Pre-Feasibility Report of Quartz Feldspar...

Transcript of Pre-Feasibility Report of Quartz Feldspar...

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

Pre-Feasibility Report of

Quartz & Feldspar Mine (Under the Guidelines of Ministry of Environment and Forest

in terms of the provisions of EIA notification 2006 and specifically in circular

No J-11013/41/2006-IA.II (I) dated 30th

December, 2010)

LOCATION OF THE MINE

S.F.No. 176/3B

Mavurettipatty Village,

Tiruchengode Taluk,

Namakkal District,

Extent: 1.26.5Ha (less than 5Ha)

Category: B2 Project

LESSEE

K.Murugesan,

Prop. M/s. Sri Mahalakshmi Mines & Minerals,

22/121-A, Kaalaikadier Office Opp.,

Nethimedu,

Salem District – 636 002

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

1. EXECUTIVE SUMMARY

The Scheme of Quarrying is prepared in respect of Quartz & Feldspar quarry belongs to

Thiru. A K.Murugesan. The lease was granted to vide Rc.No. 5909/MM6/2007, Dated:

17.11.2008 for an over an Extent of 1.26.5 Ha located in S.F.Nos. 176/3 of

Mavurettipatty Village, Tiruchengode Taluk, and Namakkal District for a scheme period

of next five years subjected to submission of Environment clearance from DEIAA,

Namakkal, consent for Establishment and Consent for operation from TNPCB.

SALIENT FEATURES OF THE PROJECT

S.NO PARTICULAR DETAILS

1. Name of the Company K.Murugesan

2. Type of Project Quartz & Feldspar Quarry

3. Location of the Quarry Survey Nos. 176/3B

Mavurettipatty Village,

Tiruchengode Taluk,

Namakkal District,

Tamilnadu State.

4. Quarry lease area 1.26.5Ha

5. Latitude 11019’24.21”N to 11

019’28.78”N

6. Longitude 78002’08.32”E to 78

002’12.87”E

7. Topo sheet No. 58 -I/3

8. Type of land

Patta/forest/PWD

It is a Patta land - Non forest

9. Production Capacity

Description

ROM

(Ts)

Recoverable

reserves @

60% (Ts) of

ROM

Quart

z

(35%)

Feldspar

(65%)

Ts

Mineral

reject

(40%) Ts

of ROM

Side

Burden

(Ts)

Topsoil

(Ts)

Total

waste

(40%

MR +

SB)

Geological

resources 320416 192250 67287 124962 128166 243518 7544 371684

Mineable

Reserves 82891 49734 17407 32327 33156 1118 1384 34274

Year wise

Reserves 34117 20470 7165 13306 13647 405 96 14052

10. Life of Quarry Mining lease period is twenty years (20.12.2008 to

19.12.2028).

The Scheme of mining plan is prepared to submission

for a period of five years (2018 – 19 to 2022 – 23).

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

11. Method of Mining Mining operation is proposed to be carried out by

opencast mechanized method and proposed benches

are 3.0m & 5m height and width with 60º slope.

12. Ultimate depth of

Quarrying

The ultimate depth of quarry is about 19m

13. Top soil & overburden

(quantity in Ts)

There is topsoil which found thickness of 1.0m would

be generated during the present scheme of mining plan

period is about 96Ts.

14. Ground water level The depth of water table is around 40m (40m during

summer season and 35m during rainy season).

15. Nearest habitation Mavurettipatty – 1.5km – NE

16. Nearest Town Tiruchengode – 16m - NW

17. Nearest Railway station Budan Santhai Railway station -15km – NE

18. Nearest Airport Salem Airport - 51km - N

19. Nearest National

Highways & State

Highways

NH-7- Bangalore - Kanniyakumari – 15km-

Northeastern side.

SH25- Tiruchengode - Namakkal – 1km -

Southwestern side.

20. Nearest Hospital Tiruchengode – 16km – NW

21. Aerial distance to the

nearest Eco sensitive

areas, CRZ, forest, wild

life sanctuary, Interstate

boundary, critically

polluted area if the

quarry site is within

500m of these areas.

More than 500m from Eco sensitive areas, CRZ, forest,

wild life sanctuary, Interstate boundary, critically

polluted area.

22. Details of other quarries

for a radius of 500m

around the quarry site

There are no mine located within the radius of 500m

23. Man power About 13 employees

24. Water requirement &

source

Total water requirement for 1.0KLD from water

vendors & existing bore well.

25. Cost of the project The Project cost:

A. Fixed Asset cost = Rs. 14,19,460/-

B. Operational cost = Rs. 10,00,000/-

C. EMP cost = Rs. 3,55,000/-

Total cost = Rs. 27,74,460/-

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

The Prefeasibility report preparing for following condition of Government of India Ministry of

Environment and Forests (No.L-11011/47/2011 –IA-II (M) Dated: 24th June, 2013)

Tank & Odai is situated about 200m from the Western side of the lease area.

Odai is situated about 3km from the Western side of the lease area.

Puthur Lake is located 6km away from the Southeastern side.

There is no forest within the radius of 10km.

There is no Western Ghats within the radius of 10km.

There is no HACA region within the radius of 10km.

There is no interstate boundary within the radius of 10km.

There is no CRZ within the radius of 10km.

There are no Bird sanctuaries, wild life sanctuaries and National park as Act 1972, within the

radius of 10kms.

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

The following information provided by the applicant

I have applied for Environmental Clearance to DEIAA,Namakkal, Tamilnadu for

Quartz & Feldspar lease for quarrying of Mavurettipatty in S.F.No: 176/3B for over an extent of

1.26.5Ha in Mavurettipatty Village, Tiruchengode Taluk and Namakkal District.

I swear to state and confirm that within 10km area of the mine site, I have applied for

environmental clearance; none of the following is situated.

Protected areas notified under the wild life (Protection) Act, 1972

Critically polluted areas as notified by the central pollution control board constituted

Under water (Prevention and Control of Pollution) Act 1974.

Eco-Sensitive areas as notified

Interstate boundaries and international boundaries within 5km radius from the boundary of the

proposed site.

There is no quarry located within the radius of 500m radius from periphery of the proposed

quarry.

There will not be any hindrance or disturbance to the people during transportation. No villages

are enrooted during transportation.

No habitations /villages observed within 300m radius from the periphery of quarrying area.

I swear that Afforestation will be carried out during the course of mining operation and

maintained.

The required insurance will be taken in the name of the labourers working in my quarry site.

Approach road belongs to us only and no other private patta roads encountered.

I will not engage any child labour in my mine site and I aware that engaging child labour is

punishable under the law.

All types of safety / protective equipment will be provided to all the labourers working in

quarrying area.

There is no permanent structures, temples etc., are located within 500m radius from the

periphery of my quarry.

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

2.0 INTRODUCTION OF THE PROJECT OR BACKGROUND INFORMATION

(i) Identification of project and project proponent: In case of quarrying project, a copy of

mining lease/letter of intent should be given

Identification of Project

Name of the Project Mavurettipatty Quartz & Feldspar Quarry

Lease area 1.26.5Ha (Patta land) -Non forest

Location

Survey No. 176/3B

Mavurettipatty Village, Tiruchengode Taluk,

Namakkal District and Tamilnadu State.

Topo sheet No. 58 -I/3

Project Proponent Name with Address

K.Murugesan,

Prop. of M/s. Sri Mahalakshmi Mines & Minerals,

No.22/121-A, (Opposite to) Kaalaikadier Office,

Nethimedu,

Salem District – 636 002

Mobile No: 98427 44845 & 95242 43236

Email id: [email protected]

In case of mining project, a copy of mining lease/letter of intent should be given

I. The Mining lease was granted under Rc. No. 5909/MM6/2007, Dated: 17.11.2008.

II. The Mining plan was approved by the IBM, Regional controller of mines, Chennai

vide Letter. No: TN/NMK/MP/QF-1701.MDS, Dated: 23.10.2008.

III. The Second Scheme was approved by Commissioner of Geology and Mining,

Chennai, vide Rc.No.7531/MM10/2017/NMK/Q&F/ SOM Dated: 08.11.2018.

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

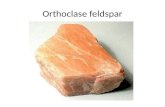

(ii) Brief description of nature of the project

The opencast mining operation is proposed by the formation of benches. Two benches are

proposed on the mineral to form at 1.0m, 3.0m and 5.0m height and width with 45º, 60º slopes.

The mine is well exposed the pegmatite rocks consist of quartz and feldspar. Quartz is identified

by concoidal fracture, vitreous lusture and granular grains. Orthoclase Feldspar identified by

pinkish white in color, pearly lusture on cleavage faces. The quarry lease area is 1.26.5Ha; the

life of mine is twenty years.

The total quantity of Mineable reserves of Quartz & Feldspar (60%) of ROM is about

49734Ts (17407Ts of Quartz @35% & 32327Ts of Feldspar @65%) and the total waste is about

is 34274Ts (33156Ts of MR @ 40% + 1118Ts of SB) is up to depth of 19.0m for the entire life

of mine.

The proposed quantity of Quartz & Feldspar (60%) of ROM mined for during this period

(as in the scheme of mining) would be about 20470Ts (7165Ts @35% of Quartz & 813306Ts

@65% of Feldspar) and the total waste is about 14052Ts (13647Ts of MR @ 40% + 405Ts of

SB) up to depth of 7.0m for a this scheme period.

The mineral reject is calculated as 40% of ROM. This includes fragments, chips, etc., the

total waste it will be proposed to dump on the Northern side of the lease area. Water requirement

for the proposed project for drinking purpose, dust suppression and afforestation would be

around 1.0KLD which will be taken from nearby villages.

(iii) Need for the project and its importance to the country and or region

The minerals of Quartz and Feldspar are used in various forms in various industries to

manufacture various products. Quartz shall be used in ceramics, glass manufacturing,

ferrosilicon, electric lining industries and paints. Feldspar shall be used in glass, ceramics,

abrasives and electrodes.

This project will give employment opportunities to 13 members directly and 8 members

indirectly, besides this Quartz and Feldspar is well known in the international supermarket which

will fetch a good foreign exchange to the nation.

Mineral Industries of the state of Tamilnadu provides employment opportunities for the

people of the state as well as in the specific project area. The quarrying is one among the major

core sector industries which plays a vital process of country’s economic development and

foreign exchange.

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

(iv) Demand and supply gap

Quartz and Feldspar is one among the most used in various industries to manufacture

different kind of product. The demand of Quartz and Feldspar is ever growing with the growth of

ceramics, glass manufacturing, ferrosilicon, induction furnaces lining, electric lining and paint

industries.

The mineral is widely used in walls and floor tiles other ceramic product, soaps and

detergents, paints, paper, cosmetic and plastic. The requirement for the mineral is very high in

the nearby cities and towns.

(v) Imports vs indigenous production

There is no import of Quartz and Feldspar at present in India. India especially the

peninsular India (southern India) has good resource of Quartz and Feldspar and has a great

demand in the international supermarket. Indigenous Quartz and Feldspar almost shares more

than 50% requirement in the world.

(vi) Export Possibility

There are many possibilities for export the Quartz and Feldspar to foreign countries

especially to Japan, Malaysia etc., as the Indian Quartz and Feldspar is one of the mostly

important industries in the world. All the international Quartz and Feldspar players are in the

requirement for industries either domestic or exports. Hence there is a bright possibility for

export of Quartz and Feldspar most of the industries.

(vii) Domestic/Export Markets

The applicant after will fetch a good domestic market as mentioned earlier. The applicant

does not have any other mine in Tamilnadu. It is propose to sell Quartz and Feldspar to industries

and domestic markets. Quartz is mainly used in ferrosilicon, silicon carbide industries and

abrasive industry. The main use of feldspar is in ceramics and porcelain industry mainly as glaze

material. It is also used in the manufacturing of some specialized electrodes.

(viii) Employment Generation (Direct and Indirect) due to the project

It is proposed to deploy about 13 employees directly and indirectly about 8 people will be

benefited from the nearby local villages.

The above man power is adequate to meet out the production schedule and the machinery

strength envisaged in the plan and also to comply with the stationary provisions of mine safety

regulation.

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

It is been ensured that the labors will not be deployed less than 18 years, No Child

labors will engaged or entertained for any kind of quarrying operations. All the labors

engaged for mining operations will be insured till the end of life of mine.

3.0 PROJECT DESCRIPTION

(i) Type of project including interlinked and interdependent projects, if any

This is a quarrying project for production of mine deposit at proposed production is about

@ 60% of ROM 20470Ts (7165Ts @35% of Quartz & 13306Ts @65% of Feldspar) no other

allied actions like processing and polishing is proposed in this project.

(ii) Location (map showing general location, specific location, and project boundary & project

site layout) with coordinates

� The area is located in S.F.Nos. 176/3B, Mavurettipatty Village, Tiruchengode

Taluk and Namakkal District.

� The entire quarry lease area falls in the Patta land with lease area is exhibits plain

terrain.

� The Altitude of the area is above 201m MSL.

� The area is mentioned in GSI Topo sheet No. 58 -I/3

� The Latitude between of 11019’24.21”N to 11

019’28.78”N

� The Longitude between of 78002’08.32”E to 78

002’12.87”E on WGS 1984

datum.

PROJECT BOUNDARY OF THE LEASE AREA

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

LOCATION MAP OF THE PROJECT AREA

v

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

DRAWING SHOW THE SURFACE PLAN WITH CO-ORDINATES

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

DRAWING SHOW THE ENVIRONMENTAL PLAN

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

(iii) Details of alternate sites considered and the basis of selecting the proposed site, particularly

the environmental considerations gone into should be highlighted

The opencast mining is proposed in the area for excavation of Quartz and Feldspar with

7.0m depth. The quarry is proposed in the applicant patta land hence alternate site for this project

is not considered. The project is site specific.

(iv) Size or magnitude of operation

The total area of the project is about 1.26.5 Ha. It is proposed for production (60%) of

ROM is about 20470Ts (7165Ts @35% of Quartz & 13306Ts @65% of Feldspar) by open cast

mining by deploys jackhammer drilling and blasting, hydraulic excavation of Quartz and

Feldspar from pithead to glass and ceramic manufacturing industries.

(v) Project description with process details (a schematic diagram/flow chart showing the

project layout, components of the project etc. should be given)

Details regarding topography, Geology of the area, Method of mining, Machineries

required and production details area given below:

Physiography

The area is almost plain terrain. The general drainage pattern of the area is dentritic pattern.

Only mining activity is being carried out in and around the area. In some areas agriculture is done

with lift irrigation. The main crops being millet, paddy, pulses etc. are grown as seasonal crops.

There is no Forest or Animal Sanctuaries near the area. There is no thick vegetation. Water table is

found at a depth of 40m during summer and 35m during rainy season. The area exhibits a

subtropical climate and the temperature that goes upto 420C in summer and falls down to 25

0C in

December – January. The wind direction is NE-SW and vice-versa. Average annual rainfall is about

750mm in Northeast and Southwest monsoon season.

Geology of the area

The Namakkal district is mostly underlain by the Archean crystalline, metamorphic

complex. The geology of the district is complicated due to recurring tectonic and magmatic

activities occurred during the pre-cambrian period. The famous Sittampundi complex is popularly

known for its complex geology is situated in this district. It forms a part of massive intrusion of

granites and pegmatites.

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

These rocks are exposed at some distance from the area. The gneisses are well foliated and

banded with alternate layers of feldspathic Biotite-hornblende minerals. Granites and pegmatites

have intruded the gneisses and they are of Archaean Age. Being more resistant than the gneisses

to erosion, the granites and pegmatites stand out as residual ridges in this area.

The general geological sequence of the rocks in the area is:-

AGE ROCK TYPE

Recent Thin reddish and gravelly soil

-----------------Unconformity-----------------------------------------

Archaean - Pegmatites and granite

Gneisses

- Pink pegmatoidal syenite

- Migmatites (Hb –Bi gneisses).

The area was surveyed in detail to prepare a Geological map in the scale 1:1000 Showing

the various formations and attitude of the deposit.

The physical attitude of the band is given below:

Strike length (m) - 118

Width (m) - 66 (max)

Depth (m) - 19m (1m Top soil+ 19m Quartz & Feldspar)

Strike direction - N700E - S70

0W

Dip amount - SE700

Colour of Quartz is white, massive in form, hardness 7.0, specific gravity 2.6, absence of

cleavage; streak is white, vitreous in luster. Colour of Feldspar is pink, massive in form, hardness

6, specific gravity 2.6, two sets of cleavage, streak is white, sub-vitreous in luster. Major

geological disturbances are totally absent in this area. Recovery of minerals is estimated as 60%

of the total excavation of the ore body. The recovery percentage is based on the knowledge

gained from the working mine in this belt.

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

Method of Mining:

Mining would be carried out by the opencast method of working. Since the daily rate of

production is very limited, no heavy earth moving machinery is required. The Quarrying

operation would be done in a systematic way by forming benches with all safety aspects as

stipulated in the Mines Act, Mines Rules and Metalliferous Mines Regulations.

Machineries like Jackhammer drilling, tractor mounted compressors and blasting by

developing the benches at 3.0m & 5.0m height and width. The drilling is carried out with

jackhammer of small diameter (30-32mm) at shallow depth and blasted with class 2 slurry

explosives with charge ratio as 0.2 to 0.3. The quarry would be operated with hydraulic

excavation & laborers with one shift only.

Open Cast Working

It is proposed to carry out quarrying operation by open cast method.

The dimension of the benches is proposed at 3m height and 5m width for the easy

movement of men and machinery during mining activities. The slope of the benches is

maintained at 60o and less for the safety factors of the machines and men working inside the

mine. There is one existing pit and the dimension is 63m x 70m (avg) x 7m (d).

The top soil is of 1m thickness, one bench is maintained with 1m height. There will be

six benches in mineral with 3m height, 5m width and slope maintained as 600 from horizontal.

During the present scheme period [2018-19 to 2022-23], the mine working is proposed to be

carried out in the centre portion of the mining lease area starting from North and progress

towards Southern of the lease area upto 7m [1m Topsoil+ 6m Pegmatite (Quartz + Feldspar)]

from RL 201.0m to RL 194.0m. During the present scheme period, the mining operations are

proposed to be carried out in the first, second and third benches.

The mineral rejects and side burden (i.e. Total waste) that would be generated during the

previous scheme period was dumped on the Northern side of the lease area, the same will be re-

arranged. The mineral rejects and side burden (i.e. Total waste) that would be generated during

the present scheme period is proposed to be dumped over the existing re-arranged waste dump

situated in the Northern side of the lease area. The topsoil that would be generated during the

present scheme period will be utilized for afforestation purposes.

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

Estimation of Reserves:

Geological Resources:

Maximum Length = 117m

Maximum Width = 125m (Max)

Maximum Depth = 19m

Section ROM

(Ts)

Recoverable

Reserves

@60% (Ts)

Quartz

(35%) Ts

Feldspar

(65%) Ts

Mineral

reject @

40%

(Ts)

Side

Burden

(Ts)

Topsoil

(Ts)

Total

waste

(40%

MR +

SB)

XY-AB 100643 60386 21135 39251 40257 28958 5544 69215

XY-CD 219773 131864 46152 85711 87909 214560 2000 302469

Total 320416 192250 67287 124962 128166 243518 7544 371684

Mining- Opencast semi mechanized Method

Blasting Drilling

Quartz & Feldspar

Hydraulic excavation and

transportation to the needy

industries

SCHEMATIC DIAGRAM OF THE MINING PROCESS

Topsoil/Overburden

Utilized for afforestation

purpose

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

Mineable Reserves:

The available mineable reserves are calculated by deducting

� 7.5m safety distance from adjacent patta lands,

� 10m Safety distance from the cart Track

� 50m Safety distance from the Power line and Bench loss.

Maximum Length = 100m

Maximum Width = 65m (Max)

Maximum Depth = 19m with average 1m topsoil

Section ROM

(Ts)

Recoverable

Reserves

@60% (Ts)

Quartz

(35%) Ts

Feldspar

(65%) Ts

Mineral

reject @

40% (Ts)

Side

Burden

(Ts)

Topsoil

(Ts)

Total

waste

(40%

MR +

SB)

XY-AB 6061 3636 1273 2364 2424 713 1288 3137

XY-CD 76830 46098 16134 29964 30732 405 96 31137

Total 82891 49734 17407 32327 33156 1118 1384 34274

Year wise development and production for the next five years [2018-19 to 2022-23]

Maximum Length = 77m

Maximum Width = 59m

Maximum Depth = 7m with average 1m topsoil

Summary of year wise 2018-19 to 2022-23

Year ROM (Ts)

Recoverable

Reserves

@ 60% (Ts)

Quartz

(35%)

Ts

Feldspar

(65%)

Ts

Mineral

reject @

40%

(Ts)

Side

burden

(Ts)

Topsoil

(Ts)

Total waste

(mineral

reject

40%+side

burden)(Ts)

2018-19 7098 4259 1491 2768 2839 263 96 3102

2019-20 5959 3576 1251 2324 2384 143 - 2526

2020-21 6318 3791 1327 2464 2527 - - 2527

2021-22 6318 3791 1327 2464 2527 - - 2527

2022-23 8424 5054 1769 3285 3370 - - 3370

Total 34117 20470 7165 13306 13647 405 96 14052

Available mineable reserves reassessed as on 22.06.2018

Total Mineable Reserves ROM = 82891 tonnes

Proposed annual production ROM = 16578 tonnes

Anticipated life of the mine = 82891 / 6823

= 12 years

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

The Ultimate Pit Dimensions:

Dimensions Present size of pit Pit dimensions at the end

of present scheme period

Ultimate pit dimensions at the

end of life of mine

Length (m) 63 75 100

Width (m) 70 (avg) 67 (avg) 60 (avg)

Depth (m) 7 7 19 (max)

Machinery Required:

I. Drilling Machine:

S.No Type Nos

1. Jack Hammer 1

2. Portable Compressor 2

II. Loading

S.No Type

1. Excavator low capacity 1

III. Transport Equipment:

S.No Type Nos

1. Tippers 2

Manpower requirement:

The tentative man power required for the proposed Quartz & Feldspar Quarry shall be as

follows.

Present Employment position Additional requirements

during the SOM period

Skilled Labour

Foreman 1 -

Mate cum Blaster 1 -

Excavator operator 1 -

Semi-Skilled

Drivers 3 -

Un skilled Labour 7 -

Total 13 -

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

(vi) Raw material required along with estimated quantity, likely source, marketing area of final

products, Mode of transport of raw Material and Finished Products

This is a quarry project for exploiting Quartz and Feldspar; hence, there is no requirement

for raw material. These Quarts and Feldspar will be transported directly by industries to various

destinations as per the customer requirement.

Uses: Quartz is an important industrial mineral which finds use in glass making, ceramic

industry, electronic industry either domestic or export, building material, manufacturing of road

metals, bajri and other construction purposes. Feldspar, if it is potash-bearing variety, finds use

in ceramic industry, fertilizer industry, building material, manufacturing of road metals, bajri and

other construction purposes.

(vii) Resource optimization/recycling and reuse envisaged in the project, if any, should be

briefly outlined

No optimization/Recycling and Reuse envisaged in the proposed Quartz and Feldspar

quarry.

(viii) Availability of water its source, Energy/power requirement and source should be given

This Quarrying project does not require huge water for the project. The total water

requirement in the quarry will be around 1.0 KLD for drinking, sprinkling and afforestation.

Potable drinking water will be brought from private suppliers; the rain water will be collected

and used for the Green belt development.

Purpose Quantity Sources

Drinking &

Domestic purpose

0.5 KLD Packaged drinking water will be brought from

nearby approved water vendors.

Dust suppression 0.3 KLD From existing borehole on nearby quarry

Green belt 0.2 KLD From existing borehole on nearby quarry

Total 1.0KLD

Energy

Diesel (HSD) will be used for quarrying machineries, Jackhammer compressors and

Tippers. About 200 liters per day diesel will be brought from nearby diesel pumps.

No power is required for the project except for mine office and lighting during the night.

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

(ix) Quantity of wastes to be generated (liquid and solid) and scheme of mining for their

management/disposal.

Top soil:

There is top soil which found thickness of 1.0m would be generated during the present

Scheme of period is about 96Ts.

Overburden/Waste:

Proposed generation of waste for next five years [2018-19 to 2022-23]:

Year ROM (Ts) Mineral reject

@ 40% (Ts) Topsoil (Ts)

Side burden

(Ts)

Total waste (mineral reject

40%+side burden)(Ts)

2018-19 7098 2839 96 263 3102

2019-20 5959 2384 - 143 2526

2020-21 6318 2527 - - 2527

2021-22 6318 2527 - - 2527

2022-23 8424 3370 - - 3370

Total 34117 13647 96 405 14052

Disposal:

The mineral rejects and side burden (i.e. Total waste) that would be generated during the

present scheme period is proposed to be dumped over the existing re-arranged waste dump

situated in the Northern side of the lease area. The waste dump will be maintained at the angle of

45º slopes.

The part of the waste material has been used for road in villagers for building purposes,

cultivation and roads low laying adjacent area. And later will be used for backfilling at end of life

of quarry.

Waste water:

There will not be any process effluent generation from the quarry lease area. Domestic

effluent from the mine office is discharged in septic tank and soak pit. There is no toxic effluent

expected to generate in the form of solid liquid and gases and the no requirement of treatment of

waste.

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

(x) Schematic representations of the feasibility drawing which give information of EIA purpose

4.0 SITE ANALYSIS

(i) Connectivity

Mode Description

Road connectivity

1. The existing village road available in the mine area. This

road leads to connect Mavurettipatty village road at a

distance about 10m on Northern side of the area.

2. The Nearest National Highway (NH-7) Bangalore -

Kanniyakumari - 15km- Northeastern side.

3. The Nearest State Highway (SH25) Tiruchengode - Trichy

– 1km - Southwestern side.

Railway station &

Railway line

1. Nearest Railway station Budhan Santhai – 15km –

Northeastern side.

2. Nearest Railway line is Salem - Karur – 15km –

Northwestern side.

Air port 1. Nearest Airport is Salem -51km –Northern side.

(ii) Land Form, Land use and Land ownership

Land form:

The lease applied area is characterized by plain terrain. The area is sloping towards

South. Lease area is dry land. The attitude of the area is about 201MSL.

Land use:

The lease applied area is dry land with scattered outcrops of Quartz and Feldspar.

The area does not fall in forest land. There are no water courses flowing through the applied

Form – 1

Along with Scheme of Mining

&

Pre-feasibility Report

To Submit DEIAA

As the project is categorized in category-“B2”

The project area is (>5Ha)

Final Presentation of this project

DEAC-Grant of Environmental Clearance

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

lease area. There is no vegetation/plantation in this area. Some thorny bushes and shrubs are

observed. Present mining land use pattern is as follows:

Description Present Area

(Ha)

Area to be reclaimed at the

end of present scheme Period

(Ha)

Area at the end of

life of mine (Ha)

Area under Mining 0.44.1 0.06.1 0.60.0

Dumps 0.07.2 0.04.1 0.13.4

Mineral Stockyard - - -

Office & infrastructure 0.01.0 Nil 0.01.0

Road 0.02.0 Nil 0.02.0

Green Belt 0.03.0 0.17.0 0.20.0

Un utilized area 0.69.2 0.42.0 0.30.1

Total 1.26.5 1.26.5

Land Ownership:

The proposed quarry lease area is 1.26.5Ha. It is patta land registered in the name of

Santhi, Murugesan, Govinthan vide patta no. 1032. The Lessee has obtained consent from the

Joint Pattadhars.

(iii) Topography (along with map)

The area is almost plain terrain and gently sloping towards South. The Altitude of the area is

above 201m MSL. The area is dry and seasonal cultivation is done in the nearby areas with lift

irrigation. Water is found at a depth of about 40m in summer and 35m in rainy season. Average

annual rainfall is about 750mm during North-East and southwest monsoon. The climate is dry and

the temperature goes up to 420C in summer and falls down to 25

0C in December – January.

Google map showing the lease area

Lease area

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

GOOGLE IMAGE SHOWING THE LEASE BOUNDARY AREA

For Mavurettipatty Quartz & Feldspar Quarry

Location:

Village: Mavurettipatty

Taluk: Tiruchengode

District: Namakkal

Topo sheet No: 58 -I/3

Latitude : 11019’24.21”N to 11

019’28.78”N

Longitude: 78002’08.32”E to 78

002’12.87”E

Lease area

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

(iv) Existing land use pattern (agriculture, no n-agriculture, forest, water bodies (including

area under CRZ), shortest distances from the periphery of the project to periphery of the

forests, national park, wild life sanctuary, eco sensitive areas, water bodies (distance from the

HFL of the river), CRZ. In case of notified industrial area, a copy of the Gazette notification

should be given.

The lease area exhibits plain terrain. The region experiences semi – humid climate and

there is scanty growth of vegetation in and around the lease area (seasonal vegetation is mostly

practiced).

� Tank & Odai is situated about 200m from the Western side of the lease area.

� Odai is situated about 3km from the Western side of the lease area.

� Puthur Lake is located 6km away from the Southeastern side.

� There is no forest within the radius of 10km.

� There is no Western Ghats region within the radius of 10km.

� There is no HACA region within the radius of 10km.

� There is no interstate boundary within the radius of 10km.

� There is no CRZ within the radius of 10km.

� There are no Bird sanctuaries, wild life sanctuaries and National park as Act 1972, within

the radius of 10kms.

� There are no mines located within the radius of 500m.

(v) Existing Infrastructure

The Quartz and Feldspar project requires infrastructure like (Mine office, Labours shed,

Toilet and Rest shelter) for quarrying shall made developed by the applicant after the grant of

lease. Water for drinking purpose be supplied form the approved water vendors. A small water

tank is also proposed which will be used for water sprinkling, plantation etc.

(vi) Soil Classification

There is topsoil which found thickness of 1.0m would be generated during the present

Scheme of mining plan period.

(vii) Climatic data form secondary sources

The area exhibits a subtropical climate and the temperature goes up to 42°C in summer

and falls down to 25°C in December to January. The wind direction is NE – SW and vice –

versa.

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

(viii) Social infrastructure available

There is no social infrastructure within the radius of 1Km like schools, universities,

hospitals, prisons and community housing etc.

5. PLANNING BRIEF

(i) Planning Concept (type of industries, facilities, transportation etc) Town and Country

Planning/Development authority Classification

The total area of the project is about 1.26.5 Ha. Open cast mechanized mining by deploys

jackhammer drilling and blasting, hydraulic excavation loading from pithead to various

industries.

The project land is devoid of vegetation and lies in the backward town of Namakkal

District. There are no specific industries or factories in and around the project area. The proposed

production is around 20470Ts (7165Ts @35% of Quartz & 13306Ts @65% of Feldspar) during

this scheme period. Plenty of labors are available in the nearby villages. Facilities such as power,

Transportation and commodities infrastructure facilities are locally available near the project site

with Tiruchengode 16km in Northwestern side.

Transportation

The quarry Quartz and Feldspar are transported from mine head to customer destination

by tippers. The mode of transport of the Quartz and Feldspar produces and transported by

various industries.

Quartz is an important industrial mineral which finds use in glass making, ceramic

industry and in electronic industry either domestic or export. Feldspar, if it is potash-bearing

variety, finds use in ceramic and fertilizer industry.

(ii) Population projection

There are few villages located in the 5km radius of mine site and approximate distance

and population are given below.

S. No Name of the

Village

Approximate distance

& Direction from lease

applied area

Approximate

population

1. Mavurettipatty 1.5km –NE 400

2. Ella Nagar 2.0km-SE 300

3. Koothanpoondi 2.0km-SW 500

4. Mettupudur 2.0km - NW 300

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

Basic human welfare Amenities such as Health Center, Schools, Communication

Facilities, and Commercial Centers etc are available at Tiruchengode located at a distance of

16kms from the Northwestern side of the quarrying area.

(iii) Land use planning (breakup along with green belt etc0.)

During this period, it proposed to plant 150 Neem saplings in the south and western

boundary of the lease area. 30 trees per annum with an interval of 3m.

(iv) Assessment of Infrastructure Demand (Physical & Social)

Physical infrastructure:

� The existing road facilities are already available which shall be used and maintained.

� The labors requirement is drawn from the nearest villages. The labors will be brought by

jeeps and vans to the mine site.

� Medical facilities are available near the project site, Government and private hospitals

and other basic amenities and infrastructure facilities like communication center, school

supermarket, bus stand are also available in Tiruchengode at a distance of 16kms (NW).

� This quarrying project will provide employment for about 13 persons directly.

Social infrastructure:

� Periodical Medical checkup program for all the workers and first- aid fox with necessary

equipment will be provided.

� Training for workers regarding occupational hazards.

� Safety equipment like dust mask, shoes, gloves, helmet etc.,

(v) Amenities/Facilities

The simple methods adopted and the limited scale of activities involved in Quartz and

Feldspar quarrying does not require High Tension Electric Power supply or huge worship

facilities. The quarry work is restricted to one general shift during day time only. Machinery

repair works are attended at Namakkal town (19km- SE) and minor repairs are carried out by the

company’s staff at the quarrying site itself.

Potable drinking water is available from the nearby community wells and can be

transported to the work site in tippers. Mine office, storeroom, toilet and first-aid room will be

provided on permanent structures within the lease applied area.

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

6. PROPOSED INFRASTRUCTURE

(i) Industrial Area (Processing area)

There is no industrial or processing area proposed within the lease area.

(ii) Residential area (Non processing area)

Local person will be given priority for employment. No houses are situated within the

radius of 300m.

(iii) Green Belt

All along the lease boundary barrier side is selected for Green belt development by

planting and maintaining native species of neem saplings. It is proposed to plant 30 plants per

year. The total area for the proposed for Green belt is around 0.17.0Ha out of 1.26.5Ha.

(iv) Social infrastructure

This proposed Quartz and Feldspar mine will fetch employment for about 13 people

directly and 5 peoples will be indirectly beneficed, shopkeepers, Hotels, Machineries Transport

Contractors etc., the lease ensure to share all responsible for special benefits like water, health

care, Education benefits, and promotion of socio cultural activities of the nearby villages.

(v) Connectivity (traffic and transportation road/ Rail/ Metro/ Water ways etc.,)

Mode Description

Road connectivity

1. The existing village road available in the mine area. This

road leads to connect Mavurettipatty village road at a

distance about 10m on Northern side of the area.

2. The Nearest National Highway (NH-7) Bangalore -

Kanniyakumari - 15km- Northeastern side.

3. The Nearest State Highway (SH25) Tiruchengode - Trichy

– 1km - Southwestern side.

Railway station &

Railway line

1. Nearest Railway station Budhan Santhai – 15km –

Northeastern side.

2. Nearest Railway line is Salem - Karur – 15km –

Northwestern side.

Air port 1. Nearest Airport is Salem -51km –Northern side.

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

(vi) Drinking Water management (Source & Supply of water)

This proposed quarrying project does not require huge water either for beneficiation or

processing. Water requirement for quarrying activity is 1.0KLD. Water required for drinking and

domestic consumption for labors is around 0.5KLD. The Packaged drinking water will be

brought from approved water vendors nearby village. The domestic waste water generated will

be sent to septic tanks followed by soak pits.

(vii) Sewerage System

Toilets will be constructed as permanent structure within the area and sewage will be

discharged once in three months. The sewage waste will be collected in soak pit and the sludge

will be discharged.

(viii) Industrial Waste Management

No industrial waste will be generated from the project.

(ix) Solid Waste Management

Mineral Reject:

The proposed Quartz & Feldspar Quarry and total anticipated waste during the present

scheme period (next five years) is about 14052Ts (13647Ts of MR @ 40% + 405Ts of SB).

Disposal:

The mineral rejects and side burden (i.e. Total waste) that would be generated during the

present scheme period is proposed to be dumped over the existing re-arranged waste dump

situated in the Northern side of the lease area.

Dump Dimension: Present Scheme period

Existing & Proposed waste (i.e. Mineral

reject and side burden) Temporary Dump-I 63m X 18m X 8m(h) North

(x) Power Requirement & Supply / source

The proposed Quartz & Feldspar Quarry does not require any power supply for the mining

operation. It is proposed to operate in day time only from 8Am to 6Pm with 1 Hour lunch

interval between 1Pm to 2Pm. The domestic consumption for the lights at the night is only for

the century room, mines office etc,

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

7. REHABILITATION AND RESETTLEMENT (R & R PLAN)

(i) Policy to be adopted (Central/State) in respect of the project affected persons including home

oustees, land oustees and landless laborers (a brief outline to be given)

There is no Rehabilitation and resettlement is involved. The deployed labours will be

insured as per the Government norms till the end of the life of the quarry. Periodical medical test

will be conducted for the labors to monitor the occupational disease. The salaries and benefits

will be paid as specified by the instruction given by the labor enforcement officers.

8. PROJECT SCHEDULE & COST ESTIMATES (i) Likely date of start of construction and likely date of completion (Time schedule for the

project to be given)

The Mining lease was granted under Rc. No. 5909/MM6/2007, Dated: 17.11.2008 for a

period of twenty years.

Lease deed executed : 20.12.2008

Mining operation commenced : 05.01.2009

Lease expire : 04.01.2029

The proposed production is about (60%) 20470Ts (7165Ts @35% of Quartz & 13306Ts @65%

of Feldspar) for during this scheme period for five year.

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

(ii) Estimated project cost along with analysis in terms of economic viability of the project :

A. Fixed Asset Cost:

Land cost (Rs. 9, 64, 000/Ha) = Rs. 12,19,460/-

Labour shed = Rs. 50,000/-

Sanitary facilities = Rs. 50,000/-

Fencing cost = Rs. 1,00,000/-

Total cost = Rs.14, 19,460/-

B. Operational cost:

Machinery Cost = Rs. 8, 00,000/-

Drinking water facility = Rs. 1,00,000/-

Safety Kits = Rs. 1,00,000/-

Total operational cost = Rs. 20, 00,000/

C. EMP Estimation:

Afforestation = Rs. 50,000/-

Water sprinkling = Rs. 75,000/-

Water quality test = Rs. 30,000/-

Air quality test = Rs. 50,000/-

Noise / vibration test = Rs. 50,000/-

Cost towards Charity = Rs. 1,00,000/-

Total EMP Estimation cost = Rs. 3, 55,000/-

The Project cost:

A. Fixed Asset cost = Rs. 14,19,460/-

B. Operational cost = Rs. 20,00,000/-

C. EMP cost = Rs. 3,55,000/-

Total cost = Rs. 27, 74,460/-

� The total project cost including EMP cost (A+B+C) is about Rs. 27,74,460/-(Rupees

twenty seven lakhs seventy four thousand four hundred and sixty only)

� The total EMP cost is about Rs. 3,55,000/- (Rupees Three lakhs fifty five thousand only)

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

Population Benefit

The applicant ensures to take social responsibilities like providing School Note books,

Uniforms to the Students below poverty level beside if the villages require any borehole for

public use the applicant ensure to do so.

The applicant will also take part and contribute the native cultural activities in the nearby

villages. During summer seasons packaged drinking water will be kept will be kept in the village

for public and for tress passers. The applicant will involve and contribute all the socio cultural

allocation in and around the area. The budget provisions and allocation for all the above

activities will be around Rs. 1,00,000/- for during this period.

Mine Closure Plan:

Steps proposed for phased restoration, reclamation of already mined out areas:

� The proposal for the project is existing Quartz & Feldspar Quarry.

� After the exploitation of Quartz & Feldspar Quarry reaches its ultimate pit limit, the pit

will be partially backfilled and partially act as a good storage of water.

� Before closure the mine, a parapet wall will be constructed to prevent inadvertent entry of

cattle and human beings.

� After closure of mine, the pit will be allowed to collect seepage and rain water. This will

help to charge the nearby agricultural wells.

Measures to be under taken on mine closure as per Act & Rules:

Measure will be taken as per Act & Rules.

Mitigation measure to be undertaken for safety and restoration / reclamation of the already mined

out area:

� Drilling will be carrying out by wet drilling to control the dust into the air.

� Minimum blasting will be carrying out on limited scale.

� Mist spray on haul road will be proposed to prevent the dust propagation into the air.

� The plantation will be carried out on the safety barriers to prevent Noise, besides wet

drilling will be practiced to prevent dust.

� All the machineries will be maintained in good conditions as per RTO and TNPCB

Norms to prevent Noise, Smoke and vibration.

� Machineries will be periodically maintained by experienced mechanic to minimize noise,

Smoke and ground vibration.

PRE FEASIBILITY REPORT OF MAVURETTIPATTY QUARTZ & FELDSPAR QUARRY K.MURUGESAN

UNDER EIA NOTIFICATION 2006

9. ANALYSIS OF PROPOSAL (FINAL RECOMMENDATIONS)

(i) Financial and social benefits with special emphasis on the benefit to the local people

including tribal population, if any, in the area.

There are few tribal populations in and around the area about 13 personals directly will

be benefited by these projects, besides the government. Will get good revenue by taxes,

seigniorage fees etc., and if the applicants find the suitable export market the Government will

have a good foreign exchange to the nation.

The socio- Economic conditions of the village and distance will enhance due to the

project, hence, the project should be allowed after considering all the parameters. The detail

furnished in this scheme of mining is based on information provided by the State Government

and the lessee. By considering the merit of the project the permission may be granted.

Date : 15.11.2018

Place : Namakkal

1. Signature of the proponent

For M/s. Sri Mahalakshmi Mines & Minerals

K.Murugesan

(Proprietor)

2. Signature of the Recognized qualified person

A.Jagannathan, B.E., F.C.C., M.M.E.A.,

RQP/MAS/019/87/A

Base Line Studies is Prepared for

Over an extent of 1.26.5Ha,

S.F.Nos. 176/3B,

Mavurettipatty Village,

Tiruchengode Taluk,

Namakkal District

Quartz & Feldspar Mine

BBBAAASSSEEE LLLIIINNNEEE SSSTTTUUUDDDIIIEEESSS

The base line a study is prepared for Mavurettipatty Quartz & Feldspar Quarry. Base

line studies provide a base data for regular Environment Monitoring and Environment Impact

Assessment (EIA). The international Association for Impact Assessment (IAIA) defines the base

line studies as the process of identifying, predicting, evaluating and mitigating the Bio physical,

Social and other relevant effect of development proposals prior to major decision has been taken

and commitment mode. Hence the baseline study provides a bench mark for carrying out

environmental Impact assessment due to the course of mining activities. The purpose of these

studies is to evaluate the benefited and adverse effect of developing activities on the

neighborhood environment and the area where the quarrying is proposed to carry out.

Mr. K.Murugesan, Prop. M/s. Sri Mahalakshmi Mines & Minerals have applied for

Quartz & Feldspar Quarry lease for over an extent of 1.26.5Ha in S.F.No. 176/3B of

Mavurettipatty village, Tiruchengode Taluk and Namakkal District. The area proposed for

quarrying for the present mining period is about 0.06.1Ha which is below 15% of the total area

applied for lease; hence the impact assessment due to quarrying may be considerably low.

As per the Gazette notification 2006 the proposed project falls under B2 Category.

The area proposed for quarrying is a existing area and there are no factories, industries

within the radius of 1Km hence the atmospheric air is quite fresh. The area exhibits almost plain

terrain which is devoid of vegetation and Agriculture. In some small patches small agricultural

activities are been carried out by drift irrigation some thorny bushes and wild gars are found in

the area with scanty Palm trees (Borassus falabellifer), Tridax procumbens and Lucus aspera are

some of the common species along with Julia flora trees. The density of these about 20% to 40%

in the area and the remaining area is dry barren land.

The rest of the workforce is employed in agriculture, mining, raising livestock,

manufacturing, construction, trade and commerce. There is little agricultural activity in the town

on account of weather and irrigation facilities and the town has a set of Paper mill, oil mills, and

Automobile sectors within the town limits. The project in this area will fetch a quit considerable

employment to nearby village which in turn enhance the earning source of the nearby villages.

The comprehensive base line studies and standards constitute of collecting data on Ambient Air

quality, Dust fall rate, Water quality, Soil analyze, Noise level and Ground vibration study in the

area proposed for quarrying along with Flora and Fauna statistics.

The Methodology adopted in this project is based on the basic principles of capitalization

identification analysis and preparation of action plan to Mitigate negate or adverse impact.

Baseline studies adverse the significant environmental Issue and also provide necessary

information pertaining to the Environmental Attributes in the project area. Monitoring and

evaluating the effect of the works environment factors on health of people working on Quartz &

Feldspar Quarry.

Collection and analysis of Baseline Environmental Data.

Baseline Environmental Data plays a key role in the EIA procedure as it provides the

important information on the Environmental parameters which are likes to be affected due to the

Quartz & Feldspar quarrying activities.

Physiography

The area is almost plain terrain. The general drainage pattern of the area is dentritic pattern.

Only mining activity is being carried out in and around the area. In some areas agriculture is done

with lift irrigation. The main crops being millet, paddy, pulses etc. are grown as seasonal crops.

There is no Forest or Animal Sanctuaries near the area. There is no thick vegetation. Water table is

found at a depth of 40m during summer and 35m during rainy season. The area exhibits a

subtropical climate and the temperature that goes upto 420C in summer and falls down to 250C in

December – January. The wind direction is NE-SW and vice-versa. Average annual rainfall is about

750mm in Northeast and Southwest monsoon season.

Geology of the area

The Namakkal district is mostly underlain by the Archean crystalline, metamorphic

complex. The geology of the district is complicated due to recurring tectonic and magmatic

activities occurred during the pre-cambrian period. The famous Sittampundi complex is popularly

known for its complex geology is situated in this district. It forms a part of massive intrusion of

granites and pegmatites.

These rocks are exposed at some distance from the area. The gneisses are well foliated and

banded with alternate layers of feldspathic Biotite-hornblende minerals.Granites and pegmatites

have intruded the gneisses and they are of Archaean Age. Being more resistant than the gneisses

to erosion, the granites and pegmatites stand out as residual ridges in this area.

The general geological sequence of the rocks in the area is:-

AGE ROCK TYPE

Recent Thin reddish and gravelly soil

-----------------Unconformity-----------------------------------------

Archaean - Pegmatites and granite

Gneisses

- Pink pegmatoidal syenite

- Migmatites (Hb –Bi gneisses).

The area was surveyed in detail to prepare a Geological map in the scale 1:1000 Showing

the various formations and attitude of the deposit.

The physical attitude of the band is given below:

Strike length (m) - 118 Width (m) - 66 (max) Depth (m) - 19m (1m Top soil+ 19m Quartz & Feldspar) Strike direction - N700E - S700W Dip amount - SE700

Colour of Quartz is white, massive in form, hardness 7.0, specific gravity 2.6, absence of

cleavage; streak is white, vitreous in luster.

Colour of Feldspar is pink, massive in form, hardness 6, specific gravity 2.6, two sets of

cleavage, streak is white, sub-vitreous in luster.

Major geological disturbances are totally absent in this area. Recovery of minerals is

estimated as 60% of the total excavation of the ore body.

The recovery percentage is based on the knowledge gained from the working mine in this

belt.

Vegetation

The lease area is almost plain terrain, Quartz & Feldspar exposes in the lease area and it is

strewn with boulders of various sizes ranging from a few cm to one to half mater in diameter.

Except some small bushes there are no other trees in the applied area. Crops are only seasonal

cultivation with lift irrigation is practiced. The main crops being millet, paddy, pulses etc. are

grown as seasonal crops. There is no Forest or Animal Sanctuaries near the area. There is no thick

vegetation.

General approach to Environment

The Environmental besides data comprise of the features present of the site area its

includes environmental features such as forest area, conservation area, water bodies, industries,

wild life and fauna place of historic and importance etc.,

The data collected to cover the following.

1. Air environment

2. Noise Environment

3. Water environment

4. Ecology (Biological and Cultural Environment)

5. Physical Environment.

Air Environment

Air environment is responsible for the health of human beings, animals, wild life and

vegetation. Air pollutants emitted by project and non point source are transported dispersed or

concentrated by meteorological and topographical conditions. The atmosphere is dynamic

system which absolute range of solid, Liquid or gases from both Natural and Manmade source.

There substances travel through the air disappear and reveal among themselves and also with

other substances both physically and chemically which result in air pollution.

The Quartz and Feldspar propose to quarry is non toxic which does not emit any

undesirable pollutants in the form of solid liquid or gas. The dust emitted during the

transportation of vehicles the drilling will be carried out in wet condition to prevent dust into air

and the haul roads will be periodically sprinkled with mist water spray to prevent dust into the

atmosphere. The area in and around is quit fresh and the impact an air environment will always

be under controlled and will be monitored. No processing or beneficiation is proposed except

quarrying hence the impact an air will be controlled monitored and mitigated.

The ambient air quality within the study area on both core and buffer zone forms the

baseline information. The air quality monitoring points selected based on the Meteorological

conditions, topography of the study area and likely impact boundary location of the ambient air

quality monitoring stations was selected on the basis of wind pattern.

The ambient Air quality monitoring stations are shown in the map. Four major pollutions were

consideration significantly.

I. Particle matter - PM II. Suspended Particle Matter - SPM

III. Sulphur dioxide - SO2 IV. Nitrogen dioxide - NO2

Respectively the overall of emission we identified the direction of the wind in the

majority observed time was predominantly Northeast to Southwest direction and vice-versa.

The Air quality monitoring data is enclosed as Annexure No-I.

S.

No Test Parameters Unit Protocol Results CPCB

Standards 1 Particulate matter

(PM10) (Size less than 10µm)

µg/m3 IS 5182 Part 23-2006 42.2 100

2 Suspended particulate matter (SPM)

µg/m3 IS 5182 part 4-1999 (Reaff 2010)

32.5 60

3 Sulphur dioxide SO2 µg/m3 IS 5182 part 2-2001 (Reaff 2006)

4.1 80

4 Nitrogen Dioxide NO2

µg/m3 IS 5182 Part 6-2006 5.4 80

Noise Environment

Sound/Noise can be defined as atmospheric or airborne vibration perceptible to the ear.

Noise is usually unwanted or undesired sound. Sound loud enough to be harmful is called noise

without regard to its other characteristics hence noise has a significant impact on the quality of

life and in that sense it is a health problem in accordance with the (WHO) definition of health.

Impact of noise on environment depends on various factors such as intensity distance

from the source type of exposure and nature (Impulse or continuous), the type of activities

movement of machineries, traffic density etc., hence it is to measure the levels so as to adjust the

environment Impact and undertake amendment measures if warranted.

Standard precession noise level meter were used for the purpose. The readings in the

form of instantaneous sound measures levels were taken in the time brackets of two hours in

order to here carry out assessment of noise level in the area.

There are no heavy industries nearby; the noise level of the area will be as same as the

regional level. More over the noise level measurements does not rise for this area since class 2

slurry explosives will be used for mining and the machineries to be used shall hydraulic types, it

does not create much noise except the compressor, drilling. The traffic density in the area is very

little. The average noise level in that area is less then 90dB (A) in and around 1Km radius.

This noise level survey was carried out as per MOEF norms i.e., 1.5m above the ground

level and 2mts away from the noise emit source. At present the noise is only through the

movement of Vehicles in that area. No other significant noise emitting source found.

S.No Location Results

dB (A) CPCB Standard

Limit 1 Project site – Centre area 41.5 70*

2 Project Site SW corner 42.1 70*

3 Project site SE Corner 41.2 70* 4 Project site NE Corner 41.6 70*

Ground vibration studies

Hence the vibration source are only through the movement of vehicles where the

frequency is also very less. Hence the vibration is well below the standard permissible by

MOEF. Displacement, Velocity and acceleration of the three kinematics descriptions which are

to be studies to describe ground motion. The peak particle velocity is the more referred since the

area is virgin there is no significant measured velocity found in the area.

Water Environment

Geo Physical investigation was carried out by signal stacking resistivity meter 3 profiling

was carried out in the area applied for lease and 15 Vertical electrical sounding was carried out

to find out the lateral variation and vertical in homogeneity’s it was observed that the water table

is found to be 40mts below ground level. The water quality monitoring data is enclosed as

Annexure No-II.

Test Protocol Results Limits as per IS 10500 :

2012 Acceptable

Limit

Permissible

limit in the

absence of

alternate Colour IS : 3025 part : 4-1983

(Reaff : 2006) 10 Hazen 5 15

Odour IS : 3025 part : 5-1983 (Reaff : 2006)

Agreeable Agreeable Agreeable

pH at 250C IS : 3025 part : 11-1983 (Reaff : 2006)

7.4 6.5 – 8.5 No relaxation

Total Dissolved solids

IS : 3025 part : 16-1984 (Reaff : 2006)

1355mg/l 500 mg/l 2000mg/l

Aluminium as Al

IS : 3025 part 2:2004 (Reaff : 2009)

BDL (DL:0.004 mg/l)

0.04 mg/l

0.2 mg/l

Barium as Ba IS : 3025 Part 2:2004 (Reaff : 2009)

0.27 mg/l 0.7mg /l No relaxation

Boran as B IS : 3025 Part 2:2004 (Reaff : 2009)

BDL (DL: 0.1 mg/l)

0.4mg /l 1.0mg/l

Calcium as Ca IS: 3025 Part 2: 2004 (Reaff : 2009)

160 mg/l 70mg/l 200mg/l

Chloride as Cl IS : 3025 Part 32-1988 (Reaff . 2009)

479mg/l 250mg/l 1000mg/l

Copper as Cu IS: 3025 part 2: 2004 (Reaff : 2009)

BDL (DL:0.01 mg/l)

0.05mg/l 1.5mg/l

Fluoride as F IS : 3025 Part 60: 2008 0.72 mg/l 1.0mg/l 1.5mg/l

METHODOLOGY AND DATA ACQUISITION:

Electric Resistivity Method is well established for delineating lateral as well vertical

discontinuities in the resistive structure of the Earth’s subsurface. The present study makes use of

vertical electric sounding (VES) to delineate the Vertical Resistivity structure at depth.

Schlumberger electrode set up was employed for making sounding measurements. Since it is

least influenced by lateral in homogeneities and is capable of providing higher depth of

investigation. This is four electrodes collinear set up where in the outer electrodes send current

into the ground and the inner electrodes measure the potential difference.

The present study utilizes maximum current electrode separation AB/2. The data from

this survey are commonly arranged and contoured in the farm of Pseudo-section that gives an

approximate of the subsurface resistivity. This technique is used for the inversion of

Schlumberger VES data to predict the layer parameter namely layer resistivity and Geo electric

layer thickness. The main goal of the present study is to search the vertical in homogeneities that

is consistent with the measured data.

For a Schlumberger among the Apparent resistivity can be calculated as follows

ρa = G∆V

I

∆V = potential difference between receiving electrodes

G = Geometric Factor.

Rocks show wide variation in resistivity ranging from 10-8 more than 10+14 ohmmeter.

On a broad classification, one can group the rocks falling in the range of 10-8 to 1 ohmmeter as

good conductors. 1 to 106 ohmmeter as intermediate conductors and 106 to 1012 ohmmeter as

more as poor conductor. The resistivity of rocks and subsurface lithology, which is mostly

dependent on its porosity and the pore fluid resistivity is defined by Archie’s Law,

ρr = Fρw = a Ømρw

ρr = Resistivity of Rocks

ρw = Resistivity of water in pores of rock

F = Formation Factor

Ø = Fractional pore volume

A = Constants with values ranging from 0.5 to 2.5

SURVEY LAYOUT:

The layout for a resistivity survey depends on the choice of the current and potential

electrode arrangement, which is called electrode array. Here the present study is considered with

Schlumberger array. In which the distance may be used for current electrode separation while

potential electrode separation is kept on third to one fifth of the same. One interesting aspect in

VES is the principle of reciprocity, which permits interchange of the potential and current

electrode without any effect on the measured apparent resistivity.

EQUIPMENT:

The field equipment deployed for the study is in a deep resistivity meter with a model of

SSR – MP – AT. This Signal stacking Resistivity meter is a high quality data acquisition system

incorporating several innovation features for Earth resistivity. In the presence of random earth

Noises the signal to nose ration can be enhanced by √N where N is the number of stacked

readings. This SSR meter in which running averages of measurements [1, (1+2)/2, (1+2+3)/3 …

(1+2...+16/16)] up to the chosen stacks are displayed and the final average is stored

automatically, in memory utilizing the principles of stacking to achieve the benefit of high

signals to noise ratio. Based on these above significations the signal stacking resistivity meter

was used for (VES) Vertical Electric Resistivity Sounding.

MEASUREMENTS:

Measurements of ground Resistivity is essentially done by sending a current through two

electrodes called current electrodes (C1& C2) and measuring the resulting potential by two other

electrodes called potential electrode (P1& P2). The amount of current required to be sent into the

ground depends on the contact resistance at the current electrode, the ground resistivity and the

depth of interest (Here 1000feet).

DATA PRESENTATION:

The field data obtained from a Vertical Electrical Resistivity Sounding is conventionally

plotted on a paper with the help of slum software. (A computer aided diagram).

GEOPHYSICAL DATA INTERPRETATION

The geophysical data’s was obtained to study the lateral variations, vertical in

homogeneities in the sub – surface with respect to the availability of groundwater. From the

interpreted data, it has inferred that the area has moderate groundwater potential in the

investigated area.

There are no streams, water bodies or water course within the radius of 500mts and the

rainfall in the area is poor varying for maximum 50 days in a year. The average rainfall is about

400mm as recorded by the meteorological department in the last three years. In some areas of the

District there was no Rainfall recorded for the last 3years. The underground water is portable

without any adverse health effects. There are no boreholes or open wells in the project area

hence the water collected in the area for analysis.

In summer the water drains and the well will be in dry condition. The quality of the water

from well has been analyzed for records. The Quartz & Feldspar quarrying does not require any

water for its operation. No beneficiation or processing is proposed in the project. The water

required is only for drinking and domestic purpose for which the water will be brought out from

authorized water vendors from the nearby towns.

As water is very vital natural resource and most essential for the survival of human beings, the

same will be consumed only after carrying out scientific studies and will be allowed if it is

within the prescribed standards.

Soil Analysis

As mentioned earlier the area applied for lease is exhibits almost plain terrain. The soil is

the main unit for the eco system because of the dependence of flora and fauna. As the soil is

acidic there are no thick flora noticed except some common species which are native of the

terrain.

The mining activities may have impact on soil. The soil samples were called in 50mts

grid fashion by average and after coning and quartering the same was send to laboratory for

investigation. The following sources are obtained from Agricultural department.

The soil analysis report is as below

S.

No

Test parameters Method Results

1 PH @250C Is 2720 part 26 (Reaff:2011) 7.5

2 Conductivity @250C Is 14767 : 2000 (Reaff : 2010) 350µmhos/Cm

3 Moisture content Is 2720 part 2: 1973 (Reaff : 2010) 6.3% 4 Organic matter Is 2720 part 22: 1972 (Reaff : 2010) 0.36

Climate

The rain fall data of Namakkal region in a year is 400mm. Temperature falls between

42°C - 25°C. the wind direction is in NE-SW and vice –versa..

Flora and fauna in and around the area

The Quartz & Feldspar Quarrying projects like this which involves very limited

operations like secondary drilling and blasting, Conservation of Flora and Fauna along with

ecology do not have significant impact of the overall eco system. A detail study related to flora

and fauna was carefully observed physically by environmental engineers, Botanist and zoologist.

The following table shows the flora and Fauna available at the region.

List of Faunas

S.No Common Name Scientific name

1. Goat Capra hircus

2. rat Rattus norvegicus

3. Crow Corvus splenders

4. Squirrel Rodentia scrurus,

5. Ant Hymenopterous formicida,

6. Cat Felsis catus

7. Cow Bos taurus indicus

S.No Common Name Botanical name Pictures

1 Neem Azadirachata indica

2 Ground nut Arachis hypogaea

3 Mango Mangifera indica

4 Coconut Cocos nucifera

5 Maize Zea Mays

6 Sappathikali Opuntia dillenii

7 Pirandi Cissusqua drangularis

8 Gingelly Sesamum Indicum

Conclusion

The base line studies relents no hazardous levels of dust and noise and prevailing at the

project area. A well implemented environmental Management plan as discussed in the mining

plan will help in mitigation the adverse effects due to quarrying activities.

The project is a small operation were limited activities are being carried on the noise

creating device will be only jack hammer drilling which will always be mitigated in wet

condition to prevent noise and dust in the air. The movement of vehicles is very minimal. The

entire vehicle used will be periodically maintained by well experienced mechanic and kept under

TNPCB standards, emission testing will be carried out periodically and water will be sprinkled

periodically to prevent dust into air. The small quantity of non humus rich surface soil will be

removed and preserved in the boundary barrier to facilitate the Afforestation.

Blasting will be used for only losing effect and not shattering effect hence the fly rock

problem will not arise. The flora in the area is only small bushes as much of the area is exhibits

almost plain terrain. No trees are proposed to uproot for the project and Infect Trees will be

planted on boundary barrier which will act as acoustic sound barriers. Environmental care and

attitude of preventing environment is inducted to the proponent and advice to carry out and

mitigate the minor impacts due to quarrying. Appropriate persons are advice to get employed to

protect the Environment and Ecology of the area.

Date : 15.11.2018 Place : Namakkal

1. Signature of the applicant with Name and Full Address

For M/s. Sri Mahalakshmi Mines & Minerals K.Murugesan (Proprietor)

2. Signature of the Recognized qualified person

A.Jagannathan, B.E., F.C.C., M.M.E.A., RQP/MAS/019/87/A

![PRE-FEASIBILITY REPORT Of Quartz & Feldspar Mineenvironmentclearance.nic.in/.../Online/TOR/...prefeasibilityreport.pdf · Submission of SRS: File no. J-11015/05/2010-IA.II [M] Since](https://static.fdocuments.in/doc/165x107/5e75c9540d74ae699666aff0/pre-feasibility-report-of-quartz-feldspar-mine-submission-of-srs-file-no.jpg)