjunction with the receipt terminal.

f) The main pumping units will be shutdown automatically in the event of low suction pressure

or high discharge pressure, mechanical seal failure, high vibration, high casing temperature

etc.

g) Unit Control Panels (UCP) is envisaged at pumping stations. Pump start / stop / interlocks /

trip functions will be implemented in the pump UCP and this UCP will be interfaced to the

station PLC system for stop / trip / ESD from station / SMC and for status monitoring.

h) Corrosion Inhibitor dosing facilities shall be provided at dispatch station & IPS for controlling

corrosion in the pipeline. Electric Resistance probe for corrosion monitoring shall also be

provided.

i) The sump pump and / or slop transfer pump will be tripped in case of low liquid level in the

sump tank.

j) Thermal relief / safety valves shall be provided as per the requirement / standards such as

API 521 and shell DEP equivalent.

Fire Fighting Facilities i) Existing fire water network of the plant shall be extended to cover the facilities at DT and RT

under this project.

ii) Existing Fire water system is designed to fight two major fires anywhere within the plant as

per the provisions of OISD-116/OISD-117. Adequacy of existing fire water system has been

done to meet the OISD-116/OISD-117 requirements.

Projects & Development India Limited, Sindri 4 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

iii) Hydrant & Monitors:

Double outlet hydrants and monitors shall be provided at 30M interval around proposed

area. The ring main shall be provided above ground around proposed areas on independent

concrete sleepers.

iv) Fire fighting facilities for Mainline pump house:

The mainline pump houses are provided with fixed water spray system as per requirement

of OISD-116/OISD-117 and NFPA-15.

v) Adequate no. of portable fire extinguishers shall be provided at all strategic locations.

WATER & POWER REQUIREMENT Water requirement for the proposed BPPL project is very minimal to the tune of 20 KLD, mainly

for potable use by workers across the pipeline length, dispatch & receipt terminals and SV & IP

stations en-route. There will be one time requirement of 71,000 KL of water for hydro-testing of

the pipeline and tank augmentation at Panki, Kanpur.

Two nos. of HT plant feeder from existing HV switchboard (HT-223 at Substation No. 7) from

Bina Refinery shall be provided by Owner/BPCL to the battery limit of Dispatch Terminal at Bina

to meet the total power requirement (of new 6.6kV switchboard) at the Dispatch Terminal. At

Panki receiving terminal (RT), the incoming power shall be fed from existing emergency

switchboard so that there shall be no separate new Emergency DG for RT.

ENVIRONMENTAL ASPECTS The design approach built into the FEED to avoid/minimize emissions to the air is as follows:

• Fugitive emissions from valves will be avoided or minimized by selection of suitable valve

packing, seals etc.

• Fugitive emissions from pumps will be minimized by use of dual seals or seal-less pumps

when handling high vapour pressure and hazardous material

• Fugitive emissions from flanged connections will be reduced by minimizing the number of

flanged connections in high pressure service.

• Asbestos will be replaced with safer materials wherever possible.

• Only non-Ozone Depleting Substances will be used.

• The Pipeline is a closed loop system and no hydrocarbon will be released to open

atmosphere.

LAND FORM, LAND USE AND LAND OWNERSHIP The Right of User (ROU) for laying the pipeline will be acquired as per The Petroleum &

Minerals Pipelines (Acquisition of Right of User Inland) Act, 1962 through the Competent

Projects & Development India Limited, Sindri 5 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

Authority nominated for the project after notification in the Central Government Gazette and

payment of compensation shall be provided directly to the land owners as stipulated in the act.

MANPOWER REQUIREMENT About 400 people shall be employed directly/indirectly during the construction phase. The

requirement of manpower is expected to be met through internal deployment as well as thru

induction of competent manpower as per company’s rules. The existing manpower at Bina and

Panki (Kanpur) would be adequate to handle the operation phase.

R&R PLAN The ROU shall be acquired by BPCL for laying of pipeline and shall be handed over back to the

land owners for cultivation purpose. Compensation for loss of crop during construction phase shall

be paid as per Govt. Policy hence, the rehabilitation and resettlement is not applicable for this

project.

PROJECT SCHEDULE & COST ESTIMATES The project completion period has been estimated to be about 36 months after the grant of

authorization from PNGRB. The estimated cost of laying proposed 18” multi-product pipeline

and augmentation of tankages at receipt terminal is Rs.1542 Crores.

CONCLUSION The proposed pipeline will ensure cost-effective transportation and uninterrupted supply of

petroleum products from Bina to Panki (Kanpur) to cater to the North Indian market of UP,

Uttarakhand and Bihar. This will reduce Rail traffic between Bina to Kanpur and is envisaged to

yield investment returns more than 12%. There are no hilly terrains en-route the pipeline and the

forest area also is less dense calling for minimum cutting of trees etc. The river crossings are

minimum with sufficient space available on either ends to place machinery for boring/auguring

and mostly with a rocky bed that ensures that the pipeline will not be subjected to scouring and

there-by least damage to the pipeline during its operating life. The acquisition of land for ROU

shall be done by following the latest guidelines with least disturbance to land and compensation

to the project affected people as per Govt. guidelines. The pipeline does not call for any

demolition or re-alignment of any existing structure causing social disturbance.

Considering the above facts, the TOR may be granted for the proposed project for preparation

of EIA report as per the guidelines.

Projects & Development India Limited, Sindri 6 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

1.0 INTRODUCTION 1.1 BACKGROUND Bharat Petroleum Corporation Limited (BPCL) with an equity base of Rs.723.08 Crore,

is a leading player in the Petroleum Sector in the country. BPCL currently has

Refineries at Mumbai and Kochi with capacities of 12 MMTPA and 15.5 MMTPA

respectively. BPCL has a major stake in BORL (Bharat Oman Refineries Limited)

Refinery at Bina with complete marketing rights. The Bina refinery is operating at

capacity of 6 MMTPA and is undergoing low cost expansion to 7.8 MMTPA.

BPCL proposes to lay a 356 Km long cross-country multi-product petroleum pipeline of

18” dia. from its Bina Despatch Terminal to Panki POL terminal (Kanpur). BPCL has

already submitted its bid to PNGRB for the proposed pipeline and is the sole bidder

(after opening of the technical bid by PNGRB). The proposed Bina - Panki pipeline

(BPPL) will replace Rail wagon transport there-by yield savings in fuel expenditure on

transport as well as reduce traffic on Bina-Kanpur rail sector.

1.2 DFR & EIA CONSULTANT BPCL envisaged the Detailed Engineering Survey, Cadastral Survey and

miscellaneous works for Bina - Panki (Kanpur) Multiproduct Petroleum Pipeline

Project. In view of this, BPCL entrusted M/s. N. K.Buildcon Pvt. Ltd., Jaipur to carry out

survey works, M/s Engineers India Limited (EIL) to prepare Detailed Feasibility Report

(DFR)and M/s Projects and Development India Limited, Sindri, Dhanbad (a QCI-

NABET accredited EIA consultant) for environmental clearance activities.

2.0 PROJECT PROPOSAL BPCL proposes to lay 18" dia. Bina-Panki pipeline (BPPL) for transfer of petroleum

products viz. Motor Spirit (MS), High Speed Diesel (HSD), Superior Kerosene Oil

(SKO) and Aviation Turbine Fuel (ATF) from Bina Despatch Terminal to PankiPOL

Terminal (Kanpur) for distribution in the region of Kanpur, Mughalsarai, Aonla,

Shahjahanpur, Baitalpur, Gonda in Uttar Pradesh, Kathgodam in Uttarakhand and

Muzaffarpur in Bihar. The pipeline is proposed to pass through Sagar&Tikamgarh

districts of Madhya Pradesh (MP) and Lalitpur, Jhansi, Jalaun, Kanpur Dehat and

Kanpur Nagar districts of Uttar Pradesh (UP). The Right of Use (ROU) for laying the

pipeline will be acquired as per the Petroleum & Mineral Pipeline (Acquisition of Right

of User in Land) Act, 1962 through the Competent Authority nominated for the project

Projects & Development India Limited, Sindri 7 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

after notification in the Central Government Gazette and necessary compensation

shall be paid directly to the land owners as stipulated in the act. The pipeline will be

provided with 10 nos. of Sectionalizing Valve (SV) Stations and 1 no. of Intermediate

Pigging (IP) station along with dispatch and pumping station at Bina and receipt

terminals at Panki (Kanpur).

The proposed BPPL will be able to supply HSD, MS, SKO & ATF to this terminal. The

total volume (including 25% common carrier volume) assessed for transportation

through Bina-Panki pipeline is as follows:

Commissioning Year: FY 2020-21: 2.78 MMTPA

Phase-1: FY 2025-26: 3.45 MMTPA

The mainline / booster pumps with VFD shall be designed in such a way so as to meet

the Phase-1 throughput.

The existing Panki Terminal will be augmented with a pipeline receipt terminal facilities

consisting of receipt manifold, Control room, inter-tank transfer pumping facilities, Tank

wagon loading facilities including pump house and automation, additional product

tankage of 1,60,416 KL in Phase- I and 52,900 KL in Phase- 2. The Panki POL

terminal already has 30,400 KL of tankage for product storage. Total tankage will be

1,90,816 KL at the end of Phase-1 and2,43,716 KL at the end of Phase-2. The existing

Panki Terminal handles HSD, MS, SKO, ATF, Ethanol and Hexane. The proposed

BPPL will be able to supply HSD, MS, SKO & ATF to this terminal.Necessary EC for

the existing facilities have been accorded by State Environment Authority vide letter

ref. 69/Parya/SEAC/3287/2015/DD(Sh.) dt.13.04.2016.

The receipt terminal at Panki (Kanpur) is proposed to undergo tankage augmentation

(total 10 nos. tanks) with storage capacity of 2,13,316 KL. The details of storage

capacity shall be as below:

i. MS : 4 x 32,500 KL (FRT, 38m dia., 18m height)

ii. HSD : 4 x 20,400 KL (FRT, 48m dia., 18m height)

iii. Slop : 2 x 858 KL (CRT, 9m dia., 13.50m height)

Table- 1.1 Proposed Facilities at Panki Terminal

S. No. Facility Description 1 Pipeline Receipt Manifold 60m x 60m 2 Admin / Control Room Building 45m x 25m 3 Engineering Store 30m x 8m

Projects & Development India Limited, Sindri 8 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

Figure-1.1 Schematic Arrangement for Bina-Panki Pipeline

Projects & Development India Limited, Sindri 9 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

Table- 1.2 Pipeline Facilities

Sl. No.

Pipeline Parameters Bina Dispatch Terminal

Intermediate Pigging Station

Panki Receipt Terminal

1 Service Petroleum Products

Petroleum Products

Petroleum Products

2 Max Flow Rate, m3/hr 520x1.1 520x1.1 520x1.1

3 Design Pressure, Kg/cm2g

19 99 99

4 Allowable pressure drop, Kg/cm2g

1 (max for dirty condition)

1 (max for dirty condition)

1 (max for dirty condition)

5 Design Temp., 0C 65 65 65 6 MOC CS CS CS 7 Corrosion Allowance,

mm 3.0 3.0 3.0

8 Booster Pumps, m3/hr 520x1.1, (1+1) - - 9 Mainline Pumps, m3/hr 520x1.1, (1+1) - - 10 Flow meters, m3/hr 520x1.1, (1+1) 520x1.1, (1+1) 520x1.1, (1+1) 11 Control valves, m3/hr 520x1.1 520x1.1 12 Sump tank, m3 20 20 20 13 Pig Launcher For launching

intelligent pig Receiving intelligent pig

14 Basket filters 520x1.1, (1+1) 520x1.1 (1+1) 520x1.1 (1+1) 15 Service water 5 m3/hr

(intermittent), Service water at Bina will be fed from existing source of Bina Terminal

- 5m3/hr (intermittent)

16 Power Main incomer 2nos. feeders will be fed from Bina Refinery.

- From the existing Panki substation after enhancement of connected load / existing transformer

17 Sectionalizing valves

Provided as per ASME B 31.4. & OISD-141 and PNGRB regulations.

18 Pipeline roughness 45 microns

19 Pipeline Corrosion protection

Pipeline Internal Protection Suitable corrosion inhibitor injection system shall be provided for pipeline with suitable automated system for controlling dosing rate as per requirement. Pipeline External Protection Ø 3LPE external coating shall be provided. Ø Cathodic protection by impressed current for buried portion of pipeline shall be provided for PL.

Projects & Development India Limited, Sindri 10 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

20 Operating Hours 8000 Hrs./Annum 21 Basis for hydraulic

Calculation Pipeline hydraulics shall be carried out based on HSD with Sp. Gravity 0.820, dispatch temperature of 350C and Kinematics viscosity 2.1 at 40 0C at subsoil temperature of 25ºC and 8000 hrs per annum operation.

3.0 PROJECT BENEFITS Pipelines are by far the most superior mode of transportation for petroleum products,

as they have considerable advantage in being able to move large quantities quickly,

economically and reliably over long distances with fewer associated impacts on the

environment. It is for this reason that pipeline transportation is preferred over road and

railway transportation. The general advantages of pipelines with special reference to

the proposed pipeline are described below:

a. Pipeline, being underground, will involve lesser direct contact with the populace

thereby reducing its hazardous impact as well as provide better overall security.

b. Pipeline mode is mechanized and automatic with in-built safety features and

therefore less liable to human errors.

c. Due to easier and accurate monitoring of transfer rate & volume with on-line

instruments, the operator sitting in the control room can immediately detect any

leakage.

d. Pipeline transportation minimizes the detrimental environmental emissions

associated with other modes of transport. It completely eliminates noise pollution.

e. There is no loss of gas in transport resulting in conservation of energy source.

f. Pipeline transportation results in lower consumption of energy as compared to

other modes of transport.

g. Installation of pipeline will contribute to socio-economic growth and development of

the region.

h. Highest safety, most economical, energy efficient, environment friendly &minimum

handling loss amongst all modes of transportation of gas.

i. Continuous, uninterrupted, silent and smooth transfer of custody.

j. Reduction/mitigation of hazards & risks by performing HAZID & HAZOP during

detail design stage.

Projects & Development India Limited, Sindri 11 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

4.0 PIPELINE ROUTE Four Alternatives are proposed from Bina Dispatch Terminal, Sagar, Madhya Pradesh

to Panki Receipt Terminal, Kanpur, Uttar Pradesh. The alternative routes are

described briefly below:

Alternative –A

The proposed route will start from Bina and runs near via Semarkhedi, Bildho,

Dhudwani, Dhaura, Lalitpur, Mirchwara, Bar, Mohangarh, Sakrar, Pirona, Ait, Orai,

Chamari, Kamalpur, Sangasiyapur, Pur, SinghpurDewani, and Panki.

Alternative - B:

The Proposed route will Stat from Bina and will run near Balabahat, Banpur,

Kelgawan, Digaura, Ladhaura, Kharon, Ranipur, Gurusarai, Saidnagar, Orai, Kalpi,

Bhognipur, Pukhryan, Akbarpur and Terminates at Panki.

Alternative –C:

The Proposed Pipeline will run near Dhaura, Pali, Bar, Mohangarh, BiroraKhet,

Teharka, Tehrauli, Gurusarai, Saidnagar, Orai, Kalpi, Bhognipur, Pukhryan, Akbarpur

and Panki. The proposed alt. C follows the same route as of alternative A up to

khiriyabant. Thereafter, the pipeline route crosses NCR Jhansi-Manikpur branch Line.

Alternative C matches the Alternative B at Malehta before Betwa River.

Alternative – D:

The Proposed route will Stat from Bina and will run near Balabahat, Banpur,

Kelgawan, Digaura, Ladhaura, Kharon, Ranipur, Gurusarai, Saidnagar, Orai, Kalpi,

Bhognipur, Pukhryan, Akbarpur and Terminates at Panki. The proposed alt. D follows

the same route as of alternative B up to Lidhorakhas Village.

After analyzing four alternatives, it is observed that alternative A is much closer than

other alternative routes from Rajghat Reservoir & Mahavir Swami Wild life sanctuaries

which is environment sensitive areas and crossing forest stretch at downstream of

Betwa river crossing .forest boundary is starting immediately at downstream bank of

Betwa river at crossing location hence from execution point of view of River crossing

by HDD method may require extra efforts inside forest boundary or may increase the

length of HDD considering limit of crossing beyond forest boundary. Width of Yamuna

River at crossing location in Alternative A is more than other alternatives routes.

Alternative A passes through ravines near Yamuna River crossing which require extra

effort from construction point of view.

Projects & Development India Limited, Sindri 12 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

Alternative B route is passing more farther distance from the Rajghat Reservoir &

Mahavir Swami Wild life sanctuaries than alternative A& C and having Lesser width of

major river i.e. Betwa& Yamuna at crossing locations.

Alternative C is having common route up to KM 190 with Alternative A and after that up

to KM 222 having route joining Alternatives A & B after that having common route up

to receipt terminal with Alternative B. Alternative C is Shortest length from BINA DT to

Panki RT.

Alternative D is having common route with Alternative B except deviated from

Alternative Bat Lidhora Khas and again matching the alternative B after crossing NH-

76.

In view of Sand mining, more undulation, more steep terrain, Close vicinity of stone

quarries and lesser distance from Wild life sanctuaries boundaries, Alternative A& C is

not recommended.

Alternative B & D routes are having same features except in view of road

approachability for construction, Operation & Maintenance. Alternative D is having

more accessibility through road than Alternative B hence, Alternative D (Ann.-I) is

selected as most feasible route.

4.1 Forest Details

Table- 1.3 Forest Crossings

Sl. No. Name of Forest Length in Km State 1 Balabahat P.F. 0.98 Uttar Pradesh 2 Balabahat R.F. 5.54 UP 3 RichhaMaholi R.F. 0.80 UP 4 Gauna R.F. 1.20 UP 5 BaidauraP.F. 0.08 Madhya Pradesh Total Forest Length in MP 0.08

Total Forest Length in UP 8.52 Grand Total 8.60

4.2 Pipeline Crossings

Table- 1.4 NH

RAILWAY SH Other Roads

VillageRoads

River Canal Nala Foreign Pipeline

3 6 6 143 229 11 65 68 1

Projects & Development India Limited, Sindri 13 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

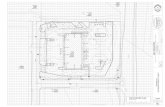

Figure-1.2

Fig.-1.3

Project location & Pipeline routes

Projects & Development India Limited, Sindri 14 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

5.0 PROJECT& PROCESS DESCRIPTION 5.1 TYPE OF PROJECT A cost-effective and uninterrupted supply of petroleum products to the end users is the

prime aim of the proposed project. This will reduce Rail traffic between Bina to Kanpur

and is envisaged to yield investment returns more than 12%. The pipeline is not

passing through any eco-sensitive areas.

The proposed 18” multi-product pipeline will carry petroleum products viz. Motor Spirit

(MS), High Speed Diesel (HSD), Superior Kerosene Oil (SKO) and Aviation Turbine

Fuel (ATF) from Bina to Panki (Kanpur). The proposed pipeline is designed for a

capacity of 6.0 MMTPA.

5.2 PROJECT FACILITIES Project (pipeline) battery limits:

g) Dispatch station at Bina including booster pumps (1Working + 1 Stand by),

mainline pumps (1Working+ 1Stand by), basket filter, metering, Corrosion Inhibitor

dosing and scrapper launcher along with associated facilities.

h) Intermediate pigging station (IPS) including scrapper Receiver/Launcher, filter,

metering, Corrosion Inhibitor dosing and associated facilities.

i) 355km (approx.) Cross Country pipeline from Bina to Panki.

j) Receipt terminal at Panki including scrapper receiver, filter, metering and

associated facilities.

k) Sectionalizing Valve Stations as per code and profile requirement.

l) Providing SCADA (Supervisory Control & Data Acquisition), LDS (Leak Detection

System), CP (Cathodic Protection) & ESD (Emergency Shut Down), Telecom and

Instrumentation system etc.

5.2.1 Bina Despatch Terminal The Petroleum products namely MS, HSD, SKO & ATF will be pumped from storage

tanks. To ensure adequate NPSH to mainline pumps, booster pumps are provided.

Basket filters are provided to remove the suspended particles. Flow is measured using

ultrasonic / mass flow meters which are provided along with flow computer. Density

meter is provided downstream of flow meters to measure the density of petroleum

product and to signal the batch. Signal from density meter is fed to the dual-stream

common flow computer. The Flow computer indicates the corrected volumetric flow

Projects & Development India Limited, Sindri 15 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

rate as well as the mass flow rate of the products to be transported. Corrosion Inhibitor

will be injected in the pipeline to prevent internal corrosion of the Pipeline. Corrosion

Inhibitor dosing tank and corrosion inhibitor dosing pumps have been provided for this

purpose.

One no. of sump tank have been provided for collection of drains from various points

such as header drains, scraper drain, line flushing, TSV discharge etc. and to cater the

requirement of separate storage of MS & HSD slops. The slops from these tanks can

be transferred back into the pipeline with the help of sump pump. The product will also

be routed to the upstream header of booster pumps. Pig launcher is provided at Bina

dispatch station for pigging operation. The entire Pipeline system is a close loop

system and no hydrocarbon will be discharged to open atmosphere.

5.2.2 Intermediate Pigging Station One Intermediate pigging station has been provided between Bina and Panki for

receiving and launching of pigs. Basket filters are provided for removing the solid

particles from the products. Flow is measured using ultrasonic / mass flow meters

which are provided along with flow computer. Density meter is provided downstream of

flow meters to measure the density of petroleum product and to signal the batch.

Signal from density meter is fed to the dual-stream common flow computer. The Flow

computer indicates the corrected volumetric flow rate as well as the mass flow rate of

the products to be transported. Scraper Receiver and Scraper Launcher are provided

for pigging operation. A sump tank is provided for collection of slops from various

points such as header drains, scraper drain, line flushing, TSV relief etc. The collected

slop is pumped back into HSD product passing through mainline with the help of the

sump pump and one slop transfer pump.

5.2.3 Panki Receipt Terminal Scraper Receiver is provided for pigging operation at Panki Receipt terminal. A sump

tank is provided for collection of slops from various points such as header drains,

scraper drain, line flushing, TSV relief etc. The collected slop is pumped into the slop

tanks with the help of the sump pump. The petroleum products will be transported to

the respective tanks at Panki receipt terminal. Further, necessary hook-up will be

taken at the Panki terminal for transporting of ATF also. Pipeline will be hooked-up to

product manifold for transferring MS/HSD/SKO/ATF to the storage tank. A provision for

Projects & Development India Limited, Sindri 16 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

filter coalesce is provided in the ATF line to remove any water droplets at the receipt

terminal.

5.2.4 PIPELINE COVER & BACKFILLING The pipeline shall be buried to ensure a minimum cover of 1.2 meter below natural

ground level except at Rocky Stretch/ river/ rail/ road/ canal/ waterways crossing

where minimum cover shall be as given below or as per the requirements of statutory/

local authorities, whichever is more stringent. The minimum pipeline cover for various

locations and crossings shall be as follows:

Table- 1.5

Details of Pipeline Cover Sl.No. Location Minimum Cover (m)

1 Industrial, Commercial, residential, Cultivated, agricultural and barren areas

1.2 (for Normal soil)

2 Rocky Terrain 1.0 3 Unlined Canals / Drains / Nalas (Open cut) 2.0 (for Normal soil)

1.5 (for Rocky strata) 4 River Crossings (Open cut method) River Crossings (Below Scour) 2.5 (for Normal soil)

1.5 (for Rocky strata) River Crossings (When scour level is not

known) 3.5 (for Normal soil)

1.5 (for Rocky strata) 5 Drain / ditches at road & railway 1.5 6 Horizontal Directional Drilling Rivers 2.5 (Below Scour depth)

or 5.0 (below bed)

whichever is lower National Highway 5.0 State Highway 5.0 Railway 5.0 Lined Canal 5.0

7 Lined Drains or or Lined Nalas 1.5 8 Uncased road crossings/station approach 1.2

Piping at stations shall be installed above ground at grade level with adequate

supporting. Piping shall be provided with sufficient flexibility for minimizing the

stresses.

Projects & Development India Limited, Sindri 17 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

5.3 PROCESS DETAILS The specification of petroleum products to be transported thru proposed pipeline shall

be as follows:

Table- 1.6 Product Specification

Sl.No.

Products Sp. Gravity Viscosity cSt Reid Vapour Pressure (RVP), Kg/cm2, max at38oC

Flash Point, (C) Abel, min

1 HSD 820-845 kg/m3 at 150C

2.1 at 400C 5.0 at 25 0C

0.1 37-66

2 MS 720-775 kg/m3 at 150C

0.51 at 37.80C 0.7 at 200C

0.61 < 10

3 SKO 780-830 kg/m3 at 150C

1.18 at 37.80C 1.53 at 20 0C

0.3 35

4 PCK 780-830 kg/m3 at 150C

1.18 at 37.80C 1.53 at 20 0C

0.3 35

PCK specification is similar to SKO the only difference is the percentage sulfur in pipeline compatible kerosene (PCK) which is 35ppm in PCK.

Table- 1.7

Permissible contamination level (% vol) Sl. No.

Main Product Contaminant (% Vol) MS SKO PCK** HSD

1 MS -- NIL 1* NIL 2 SKO NIL -- -- NIL 3 PCK NIL -- -- NIL 4 HSD NIL NIL 2 – * 2% if MS RON is 91.8 and more ** Normally all Euro 4 products are pumped with PCK (pipeline compatible kerosene) and not SKO. SKO is plugged between 2PCK batch.

5.3.1 Operation & Control Philosphy

k) Instrumentation and Control system shall be provided for safe and efficient control

of petroleum products pipeline.

l) PLC (programmable logic control) based control system shall be provided at

Dispatch stations, Receipt stations for the process interlocks / shutdown logic /

MOV’s (motor operated valve) operation and station monitoring whereas panel

based monitoring/ control system (Working on 48V DC) shall be provided at

intermediate pigging station. Control panels are provided for mounting the flow

computers & other instruments. All controls, recording and link to remote indicating

devices shall be through PLC located in the control rooms at dispatch station.

Projects & Development India Limited, Sindri 18 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

m) SCADA (Supervisory Control and Data Acquisition) system is envisaged to ensure

effective and reliable control, management and supervision of pipeline from

centralized location using Remote Telemetry Units (RTU) along the pipeline route.

The SMCS (SCADA monitoring and control station) for this pipeline shall be

provided. Real time leak detection system & Batch tracking integrated with SCADA

network will be provided. Intrusion detection and negative pressure wave based

leak detection system shall be explored.

n) All essential control parameters of receipt terminals shall be integrated suitably in

SCADA system and PLC control.

o) All supply operations for the pipeline system shall be under the control of dispatch

stations which shall ensure the supply of the product at normal operating

conditions. The dispatch station shall make all necessary arrangements for the

petroleum products dispatch and ensure proper lining up of the system in

conjunction with the receipt terminal.

p) The main pumping units will be shutdown automatically in the event of low suction

pressure or high discharge pressure, mechanical seal failure, high vibration, high

casing temperature etc. Very high station discharge pressures will also shutdown

the pumps. At the pump discharge, a pressure control valve shall be provided to

control the pipeline inlet pressure within MAOP of the existing pipeline. Low signal

selector is provided for selecting the low signal either from pump discharge or from

suction side pressure controllers. This pressure control valve normally controls the

pipeline inlet pressure and the pump suction pressure controller over rides the

discharge pressure controller if the suction pressure falls below the set value and

pipeline inlet pressure is maintained at pre-set value.

q) Unit Control Panels (UCP) is envisaged at pumping stations. Pump start / stop /

interlocks / trip functions will be implemented in the pump UCP and this UCP will

be interfaced to the station PLC system for stop / trip / ESD from station / SMC and

for status monitoring. Metering facilities shall be provided (1W+1S, at each station)

with bypass line at the dispatch station, IPS and receipt terminals with flow

computers to compute corrected volumetric flow rate as well as mass flow rate.

Flow meter shall be ultrasonic flow meter. Density and viscosity meter (1 no. at

each station) shall be provided at the dispatch terminal, IPS and at Panki receipt

terminal density meters at SBV and in terminal.

Projects & Development India Limited, Sindri 19 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

r) Corrosion Inhibitor dosing facilities shall be provided at dispatch station & IPS for

controlling corrosion in the pipeline. Operation of CI dosing pumps shall be local.

Corrosion monitoring system with corrosion probe and coupons located at 6 o’clock

position in the station piping shall be provided at two suitable locations for

monitoring corrosion in the pipeline. Electric Resistance probe for corrosion

monitoring shall also be provided.

s) The sump pump and / or slop transfer pump will be tripped in case of low liquid

level in the sump tank.

t) Thermal relief / safety valves shall be provided as per the requirement / standards

such as API 521 and shell DEP equivalent.

5.3.2 Shutdown of Pipeline Shutdown of any station along the pipeline may cause shutting down of the entire

pipeline operation. Shutdown of the pipeline, if required, can be done either manually

or through SMCS. However, Shutdown will be done manually only when the SMCS is

not working due to any reason. Any station willing to have shutdown will request

SMCS for the shutdown of the pipeline.

A. Shutdown of Pipeline through SMCS Shutdown of the pipeline, if required, will be done manually and through the SMCS.

Through SMCS shutdown can be done using prompts and without prompts.

B. Shutdown of Pipeline through SMCS without Prompts Pipeline can be taken into shutdown by actuation of a single command in the SMCS.

Here the operator is not required to follow the shut down steps. SMCS will follow all

the steps to take smooth shut down of pipeline.

C. Shutdown of Pipeline through SMCS with Prompts Pipeline can be taken into shutdown by actuation of sequence of prompts in the

SMCS. Here the operator is required to follow the shutdown steps to take smooth shut

down of pipeline. Pipeline can be taken into shutdown manually only when SMCS is

not working due to any reason. Here the operator is required to follow the shutdown

steps to take smooth shut down of pipeline.

E. Shutdown of Receipt Terminal In case of fire, a big leak or other such emergencies, it is important to shutdown the

receipt terminal at Panki. Pipeline can be isolated completely by closing the station

isolation valves by pressing ESD push buttons, which can be closed from SMCS. For

Projects & Development India Limited, Sindri 20 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

the shutdown of pipeline operator at receipt terminal will inform to the pipeline control

room. The fire alarm should be raised and appropriate steps should be taken.

5.3.3 Start - Up a. Initial start up Initially, pre-flush water is pushed by running booster pump by lining up the tank which

is having water. A first batching pig is then launched with water by running one booster

pump and pipeline is filled with water. Once backpressure starts increasing start one

Mainline Pump. After some time, another Booster and another Mainline Pump can be

started. As earlier second batching pig shall then be launched and further filling up of

water is done. Finally, insert third batching pig and operate the pumps on Petroleum

products to propel the pig trains. Thereafter, pig train is propelled by operating booster

and mainline pumps in series.

b. Start up after emergency shutdown Start Booster Pump with minimum flow bypass on auto mode. Start Mainline Pump.

Check suction pressure at the dispatch terminal. Once pressure reaches,

above5kg/cm2, ensure that flow is established up to tank at Panki. Once flow is

established, start corrosion inhibitor dosing subsequently.

5.3.4 Fire Fighting Facilities

vi) Existing fire water network of the plant shall be extended to cover the facilities at

DT and RT under this project.

vii) Existing Fire water system is designed to fight two major fires anywhere within the

plant as per the provisions of OISD-116/OISD-117. Adequacy of existing fire water

system has been done to meet the OISD-116/OISD-117 requirements. Fire water

network is laid in closed loops to ensure multi directional flow in the system. The

same shall be followed for the fire water network for the new area and same shall

be hooked up to the existing network at adequate places. 12” fire water header

size required upto proposed area from hook-up point.

viii) Hydrant & Monitors:

Double outlet hydrants and monitors shall be provided at 30M interval around

proposed area.

The ring main shall be provided above ground around proposed areas on

independent concrete sleepers.

ix) Fire fighting facilities for Mainline pump house:

Projects & Development India Limited, Sindri 21 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

The mainline pump house are provided with fixed water spray system as per

requirement of OISD-116/OISD-117 and NFPA-15.

x) Adequate no. of portable fire extinguishers shall be provided at all strategic

locations.

5.4 CODES & STANDARDS The following industry Codes & Standards shall be applicable for the proposed

pipeline:

Table- 1.8 Codes & Standards

Codes/Standards Title ASME B 31.4 Pipeline Transportation System for liquids & Slurries API 5L Specification for Line Pipe DIN EN ISO 21809 Part 1 External coatings for buries or submerged pipelines

used in pipeline transportation systems, Part 1: Polyolefin coatings (3-ayer PE & 3- layer PP)

ASME B 16.5 Pipe Flanges and Flanged Fittings: NPS ½ through NPS 24 metric/inch standards

ASME B 16.34 Valves Flanged, Threaded and Welding End ASME B 16.20 Metallic Gaskets for Pipe Flanges: Ring-Joint, Spiral

Wound and Jacketed ASME B 16.9 Factory Made Wrought Butt Welding Fittings MSS-SP-75 Specification for High Test Wrought, Butt Welding

Fittings MSS-SP-97 Integrally Reinforced Forged Branch Outlet Fittings-

Socket Welding, Threaded, and Butt-welding Ends ASME B 16.11 Forged Fittings, Socket Welded & Threaded ASME B 16.25 Butt Welding Ends

6.0 WATER& POWER REQUIREMENT Water requirement for the proposed BPPL project is very minimal to the tune of 20

KLD, mainly for potable use by workers across the pipeline length, dispatch & receipt

terminals and SV & IP stations en-route.

Two nos. of HT plant feeder from existing HV switchboard (HT-223 at Substation No.

7) from Bina Refinery shall be provided by Owner / BPCL to the battery limit of

Dispatch Terminal at Bina to meet the total power requirement (of new 6.6kV

switchboard) at the Dispatch Terminal. At Panki receiving terminal (RT), the incoming

power shall be fed from existing emergency switchboard so that there shall be no

separate new Emergency DG for RT. During construction phase, High Speed Diesel

(HSD) of approx. 250 L / day shall be used in DG sets. During operation phase, the

Projects & Development India Limited, Sindri 22 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

power consumption shall be 2.8 MWhr and met thru available State Electricity Supply

Company in the respective area. The system shall operate on constant V/F supply with

required voltage boost capability in low frequency mode of operation. Variable speed

drive shall be arranged so that it can be operated in an open circuit mode,

disconnected from the motor for start-up adjustments and trouble-

shooting/maintenance.

7.0 ENVIRONMENTAL ASPECTS The design of the proposed pipeline will be on minimum pollution basis and include all

the features required to ensure that control of all forms of pollution will comply with

regulatory & governmental requirements.

The design approach built into the FEED to avoid/minimize emissions to the air is as

follows:

• Fugitive emissions from valves will be avoided or minimized by selection of suitable

valve packing, seals etc.

• Fugitive emissions from pumps will be minimized by use of dual seals or seal-less

pumps when handling high vapour pressure and hazardous material

• Fugitive emissions from flanged connections will be reduced by minimizing the

number of flanged connections in high pressure service.

• Asbestos will be replaced with safer materials wherever possible.

• Only non-Ozone Depleting Substances will be used.

• The Pipeline is a closed loop system and no hydrocarbon will be released to open

atmosphere.

7.1 Waste Generation, Management & Disposal There is no continuous source of waste generation. The waste water in the form of

sanitary waste at stations shall be treated anaerobically and disposed off through septic

tanks.

The excavated soil generated while laying of pipeline shall be placed around and on top

of the pipe as soft soil / sand padding so that thickness of padding shall be at least 300

mm on top of pipe corrosion coating. Disposal of debris and surplus material to

designated disposal areas or designated place(s), as the case may, shall be carried out.

The proposed project falls under non-polluting activities. There will be no industrial

wastewater generation, no sludge/solid waste generation and no air pollutant generation

Projects & Development India Limited, Sindri 23 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

except by intermittent operation of the DG sets & Fire water pumps. Hence,

management of industrial waste is not applicable at this point.

Insignificant solid waste generation during operation of the pipeline in the form of oily

sludge during pigging cannot be ruled out. This shall be tested for determining its

characteristics and disposed off thru CPCB approved recyclers as per the current

practices of BPCL. Thus, any significant impact, practically immeasurable, on the nature

of soil and physical features due to spillage or disposal of solid wastes is not foreseen.

8.0 LAND FORM, LAND USE AND LAND OWNERSHIP The Right of User (ROU) for laying the pipeline will be acquired as per The Petroleum

& Minerals Pipelines (Acquisition of Right of User Inland) Act, 1962 through the

Competent Authority nominated for the project after notification in the Central

Government Gazette and payment of compensation shall be provided directly to the

land owners as stipulated in the act.

Pipeline will be laid in ROU land which has a width of 30m and ownership will remain

with the land owner. Land for Sectionalizing Valve (SV) station and Intermediate

Pigging (IP) station coming along the route of the pipeline will be procured. There

would be 11 such stations along the route (10 SV stations and 1 IP station) and the

land requirement will be approx. 2,500 m2 per SV station and approx. 11,000 m2 for the

IP station. Land for dispatch facility at Bina and receipt facility at Panki is already

available with BPCL.

Provision of Rs.66.28 Crore is kept for ROU acquisition and for crop & tree

compensation.

9.0 MANPOWER REQUIREMENT About 400 people shall be employed directly/indirectly during the construction phase.

The requirement of manpower is expected to be met through internal deployment as

well as thru induction of competent manpower as per company’s rules. The existing

manpower at Bina and Panki (Kanpur) would be adequate to handle the operation

phase.

10.0 REHABILITATION AND RESETTLEMENT (R&R) PLAN The ROU shall be acquired by BPCL for laying of pipeline and shall be handed over

back to the land owners for cultivation purpose. Compensation for loss of crop during

Projects & Development India Limited, Sindri 24 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

construction phase shall be paid as per Govt. Policy hence, the rehabilitation and

resettlement is not applicable for this project.

11.0 PROJECT SCHEDULE & COST ESTIMATES 11.1 Project Schedule The pre-project activities that have to be completed before the physical execution of the

project are briefly enumerated below:

i) Approval of the project by BPCL- Approved ii) Appointment of owner’s project management team- Approved iii) Statutory approvals and licenses from all the concerned external agencies. iv) Financial clearance and commitment from financial institutions v) Preparation of EIA Study and clearance by State and Central Pollution Control

Boards vi) Risk Analysis Study vii) Survey and soil Investigation of the site viii) Appointment of Engineering Consultant (EC) ix) Approvals from the Chief Controller of Explosives and Chief Electrical Inspector x) Authorization from Petroleum and Natural Gas Regulatory Board (PNGRB). xi) All the above activities along with construction of compound wall and land

development activities have to be completed before the physical execution of the project.

The project completion period has been estimated to be about 36 months after grant of

Environmental Clearance.

Fig.: 1.3 Overall Project Schedule

Projects & Development India Limited, Sindri 25 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

The proposed Bina-Panki pipeline project is scheduled to be completed within 36

months from the date of receipt of statutory clearances including MOEFCC.

11.2 Cost Estimates

The basic assumptions made for working out the capital cost estimate are as under:

• Project shall be executed on EPCM Basis.

• Cost estimate is valid as of Apr-2017 price basis.

• No provision has been made for any future escalation

11.2.1 Financial Analysis Financial analysis has been carried out for calculating Transportation Tariff to achieve

internal rate of return (IRR) 12% on equity after tax.

Table- 1.9

Financial Parameters 1 Construction Period 3 years 2 Project life 25 years 3 Debt / Equity Ratio 1:5:1 4 Expenditure Pattern Equity Before Debt (B) 5 Loan Repayment Period 25 years 6 Moratorium Period 2 year 7 Interest on long term Loan 10.0 % 8 Capital Phasing (Total Capital) 8.1 1st Year of construction 15% 8.2 2nd year of construction 40 % 8.3 3rd Year of Construction 45 % 9 Capacity Build-up 9.1 1st Year 87 % 9.2 2nd Year 91 % 9.3 3rd Year 96 % 9.4 4th Year 100 % 10 Corporate Tax Rate 34.61 % 11 MAT 0%

The estimated cost of laying proposed 18” multi-product pipeline and augmentation of

tankages at receipt terminal is Rs.1495 Crores.

Revenue considered for financial analysis is based on client’s input is as follows:

Projects & Development India Limited, Sindri 26 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

Table- 1.9 Pipeline cost

Sl. No. DESCRIPTION Cost (Rs. Crore) 1 Capital Cost (Excluding Financing Charges,

Line Pack Cost, Working Capital Margin, Escalation During Implementation Phase)

1167.97

2 Variable Operating Cost (Annual) 11.84 3 Fixed Operating Cost (Annual) 27.98 4. Total Operating Cost (Annual) 39.82

The estimated cost of laying proposed 18" pipeline and augmentation of tankages at

receipt terminal is Rs.1495 Crores.

Table- 1.10 Revenue

Year of Operation Rs Lakhs 2021 20783 2022 22690 2023 24817 2024 26860 2025 29063 2026 31501 2027 34153 2028 37060 2029 40226 2030 43707 2031 47198 2032 50995 2033 52480 2034 54579 2035 56765 2036 59033 2037 61397 2038 63851 2039 66406 2040 69062 2041 71822 2042 74698 2043 77683 2044 80792 2045 84024

Projects & Development India Limited, Sindri 27 of 27

Pre-Feasibility report for TOR of Proposed 356km long, 18 inch Multi product petroleum pipeline from Bina to Panki (Kanpur) & augmentation of tankages at receipt Terminal, Kanpurof M/S BPCL, Mumbai

12.0 CONCLUSION The proposed pipeline will ensure cost-effective transportation and uninterrupted

supply of petroleum products from Bina to Panki (Kanpur) to cater to the North Indian

market of Kanpur, Mughalsarai, Aonla, Shahjhanpur, Baitalpur, Gonda (UP),

Kathgodam (Uttarakhand) and Muzaffarpur (Bihar). This will reduce Rail traffic

between Bina to Kanpur and is envisaged to yield investment returns more than 12%.

The pipeline is not passing through any eco-sensitive areas. The natural gradient of

the route means a high level at Bina and lower level at Kanpur is a technical

advantage with requirement of low power to transfer the product. There are no hilly

terrains en-route the pipeline and the forest area also is less dense calling for

minimum cutting of trees etc. The river crossings are minimum with sufficient space

available on either ends to place machinery for boring/auguring and mostly with a

rocky bed that ensures that the pipeline will not be subjected to scouring and there-by

least damage to the pipeline during its operating life. The acquisition of land for ROU

shall be done by following the latest guidelines with least disturbance to land and

compensation to the project affected people as per Govt. guidelines. The pipeline does

not call for any demolition or re-alignment of any existing structure causing social

disturbance.

Considering the above facts, the TOR may be granted for the proposed project for

preparation of EIA report as per the guidelines