POWER-GEN INTERNATIONAL Orlando, Florida 2006 Air …spxcooling.com/pdf/PowerGen_2006.pdf · ·...

Transcript of POWER-GEN INTERNATIONAL Orlando, Florida 2006 Air …spxcooling.com/pdf/PowerGen_2006.pdf · ·...

William Wurtz

Philippe Nagel

POWER-GEN INTERNATIONAL

Orlando, Florida 2006

Air Cooled Condensers:

Application and Innovative Designs for

Today's Power Plants

2

The utilization of Air Cooled Condensers inpower plants has increased exponentiallyaround the world over the last 15 years.Previously, the use of Dry Cooling for powerplant applications was typically used when therewas a limited supply of available water for thesteam cycle condensation. Currently, Air CooledCondensers are justified based on new plantevaluation factors including the availability andactual cost of water, environmental impact (drift,plume, blow down, water treatment chemicals,Legionella risk, etc.) flexibility in site selection,and a reduced time period for securing air andwater environmental permits.

SPX, a world leader in cooling technologiesfor power plants, will review the current trends intoday’s Dry Cooling power market, and alsodescribe in detail three unique state-of-the-artproblem solving Air Cooled Condenser (ACC)designs for both small and large power plants.

Abstract

The innovative ACC designs will include:

An advanced design and project executionplan for a Dry Cooled 500 MW Combined CyclePower Plant (CCPP). This project consisted of anew modularisation concept for an Air CooledCondenser barged over 500 km and erected inNew York City, saving both millions of dollars insite erection costs and many months of siteerection time compared to traditional methods ofACC execution. This project description willcover the key challenges, the innovativesolutions and the various steps of the project.Details of the different phases of constructionwill illustrate today’s largest and most advancedmodularisation and preassembly of an AirCooled Condenser ever executed worldwide.

A new unique modularised ACC designconcept—Hexacool ®—optimised for smallbiomass incineration plants. This revolutionaryconcept provides many advantages includinglow noise emissions, lower material costs and aquicker / lower cost site erection.

3

REASONS

• Environmental regulations for water saving

• Environmental regulations, limiting the temperature increase in

rivers and seaside

• Local regulations favoring equipment without a plume discharge

• Flexibility in the selection of the power plant site

• Life expectancy exceeding power plant life

• Shorter lead-time for power plants permits

Dry Cooling for Power PlantsA Rapidly Growing Market

The valuation of these advantages can offset the additional

Capital Cost of Dry compared to Wet Cooling

5

Overview

• Combined Cycle Power Plant – Astoria Energy – Queens, NY

• 500 MW/Dry Cooling located on Long Island, New York City

• 24 Air Cooled Condenser Modules to be installed

• Aggressive schedule

• Limited lay down area.

• Expensive labor in New York penalizing construction under client

responsibility.

10

• Barge stability

• 300 ton modules handling to and from barges

• Modules design for proper handling

• Modules lifting and precision for alignment

Challenges

20

Conclusion

• The project has been a total success

• ACC Erection was on schedule

• Cited by third parties as a model for “Best Safety Practices”

• Very important saving in labor for client compared to a

traditional method of erection

• A New Air Cooled Condenser Concept for small Industrial

and Power Plants (Biomass, Waste to Energy, etc..)

• Innovative shape of ACC presenting remarkable benefits

• Trade Mark : Hexacool®

• Extremely Positive Market Reaction

• Positive Market Penetration

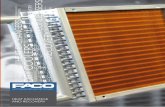

What is Hexacool?

Simplified piping and ducting routingOptimal Layout

This innovative environmentally friendly design is a trend setter in the

industryLow Impact Aesthetic

Unit designed for easier cleaning and maintenanceEasy Access

Induced draft concept reduces risk of hot air recirculation for higher

efficiency in all operating conditions

Reduced Hot Air

Recirculation

Improved performance during windy conditionsDecreased Wind

Sensitivity

Compact simplified design with greater degree of prefabrication in workshopSimplified Installation

Procedure

Easy to build in the fieldFaster Installation

Low profile design – Total height is lower than an A-Frame design.

Easier integration in urban environmentReduced Height

Loads on foundations are reducedLighter

A cost-effective solution for high quality productCost Effective

HEXACOOL ACC - Benefits