Preparation of silica nanoparticle through coating with...

Transcript of Preparation of silica nanoparticle through coating with...

Indian Journal of Chemistry Vol. 46A, December 2007, pp. 1955-1958

Preparation of silica nanoparticle through coating with octyldecyltrimethoxy silane

N Venkatathri

Department of Chemistry, Anna University, Chennai 600 025, Tamil Nadu, India

Email: [email protected]

Received 13 March 2007; revised 29 October 2007

Silica nanoparticles have been prepared using tetrethylorthosilicate, water, aqueous ammonia, ethanol and octadecyltrimethoxy silane as constituents. Kinetics studies have been carried out to characterize the material by analyzing the yield, which follows an S type curve. At the eighth hour, the yield reaches maximum in time (hours) versus yield (%) plot. In conventional synthesis, a part of the product particles is small in size (100 nm, 80%) while the remaining is bigger in size (300 nm, 20%). The particle size is normalized on addition of octadecyltrimethoxy silane and is increased to a small extent (400 nm). The sample has been analyzed by XRD, SEM, TEM, E-DAX, FT-IR, N2 adsorption and 28Si MASNMR techniques. The sample is amorphous with surface area of 93.54 m2/g and contains Q2, Q3 and Q4 species. TEM reveals the particles to be core shell type which is absent in ODTS-free samples. The samples show Si-O-Si tetrahedral skeletal vibrations.

IPC Code: Int. Cl.8 B82B3/00

Amorphous silicate nanoparticles are used in many applications including ceramics, catalysis, pharmaceutical, electronic packaging and chemical-mechanical polish.1-5 In particular, methods for controlling the nanospheres, size and distribution, have received special attention because they exhibit peculiar and desirable properties in the wafer polishing process. Monodisperse silica nanospheres were first synthesized by Stober et al.

6 using sol-gel method, which induces high purity in the resulting particles. Bogush and Zukoski7 have reported the influence of reaction parameters such as ammonia and water contents on the particle size and distribution.

Recently, silica nanospheres have been considered effective candidates for chemical-mechanical polishing materials, and several investigators have reported ways to control particle size by using reactor type and varying the concentrations of ammonia, water and alcohol solvent.8-10 They have also examined the influence of reaction method (such as semi-batch reaction and batch reaction) on particle size and distribution. A relatively slow rate of

hydrolysis of TEOS occurred during the semi-batch process, which resulted in larger silica particles and a narrower size distribution.9

The mechanism of the silica nanospheres was generally suggested to be via hydrolysis of silica source to form the hydrolyzed monomer. Subsequently, this intermediate reaction product condenses and eventually forms silica. A common problem during silica nanosphere synthesis is bimodal particle size is formed. To avoid this, several attempts have been made by varying the reaction constituents. Here, a successful method is reported wherein a silicon source (octadecyl trimethoxy silane) is added. Further, the materials have been characterized by conventional physicochemical techniques.

Experimental Synthesis of silica nanosphere using ammonia

catalyst and ethanol solvent was carried out as follows: Aqueous ammonia (3.14 ml, 28-30%, Aldrich, USA) was added to a solution containing 74 ml of ethanol (99%, Aldrich, USA) and 10 ml of deionized water. Tetraethoxysilane (TEOS) (6.0 ml, 98%, Aldrich, USA) was added to the above prepared mixture at 298 K with vigorous stirring. The reaction mixture was stirred continuously for 1 h to yield uniform silica spheres. A mixture containing 5 ml of TEOS and 2 ml octadecyltrimethoxy silane (C18TMS, 90%, Aldrich, USA) was added to the colloidal solution containing the silica spheres (11.4 SiO2: 6 NH4OH: 1 C18TMS: 149 H2O: 297.5 EtOH) and further reacted for 1 h. The resulting octadecyl group incorporated silica nanocomposite was retrieved by centrifugation, and further calcined at 823 K for 6 h under air atmosphere to produce the final solid core/mesoporous shell silica material. Silica nanosphere was synthesized by the same procedure without adding ODTS, for comparison.

The particle size and shape were analyzed with a Topcon, SM-300 scanning electron microscope. The copper disc was pasted with carbon tape and the sample was dispersed over the tape. The disc was coated with gold in ionization chamber before microscopic analysis. E-DAX analysis was also carried out with the same instrument. Transmission electron microscopic (TEM) studies were performed on a JEOL JSM-2000 EX electron microscope

INDIAN J CHEM, SEC A, DECEMBER 2007

1956

operated at 200 kV. The TEM sample was prepared by dipping a Cu grid coated with carbon films in sample suspension with water as solvent (solution was sonicated for 20 min). X-ray diffraction analysis was carried out using Mac Science Co. Ltd., MO3XHF22 instrument in the range 5-45o. BET surface area analysis were carried out using Micromeritics Tristar surface area and porosity analyzer. All the samples synthesized in this study were analyzed by FT-IR spectroscopy (Nicolet 60SXB). The 29Si MASNMR was analyzed using Bruker 400 MHz spectrometer.

Results and discussion

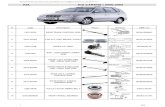

The yields of silica nanosphere synthesized with ODTS at different time intervals (in hours) follow a half S type curve (Fig. 1). The yields were calculated

in comparison with the theoretical silica yield from the total silica input. Maximum yield was observed at 8 h.

The morphology and particle size were studied from the scanning electron micrograph of the product (Fig. 2). The sample synthesized without ODTS shows bimodal particle size. The smaller sized particles are present in larger proportion (100 nm, 80%) while the bigger sized particle (300 nm) are present in smaller proportion (20%). However, on addition of ODTS the particle size are normalized (400 nm, 100%). Octadecyl group in trimethoxy silane molecule increases the electron density around the silane atom. So, the basicity in oxide group is increased. The former modified silanol groups show less reactivity and slower reaction as compared to silanol groups from TEOS. As the reaction is slow the particle size is increased. Another view is that except the octadecyl group, other methoxy groups are easily hydrolyzable. So, this alkyl group spreads like a sponge around the silica sphere and sterically hinders further growth. E-DAX spectrum of the calcined sample shows a peak for Si and O and no other impurities is observed.

TEM analyses of samples with and without ODTS are shown in Fig. 3. The samples synthesized without ODTS are normal, while the sample synthesized with ODTS shows a core shell type structure with shell width 50 nm. Results show that the ODTS create the core shell.

X-ray diffraction analysis of the sample in the range 5-80o shows a prominent peak at 23o. On calcination the pattern does not change. This is similar to the earlier reports on other silica nanosphere.16

Fig. 1—Time (hours) versus yield (%) plot of silica nanosphere synthesis from ODTS.

(a) (b)

Fig. 2—SEM photographs of: (a) silica nanosphere, and, (b) silica nanosphere from ODTS.

NOTES

1957

Fig. 4—FT-IR spectrum of silica nanosphere from ODTS.

The weight loss due to calcination from room temperature to 950oC is 18.6%. This may be due to the loss of chemisorbed octadecyl trimethoxy group and physisorbed water and ethanol.

The FT-IR spectrum (Fig. 4) of the as-synthesized sample shows peaks around 1700 and 3430 cm-1 corresponding to the carboxyl and hydroxyl groups12 respectively. The adsorption peak belonging to the Si-O stretching vibration of Si-OH bond12 appears at 960 cm-1. The weak peaks at 2855 and 2920 cm-1 belong to the stretching vibrations of C-H bonds, and show that a few organic groups are adsorbed on the spheres. The strong peaks near 1100, 802 and 467 cm-1 agree with the Si-O-Si bond, which implies the condensation of silicon alkoxide.13

Nitrogen adsorption – desorption isotherms plot for the calcined sample were studied. The sample has a

Fig. 5—The 28Si MASNMR spectrum of silica nanosphere from ODTS.

surface area of 93.54 m2/g, pore volume 0.39 cm3/g and pore size 182.42 Å. The isotherms may be categorized as type II. The lower BET surface area is due to of the non-porous nature of the sample. The 29Si MASNMR spectrum of silica nanosphere (Fig. 5) shows three distinct lines at –90, -98 and -110 ppm attributed to Q2, Q3 and Q4 species respectively.14 The peak intensity are in ratio of 1: 2.5: 2.5.

The mechanism of synthesis is proposed as follows: Tetraethyl orthosilicate monomers are hydrolyzed to hydroxides with liberation of ethyl alcohol. The hydrolyzed silicates then condensed to form polymeric silica with ammonia acting as catalyst15,16 and ODTS as a particle size normalizer, which activates the nucleation step in the particle growth.

In the present study, a bimodal synthesis of silica nanosphere is observed in conventional silica nanosphere synthesis. The particle size are normalized

(a) (b)

Fig. 3—TEM photograph of: (a) silica nanosphere, and (b) silica nanosphere from ODTS.

INDIAN J CHEM, SEC A, DECEMBER 2007

1958

on addition of octadecyltrimethoxy silane. Yield with respect to time follows a S type curve. The sample synthesized using ODTS is amorphous with core shell structure and surface area 93.54 m2/g. It exhibits Si-O-Si tetrahedral skeletal vibrations and contains Q2, Q3 and Q4 species.

Acknowledgement The author (NU) thanks Brain Pool Program, South

Korea for a fellowship.

References 1 Iler R K, The Chemistry of Silica, (Wiley, New York) (1979). 2 Sacks M D & Tseng T Y, J Am Ceram Soc, 67 (1984) 526. 3 Masuda R, Takahashi W & Ishii M, J Non-Cryst Solids, 121

(1990) 389. 4 Yamashita D M, Mori H & Maekawa T, J Ceram Soc Japan,

100 (1992) 1444. 5 Taira M & Yamaki M, J Mater Sci Mater Med, 6 (1995) 197.

6 Stober W, Fink A & Bohn E, J Coll Interf Sci,

26 (1968) 62. 7 Bogush G H & Zukoski C F, J Non-Cryst Solids, 104 (1988)

95. 8 Park S K, Kim K D & Kim H T, Coll Surf A:

Physicochem Eng Aspects, 197 (2002) 7. 9 Kim K D & Kim H T, J Sol-Gel Sci Tech, 25 (2002) 183.

10 Sadasivan S, Rasmussen D H, Chen F P & Kannabiran R K, Coll Surf A: Physicochem Eng Aspects, 132 (1998) 45.

11 Li Y, Xu C, Wei B, Zhang X, Zheng M, Wu D & Ajayan, P M, Chem Mater, 14 (2002) 483.

12 Shan Y, Gao L & Zheng S, Mater Chem Phys, 88 (2004) 192.

13 Agger J R, Anderson M W, Pemble M E, Terasaki O & Nozue Y, J Phys Chem B, 102 (1998) 3345.

14 Gontier S & Tuel A, Stud Surf Sci Catal, 105 (1997) 29. 15 Szostak R, Handbook of Molecular Sieves, (Van Nostrand

Reinhold, New York), (1992). 16 Yun D S, Kim H J & Yoo J W, Bull Korean Chem Soc, 26

(2005) 1.